Numerical investigation of flow mechanisms of tandem impeller inside a centrifugal compressor

2020-01-09ZilingLIXingenLUShengfengZHAOGeHANChengwuYANGYnfengZHANG

Ziling LI, Xin’gen LU,*, Shengfeng ZHAO, Ge HAN,Chengwu YANG, Ynfeng ZHANG

a Key Laboratory of Light-Duty Gas-Turbine, Institute of Engineering Thermophysics, Chinese Academy of Sciences, Beijing 100190, China

b University of Chinese Academy of Sciences, Beijing 100049, China

Abstract This study numerically investigated a single stage centrifugal compressor‘‘Radiver’’with a wedge diffuser and several tandem-designed impellers to explore the flow phenomena within the tandem impeller and the potential to enhance compressor performance. The results demonstrate that tandem design and clocking fraction (λs) significantly affects the compressor performance.The compressor stage with tandem impellers of Series A of boundary layer growth interruption alone are observed to have a widely operating range but efficiency and total pressure ratio penalty compared with that of conventional impeller. The tandem impeller with at least the same impeller efficiency as the conventional design is considered as a critical design criteria so that further modification process based on the flow characteristic of tandem impeller is necessary. In order to restrain the inducer wake and exducer shock losses, parameters modification of blade angle and thickness distributions are necessary and the modified tandem impeller of Series B is obtained.The modified tandem impeller with 25% clocking arrangement shows an 8.45% stall margin increase and maintains the total pressure ratio and efficiency as the conventional design, which proves the potential of tandem impeller to improve compressor stage performance.It is noteworthy that the tandem impellers of Radiver have not shown obviously balanced exit flow field and the fundamental mechanism of stall margin extending of tandem impeller lies on the improved impeller/diffuser matching performance resulting from the incidence angle variation at diffuser inlet.

KEYWORDS Centrifugal compressor stage;Flow mechanism;Impeller/diffuser matching;Stall margin;Tandem impeller

1. Introduction

Nomenclature Vmmeridional velocity Vtcircumferential velocity LELeading Edge PSPressure Side SMchange percentage of the Stall Margin SSSuction Side TETrailing Edge ˙mcorrected mass flow ˙mchoke corrected mass flow at the choke point ˙ms,tandem corrected mass flow of tandem impeller at the near-stall point ˙ms,baseline corrected mass flow of baseline impeller at the near-stall point βrelative flow angle with reference to the meridional direction λstandem blade relative clocking angle as a fraction of the blade pitch πs,tandem total pressure ratio of tandem impeller at the near-stall point πs,baseline total pressure ratio of baseline impeller at the near-stall point

Centrifugal compressors are widely used in small gas turbines for aeronautical applications due to their high pressure ratios,ease of manufacturing, and ability to enable engines to be more compact. However, centrifugal compressors often suffer relatively low efficiency and a terrible operating range especially due to the intense interaction between the impeller and diffuser.Over the years,the aerodynamic design of centrifugal compressors has received much less attention than axial compressors due to the fact that the application of axial compressors in large gas turbines attracts large and continuous research funding from the related organization, whereas the application of centrifugal compressors as well as the current pollution crises have demanded the optimization of these machines. Numerous researches have devoted to the improvement of centrifugal compressor performance by many innovative ideas, such as tandem-bladed impeller, blade boundary layer suction and blowing, vortex generators, blade lean and sweep, casing treatment, all of these are commonly applied to axial compressors. In this paper we aim to investigate the tandem impeller inside centrifugal compressors to explore the flow phenomena within the impeller and the potential to enhance compressor performance.

