Effect of heat treatment on microstructure and properties of single crystal copper cold-welded joints

2019-10-22HuangYongRanXiaolongYanXiaojuanGuoTingbiao

Huang Yong , Ran Xiaolong , Yan Xiaojuan , Guo Tingbiao,3

黄勇,冉小龙,严晓娟,郭廷彪

1.School of Materials Science and Engineering,Lanzhou University of Technology,Lanzhou 730050,China;

2.State Key Laboratory of Advanced Processing and Recycling of Nonferrous Metals,Lanzhou University of Technology,Lanzhou 730050,China;

3.Key Laboratory of Nonferrous Metal Alloys and Processing,Lanzhou University of Technology,Lanzhou 730050,China

Abstract With the means of electron backscattered diffraction (EBSD),mechanical properties test and digital eddy current metal conductivity,the single crystal copper cold-welded joint was tested and analyzed,the structure change of cold-welded joint and the effect of heat treating on the structure and property of cold-welded joint were discussed.The results show that:The deformation area of the single crystal copper cold welded joint is broken,the crystalline grain at the interface of the joint is refined,and the single crystal structure is still maintained in the base metal area.The hardness of the deformation area increases greatly,the conductivity of the joint does not change much,and the tensile strength of the joint reaches about 70% of that of the base metal.At the interface of the heat treating joint,the single crystal structure of the deformation area and the base metal area are destroyed,and the grains grow up at the interface and the orientation is different.The hardness of the joint interface is much lower than that of the non-heat treating joint,the electrical conductivity of the joint is good,and the tensile strength of the joint is higher than that of the base metal.

Key words single crystal copper,cold pressure welding,heat treatment,conductivity

0 Introduction

Single crystal copper is a kind of oxygen-free copper with high purity.The whole copper rod consists of only one grain with a specific orientation which is no“grain boundary”between grains (“grain boundary”will reflects and refracts the passing signal which will cause signal distortion and attenuation),so the single crystal copper has very high signal transmission performance,electrical property,corrosion resistance and fatigue resistance,thus it has attracted more and more attention in communication,aerospace,military industry and other important fields[1-2].

The extensive application of single crystal copper also puts up higher requirements for its manufacture and connection in the process of application.Therefore,the connection problem of single crystal copper has also been widely studied by scholars.Cold-pressure welding is a solid-state welding method by applying positive pressure on the surface of the bonding metal at room temperature to make plastic deformation of the metal to be welded.The impurities,contaminants and oxide films on the interface are extruded by plastic deformation to make the fresh metals contact closely and achieve inter-granular bonding[3].Cold pressure welding is carried out at the room temperature,and the joint has no heat input,Therefore,cold-welded joint has no weld heat affected zone compared to conventional fusion welding,and there is no softened zone and brittle metal intermediate phase,which can ensure the conductivity and corrosion resistance of the original base metal etc.,and obtain good connection joint.

At present,the connection of single crystal copper has not been reported yet.Ding,et al.studied the microstructure and properties of single crystal copper and the wire after cold drawing.After drawing,the tensile strength of single crystal copper increased and the probability of scattering of free electrons at lattice defects increases,causing an increase in the resistivity of single crystal copper[4].Yang et al.studied the recrystallization of single crystal copper with strong cold deformation at different temperatures,and discussed the influence of annealing process on its microstructure and properties.With the increase of heat treatment temperature,the recrystallization process of single crystal copper gradually changes to polycrystal,the tensile strength increases,the elongation decreases,and the resistivity increases[5].

In this work,the single crystal copper is connected by cold pressure welding.Under the condition of ensuring a certain strength,plasticity and electrical conductivity of the joint,in order to realize the effective connection of the single crystal copper,the joint is subjected to stress relief annealing.The evolution of microstructure in cold-welded joints and subsequent heat treatments and their effects on the properties of joints were investigated.

1 Material and experimental details

The test substrate was a hot-type continuous casting single crystal high-purity oxygen-free copper bar with a purity of 99.999%,the diameter was ϕ 8 mm,the length was 32 mm,and the orientation was {001},as shown in Fig.1.Welding material surface is treated with the wire brush of ϕ=0.34mm before welding.The YTD27-100 four-column hydraulic press is used to press the workpiece in cold-pressure welding,and the mold is shown in Fig.2.After welding,0.75 mm welding gap between the two positioning molds is ensured,and the process parameters are shown in Table 1.The effects of heat treatment on micro-structure,mechanical properties and electrical conductivity of welded joints under a certain amount of compression are studied by reserving the extension lengthl(l=7 mm).

