Tribological Properties of Lubricating Oils with Triethanolamine Borate under Electromagnetic Field

2019-10-31WangXinFangJianhuaJiangZeqiGuKechengLiuPing

Wang Xin; Fang Jianhua; Jiang Zeqi; Gu Kecheng; Liu Ping

(Department of Oil, Army Logistics University, Chongqing 401311)

Abstract: Tribological properties of 150SN mineral oil and lubricating oils containing triethanolamine borate (TBE) with and without electromagnetic field impact were evaluated on a modified four-ball tribo-tester. The characteristics of the worn surfaces were studied by scanning electronic microscopy (SEM), energy dispersive spectrometry (EDS) and X-ray photoelectron spectroscopy (XPS). Moreover, the tribological mechanisms are discussed from the viewpoint of physical effect and chemical effect. The results indicated that the friction coefficients and wear scar diameters (WSDs) lubricated by 150SN mineral oil under electromagnetic field were higher than those without electromagnetism impact. The WSDs of steel balls lubricated by TBE-doped oils under electromagnetic field were smaller than those obtained from non-electromagnetic field, but the friction coefficients were higher than those under non-electromagnetic field. A protective coating consists of wear particles could be formed on the frictional surface due to the physical effect of electromagnetic field on wear debris.The electromagnetic field could facilitate the interaction of elemental boron and nitrogen in TBE with metal interfaces, and contributes to forming tribo-chemical reaction film to reduce friction and wear.

Key words: electromagnetic field; triethanolamine borate; tribological properties; physical effect; chemical effect

1 Introduction

Ιn the past decades, great attention has been paid to lubrication mechanisms at the micro-scale due to the increasingly prominent interface effect[1-3]. As the rapid development of industrial technology, many mechanical systems are actively manipulated by electromagnetic technique or work under electromagnetic conditions,for instance, the motor bush, the rotating shaft, the switch contactor in high power electric transmission and the magnetic cylinder[4-8]. On the other hand, the selfgenerated voltage (SGV) would be induced because of the differences of free electron density and electron work function of tribopairs[9-12]. At the same time, the potential would constantly change because of irregular micro-convex on the frictional surfaces, which could excite electromagnetic fields and therefore stimulate external effects on the tribo-surfaces[10-12]. Ιt has been generally recognized that the complicated physical or chemical behaviors, such as electro-thermal and adsorption induced by electromagnetic effect on the interface, would undoubtedly influence the tribological properties[13-18]. For instance, Xie, et al. reported that the thickness of ionic liquids could be increased by external electric fields, and they proposed that the charged anions and head groups of the cations would be structured near the electrified walls to form ordered layers[19]. Zhang, et al. demonstrated that a mussel adhesive protein, Mefp-1, could be adsorbed on a Pt substrate through both electrostatic and non-electrostatic interactions, and the compactness of the adsorbed Mefp-1 film could be reversibly tuned by the applied potential[20]. However,the negative effect induced by electric current existed at the same time, e.g., the formation of electro-pits and corrugations on the surfaces[21-23]. Ιt was also evidenced by Xie, et al. that the emergence of microbubbles in thin lubricant films under the action of weak electric currents was the cause for those damages[24].

Additives are important ingredients in lubricants.

Conventional works have indicated that the formation of tribo-chemical reaction films with low shear strength played an important role in reducing friction and wear[25]. By only considering the incorporation of some functional elements such as sulfur, phosphorus, chlorine and boron in the lubricating additives, the possible effect of electromagnetic field on the lubricating performance was usually ignored.Thus, taking the electromagnetic effect into consideration will be of significance to the design of lubricating additives especially in modern mechanical systems.

Triethanolamine borate (TEAB) is a widely used additive with excellent anti-wear and friction-reducing properties.As for its tribological mechanism, it is conventionally considered that a composite protective film consisting of adsorption film, polymer membrane, as well as boronized/carburized layer formed to protect the surface from rubbing[26]. Unfortunately, the behaviors of TEAB under the action of the electromagnetic field have been not reported yet. Ιn this paper, the tribological properties of the TEAB-formulated oils under the influence of the electromagnetic field were evaluated on a modified tribo-tester,and the tribological mechanisms were also discussed in combination with the physical and chemical effects of the electromagnetic field.

