Tensile behaviors of ecological high ductility cementitious composites exposed to interactive freeze-thaw-carbonation and single carbonation

2019-10-15ChaiLijuanGuoLipingChenBoTangYongjianFeiXiangpeng

Chai Lijuan Guo Liping,2,3 Chen Bo Tang Yongjian Fei Xiangpeng

(1School of Materials Science and Engineering, Southeast University, Nanjing 211189, China)(2Jiangsu Key Laboratory of Construction Materials, Southeast University, Nanjing 211189, China)(3Collaborative Innovation Center for Advanced Civil Engineering Materials, Southeast University, Nanjing 211189, China)(4State Key Laboratory of Hydrology-Water Resources and Hydraulic Engineering, Nanjing Hydraulic Research Institute, Nanjing 210029, China)

Abstract:To explore the tensile property parameters in the structural design of bridge deck link slabs made by ecological high ductility cementitious composites (Eco-HDCC), the tensile properties of Eco-HDCC exposed to interactive freeze-thaw-carbonation cycles and single carbonation cycles were studied. The carbonation front of Eco-HDCC was determined by X-ray diffraction and differential scanning calorimetry-thermal gravimetric methods. Results indicate that the carbonation front of Eco-HDCC after interaction tests is deeper than that of Eco-HDCC after single carbonation tests. In addition, the ultimate tensile strength for Eco-HDCC shows an increasing trend after the interaction of 1 to 5 cycles compared with that of virgin specimens, while the ultimate tensile strength decreases after the interaction of 10 to 15 cycles. For single carbonation tests, the ultimate tensile strength of Eco-HDCC increases as cycles increase. After being subjected to interaction and single carbonation environments, both the ultimate tensile strain and tensile strain energy of Eco-HDCC decrease as cycles increase, and the decrease degrees of Eco-HDCC after interaction cycles are larger than those of Eco-HDCC after single carbonation. For general consideration, the tensile stress-strain relationship of Eco-HDCC after the interaction of 15 cycles can be adopted in the design of bridge deck link slabs for the purpose of safety.

Key words:ecological high ductility cementitious composites (Eco-HDCC); interaction cycle; single carbonation; carbona-tion front; tensile stress-strain curve; tensile strain energy

High ductility cementitious composites (HDCC) as a type of fiber-reinforced cement-based composite material has an average ultimate tensile strain of more than 0.5% and an average crack width of less than 200 μm[1]. HDCC has a promising application in bridge deck link slabs which replaces traditional expansion joints. In addition, HDCC has been used to cast bridge deck link slabs, and the results indicated that the properties of HDCC meet the design requirements of link slabs[2-3].

Bridge deck link slabs should be designed to bear tension-compression complex loads caused by shrinkage, creep and variable temperatures. The tensile property is a main factor to affect the performance in service for the bridge engineering. In addition, bridge deck link slabs made by HDCC are exposed to the atmosphere, and suffer from different environmental factors based on local climatic conditions. For instance, in the northwest zone of China, bridges are subjected to the interaction effects of freeze-thaw cycles and carbonation. However, in the south region of China, most bridges are exposed to the single carbonation environment.

According to the design theory of HDCC, more fibers will be pulled out if the matrix strength decreases, resulting in higher ductility. However, more fibers will be ruptured if the matrix strength increases, resulting in a lower ductility[4]. The matrix of HDCC will be loose after being exposed to freeze-thaw cycles, and the matrix strength will decrease, while the tensile ductility of HDCC shows an increasing trend. The matrix of HDCC will be dense after being exposed to the carbonation environment as the carbonation productions are generated, and the matrix strength will increase which leads to a decrease in the ductility of HDCC. During the interaction process of freeze-thaw cycles and carbonation on HDCC material, matrix looseness caused by freeze-thaw cycles may be compensated by carbonation. Thus, the matrix property of HDCC after interaction factors exposure is different from that of HDCC after single factor exposure. However, research has seldom been carried out to address the tensile property of HDCC after being exposed to interaction conditions.