Fig.1 Grain orientation diagram of single crystal copper base metal

Fig.2 Schematic diagram of cold-pressure welding mold:1-hydraulic press head;2-copper rod;3,6-fixed mold base;4,5-positioning mold

The micro-structure analysis of the joint was carried out by scanning electron microscope Hitachi s-3400 and matching with TSL OIM Analysis software system to carry out analysis of electron back-scattered diffraction.

The diffraction angle was 70° and the acceleration voltage was 20 kV,the scanning step is 1.5 μm.The sample was intercepted by wire cutting,and the sampling position is shown in Fig.3a.The sample size is 5 mm × 5 mm ×2 mm.The sample was polished with No.1000-No.7000 sand paper,and then conducted with mechanical polishing with the diamond with the grain size of W0.5.Finally,the surface stress layer was removed by electrolytic polishing,and the electrolytic polishing solution was divided into H2O :H3PO4:C2H5OH=2 :1 :1.The polishing voltage is 4 V and the polishing time is 7-8 min.The EBSD scanning area is shown in Fig.3b,where the dashed line is the boundary line of the end welding gap,the region A is located in the joint interface and deformation area,and the area B is in the large deformation area and the base metal area.The tensile mechanical properties of welded joints are tested by WDW-100D microcomputer controlled electronic universal material tester,and the loading force is 10 kN,the loading rate is 0.5 mm/min.The conductivity of single crystal copper before and after welding is measured by Sigma 2008 B/C digital eddy metal conductivity instrument,and the measurement error is 0.1% IACS.

2 Results

2.1 Organizational evolution

Fig.4 is a reverse pole image of single crystal copperunheated and stress relief annealed.From Fig.4a,it can be seen that after cold-pressing welding,the single crystal structure features at the interface and the deformed zone disappear,many fine grains appears at the interface,the grain size in the deformation zone is relatively large,and the grain boundaries are very irregular.

Table 1 Cold -pressure welding process parameters

Fig.3 Electron backscatter diffraction (EBSD) sampling position and scanning area (a) Sampling position (b) Scanning area

Fig.4 Grain orientations of cold-welded joints (white lines are the dividing lines of different areas) (a) Interface and deformation zone (b) Deformation zone and base metal zone (c) Heat treatment joint interface and deformation zone (d) Heat treatment joint deformation zone and base metal zone

The contrast between grains increases obviously.The base metal area is subjected to the shearing stress of the mold wall,and the orientation is directional rotation.This shows that the process of grain breakage in the cold-welding process,the interaction between the grain boundaries and the directional rotation of the grains are beneficial to improve the stability of the material[6].As can be seen from Fig.4c,large size grains were formed in the deformation zone and base metal area at the interface after heat treatment,which is due to the increase of atomic diffusivity during heat treatment and the decrease of recrystallization temperature because of the large deformation.The reversion and recrystallization of many broken fine grains during heat treatment and their growth lead to the increase of the grain size.Grains are coarse and have different orientations outside the deformation area[7-9].There are a lot of annealing twin crystal structures in the interface zone,deformation zone and base metal area.

