Compatibility Evaluation between Direct Coal Liquefaction Residue and Bitumen

2019-05-10JiJieWuHaoXuYingSuoZhiWeiJianming

Ji Jie ; Wu Hao; Xu Ying ; Suo Zhi ; Wei Jianming;

Dai Qingli4; Zhang Ran4, 5; Diab Aboelkasim6

(1. School of Civil Engineering and Transportation, Beijing University of Civil Engineering and Architecture,Beijing 100044;

2. Beijing Advanced Innovation Center for Future Urban Design, Beijing 100044;

3. National Institute of Clean-and-Low-Carbon Energy, Beijing 102211;

4. Department of Civil and Environmental Engineering, Michigan Technological University, Houghton 49931, The United States;

5. School of Highway,Chang’an University, Xi’an 710064; 6. Department of Civil Engineering, Aswan University, Aswan 81542, Egypt)

Abstract: The compatibility between direct coal liquefaction residue (DCLR) and five kinds of pure bitumen (Shell-90,SK-90, ZSY-70, DM-70 and KLMY-50) was evaluated in this study. The rheological characteristics, glass transition temperatures (Tg), solubility parameters (SP) and SARA (saturates, aromatics, resins, and asphaltenes) fractions of DCLR,five kinds of pure bitumen and their blends (named as DCLR modified bitumen) were measured using the dynamic shear rheometer (DSR), differential scanning calorimetry (DSC), viscosity, and SARA tests, respectively. And the compatibility between DCLR and pure bitumen was characterized with three approaches, viz. the Cole-Cole plot, Tg, and the solubility parameter difference (SPD) method. Since each method has its own working mechanism, the compatibility ranking for the DCLR and five kinds of pure bitumen is slightly different according to the three approaches. However, the difference is pretty close and sometimes can be ignored. The general compatibility ranking decreases in the following order: Shell-90≈SK-90>DM-70≈ZSY-70>KLMY-50, which is affected by the asphaltenes content and the colloid index (Ic) value in the pure bitumen. Pure bitumen with lower asphaltenes content and colloid index (Ic) value has better compatibility with DCLR.

Key words: direct coal liquefaction residue (DCLR); pure bitumen; compatibility; Cole-Cole plot; glass state temperature(Tg) approach; solubility parameter difference (SPD) method

1 Introduction

Direct coal liquefaction (DCL) technology refers to the reaction of coal with hydrogen in the presence of catalyst at high temperature and pressure, resulting in the formation of coal pyrolysis liquid products[1-2]. Direct coal liquefaction residue (DCLR) is a by-product of the DCL process, which accounts for 30% by weight of raw coal. It has been reported that the DCLR contains 30%to 50% of heavy oils and asphaltenes, which are the valuable resource for potential development as a bitumen modifier[3]. Ji, et al. found that the DCLR can improve the high-temperature properties of bitumen, albeit with some negative effects on the low-temperature properties[3].Also, Ji, et al. used infrared spectroscopy (IR)[4-5]and gel permeation chromatography (GPC)[4-6]to investigate the mechanism of DCLR on modification of bitumen. And it was concluded that the modification was mainly a physical process[7-8]. Some researchers after having studied the effect of DCLR on the properties of bitumen had concluded that the high-temperature properties of bitumen were enhanced and the adhesion between bitumen and aggregate could be strengthened subsequently[9]. In the current scenario,the DCLR has a promising potential to serve as a bitumen modifier to improve the high-temperature performance and avoid the moisture damage.

During the modification process, the compatibility between the modifier and pure bitumen is directly related to the subsequent properties of the modified bitumen, which is a paramount issue that is worthy of tudying. Recently, some scholars have investigated the compatibility between pure bitumen and different modifiers, such as styrene-butadiene-styrene (SBS)[10],rubber powder[11], low-density polyethylene (LDPE)[12],and high-density polyethylene (HDPE)[13], by using the dynamic shear rheometer (DSR)[13-14], the differential scanning calorimetry (DSC)[15], the solubility parameter(SP)[13], and the SARA tests. And some nontraditional analyzing methods have also been applied to evaluate the compatibility, such as the Cole-Cole plot[16], the Tg(glass transition temperature) approach[17], and the solubility parameter difference (SPD) method[18]. It has been found that the aforementioned three analytical methods are the simple and convenient ways to evaluate the compatibility between pure bitumen and different modifiers[19-20].