The term‘‘Tandem impeller”refers to a centrifugal impeller divided into two parts which are placed in series in close axial proximity and circumferential displacement. Tandem impeller is thought to be a new flow control method which may affect the formation of boundary layers on blade surfaces and reduce the highly distorted impeller exit flow field. Compared with numerous publications on tandem-bladed axial compressor,limited studies have focused on tandem impeller with centrifugal compressor. A brief survey of previous studies on tandem impeller is summarized here.The first publication about tandem impeller by NASA Lewis Research Center1published as early as 1977 performed an experimental research on a compressor stage with tandem bladed impeller and vane diffuser. The result of this research showed that the tandem configuration can restart the boundary layer at the aft blade. Almost at the same time,Boyce and Nishida2examined a tandem impeller design with a clocking fraction of λs=33%between the inducer blade pressure surface and exducer blade suction surface. The authors found that the tandem arrangement improved the impeller efficiency slightly and eliminated the separation on the splitter blade compared with corresponding conventional compressor.Lindner3, Gui4and Bache5et al. investigated tandem bladed impellers at low Mach numbers and observed an improvement in balanced impeller flow field.However,Cheng et al.6numerically investigated two versions of tandem impellers with clocking fractions of λs=22.5% and 7.5% and found that both tandem designs delivered lower efficiencies than the baseline because of the large flow distortions and flow separations.

Then, two extensive experimental studies of tandem impeller with adjustable geometries in a centrifugal compressor rig were performed by Josuhn-Kadner and Hoffmann.7,8The results showed that the circumferential clocking fraction had quite a bit impact on impeller performance and the optimum performance was found to be at λs=0% while the poorest performance was found to be at large λs.Besides,the clocking position of λs=27% was observed to have yielded a pronounced reduction in the jet and wake velocity differences compared to the λs=0% clocking position. Roberts and Kacker9numerically studied different centrifugal compressor geometries and obtained the similar conclusions with an efficiency penalty and balanced flow field of the tandemimpeller design. In 2005, the research of Hanus et al.10concluded that tandem impeller had a potential to improve the isentropic efficiency of a centrifugal compressor stage benefited from balanced impeller exit flow. Danish11performed a detailed parameter study of tandem impellers applied to turbocharger and found that all tandem configurations with different clocking positions and axial space performed worse than the conventional configuration, and the effect of the circumferential clocking fraction on the performance was not significant. Apart from the aforementioned works, in recent years,Ju and Zhang12computational studied a tandem impeller concentrated on the comparison between baseline tandem impeller, splitter impeller and tandem impeller optimization.The results showed that baseline tandem impeller has more uniform flow field but lower efficiency than the splitter impeller, and the tandem impeller efficiency can be increased by appropriate optimization. Erdmenger and Michelassi13reported that it was possible to design tandem bladed centrifugal compressors with similar or slightly better performance at the design point and a significant performance gain under offdesign conditions. Also, Hlava´cˇek and Hanus14performed a tandem impeller research in 2016 and found a configuration which improved compressor performance (stage efficiency and stall margin) by modifying the shape of the axial inducer blade, the circumferential clocking fraction and the exducer blade transversal lean angle. Li et al.15reported that tandem impeller does have the ability to enhance compressor performance due to the redistributed impeller flow field and improved diffuser performance. The authors concluded that the impeller/diffuser matching should be the most critical issue of tandem impeller compressor design.

In spite of the wide range of results on the tandem impellers, previous research provides useful information about its flow mechanism, aerodynamic performance and design guidelines. There are three aspects commonly on the publications.First, tandem impellers are expected to positively affect the formation and growth of impeller boundary layer, which should restrain the separation region. Second, tandem impellers seem to have the ability to improve flow uniformity at impeller exit and overall stage performance, and the flow uniformity at impeller exit is supposed to be related with the circumferential clocking fraction. Last, appropriate tandem impeller optimization by modifying several design parameters has the potential to further improve the tandem impeller performance.

In the present study,the single stage centrifugal compressor‘Radiver’ with a wedge diffuser is chosen to analyze the flow characteristics of the tandem impeller. Primary analysis is placed on the flow structure in tandem impeller, the modification of tandem impeller and the underlying principles of the matching between the tandem impeller and the vane diffuser.The aim of this study is not only to explore the three aspects of considerations above, but also clarify the mechanism of the effect of tandem impeller together with finding out the design guideline of tandem impeller.

2. Investigated compressor and numerical method

The centrifugal compressor Radiver with a wedge diffuser is developed by the Institute of Jet Propulsion and Turbomachinery at RWTH Aachen, Germany. The most important design parameters of the compressor are collected in Table 1.As shown in Fig. 1, the diffuser parameters such as the radius ratio(r4/r2)between impeller exit and diffuser inlet and the diffuser vane angle (α4ss) are adjustable. For Radiver, the steady and unsteady measurement results of the test case have been published in Ref.16,17.