HDCC contains quartz sand and Kuraray-Ⅱ PVA fibers resulting in a high cost. Thus, it is not suitable for promotion in engineering applications. Using river sand and domestic PVA fibers to replace quartz sand and Kuraray-Ⅱ PVA fibers in traditional HDCC, Zhang et al.[5]prepared an ecological HDCC (Eco-HDCC) material. The compressive strength of Eco-HDCC was 24.3 to 50.0 MPa and the tensile ductility was 0.5% to 3.0%. The cost of Eco-HDCC was only 1/3 of that of traditional HDCC.

To satisfy the requirements of bridge pavements, the Eco-HDCC mixture with a compressive strength above 40 MPa was selected[6]. In this paper, the tensile behaviors of Eco-HDCC exposed to interactive cycles and a single carbonation environment were compared. In addition, X-ray diffraction (XRD) and differential scanning calorimetrythermal gravimetric (DSC-TG) methods were adopted to reveal the carbonation front after different interaction cycles or carbonation cycles.

1 Experimental Program

1.1 Materials

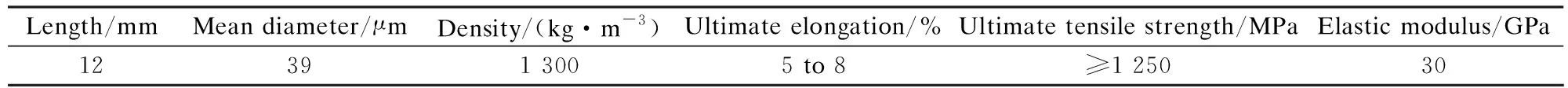

The P·Ⅱ 42.5R Portland cement (C) and Class F fly ash (FA) were used as the binding materials. River sand was selected as the fine aggregate. Its bulk density, fineness and maximum diameter were 1 570 kg/m3, 1.68, and 1.18 mm, respectively. The short PVA fibers produced in China were screened and their main properties are presented in Tab.1. Polycarboxylate superplasticizer with a 40% water-reducing rate was used to adjust the workability of the fresh Eco-HDCC paste. These materials were mixed with tap water. Moreover, the mixture proportion of Eco-HDCC with a designed compressive strength of 40.0 to 48.0 MPa was selected. In addition, the mass ratio of water to cementitious material(C+FA)

Tab.1 Physical and mechanical properties of PVA fibers

was 0.3, and the mass ratio of sand to cementitious material(C+FA) was 0.3. The mass ratio of fly ash to cement was 1.5, and the mass ratio of polycarboxylate superplasticizer to cementitious material(C+FA) was 0.08%. The volume content of the PVA fiber was 2% in the study. Moreover, the fluidity of the fresh Eco-HDCC paste was (190±3)mm.

1.2 Specimen preparation

A mixer for mixing mortars was used to prepare Eco-HDCC material. The procedures for mixing Eco-HDCC specimens were as follows. Cement, fly ash, river sand and polycarboxylate superplasticizer powder were mixed for 90 s at a low speed. Then, water was added and mixed for 240 s at a high speed. Finally, fibers were added slowly and mixed for 120 s at a high speed.

The compressive strength and tensile property of Eco-HDCC were examined in the test[1]. Besides, the carbonation fronts of interaction tests and single carbonation tests were measured. The detailed dimensions and number of Eco-HDCC specimen are listed in Tab.2.

Tab.2 The dimensions and number of Eco-HDCC specimen

All the fresh Eco-HDCC specimens were placed in laboratory with the temperature of (21±2) ℃, and demolded at an age of 24 h. Then, the specimens were cured in a curing room with the temperature of (23±2) ℃ and the relative humidity of (95±2)% until 28 d.

1.3 Test procedures

1.3.1 Interaction test

Based on the environment conditions for bridge deck link slabs in the northwest zone of China, an interaction test programs of freeze-thaw cycles and carbonation were determined. Notably, during the freeze-thaw process, the carbonation speed was very low because of low temperatures[7-8]. Also, during the carbonation process, the freeze-thaw cycles were not considered because the temperature was higher. Thus, the carbonation phenomenon and freeze-thaw cycles were not considered at the same time. In addition, the mean freeze-thaw cycles are about 118 per year in winter lasting for three months[7-9], and the carbonation lasts for nine months. According to the study on the relationship between tests in the field and accelerated tests in lab, 118 freeze-thaw cycles in the field can be equivalent to 10 cycles in the lab for accelerated freeze-thaw tests, and nine months in the field is equivalent to 9.7 h in the lab for accelerated carbonation tests[8-11]. Therefore, an interaction cycle can be equivalent to the environmental condition per year in the northwest zone of China.