Unfortunately, the compatibility between DCLR and pure bitumen has not been thoroughly studied, which hinders the understanding of the modification mechanism.Hereby, the main purpose of this paper is to investigate the compatibility between DCLR and pure bitumen using three test methods (DSR, DSC, and SP tests) and three corresponding analytical approaches (the Cole-Cole plot,the Tgapproach, and the SPD method). On the basis of the current investigation, the compatibility between DCLR and pure bitumen was evaluated and discussed. And the most suitable evaluation method was recommended.

2 Materials and Methods

2.1 Materials

2.1.1 Bitumen and DCLR

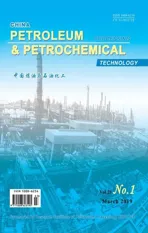

Five kinds of commercial pure bitumen samples with different penetration grades were used in this study,including Shell-90 and SK-90 with a penetration of 80/100 obtained from the Shell Company and the SK Company, respectively, ZSY-70 and DM-70 with a penetration of 60/80 obtained from the China National Petroleum Corporation and the Dongming Company in Shandong Province of China, respectively; and KLMY-50 with a penetration of 40/60 obtained from the Karamay Oil Company in Xinjiang Province of China. The SARA analysis results and physical properties of bitumen samples are given in Table 1.

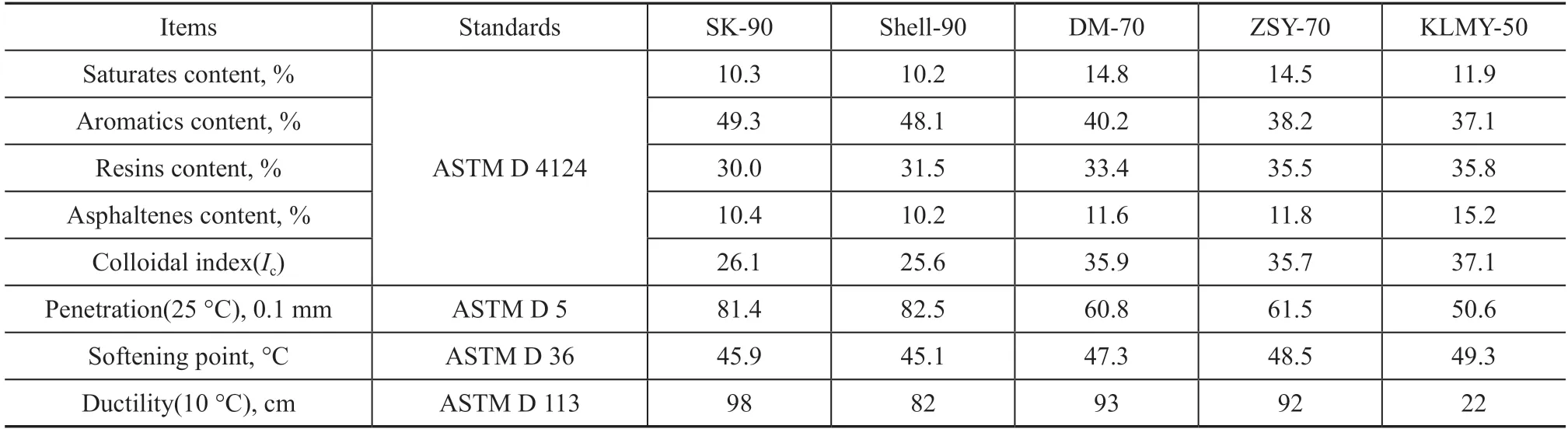

The DCLR was produced by the Shenhua Coal Liquefaction Company in the Inner Mongolia Autonomous Region of China, which is a black powder,as shown in Figure 1. The maximum particle size is less than 2 mm. The physical properties and SARA analysis results are listed in Table 2.