All computations are performed with the Euranus solver of NUMECA FineTM/Turbo. The three-dimensional steady compressible Reynolds-averaged Navier-Stokes equations are solved based on a cell-centered explicit finite-volume scheme according to Jameson.A 4-stage explicit Runge-Kutta integration scheme is used for the steady-state flow solution. Fourthorder Runge-Kutta scheme and second-order central scheme coupled with the second and fourth-order artificial dissipationterms are used for temporal discretization and spatial discretization, respectively. Several acceleration approaches,such as local time stepping, multi-grid strategy and residual smoothing are applied to accelerate the convergence to the steady state.

Table 1 Design parameters of Aachen Radiver compressor.

Fig.1 Radiver compressor stage with wedge diffuser.

The Spalart-Allmaras turbulence model is applied for turbulence closure. The rotor/stator interface is modeled using the full non-matching mixing plane method.In order to satisfy the modeling of viscous sub-layer in the turbulence model,the normalized distance from the wall of the first node y+is below 2 in all computations of this paper. The grid size of the compressor single-passage mesh is 1.9 million, which satisfies the requirement of grid independency in steady-state simulations.Block-structured grids are independently generated for the impeller blade passage,tip clearance region and wedge diffuser passage to predict the coupled flow through the centrifugal impeller and wedge diffuser. Fig. 2 shows passage mesh for compressor with conventional impeller and a typical tandem impeller design.

As for boundary conditions,the total pressure of 101325 Pa and total temperature of 288.15 K are imposed with a fully axial velocity at impeller inlet,and the averaged static pressure is imposed at diffuser exit. Outlet boundary conditions are changed depending on the operation condition, which ranges from choke to near-stall. The ‘‘near-stall point” is judged to be the last stable condition prior to incurring a numerical stall,a continual drop in mass flow rate and pressure ratio with increasing iteration count. The non-slip and adiabatic conditions are adopted on the solid wall and periodic boundary condition is set on the periodic surface.

Fig.2 Computational grids of tandem impeller and baseline impeller.

To validate the numerical method of the prediction of the Radiver centrifugal compressor, performances and flowfields from numerical computations and experimental measurements are compared at 80%rotation speed with the diffuser set up of α4ss=16.5°, r4/r2=1.14, as most of the published measurements are at this speed and diffuser configuration. As shown in Fig.3,the experimental and the calculated‘‘Radiver”characteristic of compressor stage efficiency and pressure ratio agree well in magnitude and tendency,which proves the ability of the simulation to predict compressor performance. Besides,the computed choking massflow is 2.199 kg/s, which is basically the same with the experimental choking massflow of 2.191 kg/s. Fig. 4 shows the flowfield and the spanwise plot of flow angle at the impeller outlet at the operating point of ˙m/ ˙mchoke=0.83 (the green point in Fig. 3). The quantity distributions at the impeller outlet and magnitude of the flow angle are successfully captured. To sum up, the numerical model used in this paper is adequate for this investigation.