Based on the environment conditions for bridges in the southern region of China, a single carbonation factor was considered. The carbonation age was 9.7 h per cycle.

As the designed service life is 15 years for expansion joints in the bridge structure[12], bridge deck link slabs for replacing traditional expansion joints were designed to last for 15 years at least. In addition, interaction tests and single carbonation tests can be designed for 15 cycles. In the study, Eco-HDCC specimens were exposed to 0, 1, 3, 5, 10 and 15 cycles[8].

The detailed interaction process for each interaction cycle is shown as follows: 1) Eco-HDCC specimens were immersed into water for 4 d; 2) Specimens were subjected to freeze-thaw tests for 10 cycles; 3) Eco-HDCC specimens were dried with a temperature of 60 ℃ for 2 d; 4) Carbonation tests of Eco-HDCC specimens for 9.7 h were carried out. After one interaction cycle, the interaction process was conducted again for another interaction cycle[8]. For single carbonation tests, specimens were placed in a carbonation chamber for 9.7 h per cycle. Rapid freeze-thaw cycle tests and accelerated carbonation tests were conducted based on the durability code of concrete(GB/T 50082—2009)[13].

1.3.2 Tensile behavior

〗The uniaxial tensile property test of Eco-HDCC was carried out by using an electro hydraulic servo fatigue testing machine. Aluminum plates were glued on both sides at the ends of coupon specimens to facilitate gripping. Two linear variable differential transformers were used to measure tensile strain. In addition, all of the tensile tests for Eco-HDCC were performed at a constant loading rate of 0.2 mm/min[8].

After the tensile test, the dog-bone specimens were cut into small prism samples with a dimension of 13 mm×30 mm×10 mm for fiber dispersion tests. According to the organic PVA fiber dispersion method[14], the degree of PVA fiber dispersion was evaluated.

1.3.3 Carbonation front

The carbonation front was determined by the transition point of contents for Ca(OH)2and CaCO3, and the transition point is defined as the point where the contents of Ca(OH)2and CaCO3tend to be steady with the increase in depth from the specimen surface[8, 15].

The prism specimens of Eco-HDCC with five surfaces sealed by paraffin were placed in a carbonation chamber, and only one surface with a size of 100 mm×400 mm was allowed to carbonize.

After predetermined interaction cycles and carbonation ages, the specimens of Eco-HDCC were drilled into powders. Powders were taken every 1 mm and were screened by a 0.075 mm sieve. In addition, the XRD method was used to analyze the diffraction intensity of calcium hydroxide (Ca(OH)2) and calcium carbonate (CaCO3). According to the diffraction intensity, the range of the carbonation front was determined roughly. In addition, the DSC-TG test was conducted to calculate the contents of Ca(OH)2and CaCO3within the range of the carbonation front. Then, the carbonation front could be obtained accurately[8].

2 Results and Discussion

2.1 Fiber dispersion

The fluorescent liquid can be absorbed by organic PVA fibers, and the fibers present a light blue color. Another inorganic matrix is dyed by residual fluorescent liquids and this matrix exhibits a green color. The PVA fiber dispersion image is shown in Fig.1.

The fiber dispersion performance is evaluated by the fiber dispersion coefficientα, and it is calculated by[14]

Fig.1 PVA fiber dispersion image

(1)

wherexiis the number of fibers in thei-th image;xais the average number of fibers in the total image;nis the total number of images.

Based on the statistical results of the fiber dispersion images, the fiber dispersion coefficient is 0.91, which is close to 1.0. Thus, the fiber dispersion performance is superior.