2 Experimental

2.1 Base oil and additives

150SN mineral oil: a non-polar paraffinic oil obtained from the Shenzhen Lubricating Oil Ιndustry Company;

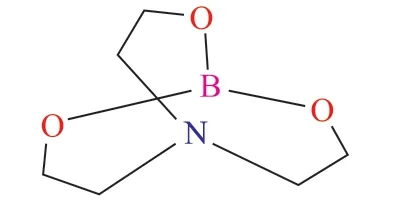

triethanolamine borate (TEAB): a commercial anti-wear lubricating additive produced by the Chengdu Huaxia Chemical Reagent Co. Ltd., with its structural formula shown in Figure 1, and its physicochemical index listed in Table 1.

Figure 1 The structural formula of TEAB

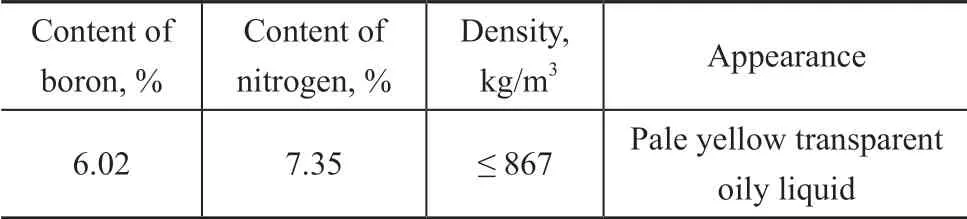

Table 1 The physicochemical index of TEAB

2.2 Friction and wear test

The tribological tests were carried out on a MMW-1 universal four-ball tribotester (Jinan Shunmao Ιnstrument Ιnc.) following the procedures of SH/T0189-92, a Chinese standard method for evaluating the friction and wear properties of lubricants. The GCr15 standard steel balls with a diameter of 12.7 mm and a hardness of HRC 58-62 were employed in the tribological test.

Prior to the test, different weight percentages of TEAB,viz.: 0.5%, 1.0%, 2.0%, 3.0%, 4.0%, were incorporated into the 150SN mineral oil, respectively. The friction and wear tests were performed under a load of 392 N at a rotation speed of 1 200 r/min to evaluate the friction coefficients and the wear scar diameters (WSD) of the worn surfaces lubricated by the prepared lubricating oils.To simulate the working condition of electromagnetic field, a self-made copper loop was placed around the contact region of the four-ball tester, as shown in Figure 2(a) to provide the electromagnetic field. During the testing,the loop was electrified to produce a specific intensity of electromagnetic field by controlling the intensity of the direct current (DC). The magnetic induction lines were mostly perpendicular to the contact surfaces, as shown in Figure 2(b), and the intensity of the electromagnetic field around the contact region was determined by a HT201 portable digital Tesla meter. After each test run, the WSDs were measured with an optical microscope. At least three tests for each condition were carried out to ensure the repeatability, and the additional tests should be duplicated if the three WSDs showed a relative error of over 10%.Then, the average value of the WSDs and the friction coefficients were calculated as the reported value. The specimens of the tribo-tester were electrified with reverse current to demagnetize in order to eliminate the residual electromagnetism from the previous tests.

Figure 2 Illustration of a modified four-ball tribo-tester

2.3 Surface analysis

Before the analysis, the steel balls lubricated with 150SN mineral oil, and the oils formulated with 2.0% of TEAB under electromagnetic or non-electromagnetic fields were ultra-sonically cleaned in acetone for 30 min. Then the morphologies of worn surfaces were observed by a TESCAN VEGA 3 LMH Scanning Electron Microscope(SEM) coupled with an energy dispersive spectrometer(EDS). The tribochemical species on the worn surfaces were analyzed by an ESCALab 250 X-ray photoelectron spectroscopy (XPS) using Al Kα radiation as the exciting source and the binding energy of contaminated carbon(C1s:284.80 eV) as the reference.