3. Description of tandem impeller

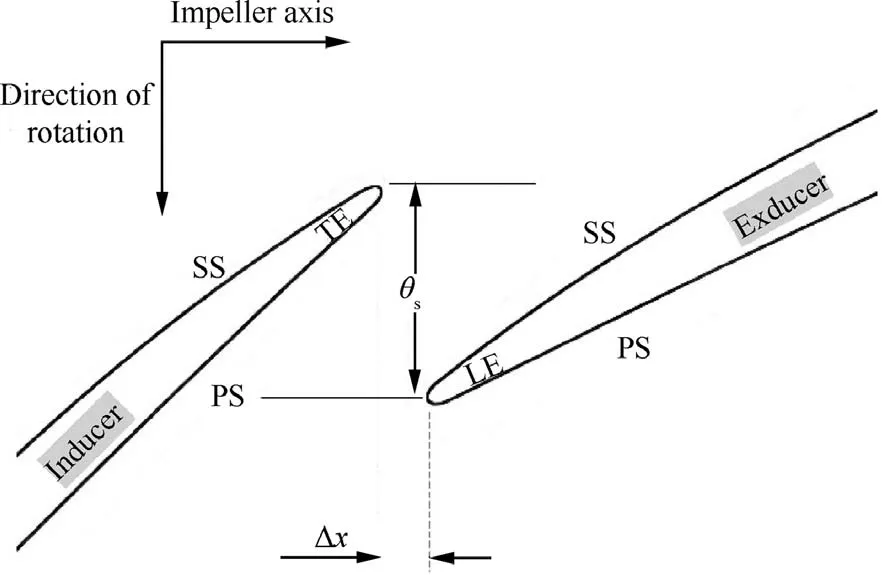

Based on the Radiver impeller design, the tandem impeller is designed to be geometrically similar to the baseline impeller.For the tandem-designed impeller, as shown in Fig. 5, the baseline impeller is divided into a separated inducer and an exducer at the meridional position of 20%impeller axial chord length, at which the meridional flow path starts its intense turning from axial direction to radial direction.

where N(b,e)is the impeller blade number.The investigation of tandem impeller is conducted with the diffuser configuration of α4ss=16.5°, r4/r2=1.10 since a lower radius ratio (r4/r2)between impeller exit and diffuser inlet shows more typical impeller/diffuser interaction. Four tandem-impeller configurations of Series A at clocking fractions of 0%, 25%, 50% and 75% are considered.

At 100%design speed,the overall performance of the compressor stage and impeller with the conventional impeller and tandem impellers of Series A design are presented in Figs. 7 and 8, respectively. In the attempt to conveniently compare the compressor operating points of various designs, noting that the mass-flow rates have been normalized using the choke flow rate. The figures clearly show that tandem design and clocking fraction λssignificantly affects the compressor performance. Compared with compressor stage with baseline impeller, tandem impeller compressors with clocking fraction of λs=25% and 50% show much more improved stall margin,which achieves a maximum 5.6% increase for λs=25%arrangement.However,the compressors with Series A tandem impeller are found to be with efficiency and total pressure ratio penalty, and all the parameters are observed to decrease continually as a function of λs. The stage performance variation depends on the impeller performance variation.

On the one hand, the tandem impeller with 0% clocking arrangement does have improved the impeller isentropic efficiency,which proves the advantage of impeller boundary layer growth interruption. On the other hand, considering the diffuser total pressure loss coefficient and static pressure recovery coefficient improvement for λs=25%, 50% and 75% configurations as shown in Fig.9,the tandem impeller efficiency and total pressure ratio deterioration result in the stage performance deterioration.In other words,the tandem impeller with at least the same impeller efficiency as the conventional design is critical.

Fig.3 Calculated and experimental characteristics of compressor Radiver at 80% design speed.

Fig.4 Calculated and experimental flow characteristics at impeller outlet of Radiver.

Fig.5 Tandem impeller meridional flowpath profiles.

Fig.6 Tandem impeller clocking position definition.

4. Flow mechanisms of tandem impeller

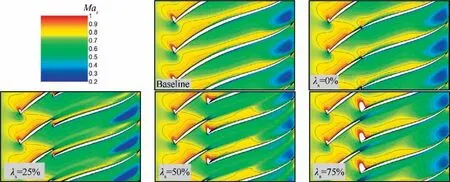

The flow inside impellers is inherently three-dimensional and is dominated by the centrifugal and Coriolis forces.The complex impeller flow-field directly determines the impeller performance and thereby further affects the compressor stage performance.To explore the flow mechanism of tandem impeller,we choose the operating point of ˙m/ ˙mchoke=0.948,which is close to the near stall point of the baseline compressor stage,to explore the flow mechanism of the tandem impeller.The flood contours of the relative Mach number (Mar)at 20%,50%, 75% and 95%spans for the baseline and four tandem-impeller cases are shown in Figs. 10-13.