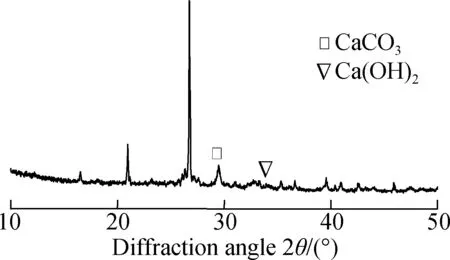

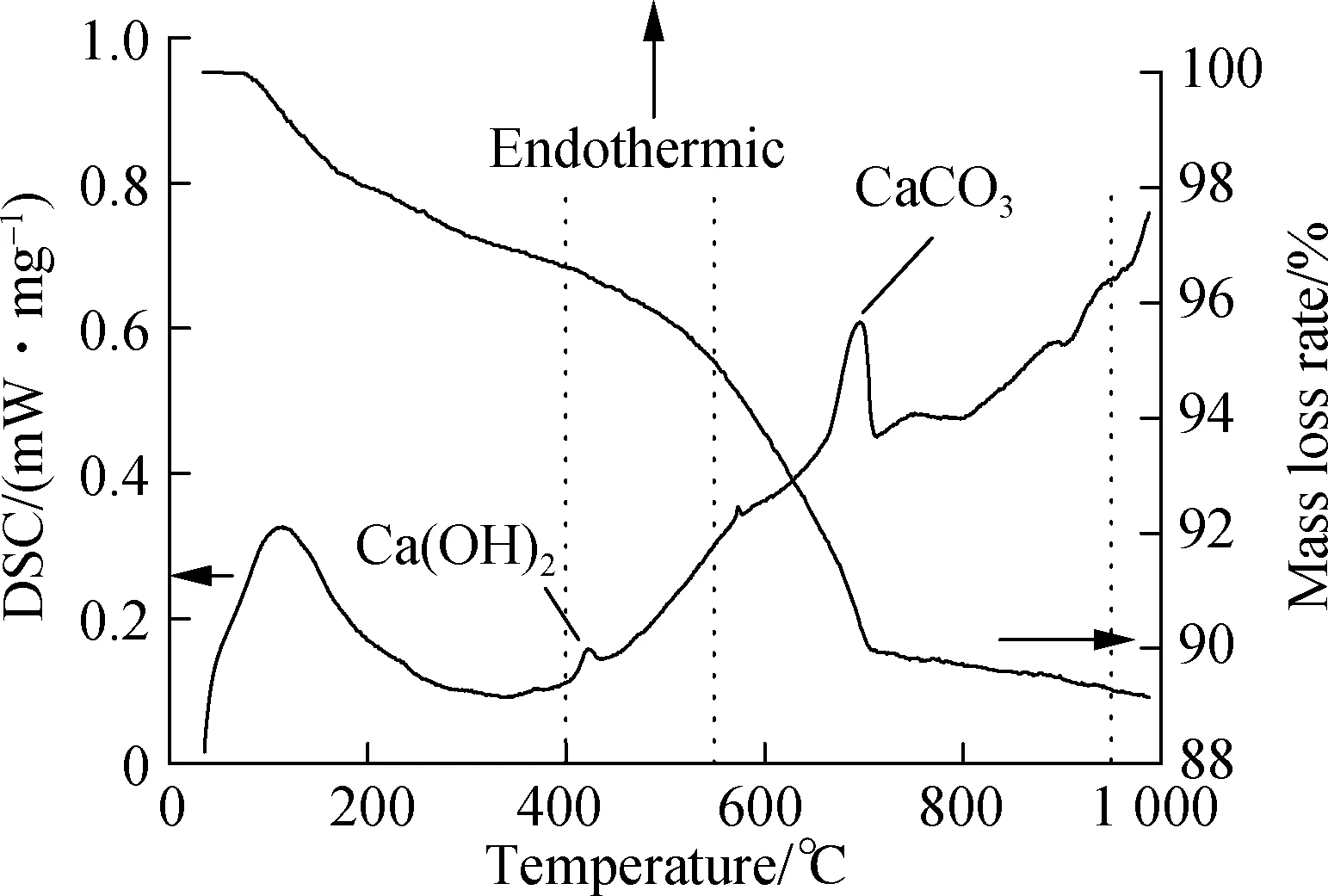

2.2 Carbonation front

The XRD and DSC-TG analysis results of Eco-HDCC with the interaction of 3 cycles are presented in Fig.2. Notably, there is an endothermic peak corresponding to the decomposition of Ca(OH)2at around 420 ℃ and an endothermic peak corresponding to the decomposition of CaCO3at around 700 ℃. The dehydration of Ca(OH)2is

(a)

(b)

calculated by the mass loss rate with a temperature from 400 to 550 ℃, while the decomposition of CaCO3is determined by the mass loss rate with the temperature range from 550 to 950 ℃[8, 15].