Figure 1 DCLR

2.1.2 Preparation of DCLR modified bitumen

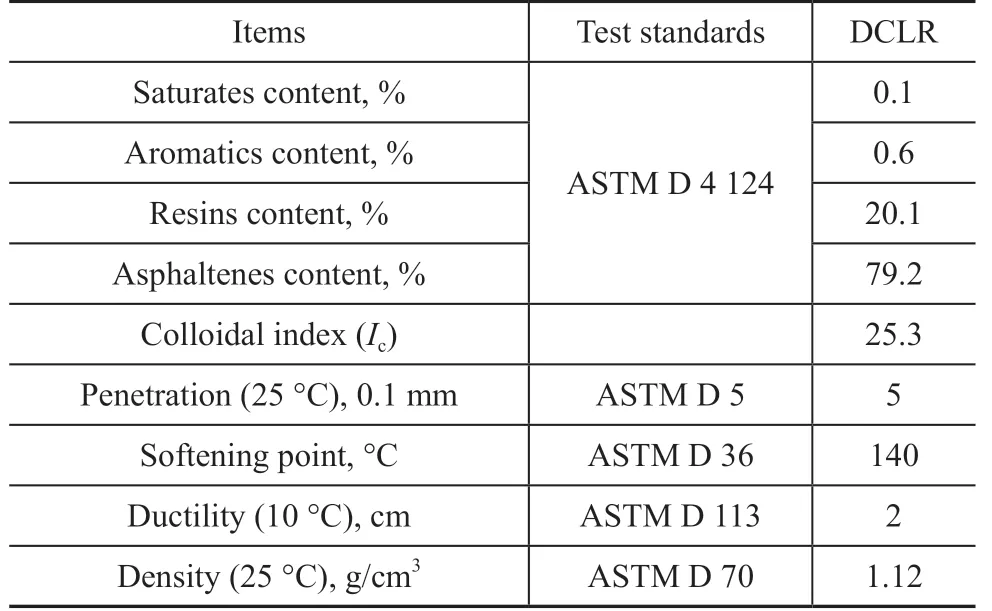

Firstly, the DCLR was melted at 170—180 C and pure bitumen was heated until it remained in a totally flowing condition. Secondly, 600 g of pure bitumen were pouredinto a metal container and the DCLR (8% by weight of pure bitumen) was added to the pure bitumen slowly at a rate of 10 g/min. Hereby, the blend was named as the DCLR modified bitumen. Thirdly, the DCLR modified bitumen was subject to shearing using a high-speed shear mixer with a rotary speed of 4000 r/min continuously for 1.5 h at 150 C. Finally, after completion, the prepared samples were cooled down to room temperature and stored for further testing. It is noteworthy that all the prepared samples were tested as unaged materials. The properties of five kinds of DCLR modified bitumen samples are shown in Table 3.

Table 1 SARA analysis and some physical properties of five kinds of pure bitumen samples

Table 2 SARA analysis and some physical properties of DCLR

2.2 Test methods

2.2.1 Dynamic shear rheometer (DSR) test

According to AASHTO T315-09, the rheological characteristics of DCLR, pure bitumen and DCLR modified bitumen were tested by an AR1500 advanced rheometer in the controlled-strain mode. During the tests, a continuous sinusoidal alternating strain was applied. Testing conditions included: a strain level value γ of 1%, a test frequency ω of 0.1—100 rad/s, a plate diameter Ф of 25 mm, and a gap height h of 1 mm. The test temperature was 30 C,40 C, 50 C, 60 C, and 70 C, respectively. During the measurement, the complex modulus (G*) and phase angle(δ) were determined, through which the storage modulus(G' = G*·cosδ) and loss modulus (G"=G*·sinδ) could be calculated. Consequently, the η" values (η"=G'/ω) and η'values (η'=G"/ω) were obtained.

2.2.2 Differential scanning calorimetry (DSC) test

According to the ASTM test method D3418-2003, the Tgof DCLR, pure bitumen, and the DCLR modified bitumen were determined using DSC. The samples were tested under a temperature range of -50— 200 C at a temperature increase rate of 10 C/min.

2.2.3 Solubility parameter (SP) test

The SP of DCLR and pure bitumen was tested by the viscosity method using a Negra viscometer based on ASTM D 1665.

