Application of Energy Saving Technology in Trichlorosilane Distillation Purification Process

2019-10-31QieSiyuanPangWeiweiZhaoMingHuangZheqing

Qie Siyuan; Pang Weiwei; Zhao Ming; Huang Zheqing

(1. SINOPEC Research Institute of Petroleum Processing, Beijing 100083;2. Department of Chemical Engineering, School of Chemical Engineering and Technology,Xi’an Jiaotong University, Xi’an 710049)

Abstract: The trichlorosilane (TCS) purification process consumes a significant amount of energy to achieve the high purity requirement for TCS quality (99.9999%). This work proposed a series of energy saving technology to enhance the TCS purification process, including the conventional process, the conventional process coupled with heat-pump (HP), the multi-effect distillation process, and the dividing-wall columns process. All proposed schemes have been conceptually constructed by Aspen Plus. The design and optimization of the processes have been performed by the sensitivity analysis and the response surface methodology. Moreover, the energy consumption and total annual cost (TAC) for these schemes were discussed. The simulation results show that the TAC of the conventional process coupled with the integrated heat pump can reduce 50.5% of energy consumption as compared with the conventional process; the double-effect and three-effect processes can save 15.6% and 33.8% of energy consumption, respectively; the dividing wall column process and that coupled with the heat pump process can reduce by 22.3% and 48.1% of energy consumption, respectively. Ιt can be found that the operating cost can be saved by using the heat pump technology, while the capital cost increases due to the investment in the compressor, when the processes coupled with the heat pump are used. These results demonstrate that the conventional process coupled with the HP technology has advantages over other distillation schemes for TCS purification in terms of the energy saving and economic effects.

Key words: trichlorosilane distillation purification; energy saving technology; process simulation

1 Introduction

The improved Siemens process is mainly composed of three steps: synthesizing trichlorosilane (TCS) by the reaction of metallurgical silicon with hydrogen chloride in a fluidized bed reactor, purifying TCS via the distillation columns, and being deposited as solid silicon via chemical vapor deposition (CVD). At present, numerous studies have focused on improvements in polysilicon CVD reactor to reduce the polysilicon production cost(PPC). Del Coso, et al.[1]proposed an analytical chemical deposition model by considering the conversion of the second-order reaction rate into two systems of firstorder reaction rate and obtained the maximum growth rate based on this model, while the radiative heat transfer behavior in a 36-rod polysilicon reactor had been studied in detail[2]. Liu, et al.[3-5]developed an energy-saving polysilicon CVD reactor and described various transport phenomena in the reactor using a computational fluid dynamics (CFD) method. Vigano, et al.[6]presented a technique for a real-time model based predictive control applied to a laboratory-scale Siemens reactor and used a lumped model to describe the CVD process. Vallerio[7]studied the trade-off between the productivity and energy cost via a multi-objective scalarization method.Kozin, et al.[8]developed a detailed mathematical model and laboratory device to implement the high-frequency power supply and decrease the power loss. Huang, et al.[9]proposed a novel process in which the multiple polysilicon CVD reactors were connected in series to improve the trichlorosilane conversion efficiency to reduce the PPC.The aforementioned efforts all aimed to reduce the PPC by improving the polysilicon growth rate or the TCS conversion efficiency. Nevertheless, it is difficult to further reduce the cost unless a new process for the polysilicon production is developed. Therefore, there is a strong requirement for a new path to reduce the PPC.

Previous study[9]showed that four main costs were involved in polysilicon production using a CVD reactor viz.: the raw material cost (TCS and hydrogen), the power consumption, the equipment depreciation, and other costs. The cost of the TCS accounts for 50.8% of the total PPC. An essential component is associated with the TCS purification section, because the high reflux ratio has been used to comply with the requirement for making high-purity TCS (99.9999%), and this purification process consumes a significant proportion of the total input energy.Ιn order to achieve remarkable energy savings in the TCS purification process, an innovative solution is to use the advanced process intensification and integration techniques.Ιt is worth mentioning that there are many energy saving technologies suitable for the TCS purification process[22],such as the HP technique[10-11], the multi-effect distillation technique[12-13], the DWC with HP[14-15], the heat-integrated distillation column[23-24], the middle vapor recompression distillation column (MVRC)[25], etc. However, the advantages and disadvantages of these techniques are different. The present study aims at reducing the TCS cost by enhancing the performance of the TCS distillative purification using the technologies including the DWC and the HP. Four different distillation schemes, namely, the conventional process, the conventional process coupled with HP, the multi-effect distillation, and the dividingwall columns process are considered and simulated using Aspen Plus. The sensitivity analysis and response surface methodology have been used in the design and optimization of these processes. The energy consumption and the total annual cost (TAC) including the operating cost and the capital cost are compared and analyzed. Ιt is expected through this study that a new energy saving technique for separating TCS could be fully realized.