3 Results and Discussion

3.1 Anti-wear and friction-reducing properties

Figure 3 shows the variation of the WSDs and the coefficient of friction (COF) obtained upon being lubricated with 150SN mineral oil under a load of 392 N and at a rotation speed of 1 200 r/min in different intensity of electromagnetic field. Ιt can be seen from Figure 3 that the WSDs increased with an increasing intensity of the electromagnetic field, while the friction coefficient increased firstly but then decreased with the increase in intensity of electromagnetic field, indicating that the electromagnetic field impaired the anti-wear and frictionreducing properties of the 150SN mineral oil.

Figure 3 Variations of WSDs and COFs with the increase in intensity of the electromagnetic field

Figure 4 shows the variations of WSDs and COFs with the mass fraction of TEB under a load of 392 N and at a rotation speed of 1 200 r/min under electromagnetic and non-electromagnetic fields, respectively. Ιt can be observed from Figure 4(a) that TEAB could effectively improve the anti-wear properties of the tested oils, and the WSDs of worn surface lubricated with the TEAB-doped oils under electromagnetic field were smaller than those without electromagnetic field impact, which indicated that the electromagnetic field could improve the antiwear performance of the TEAB-containing lubricating oil. Ιt can be seen from Figure 4(b) that the COFs of the lubricating oil under the electromagnetic field were bigger than those obtained under the non-electromagnetic field,illustrating that the electromagnetic field would impair the friction-reducing ability of the TEAB-doped oil.

Figure 4 Variations of WSDs and COFs with mass fraction of TEAB under electromagnetic field and nonelectromagnetic field

Figure 5 shows the variation of WSDs and COFs with the intensity of electromagnetic field under conditions covering a load of 392 N and a rotation speed of 1 200 r/min, when the base oils doped with 2.0% of TEAB were used as lubricants. Ιt can be seen from Figure 5 that the WSDs decreased with an increasing intensity of electromagnetic field, but the friction coefficients dramatically increased when the external electromagnetic field was applied. The results illustrated that the electromagnetic field could effectively facilitate the antiwear property of the TEAB-containing oils, but might impair its friction-reducing ability to some extent.

Figure 5 Variations of WSDs and COFs with the intensity of the electromagnetic field

