Performance study of a complex thermal barrier functional coating with an electro-spark deposited burn-resistant layer

2019-10-22WangRuijunXuTianyangMaXiaobinLuoZhiheng

Wang Ruijun, Xu Tianyang, Ma Xiaobin, Luo Zhiheng

汪瑞军,徐天杨,马小斌,罗志恒

Chinese Academy of Agricultural Mechanization Sciences,Beijing 100083,China

Abstract It is necessary to develop burn-resistant and thermal barrier complex functional coatings on the titanium alloys surface due to the poor high temperature performance for titanium materials and the problem of“titanium fire”which is easily happened.MTU Aero Engines GmbH has developed a complex functional coating which has great performance of burn resistant and sealing,the coatings has already been applied on compressor blades and casing for aero-engines and showed great performance.In this study,the complex functional coating which is composed of an electro-spark deposited amorphous Ti40Zr25Ni3burn-resistant layer and a high-energy plasma spraying prepared YSZ thermal barrier layer was prepared on titanium alloys surface.Then the heat insulation ability,burn resistant performance and the bonding strength were investigated.The experimental results showed that the interface between the coating and the matrix was typical metallurgical bonded,and the average bonding strength was 36.335 MPa;when the temperature of the flame on the one side of the specimen reached 600 ℃,the average insulated temperature of the coating samples was 70.67 ℃;when the flame temperature was 350 ℃,the titanium samples without the complex functional coatings were burned,while the samples with the coating showed great performance of burn resistant even when the temperature was 750 ℃.This indicates that the new functional coating has good heat-insulating and burn-resistant performance.

Key words complex functional coatings,burn resistance,heat insulation

0 Introduction

Titanium alloys are widely applied in the field of aerospace due to their high specific strength and excellent corrosion resistance.Especially,titanium alloys have got great attentions in the design and fabrication of key components of aerospace engines to improve the thrust-weight ratio, efficiency and payload of aerospace engines.However,there exists the problem of“titanium fire”— titanium alloys could burn under certain environment,leads to severe damage,sometimes even the case for aero engines could be burned through.“Titanium fire”has become a great research area for engineering applications of titanium materials[1].

There are mainly three ways to solve the problem of“titanium fire”:(1) use of alternative structure and alternative materials,e.g.increase of the distance between titanium blade tips and stators,and replacement of titanium materials by steel;(2) use of burn-resistant titanium alloys,e.g.preparation of burn-resistant titanium alloys by adding multiple phases;(3) preparation of burn-resistant coatings on the titanium alloys surface.

The studies of burn-resistant coatings are developed quite early overseas.NASA has tested 12 kinds of materials for burn-resistant coatings,and found that ion evaporation deposited aluminum and electroplated Pt-Cu-Ni coatings have better performance of burn resistance and fatigue life;MTU Aero Engines GmbH has developed a burn-resistant and sealing complex functional coating with two-layers structure,which consists of a titanium fire protection layer and a sealing layer,this coating can be used for compressor case and blades,where cubic boron nitride was deposited on the blade tips and zirconia coatings with different core density were prepared on the case.MTU affirmed that this coating system can achieve burn-resistance and sealing for airplanes.The study of burn-resistant coatings carried out in China is relatively late,BGRIMM group and AVIC XI’AN AERO-ENGINE (GROUP) LTD developed a burn-resistant thermal spraying coating,where a microarc pulsed ion deposited burn-resistant coating which was prepared by Chinese Academy of Agricultural Mechanization Sciences (CAAMS) could increase the combustion temperature for“second combustion”of titanium alloys[2-5].

In this study,an electro-spark deposited amorphous burn-resistant layer was prepared as the bonding layer,and on the top,a thermal barrier layer was prepared.The performance studies on burn resistance and heat insulation were performed to develop a preparation method for complex functional coatings.The study can also provide useful data accumulation for applications of high-end equipment.