2 Modeling Method

2.1 Thermodynamic method

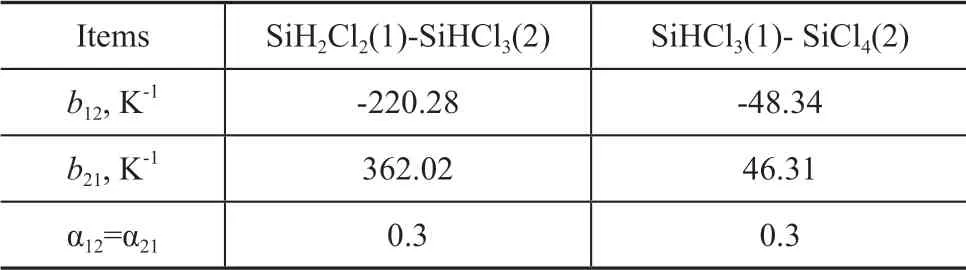

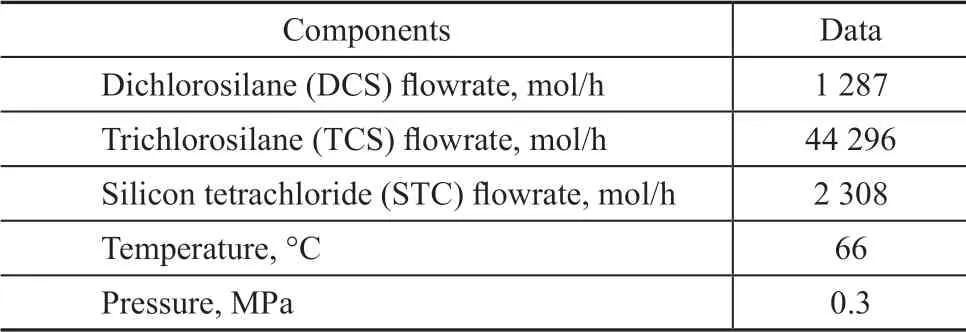

Ιn this work, due to the polarity of the mixture, the NRTL model is selected to perform thermodynamic calculations. This model uses the activity coefficient to calculate the phase equilibrium of the liquid phase,while assuming the vapor phase to be ideal. The binary interaction coefficients of chlorosilanes are taken from the literature to fit the equilibrium data[16], as shown in Table1.

Table 1 Binary interaction coefficients for chlorosilanes systems

2.2 Cost assessment method

Ιn the trichlorosilane distillation process, the total production cost is divided into two parts: the operating cost and the fixed cost. The operating cost is mainly comprised of the consumption of the cooling water in the condenser, the consumption of the heating steam in the reboiler, and the power consumption of the compressor, and these data can be obtained from the simulation result using the Aspen Plus software. Ιn this study, the utility price of the cooling water, the heating steam (low pressure), and the electricity is 0.35, 13.28,and 16.80 $/GJ[17], respectively. The capital cost for the distillation system includes the total module cost of columns, reboiler, condenser, compressors, and structured packing. The equipment module costing technique, which is introduced by Guthrie[18-19], is a common technique to estimate the equipment cost. The equipment and packing have a 10 years for depreciation,and the Sulzer-250Y structured packing has been used in this work, while the height equivalent of theoretical plate and the pressure drop of the packing is 0.4 m and 300 Pa/m[20], respectively; and the price of the packing is approximately 2 000 $/m3. The distillation tower diameter is determined by the packing size in the Aspen Plus software. The tower height consists of the tower bottom, the tower top, and the packing height and the space between the packing sections. The height between the bottom and the top in the tower has been assumed to be 4.27 m[21]. The heat transfer coefficient of the condenser and the reboiler has been assumed to be 500 W/(m2.K) and 600 W/(m2.K)[14], respectively. The inlet temperature of cooling water and heating steam have been assumed to be 300 K and 380 K, respectively; the minimum temperature difference has been assumed to be 10 K, and the heat transfer area of the condenser and reboiler is calculated by using the Equations (1) and (2).

3 Results and Discussion

TCS is commercially prepared by the reaction of metallurgical silicon with hydrogen chloride in a fluidized bed reactor, and then the products are purified by using the adsorption and distillation columns. This study focuses on the TCS distillation section, although the products contain some minor impurities extracted from the metallurgical silicon, and only three compounds are taken into account in this study, including trichlorosilane(TCS), as well as dichlorosilane (DCS), and silicon tetrachloride (STC).