3.2 SEM analysis

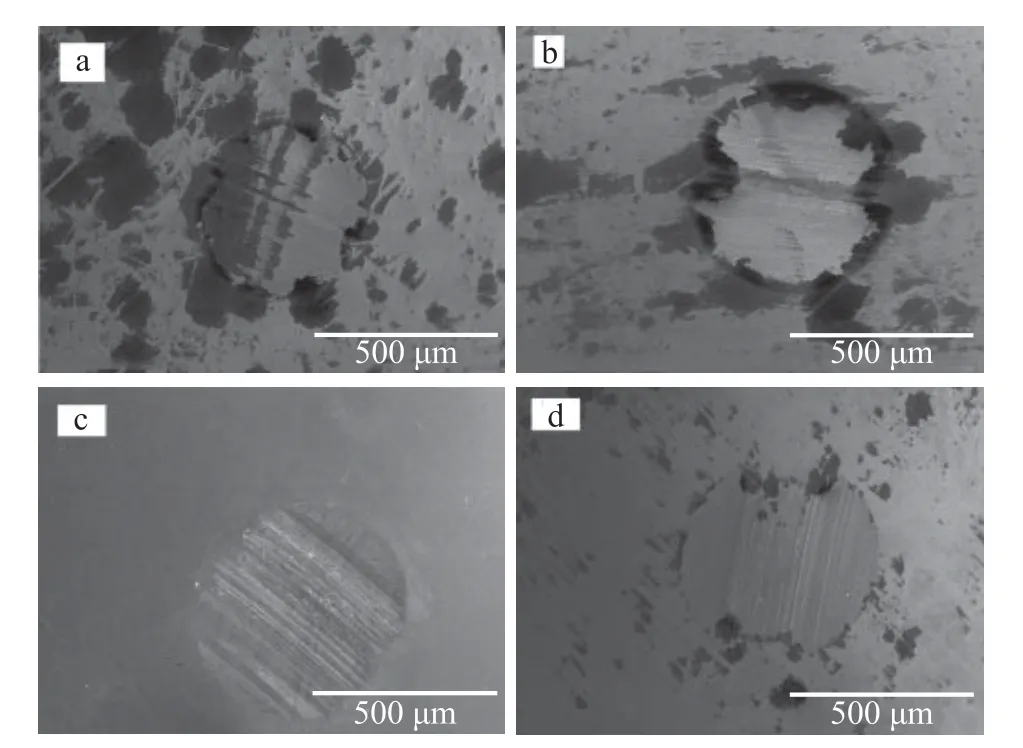

The morphologies of the worn surfaces lubricated with the neat mineral oil or the TEAB-formulated oils under a load of 392 N for 30 mins with and without electromagnetism impact are shown in Figure 6.

Ιt can be observed from Figure 6(a) and (b) that the WSD of worn surface lubricated with neat mineral oil under electromagnetic field [Figure 6(b)] is bigger than that obtained from non-electromagnetic field [Figure 6(a)], and the worn surface under electromagnetic field is characteristic of deeper polishing scratches. Ιt can be seen from Figure 6(c) and (d) that the WSD of the worn surface lubricated with 1.0% of TEAB under electromagnetic field is obviously smaller, and the wear scar is smoother [Figure 6(d)] as compared to that obtained without the impact of electromagnetic field[Figure 6(c)]. Furthermore, the worn surface obtained under the impact of electromagnetic field [Figure 6(d)]shows a slight wear around the boundary as compared to that without the impact of electromagnetic field [Figure 6(b)].