For the transonic centrifugal compressor studied in this paper, the major flow characteristics are the flow separation,low-energy fluid and shock systems. As for tandem impeller of Series A, a double shock wave structure is observed for λs=25%, 50% and 75% configurations, except for the case of the exducer aligned with the inducer blade. Apart from the passage shock wave of the inducer passage for all the impeller cases, acceleration of the exducer leading edge resulting from the large positive incidence angle induces another shock wave, which can certainly contribute to the flow losses within impellers. Besides, the inducer wake flow directly into the exducer passage and the intensity is found to increase as λsincreased, resulting in a deteriorated impeller flow field.

The flood contour of circumferential averaged entropy in the meridional plane in Fig. 14 confirms the tandem impeller loss mechanism.The entropy generation presents different patterns near the exducer leading edge,where the tandem clocking arrangements of 25%, 50% and 75% exhibit more high entropy areas because of the exducer shock wave and inducer wake development.As a result,tandem impellers with circumferential displacement show worse impeller performance compared with that of baseline impeller.

Fig.7 Overall performance of centrifugal compressor with tandem impellers of different clocking fractions.

Fig.8 Overall performance of impeller with tandem impellers of different clocking fractions.

Fig.9 Comparison of calculated diffuser characteristics.

As shown in Figs.10-13,the shape and location of the lowenergy fluid show distinct difference between different impellers, which are observed to be strongly related to the clocking fraction.At 20%span of impellers,it is clear that the high relative velocity flow near the inducer suction side energize the downstream flow along exducer pressure surface as λsis increased,and finally the relative Mach number at impeller exit obviously increased along with the high speed flow at exducer suction side. Similarly, resulting from the high momentum flow, the low-energy flow region at tandem impeller(λs=25%, 50%, 75%) rear part of 50% span appears to be circumferentially extended and chord-wisely restrained. At spans of 75% and 95%, a notable separation is found within the passage because of the turn of flow path.On the one hand,the separation region converts to the exducer suction side as λsis increased. On the other hand, the flow of tandem impeller with circumferential displacement is strongly decelerated due to the double shock structure near the tip, which extends the separation region.

Fig.10 Distribution of relative Mach number of different cases at 20% span.

Fig.11 Distribution of relative Mach number of different cases at 50% span.

Fig.12 Distribution of relative Mach number of different cases at 75% span.

When referring to the impeller discharge flow field, as shown in Fig. 15, all configurations have the notable jet/wake flow pattern, where the high momentum locates at the blade pressure side and a wide range of relatively low-velocity wake fluids are at the suction side, with the lowest-momentum flow region near the shroud. However, it is worth noting that the tandem designed impellers have not shown obviously balanced impeller exit flow field.

5. Improved design of tandem impeller

The tandem impeller design is found to have the ability to achieve more design degree of freedom compared with that of conventional design. The design parameters such as blade angle β and thickness distributions can be locally modified based on the flow characteristic,which is thought to be a superiority of tandem impeller.

Fig.13 Distribution of relative Mach number of different cases at 95% span.

Fig.14 Entropy plots for different configurations at meridional plane.

Fig.15 Meridional velocity contours at impeller outlet plane.

In this paper, a design modification of tandem impeller is implied to enhance the tandem impeller performance. As shown in Figs.16(a)and(b),the inducer tip blade angle distribution is modified by the pre-compression method to adapt to the high speed inlet flow,and the thickness distribution is redesigned based on the mechanical requirement and advanced axial compressor design methods.18As shown in Fig. 16(c),considering the flow slip effect inside the impeller passages,the blade angle at exducer inlet is modified to match the upstream flow direction to decrease the exducer leading edge shock intensity. Then, the modified tandem impeller is achieved and named as Series B. According to the investigation of Series A, the tandem configuration of λs=25% is found to be with the best performance, so that the analysis of modified tandem impeller is chosen at λs=25%configuration.

Fig.16 Improved design of tandem impeller.

Figs. 17 and 18 are the overall performance of the compressor stage and impeller with the conventional impeller and the tandem impeller of Series B design.As is seen, the modified tandem impeller with 25% clocking arrangement shows an 8.45% SM (compressor stall margin gain=(πs,tandem˙ms,baseline)/(πs,baseline˙ms,tandem)-1)increase and maintains the total pressure ratio and efficiency as the conventional design, which proves the potential of tandem impeller to improve compressor stage performance.