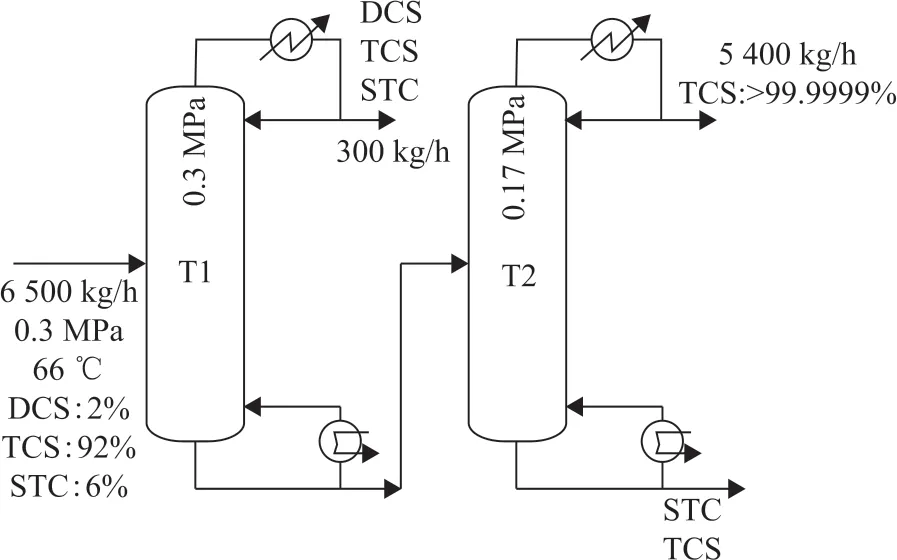

3.1 Conventional distillation process

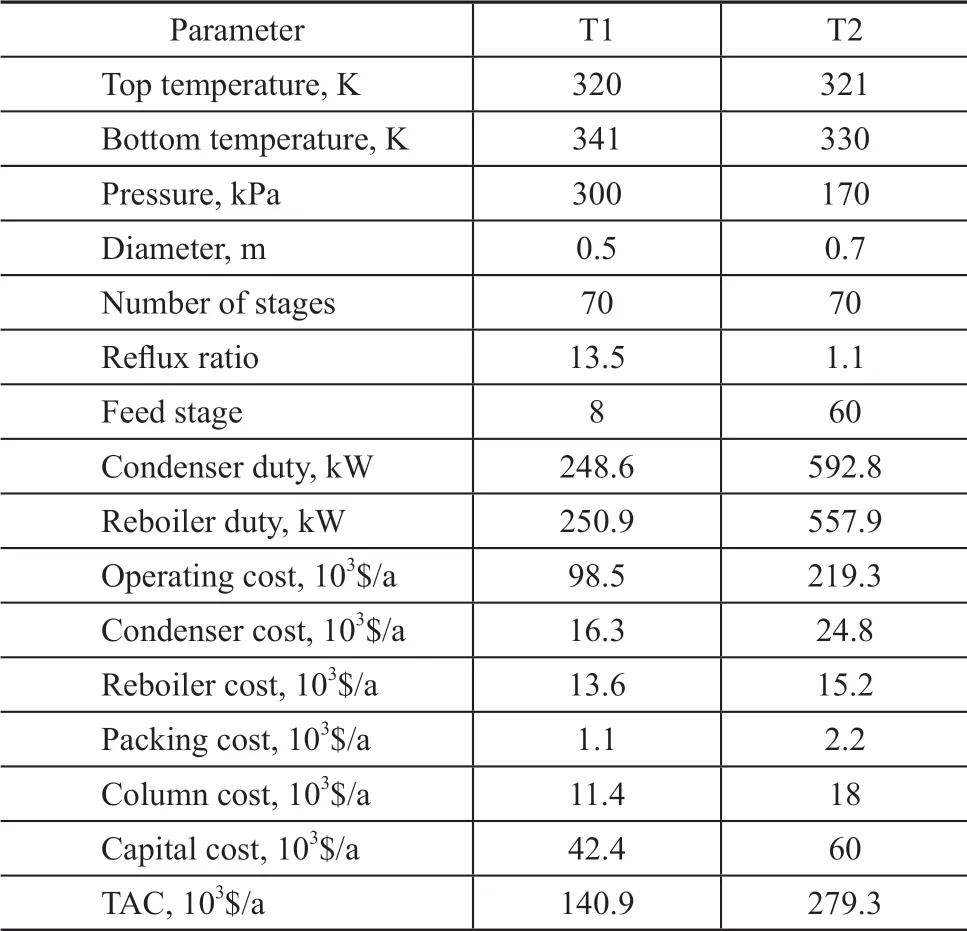

Figure 1 shows the schematic flow diagram of the conventional TCS purification process. The feed conditions, e.g., composition, temperature, and pressure,are displayed in Table 2. According to the process product requirement, a TCS purity of above 99.9999% must be reached, and a TCS recovery rate of up to 90% is assumed in this work.

