形变时效组合工艺与Al-1.0Mg-0.5Si-0.8Cu合金腐蚀行为和微观结构的关系

2019-07-26陈江华邓东慧赖玉香刘力梅

陈江华 邓东慧 赖玉香 刘力梅

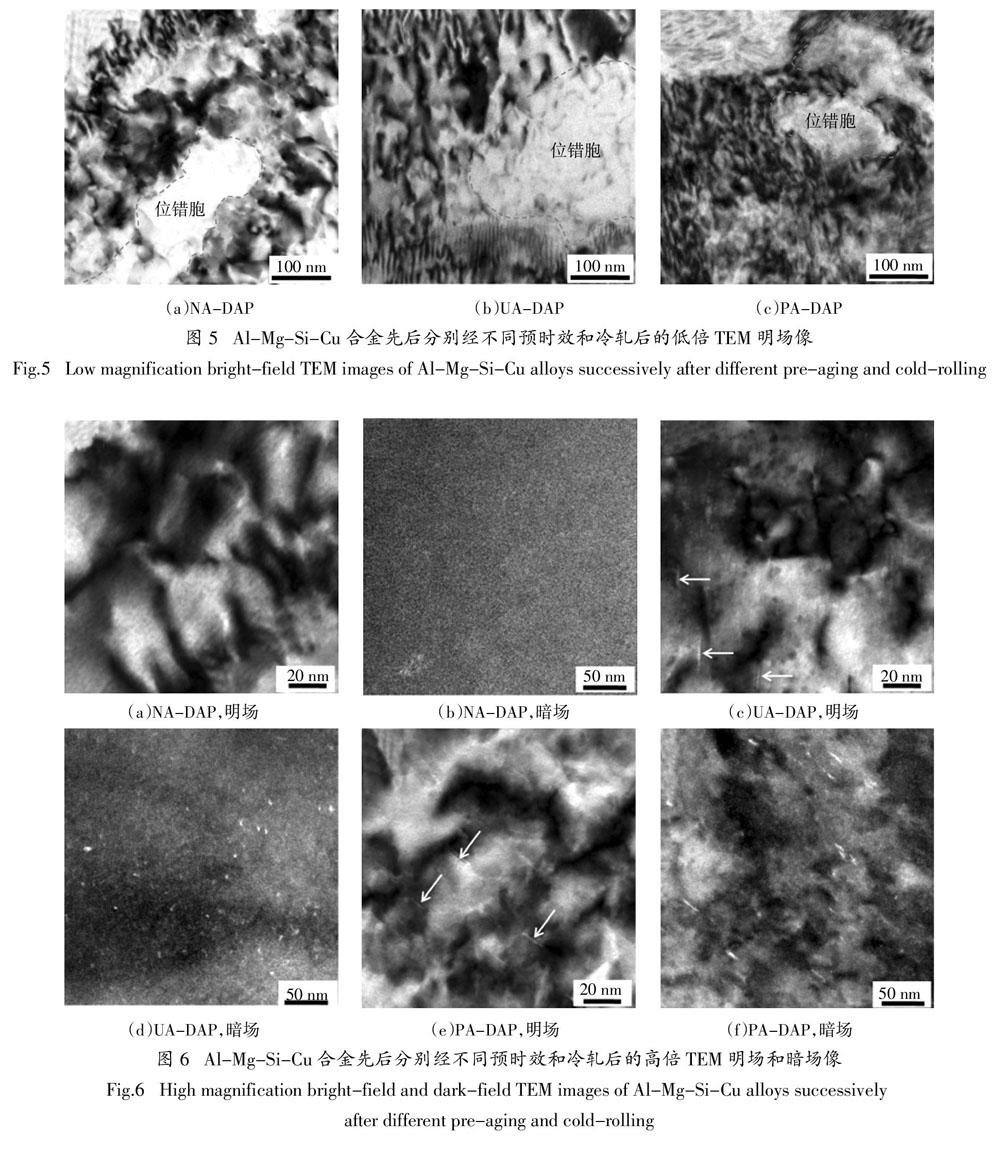

摘 要:采用硬度測试、晶间腐蚀实验、慢应变速率拉伸实验和TEM表征等手段,选取自然时效、欠人工时效和峰值人工时效3种预时效系统研究了预时效对形变时效组合工艺制备的Al-Mg-Si-Cu合金抗腐蚀性能和微观结构的影响.结果表明:预时效可以调控合金的硬度和抗腐蚀性能,3种预时效处理中峰值人工时效预处理使合金获得了硬度(159 HV)和抗腐蚀性能(最大晶间腐蚀深度为55 μm,应力腐蚀敏感指数Iδ为8.3%)的最优结合. TEM结果显示,冷轧引入的高密度位错有效提高了合金的硬度;晶内析出大量纳米级富Cu的板条状Q"相或弯曲连续状析出相,消除了晶界析出相的形成,并大大降低了基体与PFZ之间的电位差,因此显著提高了合金的抗腐蚀性能.自然时效、欠人工时效和峰值人工时效预处理的合金晶内析出程度依次增大,基体与PFZ之间的电位差依次减小,合金的抗腐蚀性能依次升高.

关键词:Al-Mg-Si-Cu合金;形变;时效;腐蚀;位错;析出

中图分类号:TG113;TG166.3;TG156.9 文献标志码:A

Study of Correlation Between Combined Deformation

and Aging Process as well as Corrosion Behavior

with Microstructure of Al-1.0Mg-0.5Si-0.8Cu Alloy

CHEN Jianghua,DENG Donghui,LAI Yuxiang,LIU Limei

(College of Materials Science and Engineering,Hunan University,Changsha 410082,China)

Abstract:Three pre-aging treatments of natural aging, artificial under-aging and artificial peak-aging were chosen to systematically investigate the influence of pre-aging on the corrosion resistance and microstructure of an Al-1.0Mg-0.5Si-0.8Cu alloy produced by combined cold-rolling and aging process using hardness measurement, intergranular corrosion test, slow strain rate technique, and transmission electron microscopy (TEM). The results show that pre-aging can tune the hardness and corrosion resistance of the alloy. Among the three pre-aging treatments, the artificial peak-aging treatment results in the optimal combination of hardness(being 159 HV) and corrosion resistance(with the maximum intergranular corrosion depth of 55 μm and the stress corrosion cracking susceptibility index Iδ of 8.3%). The TEM results reveal that the high density of dislocations efficiently enhances the hardness of the alloy. Numerous nano-sized Cu-rich lath-like Q" precipitates or curved continuous precipitates are distributed in the matrix, which eliminate the formation of grain boundary precipitates and greatly reduce the electrochemical potential difference between the matrix and PFZ,consequently significantly improving the corrosion resistance of the alloy. In the alloys pre-aged by natural aging, artificial under-aging and artificial peak-aging, the degree of precipitation in the matrix increases in sequence, so that the electrochemical potential difference between the matrix and PFZ decreases in sequence. Therefore, the corrosion resistance of the alloy is improved in sequence.

Key words:Al-Mg-Si-Cu alloy;deformation;aging;corrosion;dislocation;precipitation