At operating point of ˙m/ ˙mchoke=0.948,the flood contours of the relative Mach number at 20%, 50%, 75% and 95%spans for the baseline and modified tandem impeller cases are shown in Fig. 19. The modified tandem impeller of Series B represents almost the same flow structure with that of original tandem impeller A except for the inducer wake and exducer shock wave patterns. As for the modified tandem impeller B, the intensity of exducer shock wave between the inducer pressure surface and exducer suction surface is obviously decreased and the high entropy areas near the exducer leading edge(Fig.20)is dissipated compared with that of tandem impeller A.After these computations,a conclusion is that the modification of tandem impeller blade angle and thickness distribution based on the flow characteristic of impeller should be taken into account, so that the inducer wake and exducer shock losses can be restrained.

In order to characterize the flow uniformity of the impeller discharge flow, the meridional velocity contours at the outlet of various impellers are shown in Fig.21.As shown in the figure, the modified tandem impeller B presents a basically the same discharge flow pattern as that of the tandem impeller A, where the high momentum fluid locates at the blade pressure side and a wide range of relatively low-velocity wake fluids are at the suction side, with the lowest-momentum flow region near the shroud. However, the high momentum fluid region seems to be larger compared with that in tandem impeller A, which indicates the improved flow field inside the modified tandem impeller.

6. Discussion on stall margin extending

Either the impeller or diffuser triggers flow stall is the basis for analyzing the stall margin enhancement. According to the experiment measurement and calculation in,19,20the impeller stall margin is wider than stage stall margin,which meant that the diffuser stall margin determines the stall margin for the whole compressor.That is to say,the flow instability occurred in wedge diffuser induces the stage stall.The tandem impellers of Radiver have not shown obviously balanced impeller exit flow field as mentioned above, so it is unreasonable to owe the diffuser and stage performance improvement to the balanced flow field and a discussion on the stall margin extending mechanism is necessary.

Fig.17 Performance comparison of Radiver stage and modified tandem impeller stage.

Fig.18 Comparison of calculated diffuser characteristics of Radiver stage and modified tandem impeller stage.

Fig.19 Distribution of relative Mach number at different spans for baseline and modified tandem impeller cases.

Fig.20 Entropy plots for baseline and modified tandem impeller configurations at meridional plane.

Fig.21 Meridional velocity contours at impeller outlet plane for baseline and different tandem impeller cases.

At the operating point of ˙m/ ˙mchoke=0.948,which is close to the near stall point of the baseline compressor stage. In order to visualize the flow pattern within the diffuser passage,Fig. 22 presents the distribution of relative Mach number at seven cross-sections along the diffuser passage. All the crosssections are perpendicular to the diffuser centerline. As seen in the figure, a low-momentum flow region is recognized at the pressure surface/hub corner of the baseline diffuser. The low-momentum area at the pressure surface/hub corner is found to be gradually increased as flow moving downstream,which triggers impeller flow instability in the diffuser. However, the diffuser with modified tandem impeller is found to be with an obviously decreased low-momentum area, where the pressure surface/hub corner separation is suppressed and the flow instability is restrained.

To further visualize the flow mechanism of the suppressed diffuser flow separations by using the tandem impeller, the evolution of vortex structures within the diffuser passages are shown in Fig. 23. The legend of the streamwise vorticity coefficient, Ws, indicates the intensity and orientation of vortex, where the red part denotes the clockwise vortex and the blue part denotes the anti-clockwise vortex as looking in the direction of flow. The figure indicates that the Vortex A occupies most of the flow passage and the secondary flow induced by this intense passage vortex carries the low-momentum fluid to the pressure surface/hub corner, which eventually results in a separation. However, as for the diffuser downstream of the tandem impeller, the Vortex A is observed to be suppressed by the intense anti-clockwise Vortex B, so that the lowmomentum fluid accumulation at pressure surface corner is diminished.