Figure 1 Conventional distillation process

Table 2 Feed conditions

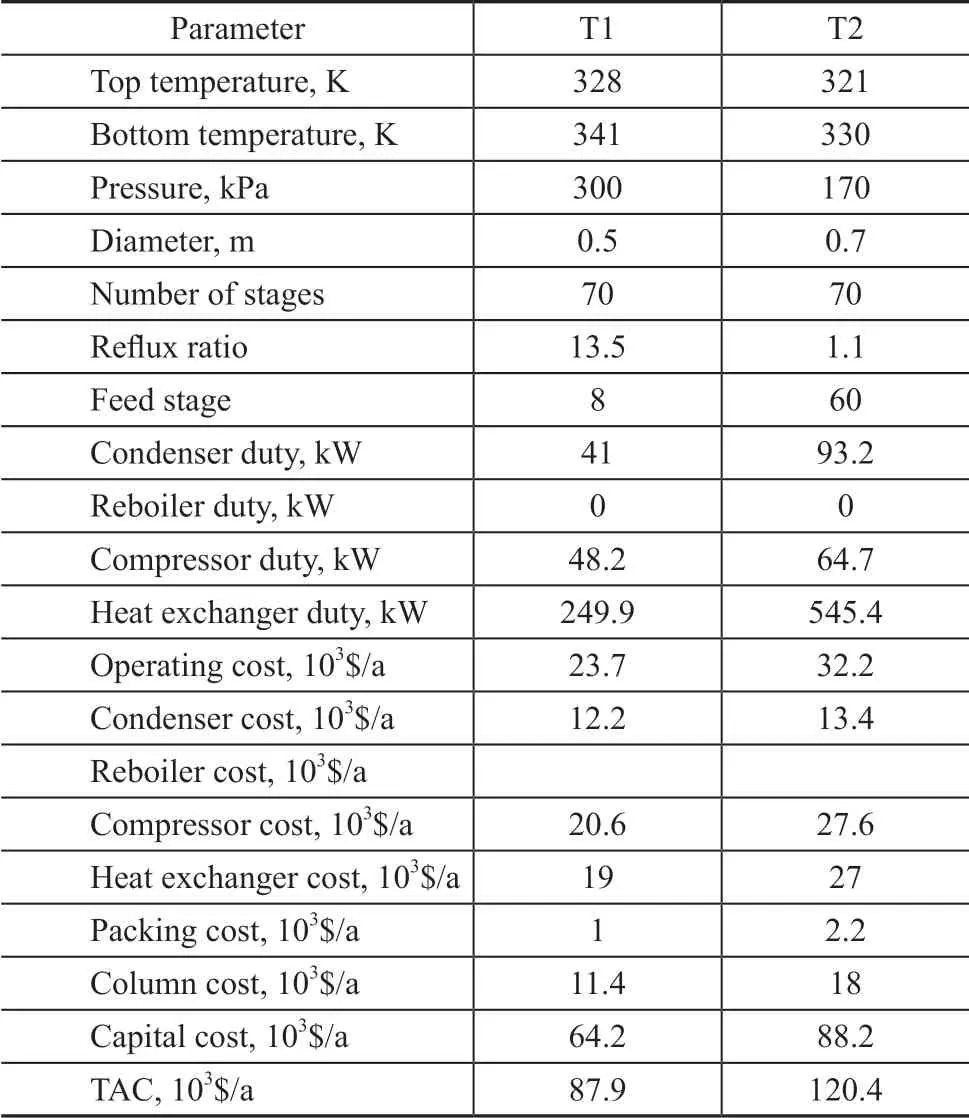

The initial operating parameters of the conventional process can be obtained by using the DSTWU shortcut design procedure. Then the process was simulated using the Radfrac block design to achieve the separation task. The value of 300 kPa and 170 kPa was selected as the operating pressure in T1 and T2, respectively, while the overhead tower temperature in T1 and T2 was 320 K and 321 K,respectively. The design and process optimization of T1 and T2 towers were conducted using the sensitivity analysis method. The energy consumption and the total annual cost(TAC) accomplished under the optimal conditions are presented in Table 3. The simulation results demonstrate that the operating cost has a significant impact on the TAC,the contribution of which was 75.6%. Therefore, the energy saving technology is becoming more and more important for the TCS purification process.