Based on the XRD and DSC-TG analysis results, the carbonation front of Eco-HDCC is determined, as listed in Tab.3. It can be seen that as cycles increase, the carbonation fronts of Eco-HDCC after interaction cycles and single carbonation cycles show an increasing trend, while the carbonation fronts of Eco-HDCC after interaction cycles are larger than those of Eco-HDCC after single carbonation.

Tab.3 The depth of the carbonation front for Eco-HDCC

To better understand the difference of carbonation fronts between interaction cycles and single carbonation cycles, the freeze-thaw damage coefficient is defined as[16]

(2)

whereλFis the freeze-thaw damage coefficient affecting the depth of carbonation front;dF+Cis the depth of the carbonation front under the interactions of freeze-thaw cycles and carbonation, mm;dCis the depth of the carbonation front under single carbonation cycles, mm. IfλF=1, freeze-thaw cycles do not affect the depth of the carbonation front; ifλF<1, freeze-thaw cycles have a positive effect on the depth of the carbonation front; ifλF>1, freeze-thaw cycles have a negative effect on the depth of the carbonation front.

As shown in Fig.3, the coefficients of freeze-thaw cycle damages are larger than 1, which indicates that freeze-thaw cycles have a negative effect on the carbonation front of Eco-HDCC. The pore structure of Eco-HDCC will

Fig.3 The coefficients of freeze-thaw cycles damages

be deteriorated after exposed to freeze-thaw cycles, resulting in a larger pore distribution[6]. The carbonation speed of Eco-HDCC will be faster during the process of interaction cycles than that of Eco-HDCC during the process of single carbonation cycles. Therefore, the carbonation fronts of Eco-HDCC after interaction cycles are larger than those of Eco-HDCC after single carbonation cycles.

Based on the DSC-TG analysis results, the CaCO3and Ca(OH)2contents of Eco-HDCC at carbonation fronts are shown in Fig.4.

Fig.4 CaCO3 and Ca(OH)2 contents of Eco-HDCC after different interaction cycles and single carbonation cycles

As shown in Fig.4, both the CaCO3and Ca(OH)2contents of Eco-HDCC decrease as the cycles increase. In addition, the CaCO3and Ca(OH)2contents of Eco-HDCC after single carbonation cycles are higher than those of Eco-HDCC after the interaction cycles.

Although the carbonation front of Eco-HDCC increases with the increase of cycles, the carbonation degree at the carbonation front decreases, resulting in a decreasing trend in CaCO3and Ca(OH)2contents. For the single carbonation tests of Eco-HDCC, the matrix will be denser due to the generation of carbonation products, and the carbonation speed will be lower. Thus, the carbonation fronts of Eco-HDCC after single carbonation cycles are lower than those of Eco-HDCC after the interaction cycles. In addition, Ca(OH)2has been converted into CaCO3products at the depth of the carbonation front, resulting in higher contents of CaCO3. However, for the interaction tests of Eco-HDCC, specimens were immersed into water for 4 d before freeze-thaw cycles, and Ca(OH)2can be consumed by fly ash. Thus, Ca(OH)2content is lower than that of Eco-HDCC after single carbonation cycles.

2.3 Tensile behavior

The compressive strength of Eco-HDCC in the study is 43.4 MPa, which meets the requirement of bridge pavements.