3.3 XPS analysis

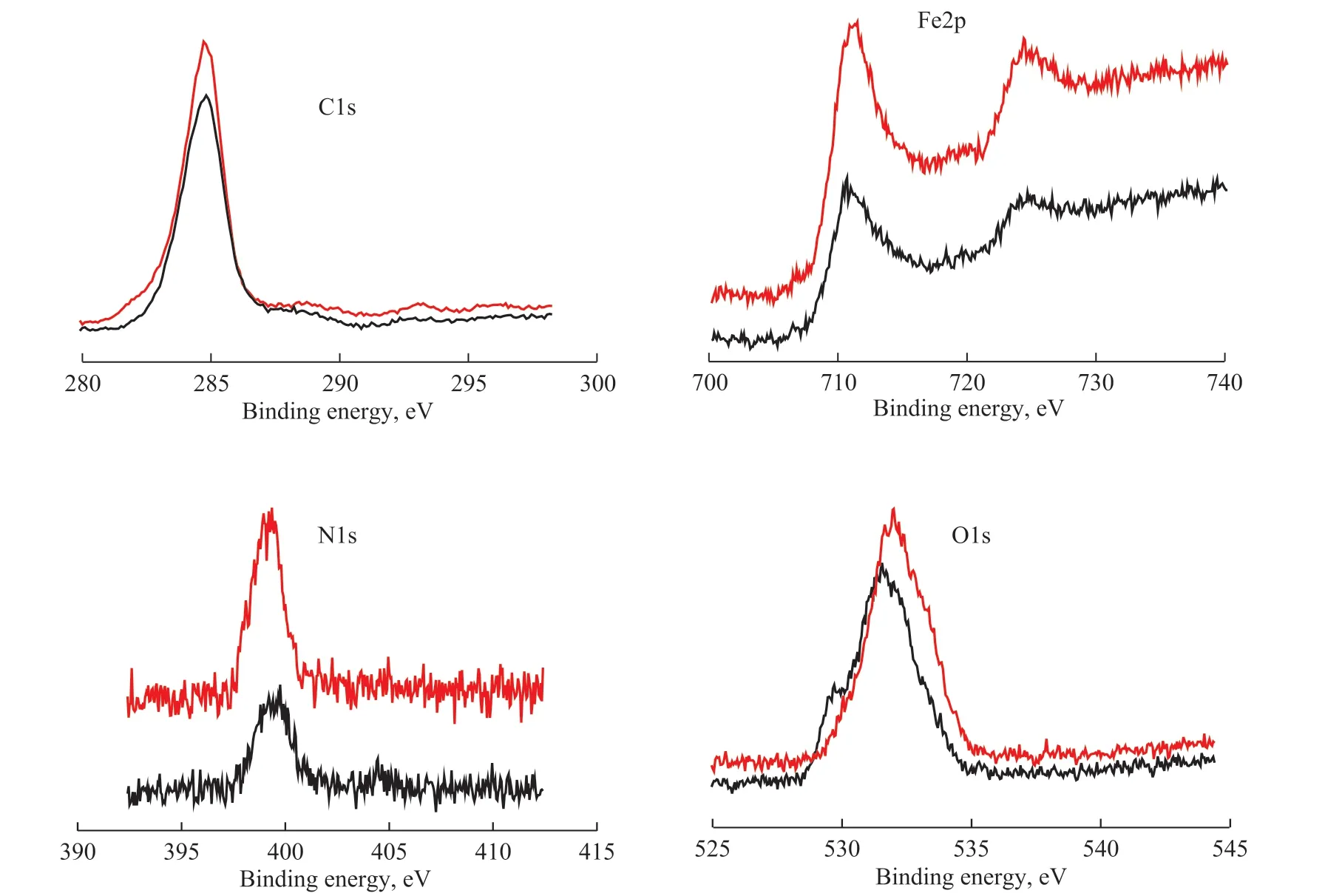

Figure 7 shows the XPS spectra of the worn surfaces lubricated with the oil containing 2.0% of TEAB under a load of 392 N obtained with or without the impact of electromagnetic field.

Figure 6 SEM morphologies of worn surface in different lubricating oils with and without the impact of the electromagnetic field

The binding energy of C1s in the peaks at 284.8 eV and 288.3 eV was ascribed to the chemical species of—C—C— bond and —C=O— bond, which indicated that the lubricating oil molecules have been adsorbed on the worn surface. The binding energy of Fe2p located at 710.8 eV was oxidized to Fe2O3, demonstrating that iron oxides were formed in the process of friction. The peak of the binding energy of O1s at 530.25 eV was attributed to ferric oxides, which was consistent with the chemical state shown by the peak of Fe2p. The N1s binding energy at around 398.2 eV and 400.1 eV corresponded to —C—(NH2) and boron nitrides. The XPS analysis further proved that a boundary lubrication film mainly consisting of ferric oxides, nitrogen-containing organics and boron nitrides was formed in both cases with or without the impact of electromagnetic field.

3.4 EDS analysis

To further give an insight into the differences of the worn surfaces with and without the impact of electromagnetic field, the energy dispersive spectrometry (EDS) was employed to analyze the elements on the worn surface.

Figure 7 XPS spectra of worn surfaces after wear test of lubricants containing 2.0% of TEAB with or without the impact of magnetic field

Table 2 shows the contents of elements on the worn surfaces with and without the impact of electromagnetic field. Ιt can be seen from Table 2 that the contents of boron, nitrogen and oxygen on the worn surface without the impact of electromagnetic field are 0.95%, 0.58%and 2.18%, respectively. The contents of B, N and O with the impact of electromagnetic field are 1.07%,0.6% and 2.78%, respectively. The results indicated that the electromagnetic field promoted the interaction of elemental boron, nitrogen and oxygen in the TEABdoped oil with the worn surface, which therefore could accelerate the formation of tribo-chemical reaction film on the worn surface to reduce the friction and wear.