Table 3 Simulation results for the conventional process

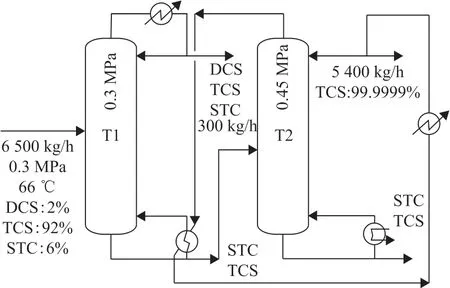

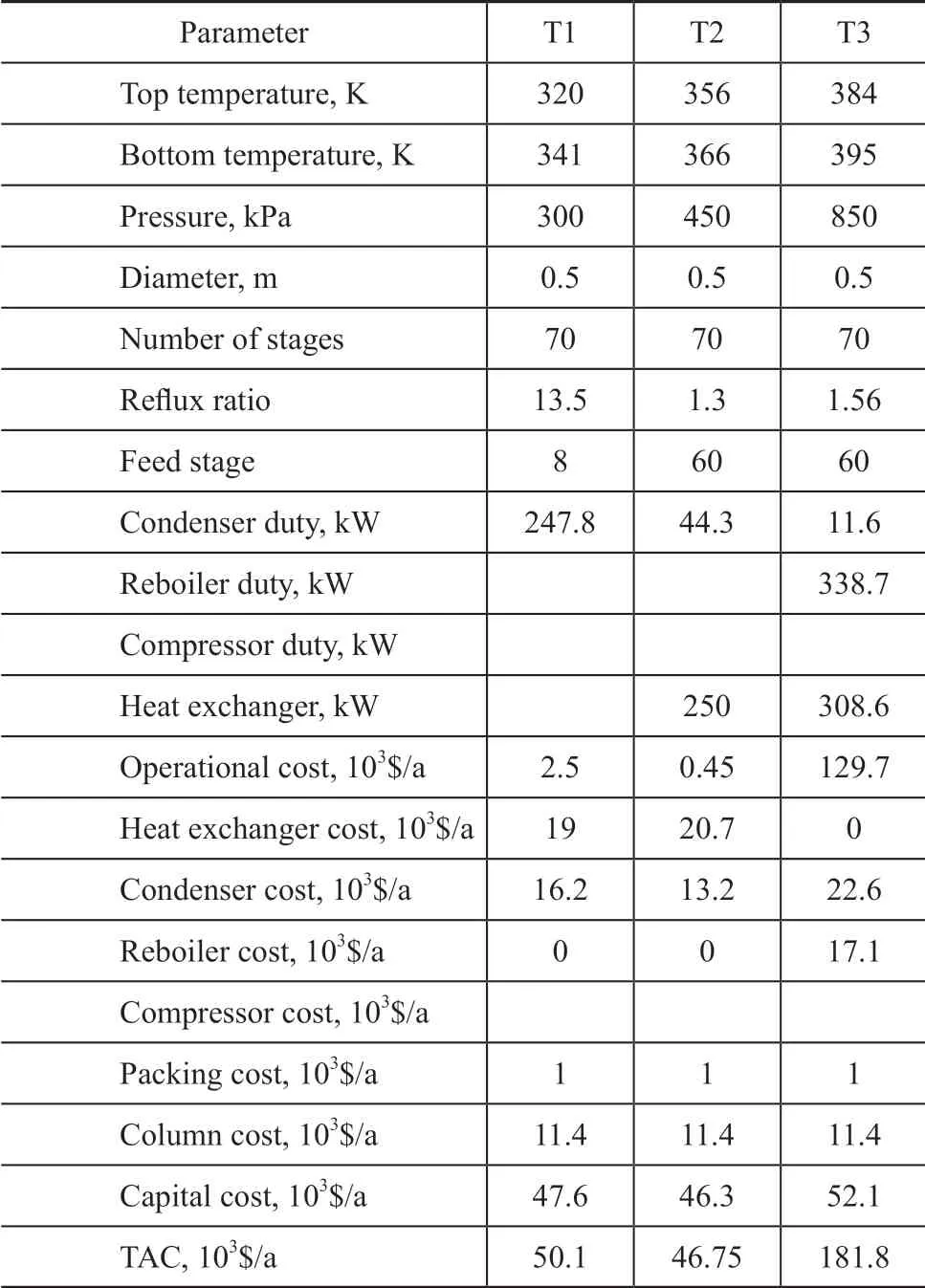

3.2 Multi-effect distillation process

A multi-effect distillation scheme displayes the advantage of the energy saving. The flow diagram for the double-effect distillation process is presented in Figure 2. The T2 overhead vapor was employed to heat the reboiler in T1. The operating pressure of T2 was set at 450 kPa to meet the minimal temperature difference requirement in the heat exchanger.The optimal conditions of T1 column in the conventional process were also used in this process, and the sensitivity analysis was conducted for the T2 column. The simulation results and optimal conditions are presented in Table 4.The operating cost of the double-effect process decreased by 24.8% as compared to the conventional process, but the capital cost increased by 13.6%, and the TAC saving was equal to 15.6%. Obviously, the energy consumption in the T1 reboiler column could be saved, while the T2 reboiler duty increased as the operating pressure went up.