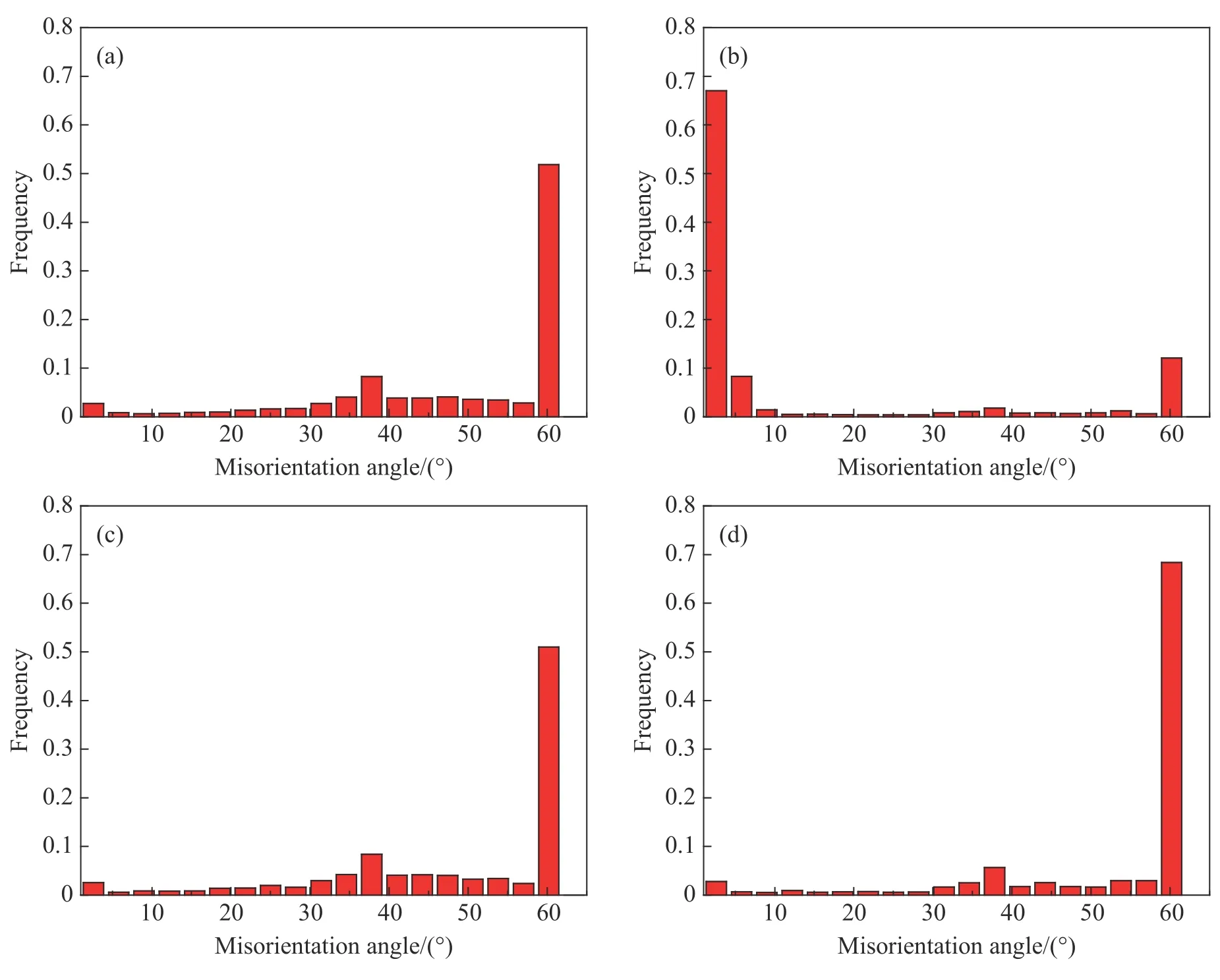

Fig.5 is the distribution map of misorientation between heat treatment joint and unheated treatment joint by cold welding.Without heat treatment,the number of the large angle grain boundary at the interface and deformation area of the cold-welded joints increases greatly,and the distribution rate of the adjacent misorientation of 60° is increased,which is due to the large amount of deformation at the joint and deformation zone,resulting in a large number of deformation twins,as shown in Fig.5a.There are a large number of small-angle grain boundaries on the deformation zone and the base material area side,because the base metal area remains single crystal structure during the deformation process,the dislocations in the base material area are greatly increased in value and intertwined,forming dislocation cells,resulting in a large increase in small-angle grain boundaries,and the deformation zone grains are broken,so there are a few large angle grain boundaries,as shown in Fig.5b.After heat treatment,the number of large angle grain boundaries in the deformation area and base metal zone increased greatly at the interface,and the grain boundaries in the deformation zone and the base metal zone changed from the small angle grain boundary to the large angle grain boundary,and the number of twins increased obviously,as shown in Fig.5c and Fig.5d.Through the analysis,it is considered that a large number of dislocations were stored at the interface,deformation zone and base metal zone in the cold pressure welding process,which provides the driving force for recovery and static recrystallization in the process of heat treatment.As a result,recrystallization grains and annealing twins with different orientations are formed at the interface and deformation area of the joints[10-12].