1 Materials and methods

1.1 Materials

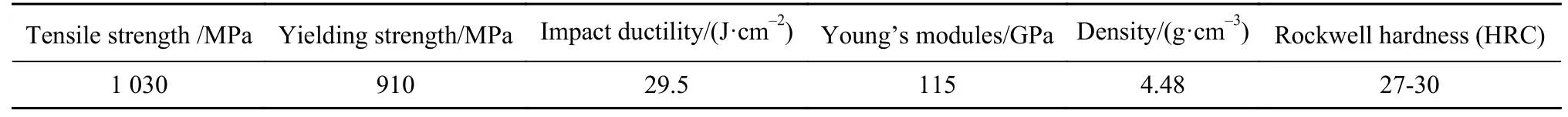

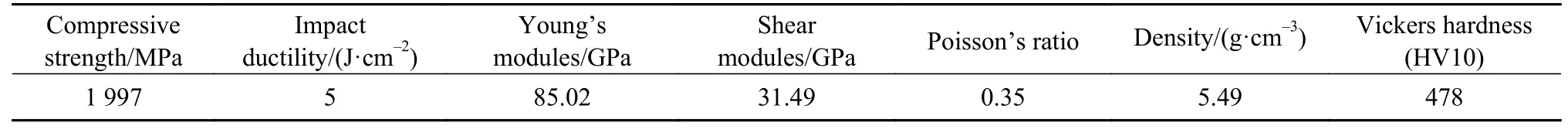

TC11 alloy was used as the titanium matrix,whose mechanical properties is showed in Table 1.A ϕ6 mm×100 mm amorphous Ti40Zr25Ni3electrode was used as the electro-spark deposition material,Table 2 shows its mechanical properties.The material ZrO2Y2O3was used for the thermal barrier layer.

Table 1 Mechanical properties for TC11 alloy

Table 2 Mechanical properties for Ti40Zr25Ni3

ϕ25.4 mm×6 mm titanium alloy specimens were prepared for bonding strength test for coatings,and ϕ30 mm×3 mm specimens were used for heat insulation tests.Samples of 125 mm×27 mm×2 mm were used for burn resistant tests.

1.2 Preparation of burn-resistant layer and thermal barrier layer

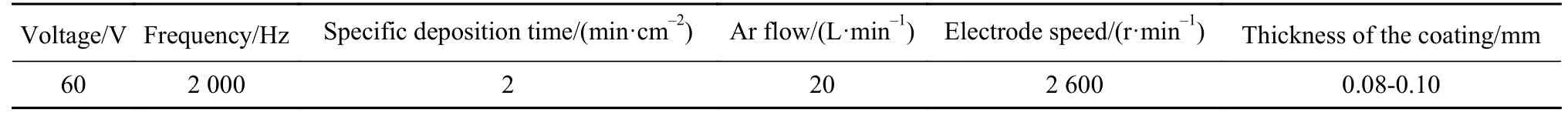

A burn-resistant layer,amorphous Ti40Zr25Ni3was prepared on the surface of titanium alloys by electro-spark deposition.The electro-spark deposition can release great energy in a short time,which forms ionization channels between the electrode and the matrix,and produces high temperature and high pressure on the matrix.Meanwhile,the micro electric field leads to the infiltration of ionized electrode material into matrix material so as to form a micro metallurgical strengthening layer.Table 3 shows the process parameters during the fabrication.Table 4 represents the process parameters for the high-energy plasma spraying thermal barrier layer.

Table 3 Process parameters for fabricating burn-resistant layer of amorphous alloys

Table 4 Process parameters for fabricating thermal barrier layer by high-energy plasma spraying