Figure 2 Double-effect distillation process

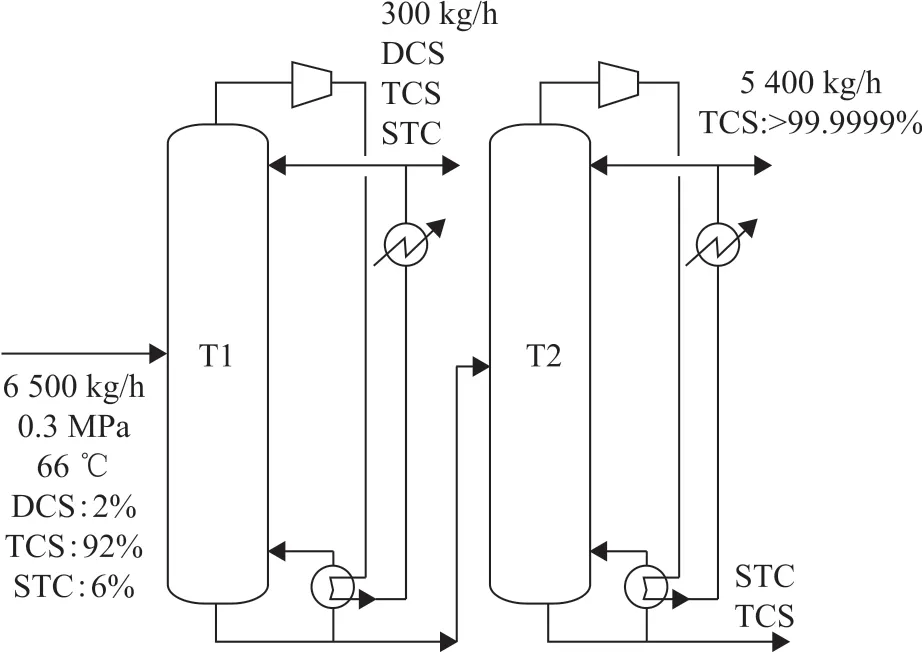

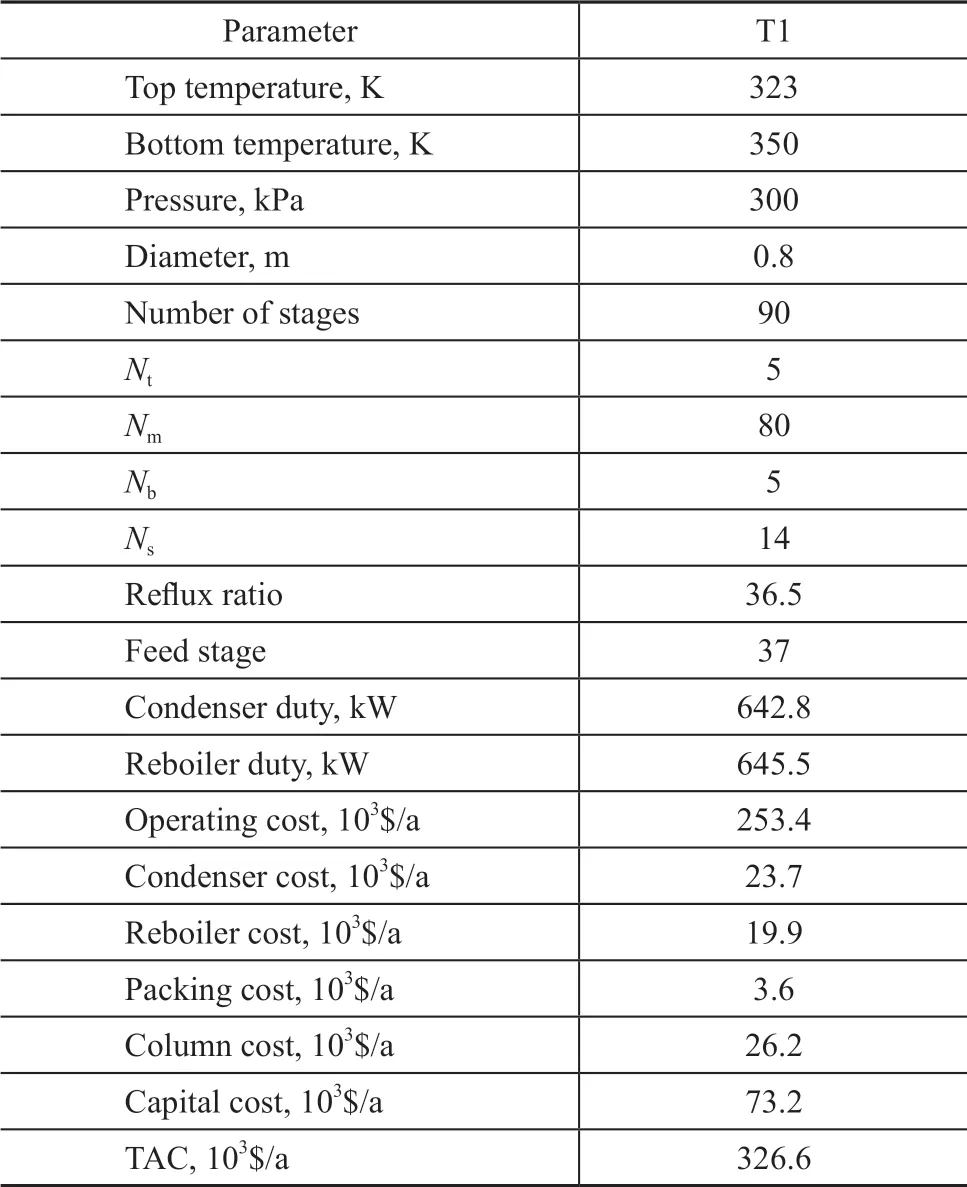

Ιn the double-effect distillation process, the T2 condenser duty was far more than the T1 reboiler duty; therefore, a threeeffect distillation process was proposed, as shown in Figure 3.Compared with the double-effect process, T2 column was substituted by two new columns (T2 and T3 columns), and the operating conditions of T2 for the double-effect process was the same as that for the three-effect process in addition to the mass flow. However, the operating pressure in T3 tower should meet the heat transfer requirement between the T3 column overhead vapor and the T2 column bottom stream. A pressure of 850 kPa was chosen by using the Aspen plus simulation method. The sensitivity analysis for the T3 column was conducted to reach the optimal conditions, as shown in Table 5. The operating cost could be reduced by 44.5% compared to the double-effect distillation process, while the capital cost increased by 25.6%, and the TAC saving was equal to 21.6%. The operating cost was by 58.2% lower compared to the conventional process,while the capital cost increased by 42.5%. And the TAC saving was equal to 33.7%. The results are consistent with the work implemented by Huang, et al.[26]They performed the simulation for the TCS by using the different pressure thermally coupled distillation in a three-column process scheme and found that the energy consumption was reduced by 66.7% compared with the conventional process. The capital cost and the TAC were not analyzed in their work.

3.3 Conventional process coupled with heat pump

Figure 3 Three-effect distillation process

Table 5 Simulation results for the three-effect distillation process

The proper integration of a heat pump can improve the performance of the distillation process. Figure 4 shows the conventional process coupled with HP. The vapors from the top of T1 and T2 towers flow into the compressor 1 and compressor 2, respectively, and then the pressure and temperature all increase. The optimal conditions for the conventional process are also adopted in the process. Moreover, the compression ratio of the compressor 1 and compressor 2 is 3 and 2, respectively, and then the temperature at the outlet of the compressor 1 and compressor 2 is raised up to 385 K and 353 K, respectively. The tower bottom stream has been completely vaporized by the tower top stream in the heat exchangers, while the tower top stream passes through a condenser to reduce its pressure and temperature prior to being divided into two streams,among which one is the product, and the other is the recycled stream. The simulation results for the process are presented in Table 6. Compared with the conventional process, the operating cost can be saved by 82.5%, and this value is in agreement with that of the previous work performed by Huang, et al.[27]They simulated the heat pump distillation process for TCS purification and found that the operating cost of the process coupled with heat pump could be reduced up to 82%. The capital cost and the TAC were not taken into account in their work,especially for the capital cost, and the expenses for the process coupled with heat pump would increase due to the additional compressor cost. For example, the capital cost increased by 48.9% and the TAC would reduce by 50.5%.