2.3.1 Tensile stress-strain relationship

The tensile stress-strain relationship curves of Eco-HDCC after being exposed to interaction cycles and single carbonation cycles are shown in Fig.5. All the curves of Eco-HDCC can be divided into four stages: the linear elastic stage, nonlinear stage, strain hardening stage and strain softening stage. Thus, the features of the four stages are inherent characteristics, and they are independent of the service conditions. The relationship between tensile stress and strain is linear at the initial stage, and micro-cracks form during the tensile loading process resulting in a nonlinear characteristic in curve. In addition, the first cracking point of Eco-HDCC occurs at the nonlinear stage with the accumulation of internal micro-cracks. During the process of tensile loading, the matrix of Eco-HDCC will crack, and the tensile stress decreases with a characteristic of sudden drop in curve. After that, the bridging effect of the fibers will act and the tensile stress of Eco-HDCC increases with a characteristic of sudden jump in curve. During the process of “drop-jump” for Eco-HDCC curves, the curves present obvious strain hardening characteristics. Moreover, as the tensile force increases, the major crack occurs. Thus, a strain softening behavior can be observed in the curves of Eco-HDCC[8].

(a)

(b)

It can be seen from Fig.5(a) that the strain hardening shape of the tensile curve for Eco-HDCC is related to interaction cycles. The strain hardening shapes of Eco-HDCC present sudden “drop-jump” characteristics after the interaction of 1 to 5 cycles, while the shapes show “smooth” characteristics after the interaction of 10 to 15 cycles. A detailed explanation has been given in Ref.[8].

From Fig.5(b), for Eco-HDCC exposed to the single carbonation environment, the strain hardening shows the characteristic of sudden “drop-jump” regardless of the carbonation cycles. There is no internal damage for Eco-HDCC exposed to the single carbonation environment. Thus, new cracks form during the process of tensile loading for Eco-HDCC resulting in the characteristic of sudden “drop-jump” in curves.

2.3.2 Ultimate tensile strength and ultimate tensile strain

The test results of the tensile property for Eco-HDCC are shown in Tab.4. In Tab.4,σF+Cis the ultimate tensile strength of Eco-HDCC after the interaction cycles of freeze-thaw and carbonation;σCis the ultimate tensile strength of Eco-HDCC after single carbonation cycles;εF+Cis the ultimate tensile strain of Eco-HDCC after interaction cycles of freeze-thaw and carbonation;εCis the ultimate tensile strain of Eco-HDCC after single carbonation cycles.

It can be seen from Tab.4 that the ultimate tensile strength for Eco-HDCC shows an increasing trend after the interaction of 1 to 5 cycles compared to that of virgin specimens, while the ultimate tensile strength presents a decreasing trend after the interaction of 10 to 15 cycles. The detailed reasons to explain the trend of ultimate tensile strength for Eco-HDCC can be found in Ref.[8]. However, the ultimate tensile strength of Eco-HDCC exposed to single carbonation cycles increases as the cycles increase. Carbonation products may increase the density of the matrix. In addition, for Eco-HDCC exposed to interaction cycles and single carbonation cycles, the ultimate tensile strain shows a decreasing trend as cycles increase.

Tab.4 Test results of tensile property for Eco-HDCC

The trend of ultimate tensile strain for Eco-HDCC after interaction cycles is illustrated in Ref.[8]. For single carbonation cycles, the matrix strength increases as carbonation cycles increase, and more fibers will rupture during the process of tensile loading. Thus, the ultimate tensile strain will decrease.

To quantitatively compare the tensile property of Eco-HDCC after interaction cycles with that of Eco-HDCC after single carbonation cycles, the freeze-thaw coefficient for ultimate tensile strengthλσand the freeze-thaw coefficient for ultimate tensile strainλεare defined as

(3)

(4)

The values ofλσandλεare shown in Tab.4. When Eco-HDCC is exposed to the interaction of 1 to 3 cycles,λσ>1, which indicates that freeze-thaw cycles have a positive effect on the ultimate tensile strength. When Eco-HDCC is exposed to the interaction of 5 to 15 cycles,λσ<1, which indicates that freeze-thaw cycles have a negative effect on the ultimate tensile strength. When Eco-HDCC is exposed to interaction cycles,λε<1, indicating that freeze-thaw cycles have a negative effect on the ultimate tensile strain.