2 Results and discussion

2.1 Cross section morphology of the complex functional coating

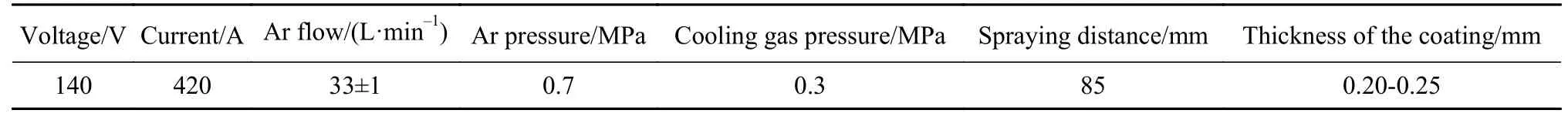

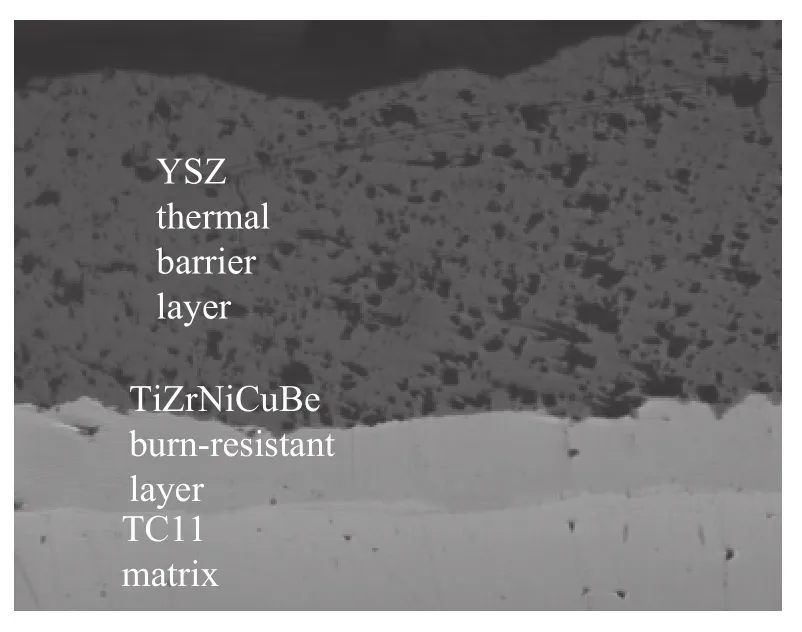

Fig.1 shows the morphology of the burn-resistant amorphous Ti40Zr25Ni3layer on the titanium alloys surface.The burn-resistant layer has a thickness of 37.7 μm.There is no defect,such as cracks and included slag.

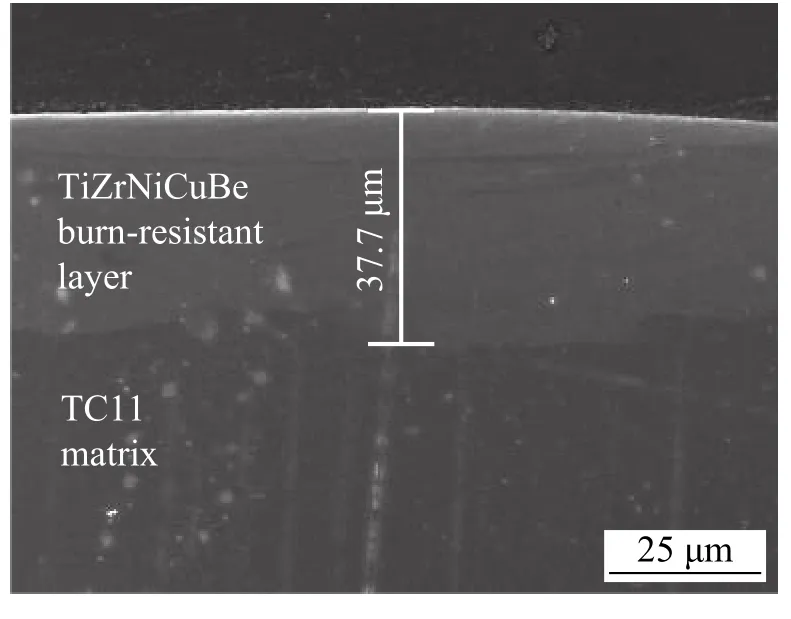

The interface between the TC11 matrix and the burnresistant layer was detected by energy spectrum analysis,As showed in Fig.2,the diffusion of elements at interface can be observed,where there is an infiltration area at the interface between the burn-resistant layer and the matrix.The elements Ti and Al in the matrix diffuse to burn-resistant layer,while element Zr and Cu in the burn-resistant layer diffuse to the matrix.This is consistent with our earlier study[6].All of these suggest the micro metallurgical bonding between the strengthening layer and the matrix.

Fig.1 Burn-resistant/bonding layer on TC11 alloy

Fig.2 Analysis of elements diffusion of interface between burn-resistant/bonding layer and the substrate

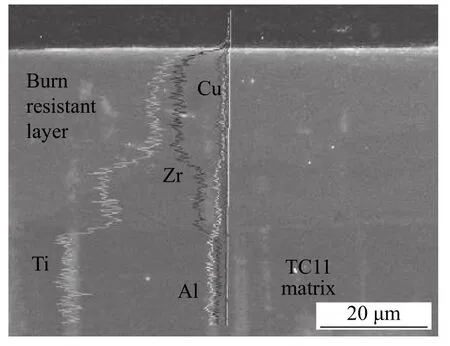

Fig.3 shows the result of phase analysis for the burnresistant layer by X-ray diffraction method.A broad diffuse scattering peak and a weak sub-strong diffuse scattering peak could be seen,which are typical amorphous phase characteristics.Fig.4 shows the morphology of the thermal barrier layer prepared by high-energy plasma spraying method.A clear interface between the titanium matrix and the burn-resistant layer can be observed,and there was no core or contaminant.The thermal barrier layer has a typical layered microstructure,and has a porosity of 15%.