Fig.5 Misorientation diagrams of cold-welded joint (a) Interface of the cold-welded joint and the deformation zone (b)Cold-welded joint deformation zone and the base metal zone (c) Heat treatment joint interface and deformation zone (d)Heat treatment joint deformation and base metal zone

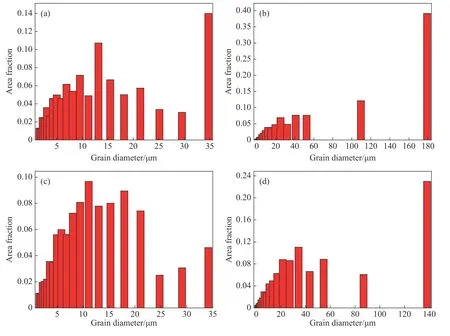

Fig.6 Grain sizes of cold welded heat-treated joints and unheated joints (a) Interface of the cold-welded joint and the deformation zone (b) Cold-welded joint deformation zone and the base material zone (c) Heat treatment joint interface and deformation zone (d) Heat treatment joint deformation zone and base metal zone

Fig.6 is a statistical chart of grain size of cold welded joints and unheated treatment joints under the same compression amount.A large number of fine grains appear at the interface and deformation zone of the cold welded joints without heat treatment,as shown in Fig.6a,with coarse grain sizes exsiting in the deformation and base metal area,as shown in Fig.6b.Through the analysis,the grain size is small due to grain refinement during cold pressure welding.During the joining process,the base material area is bound by the mold,the mold wall exerts a reaction force on the metal in the base material area,and the grain in the base material area is less sheared by the mold wall,and is not refined into fine grain structure[13-15].At the deformation zone and the connecting interface of joint with heat treatment,grains gradually grow in the process of heat treatment,the ratio of the diameter of the grains between 10-25 μm is increased,as it is indicated in Fig.6c;In the process of grains at the deformation zone and the base metal zone,the ratio of grains with large size of 20-60 μm is obvious,as it is indicated in Fig.6d.Through the analysis,it is considered that the static reversion and recrystallization in the process of heat treatment makes the gradual growth of the fine grain at the joint with heat treatment into grains of big size[16].

2.2 Texture evolution

Fig.7 is the {111} plane pole drawing of joint without heat treatment and the cold-welded joints with heat treatment under the same amount of compression.ND represents the direction of normal direction,ED represents the direction of extrusion,the strongest point for the orientation of crystal plane at the cold-welded joints without heat treatment tends to be collected at {101} crystal plane,the extreme density value at the deformation zone and the base metal zone reaches 17.833;the extreme density value at the connecting interface and the deformation zone reaches 2.316;joint interface and deformation zone of cold-welded joint after heat treatment for which the orientation point of strength tends to be collected at {100} crystal plane,the extreme density value is 3.020;the orientation point for the strength of crystal face at the deformation zone and the base metal zone tends to be collected at {111} crystal family,the extreme density value is 5.852.Through the analysis,it is considered that in the process of cold pressure welding,through the methods like recrystallization and separation of dislocation etc,the single crystal copper forms a large number of grains with different orientations at the connecting interface in the process of deformation,while the base metal zone outside of the deformation zone still keeps the single crystal structure,but the grain occurs with directional rotation under the function of shear stress.The cold-welded joints after heat treatment,the connecting interface,the deformation zone and the base metal zone occur with static reversion and recrystallization for which the texturing strength of joint is smaller[17-19].

Fig.7 The pole image of the cold-welded heat treatment joint and the unheated joint (a) Interface of the cold-welded joint and the deformation zone (b) Cold-pressed deformation zone and the base material zone (c) Heat treatment joint interface and deformation zone (d) Heat treatment joint deformation zone and base metal zone

Fig.8 is the ODF sectional drawing for the orientation of grains on the cold-welded joints,through the quantitative analysis on the texturing of the cold-welded joints,it can be found that there exist {110}<001> texturing and weaker{001}<100> texturing at the deformation zone and joint without heat treatment,there mainly exists {110}<>texturing at the deformation zone and the base metal zone.After the heat treatment,it is mainly {111}<110> texturing at the deformation zone and the connecting interface of cold pressure welding,while it is mainly {110} <110> texturing and {112}<111> texturing at the deformation zone and the base metal zone,while the strength of texturing at the base metal zone and the deformation zone of the cold-pressure welding joint after the heat treatment and the strength of texturing at the interface and the deformation zone are weaker.Through the analysis,it is considered that after the heat treatment,the dislocation,subgrain generated in the deformation process of cold welded joints provide the driving force for the reversion and recrystallization of the joint for which the grain structure of joint takes different directions and tend to be stable[20-23].