In general,the intensity of Vortex B is thought to be related to the flow angle variation at the diffuser inlet. Fig. 24 shows the spanwise distribution of the flow angle,meridional velocity Vm, and circumferential velocity Vtat diffuser inlet (impeller outlet) for the baseline and modified tandem impeller cases.It can be seen that the diffuser downstream of the tandem impeller has a lower incidence angle (flow converting to axial direction) compared with that of the diffuser with baseline impeller,which means a less positive incidence angle at the tandem impeller diffuser inlet. As for the velocity components variation, the figure shows that the Vtmagnitude has few changes between the two cases, however, the Vmmagnitude represents a great enhancement of tandem impeller diffuser,which contribute a lot to the incidence angle variation.

Fig.22 Distribution of relative Mach number in several cross-sections within the diffusers.

Fig.23 Distribution of streamwise vortex coefficient in several cross-sections within the diffusers.

Fig.24 Comparison of diffuser inlet parameters along vane span.

Fig.25 Comparison of impeller/diffuser matching line at design speed.

Due to the relatively thin leading edge, the vane diffuser performance is always highly sensitive to the incidence angle.21,22Generally speaking, the flow angle at diffuser inlet determines the operating point of diffuser, and a less positive incidence angle fundamentally shifts the diffuser operating point to the direction away from stall point.23As the sketch map shown in Fig. 25, for a given impeller flow coefficient,the diffuser downstream of the baseline impeller is operated at the original matching point(the triangle symbol).However,the operate point of the diffuser downstream of tandem impeller is moved downwards in the figure compared with that of the diffuser downstream of the baseline impeller resulting from the incidence angle variation mentioned above. As a result, a new impeller/diffuser matching line is generated for the tandem impeller stage at the range of all the impeller flow coefficients.

Based on the discussion of the impeller/diffuser matching characteristic variation, it is found that a wider operating range of mass flow is achieved for the tandem impeller stage.In other words, the tandem impeller with 25% clocking arrangement can improve the impeller/diffuser matching performance.As shown in the figure,the tandem impeller/diffuser matching line represents a lower impeller flow coefficient under the restriction of diffuser stall margin. As a result, the stall margin is extended for tandem impeller stage. To sum up,the fundamental mechanism of stall margin extending of Radiver tandem impeller lies on the improved impeller/diffuser matching performance resulting from the increased meridional velocity at impeller outlet.

7. Conclusions

(1) The impeller boundary layer growth interruption does have the advantage to improve impeller performance,however, due to the circumferential displacement of inducer and exducer, the inducer wake and exducer shock wave eventually result in the deterioration of the impeller flow field.

(2) The restraint of inducer wake and exducer shock losses is supposed to be the key factor for tandem impeller design. Simply a copy and split of the conventional impeller is not sufficient for the requirement for tandem impeller design, and the modification and optimization of tandem impeller blade angle and thickness distribution based on the flow characteristic of impeller should be taken into account.

(3) According to the parameter modification of blade angle and thickness distributions of tandem impeller, an 8.45% SM increase with the maintaining total pressure ratio and efficiency as the conventional design is achieved,which proves the potential of tandem impeller to improve compressor stage performance.

(4) As for Radiver compressor, the tandem impellers have not shown obviously balanced impeller exit flow field.The fundamental mechanism of stall margin extending lies on the improved impeller/diffuser matching performance resulting from the flow structure variation which increases the meridional velocity at tandem impeller outlet.

Acknowledgements

The financial support from the National Natural Science Foundation of China (Nos. 51876022 and 51836008) and the Radiver test cases provided by the Institute of Jet Propulsion and Turbo-machinery of RWTH Aachen University are greatly appreciated.

杂志排行

CHINESE JOURNAL OF AERONAUTICS的其它文章

- A CFD-based numerical virtual flight simulator and its application in control law design of a maneuverable missile model

- Experimental investigation on dynamic response of flat blades with underplatform dampers

- Non-random vibration analysis for general viscous damping systems

- Numerical analysis of hypersonic thermochemical non-equilibrium environment for an entry configuration in ionized flow

- Prediction of nonlinear pilot-induced oscillation using an intelligent human pilot model

- Multiple hierarchy risk assessment with hybrid model for safety enhancing of unmanned subscale BWB demonstrator flight test