2.2 Bonding strength and heat insulation performance

Fig.3 XRD analysis for the burn-resistant/bonding layer

Fig.4 Morphology for burn-resistant/bonding layer and thermal barrier layer on TC11 alloy

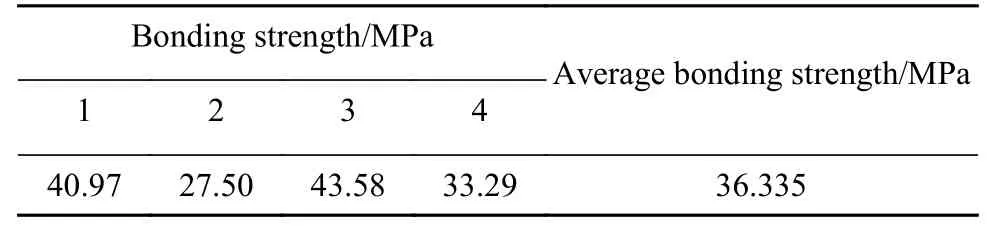

According to the test method of bonding strength of coatings (Chinese standard:HB5476-91),the bonding strength of the complex functional coating was tested.The tensile speed was 2 mm/min,and the average bonding strength was 36.335 MPa,Table 5 shows the test data.

Table 5 Bonding strengths of the functional composite coatings

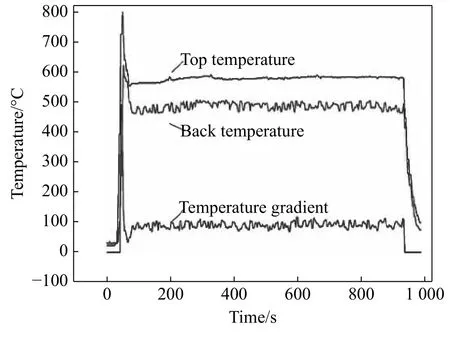

Heat insulation performance for the complex functional coatings was tested by the comparison method,which calculates the average temperature difference between the two sides of the sample with the coating and without the coating,respectively.The test process includes as follows:heat one side of the sample covered by the functional coating with flame,and meanwhile inlet the cooling gas at room temperature on the other side of the sample;record the temperatures on both sides of the sample by using a double color infrared thermometer and a K type thermocouple;when the temperature on one side of the sample reaches its setting temperature,maintain the temperature for 15 min.The average difference △T1between the temperatures on two sides of the sample can be tested after the sample cools down to the room temperature.The temperature difference△T2of the sample without the complex functional coating was also be tested by this method.

Fig.5 shows the real-time recording for the sample with the coatings.When the temperature of the flame was 600 ℃,the heat insulated temperature was 70.67 ℃.

Fig.5 Experimental results of heat insulated temperature tests

2.3 Burn resistant performance

Titanium alloys usually have dense and protective oxide on the surface.Under high temperature and high pressure environments,it transforms to the structure of β titanium,increasing the solubility of titanium in the oxygen.The decrease of the equilibrium concentration of oxygen leads to the reduction of TiO2and suboxide Ti3O5,which may lead to the peeling of the oxide[6-7].After the peeling,the temperature increases dramatically and reaches the ignition temperature for titanium.This is the basic mechanism of the ignition of titanium.