2.3 Hardness change

Fig.8 Orientation distribution function (ODF) cross-section of cold pressure welding heat-treated joints and unheated joints(a) Cold-welded joints interface and deformation zone (b) Cold-welded joints deformation zone and base metal area (c) Heat treatment joint interface and deformation zone (d) Heat treatment joint deformation zone and base metal zone

Fig.9 Hardness values at different distances from the interface

It can be seen from Fig.9 that the micro-hardness of the base metal is 64.12 HV,the hardness of the cold-welded joints without heat treatment at the connecting interface is 133.7 HV.With the increase of the distance from the connecting interface,the hardness of the copper bar is reduced,its hardness outside of the deformation zone is about 106.2 HV;The hardness at the deformation zone and the interface of the connecting joint after the heat treatment is reduced to which it approaches the hardness of base metal.The hardness value outside of the deformation zone tends to be consistent with the hardness value of the test objects without heat treatment outside of the deformation zone.This is because in the process of cold pressure welding,the serious plastic deformation refines the grain and the broken grains increases the quantity of gain boundaries,while crystal boundary plays a function of impediment in the movement of dislocation for which the single crystal copper performs the phenomenon of work hardening in the process of cold pressure welding[24-26].The reason for the decrease of hardness at the interface of the heat treated joint is that the static recovery and recrystallization process in the heat treatment process results in the decrease of dislocation density at the interface of the joint and fine grain migration and merging through grain boundaries,which leads to the increase of the grain size.As a result,the hardness value at the interface of the joint decreases.The hardness of the joint is slightly higher than that of the base metal because the grain size at the interface of the joint is finer than that of the base metal and the grain boundary plays a strengthening role at the interface of the joint.However,the deformation storage energy of the deformation zone is small.When the temperature increases,the critical diffusion activation energy of copper is not reached,so there is no large amount of recovery and recrystallization,and the hardness value tends to be the same[27].

2.4 Mechanics and conductivity test

Table 2 shows the electrical conductivity and tensile strength at the cold-welded joint of single crystal copper.It can be seen that the conductivity of single crystal copper base metal before cold welding is 55.03 MS/m.The conductivity of the joint of cold welding is 54.61 MS/m.The conductivity of the cold joint remains basically unchanged after heat treatment.It is found that the electron scattering is aggravated by the increase of the number of subgrain boundaries and the lattice distortion under large strain in the process of cold-pressed bonding,which leads to the decrease of electrical conductivity.After heat treatment,the conductivity of the cold-welded joints is eliminated by recovery and recrystallization,but the grain boundary hindrance still exists in the deformation zone,which makes the conductivity of the joint lower than that of the base metal[28-30].

Table 2 Conductivity and tensile strength of cold-welded joints

The tensile strength of single crystal copper base metal is 103.7 MPa,and the tensile strength of cold-welded joints is up to 69.23 MPa.After heat treatment,the tensile strength of the joint exceeds that of the base metal,up to 114.3 MPa.The analysis shows that the surface hardening layer is broken and the fresh metallic contact reaches the interatomic bonding in the process of cold pressure welding,so an effective bonding joint is formed.In the process of heat treatment,the appearance of a large number of twin grains greatly increased the strength of the material.The metal atoms at the interface recover and recrystallize,and the number of fine grains with different orientations increases at the interface.The increase of grain boundary quantity can strengthen the joint,so the tensile strength of the joint is higher.However,coarse grains and twin structures are formed in the deformation zone and base metal zone of the heat treatment joint,which destroy the crystal structure of single crystal copper[31-32].

3 Conclusions

(1) During the cold-welded connection of single crystal copper,the grain in the deformation zone is broken,resulting in many fine grains with different orientations at the joint interface,and the single crystal structure remains outside the deformation zone.In the process of heat treatment,the diffusion ability of atoms increases,many fine grains grow up to grain with different orientations after recovery and recrystallization,and the single crystal structure outside the deformation zone is destroyed.

(2) In the process of cold pressure welding,the hardness of deformation zone increases obviously due to broken grain,grain boundary strengthening and fine grain strengthening.After stress relief annealing at 300 ℃ for 2 hours,the hardness at the interface decreases obviously.

(3) The tensile strength of the joint is about 70% of that of the base metal by cold welding single crystal copper,and the tensile strength of the joint after heat treatment is higher than that of the base metal.After cold welding,the conductivity of the joint reaches 99.24% of that of the base metal.After heat treatment,the conductivity of the joint does not change obviously,and the single crystal structure of copper is changed to polycrystalline.

猜你喜欢

杂志排行

China Welding的其它文章

- A brief review of brazing diamond in cutting tools

- Principles and application of RES welding technology

- Interface microstructure and properties of submerged arc brazing tin-based babbit

- Welding deviation detection method based on weld pool image contour features

- The microscopic mechanical performance for nonuniform welded joint of nickel-based alloy with nanoindentation

- Performance study of a complex thermal barrier functional coating with an electro-spark deposited burn-resistant layer