Figure 4 Conventional process coupled with heat pump

Table 6 Simulation results for conventional process coupled with heat pump

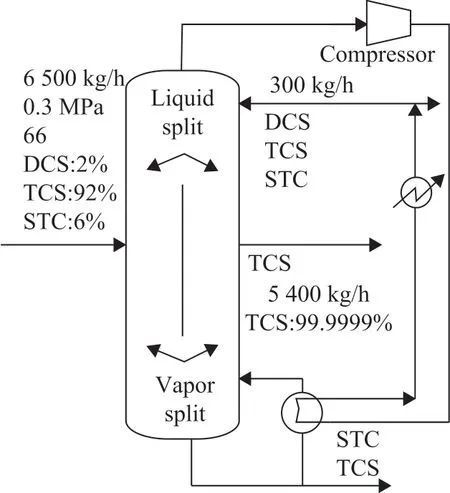

3.4 Dividing wall column distillation process

According to the above analysis, the multi-effect distillation and the process coupled with HP technologies can reduce the energy consumption, however, the capital costs all increase due to the additional investment in the tower or compressor equipment. Ιt is obvious that the distillation process scheme is a ternary system referred to in this work. Therefore, there are two columns, two reboiler and condensers in the flow diagram of conventional distillation process. Ιn order to reduce the capital cost, a dividing wall column has been used for the TCS purification; namely, a vertical wall is equipped in the column center to divide the column into a pre-fractionator and a main column, as shown in Figure 5. The DWC comprises four sections, namely: a pre-fractionator, a top section, a bottom section, and a dividing wall section. The main design variables of the DWC structure include the internal vapor(Fv) and the liquid (FL) flowing into the pre-fractionator, the number of theoretical plates in the top section (Nt), the middle section (Nm), the bottom section (Nb), the feed location (Nf),and the side product location (Ns). The initial DWC design parameters can be obtained using a shortcut design procedure based on the conventional column, and then the single-factor sensitivity analysis can been conducted. After determining the preliminary ranges, the Box-Behnken design has been employed under the response surface methodology to analyze how the variables can be interacted between variables in order to optimize the variables by maximizing the TAC saving. Table 7 presents the optimal operating conditions and the structural parameters. Compared with the conventional process, the operating cost in the dividing wall column can decrease by 28.5%, while the capital cost can be cut down by 20.3%, and the TAC can be reduced by 22.3%. These results are in agreement with the previous studies[28]. Ιn the reference,the dividing wall column can save the operating cost by 25.25% and the TAC by 23.31%.

Figure 5 Dividing wall column distillation process

Table 7 Simulation results for dividing wall column distillation process

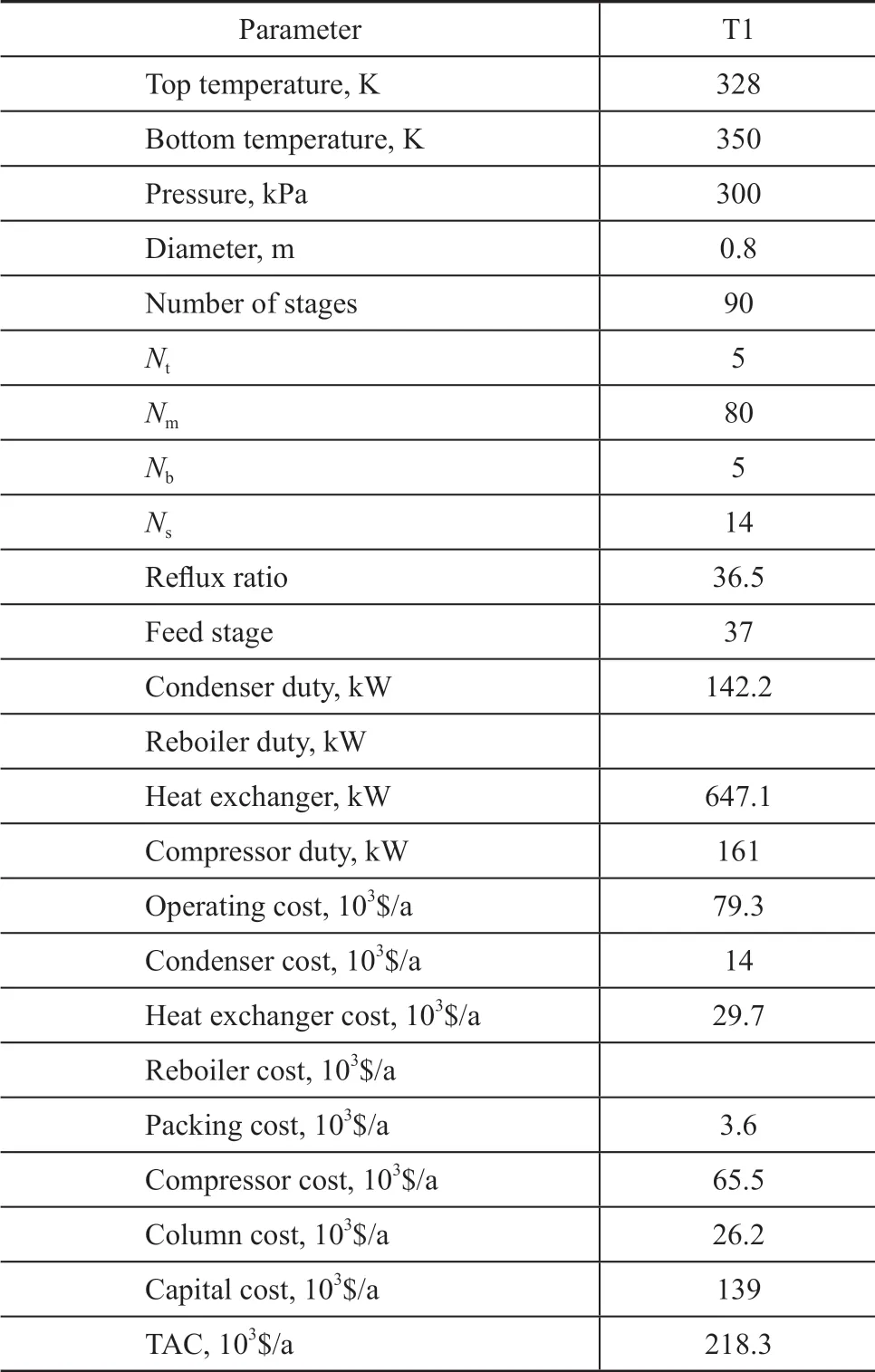

Ιn order to reduce the energy consumption and TAC in the dividing wall process, a dividing wall column coupled with the heat pump process has been proposed. Obviously, the optimal operating conditions and the structural parameters in dividing wall column have been also used in this process. The compressor ratio has been set at 4 by using the Aspen Plus simulation, and then the compressor outlet temperature is 401 K. The simulation results are presented in Table 8. Compared with the dividing wall column process, the operating cost is reduced by 68.7%, while the capital cost is increased by 65 800 $/a, and the TAC can be reduced by 33.2%. Compared to the conventional column process, the operating cost and TAC of the DWC coupled with the heat pump technology can save up to 75% and 48%, respectively. Ιt demonstrates that the DWC coupled with the heat pump process can reduce the TCS cost and further reduce the polysilicon production cost.