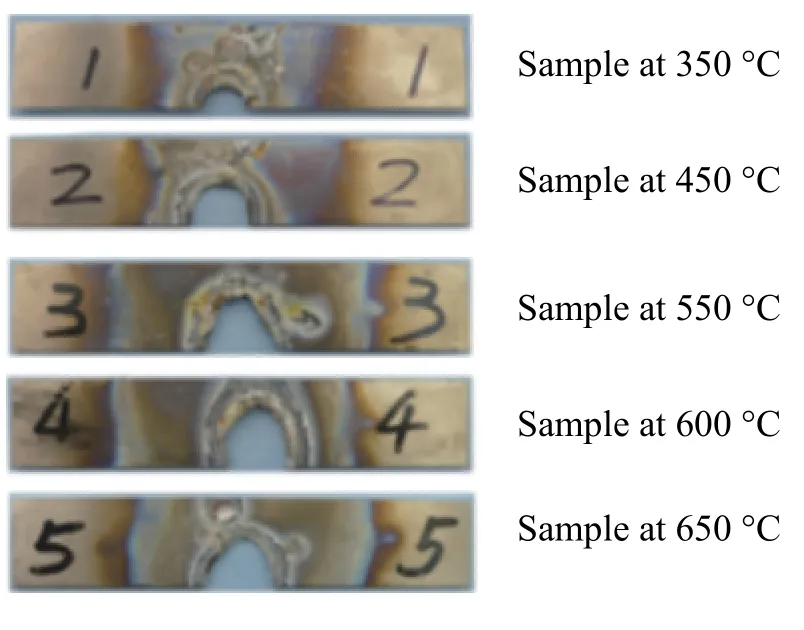

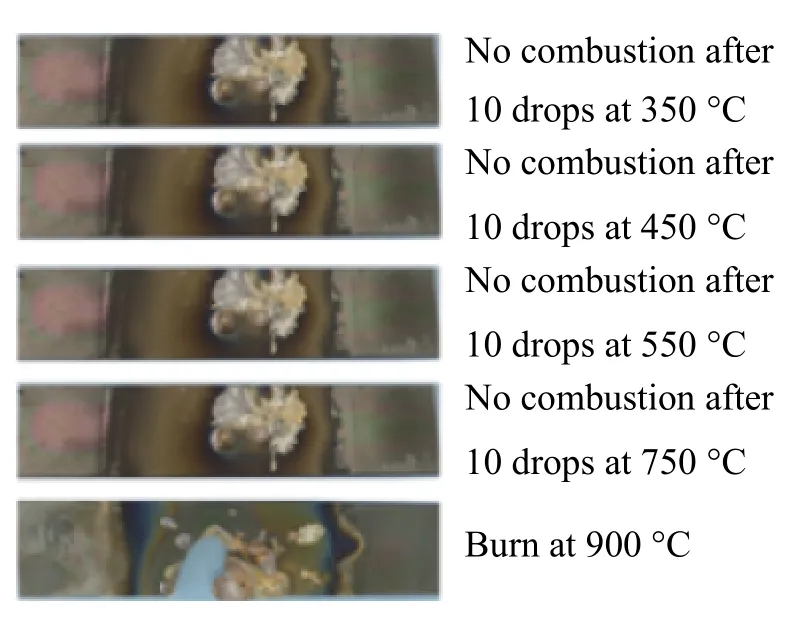

According to the critical ignition temperature of titanium,the burn resistant performance of the complex functional coating was detected by droplet combustion method.Fig.6 shows the titanium samples without functional coating.These samples were burned when the temperature was 350 ℃.Fig.7 shows the titanium samples with the complex functional coatings and these samples show great burn-resistant performance even 750 ℃.

Fig.6 Combustion test for samples without the functional coating

Fig.7 Burn-resistant performance for samples with the functional coating

One of the requirements for the combustion of titanium is that enough oxygen should be involved in the reaction.The electro-spark deposited burn-resistant layer is dense and has no defect like cracks or bubbles,which blocks oxygen into the titanium matrix.Also,there is element of Cu in the burn-resistant layer,which reduces the adsorption of oxygen on metal.During the service of the complex functional coating,the elements Ti and Cu in the coating form Ti-Cu eutectic alloy,which form a copper-rich layer with 2-4 times higher copper content at the interface between the matrix and the melt drop.Hence,the oxidation process of the titanium alloy was restrained and excellent burn-resistant performance was shown.

3 Conclusions

(1) The bonding strength results of the complex functional coating showed that the amorphous Ti40Zr25Ni3burnresistant layer and the YSZ thermal barrier layer has a high bonding strength of 36.335 MPa,due to the formation of metallurgical bonding between the burn-resistant layer and matrix.

(2) When the flame temperature reached 600 ℃ on one side of the specimen,the heat insulated temperature of the specimen with the complex functional coating was 70.67 ℃.

(3) The specimens without the coating would burn,when the flame temperature was 350 ℃,while the specimens with the coating showed great burn-resistant performance even when the flame temperature increased to 750 ℃

杂志排行

China Welding的其它文章

- A brief review of brazing diamond in cutting tools

- Principles and application of RES welding technology

- Interface microstructure and properties of submerged arc brazing tin-based babbit

- Welding deviation detection method based on weld pool image contour features

- The microscopic mechanical performance for nonuniform welded joint of nickel-based alloy with nanoindentation

- Lap joining Al5052 to Ti6Al4V by GTAW with AlSi5 filler wire