When Eco-HDCC is exposed to 1 to 3 cycles, the ultimate tensile strength of Eco-HDCC after interaction cycles is higher than that of Eco-HDCC after single carbonation cycles. This can be attributed to the carbonation effect, pozzolanic reaction and hydration reaction of Eco-HDCC after the interaction tests. After Eco-HDCC is exposed to 5 to 15 cycles, freeze-thaw cycles have a negative effect on the ultimate tensile strength resulting from the deterioration of matrix and fiber. In addition, freeze-thaw cycles have a negative effect on the ultimate tensile strain of Eco-HDCC. The fiber property will decrease after freeze-thaw cycles, resulting in a decrease for the fiber bridging effect. Especially for 15 cycles, the matrix structure of Eco-HDCC loosens severely and the fiber property worsens greatly and thus the ultimate tensile strain of Eco-HDCC exposed to interaction cycles is much lower than that of Eco-HDCC exposed to single carbonation cycles.

2.3.3 Tensile strain energy

The energy consumption capacity is an important indicator in the seismic structure design, and it can reflect the absorbed energy before failure. The tensile strain energy is defined as the area under the tensile stress-strain curve of Eco-HDCC, which can represent the energy consumption capacity during the process of tensile loading. Notably, the tensile strain energy is calculated by the curve area from the first cracking point to the ultimate point, as the strain is not constant before the first cracking point[8].

The tensile strain energy of Eco-HDCC after interaction tests and single carbonation tests are shown in Tab.5. In addition, the freeze-thaw coefficientλPis defined as

(5)

Tab.5 Tensile strain energy of Eco-HDCC

It can be seen from Tab.5 that the tensile strain energy of Eco-HDCC shows a decreasing trend as the cycles increase, which illustrates that the strain energy dissipation capacity decreases. In addition, when Eco-HDCC specimens are exposed to interaction cycles and single carbonation cycles,λP<1, which illustrates that freeze-thaw cycles have a negative effect on the tensile strain energy.

The tensile strain energy of Eco-HDCC is related to the tensile stress and the strain. The ultimate tensile strength of Eco-HDCC increases after the interaction of 1 to 5 cycles, and the ultimate tensile strength decreases after the interaction of 10 to 15 cycles, while the ultimate tensile strain decreases with the increase of interaction cycles. Because the decrease rate of ultimate tensile strain is faster than that of ultimate tensile strength, the tensile strain energy of Eco-HDCC shows a decreasing trend. As single carbonation cycles increase, the ultimate tensile strength increases while the ultimate tensile strain decreases. The strain energy decreases due to the faster decrease rate of the ultimate tensile strain. In addition, freeze-thaw cycles affect the ultimate tensile strain severely, resulting in a negative effect on the strain energy.

For general consideration, the tensile stress-strain relationship for Eco-HDCC after the interaction of 15 cycles can be adopted in the design of bridge deck link slabs for the purpose of safety.

3 Conclusions

1) The carbonation fronts of Eco-HDCC after interaction cycles and single carbonation cycles increase as cycles increase, while the carbonation fronts of Eco-HDCC after interaction cycles are larger than those of Eco-HDCC after single carbonation cycles.

2) The ultimate tensile strength for Eco-HDCC shows an increasing trend after the interaction of 1 to 5 cycles, while the ultimate tensile strength decreases after the interaction of 10 to 15 cycles. The ultimate tensile strength of Eco-HDCC increases as single carbonation cycles increase. In addition, the ultimate tensile strength of Eco-HDCC after interaction cycles of 1 to 3 is greater than that of Eco-HDCC after single carbonation cycles. When cycles are 5 to 15, the trend of ultimate tensile strength is the opposite.

3) The ultimate tensile strain and tensile strain energy of Eco-HDCC decrease as cycles increase. The ultimate tensile strain and tensile strain energy of Eco-HDCC after interaction cycles are lower than those of Eco-HDCC after single carbonation cycles.

杂志排行

Journal of Southeast University(English Edition)的其它文章

- Travel time prediction model of freewaybased on gradient boosting decision tree

- Rolling contact fatigue nondestructive testing system for a bearing inner ring based on initial permeability

- Delay-performance optimization resource scheduling in many-to-one multi-server cellular edge computing systems

- Image denoising method with tree-structured group sparse modeling of wavelet coefficients

- Projection pursuit model of vehicle emission on air pollution at intersections based on the improved bat algorithm

- Experimental investigation of oil particles filtration on carbon nanotubes composite filter