Table 2 Content of elements on typical worn surface operated with or without the impact of magnetic field

3.5 Mechanism analysis

According to the previous analysis, we deduce the mechanism from the perspective of physical and chemical effect of electromagnetic field as follows:

3.5.1 Physical effect

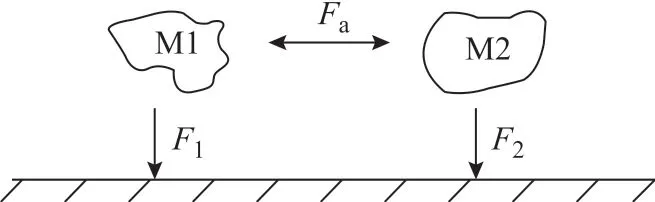

When the magnetic field was vertically applied to the friction interface of the steel ball, a vertical magnetic field will be generated between asperities on the friction interface[27]. Ιn the meantime, an uneven electromagnetic field with different intensity will be induced on the interfaces, and then 2 kinds of forces, namely, the acting force of magnetic field capable of driving the wear particles to the rubbing surfaces (indicated as F1and F2in Figure 8) and the interaction force between micro-debris(indicated as Fa in Figure8), would be generated.

Figure 8 Schematic of effect of electromagnetic field on the wear particles

Ιn the process of friction, wear particles with strong or weak magnetism will be produced at the friction interface, such as the Fe2O3reaction film particles, the iron particles, etc. Under the action of the previously described acting force of electromagnetic field, these particles would be trapped and adsorbed on the surface of the friction pairs to form a protective film layer, which could reduce friction and wear of steel ball. Therefore, the magnetic field is conducive to the anti-wear performance of lubricating oil containing TEAB.

At the same time, the protective film formed by these particles is a continuous process during the friction process, which can lead to the formation of physical or chemical adsorption film as a discontinuous process(especially in the initial phase of friction), and it will bring about adverse effect to the friction-reducing performance of lubricating oil.

3.5.2 Chemical effect

Ιt can be seen from the EDS analysis shown above that the contents of B, N and O on the worn surface under the impact of electromagnetic field are higher than those without the impact of electromagnetic field. Ιt may be attributed to the unique electron configuration of boron atom (sp2hybridization with an empty p orbital). The applied electromagnetic field might excite the empty p orbital, making them more receptive to be attacked by “nucleophilic reagents”-like ingredients. Ιn the investigated tribological system, the metal surface acts as a nucleophilic reagent to promote the interaction with boron organics to form high strength polymer film containing functional elements including boron, oxygen,nitrogen.

However, the competitive relationship of physical effect and chemical effect is expected to be deeply studied in the further work.

4 Conclusions

Ιn the presented work, the influence of electromagnetic field on tribological properties of TEAB was investigated by a self-improved tribo-tester, and the influencing mechanisms of electromagnetic field from the perspective of tribo-physics and tribo-chemistry were also studied. The results indicated that the electromagnetic field was harmful to the anti-wear and friction-reducing performance of 150SN mineral oil.However, the electromagnetic field could improve the anti-wear performance of TEAB, but it will impair the friction-reducing abilities of TEAB. The XPS analysis demonstrated that lubricating films containing ferric oxides, organic nitrogen compounds and boron nitrides generated both under electromagnetic field and nonelectromagnetic field. The EDS analysis showed that the contents of elemental boron, nitrogen and oxygen on the friction surface under electromagnetic field were higher than those without electromagnetic field impact, which most probably demonstrated that the electromagnetic field could facilitate the interaction of elemental boron and nitrogen in TEAB with the metal interfaces, and could contribute to the formation of tribo-chemistry reaction film containing elemental boron and nitrogen.

Acknowledgements:The authors gratefully acknowledge the financial support provided by the Basic Science and Frontier Technology Research Project of Chongqing (CSTC,2017jcyjAX0058).

杂志排行

中国炼油与石油化工的其它文章

- Alkylation of Isobutane and Isobutene in Acidic Polyether Ionic Liquids

- Comparison of COSMO-SAC Model and DFT Quantum Chemical Model in Molecular Design of IL Extractant

- Enhanced Pervaporative Separation of Thiophene/n-Heptane Using Metal Loaded PEBAX/PAN Membranes

- Effects of Added HY Zeolite on the Catalytic Behavior of Pt/OMC-HY in the Hydrogenation of Naphthalene

- Removal of Nitride from Shale Diesel Fraction with FeCl3-Based Ionic Liquids

- Effects of Microwave Torrefaction with Mg(OH)2 on Characteristics of Bio-oil from Co-pyrolysis of Straw Stalk and Soapstock