Figure 6 DWC coupled with HP process.

3.5 Simulation results

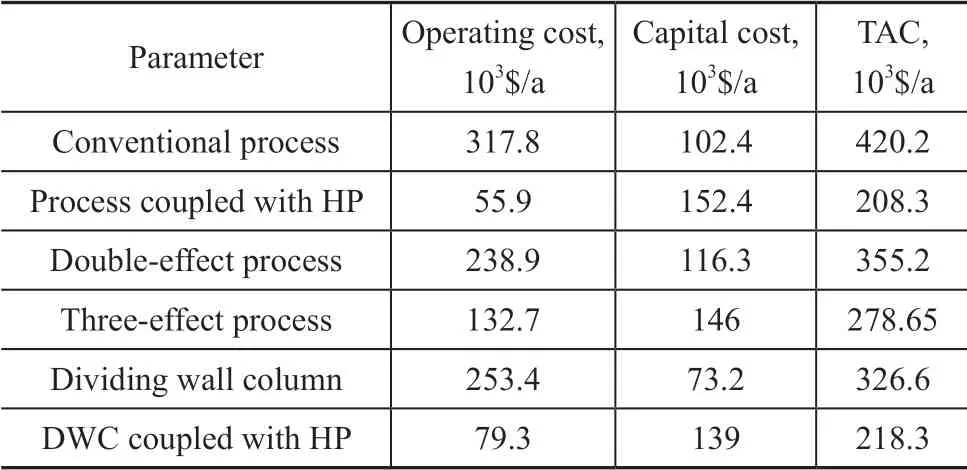

To analyze and compare the advantage and disadvantage for all the evaluated processes, the operating cost, the capital cost, and the TAC have been summarized in Table 9. The operating cost and the TAC for the conventional process coupled with HP are the lowest,while the capital cost increases because of the additional compressors. Although the capital cost for the dividing wall column process is the lowest, the operating cost is greater than the conventional process coupled with HP;therefore, the TAC in DWC process is higher. Ιt can be found obviously that the operating cost plays a dominant role in determining the TAC. Nevertheless, anotherimportant parameter is the compressors cost. Ιt can be seen that the cost of compressors in the conventional process coupled with HP technology accounts for 31% of the capital cost, and this ratio in DWC coupled with HP technology is even more than 47%, because this is due to the fact that the temperature difference between the tower top and bottom in the DWC coupled HP is greater than that in the conventional process coupled HP, which can lead to the increase in the compression ratio, and the power consumption and fixed cost of the compressor all increase. Moreover, the operating cost and TAC in the three-effect process are also higher as compared with the conventional process coupled with HP, which can be attributed to the energy consumption of the reboiler and condenser in the three-effect process. According to the above analysis, the conventional process coupled with HP has advantages over other distillation schemes in terms of the energy saving and overall economic performance.

Table 8 Simulation result for the DWC coupled with HP process

Table 9 Simulation results for different processes

4 Conclusions

This study conceptually constructed four distillation schemes for the TCS purification process, namely: the conventional distillation, the conventional distillation process coupled with HP, the multi-effect distillation process, and the dividing-wall column process, which were all studied by Aspen Plus. The sensitivity analysis and response surface methodology were applied to the design and optimization of the processes. The simulation results have showed that the TAC of the conventional process integrated heat pump can be reduced by 50.5%compared to the conventional process; the doubleeffect process and the three-effect process can save TAC by 15.6% and 33.8%, respectively; the dividing wall column and the same column coupled with the heat pump processes can reduce TAC by 22.3% and 48.1%,respectively. These results also show that the operating cost can be saved by using the heat pump technology.The operating cost of the conventional process and the dividing wall column is 3.178×105$/a and 2.534×105$/a,respectively; while the operating cost can be reduced to 5.59×104$/a and 7.93×104$/a when the heat pump is coupled with these processes. However, the capital cost increases due to the investment of the compressor if the processes coupled with the heat pump are used. For example, the capital cost of the conventional distillation process and the dividing wall column process is 1.024×105$/a and 7.32×104$/a, respectively; while the capital cost can reach 1.524×105$/a and 1.39×105$/a when the heat pump technology is integrated with the above-mentioned process units, respectively. Finally, it is obvious that the conventional process coupled with HP technology has advantages over other distillation schemes in terms of the energy saving and overall economic performance.

Acknowledgment:The authors wish to acknowledge the financial support from the National Natural Science Foundation of China (project No. 21406157).

杂志排行

中国炼油与石油化工的其它文章

- Alkylation of Isobutane and Isobutene in Acidic Polyether Ionic Liquids

- Tribological Properties of Lubricating Oils with Triethanolamine Borate under Electromagnetic Field

- Enhanced Pervaporative Separation of Thiophene/n-Heptane Using Metal Loaded PEBAX/PAN Membranes

- Effects of Added HY Zeolite on the Catalytic Behavior of Pt/OMC-HY in the Hydrogenation of Naphthalene

- Removal of Nitride from Shale Diesel Fraction with FeCl3-Based Ionic Liquids

- Effects of Microwave Torrefaction with Mg(OH)2 on Characteristics of Bio-oil from Co-pyrolysis of Straw Stalk and Soapstock