3 Analysis Approaches

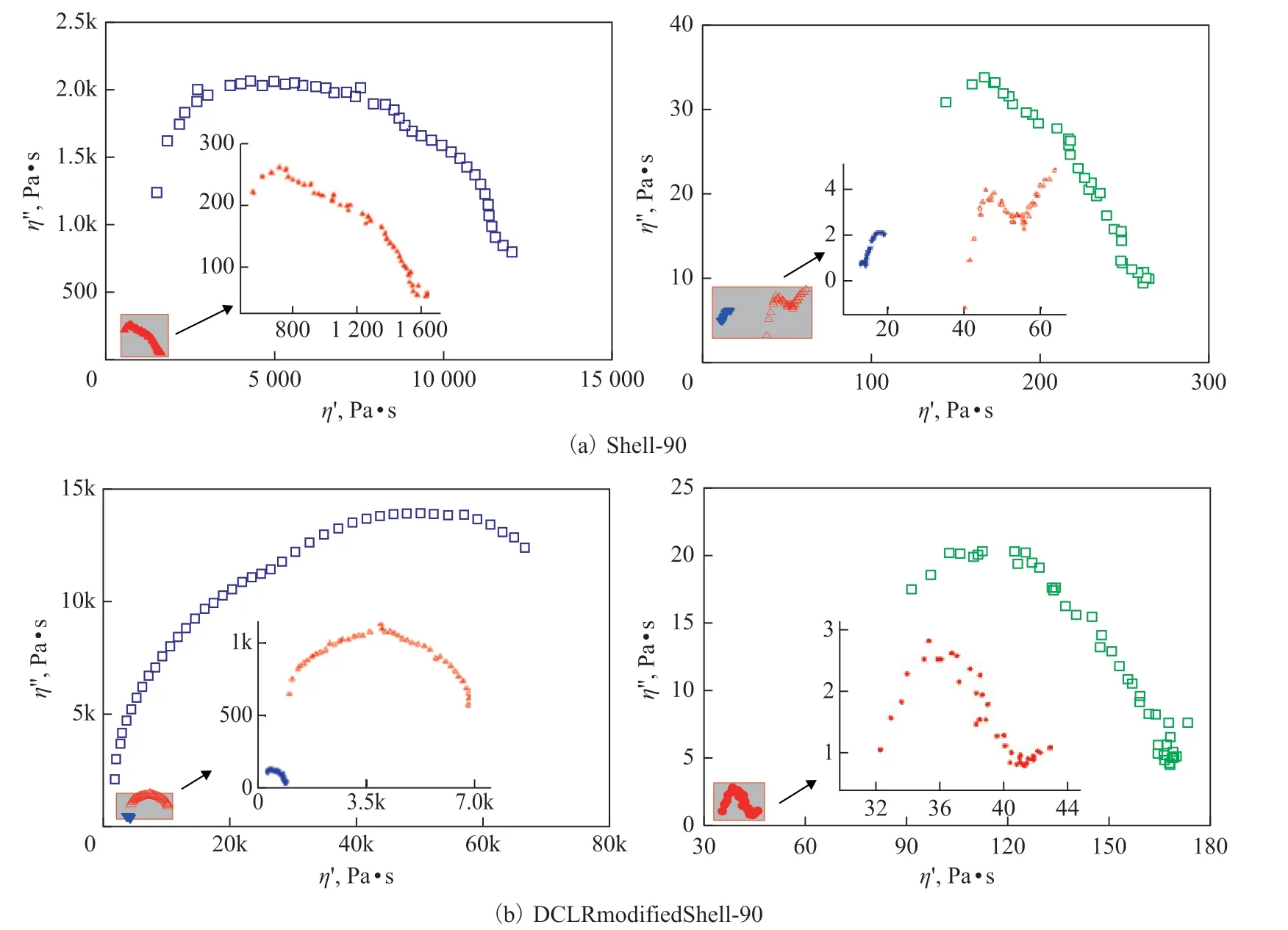

3.1 Cole-Cole plot

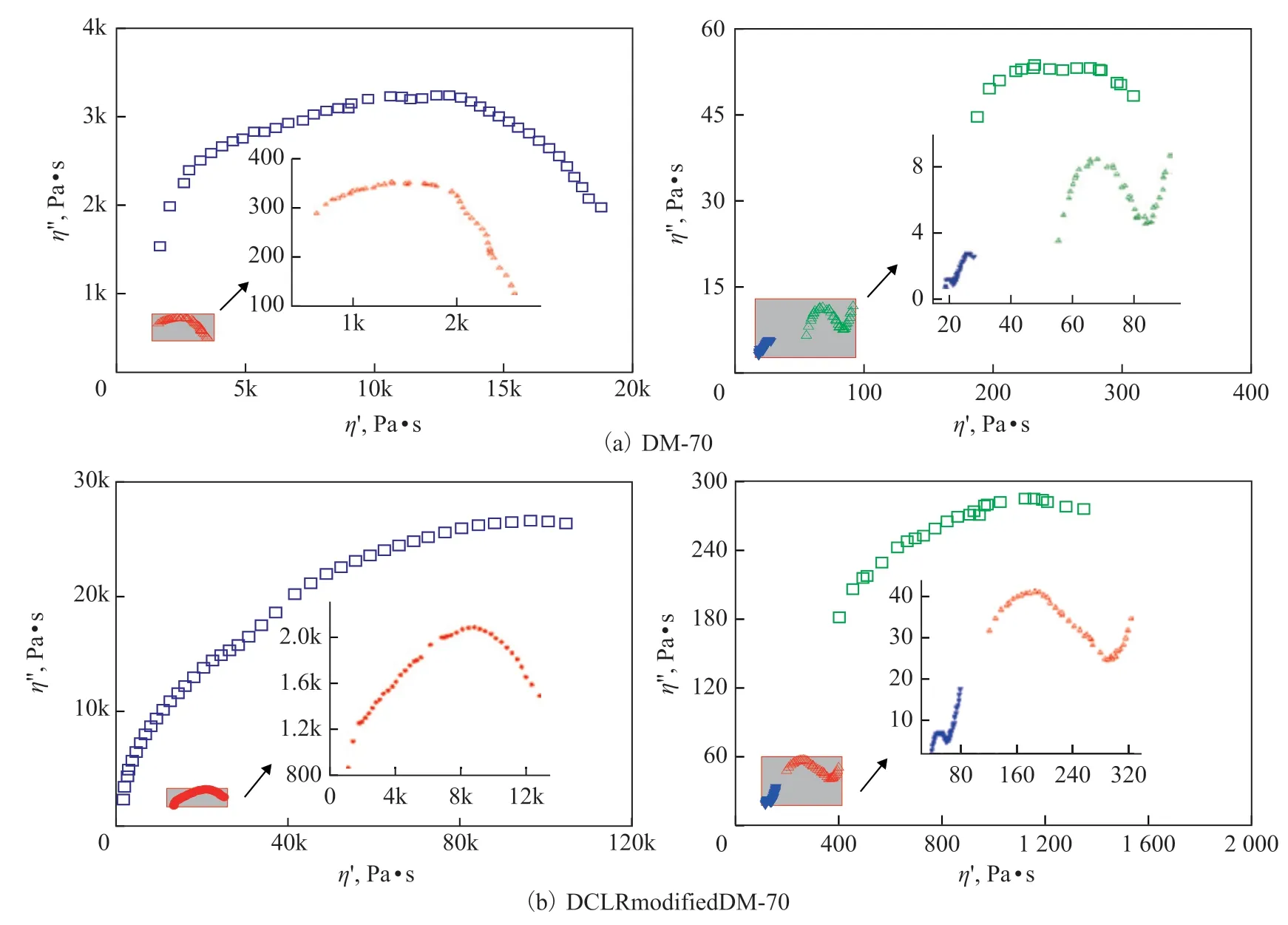

The Cole-Cole plot is a plot of η" and η' values of samples derived from dynamic shear frequency sweep tests. The η' and η" represent the pure viscosity and pure elasticity of the contribution to the viscosity,respectively. The structural system at different temperatures is controlled by the attractive forces between molecules, so the solubility characteristics of these phases are temperature-dependent. Therefore, the phase structure of the different systems is also different at different temperatures, which accordingly leads to the contribution of their viscosity, and the elastic part to the viscosity is also different[21-22]. Figure 2 demonstrates theCole-Cole plot for different systems.

Table 3 Properties of DCLR modified bitumen samples

Figure 2 Cole-Cole plot for different systems■—Compatible system; ●—Incompatible system

The Cole-Cole plot has been used to evaluate the compatibility between different systems. It is known that if two or more substances are totally compatible, the curve on the Cole-Cole plot tends to be a perfect semicircle (Curve “a” in Figure 2). However, if the two or more substances are incompatible, the curve on the Cole-Cole plot is not a perfect semi-circle and has an obvious inflection point (Curve “b” in Figure 2). In fact, each semi-circle indicates a different relaxation mechanism.The relaxation in the high-frequency section is related to the blending system, but the relaxation in the lowfrequency zone is only affected by one substance, such as the modifier. At the same time, the inflection point is related to the temperature tightly. This corresponding temperature means that the system encounters a phase separation and it is marked as the critical phase separation temperature (CPST) in this study. Hence,this CPST value can be used as a fingerprint of different systems. For instance, when a system undergoes a temperature higher than the CPST value, the system is ranked incompatible[23]. Therefore, the CPST value that we proposed from the Cole-Cole plot was firstly used to characterize the compatibility between DCLR and pure bitumen.

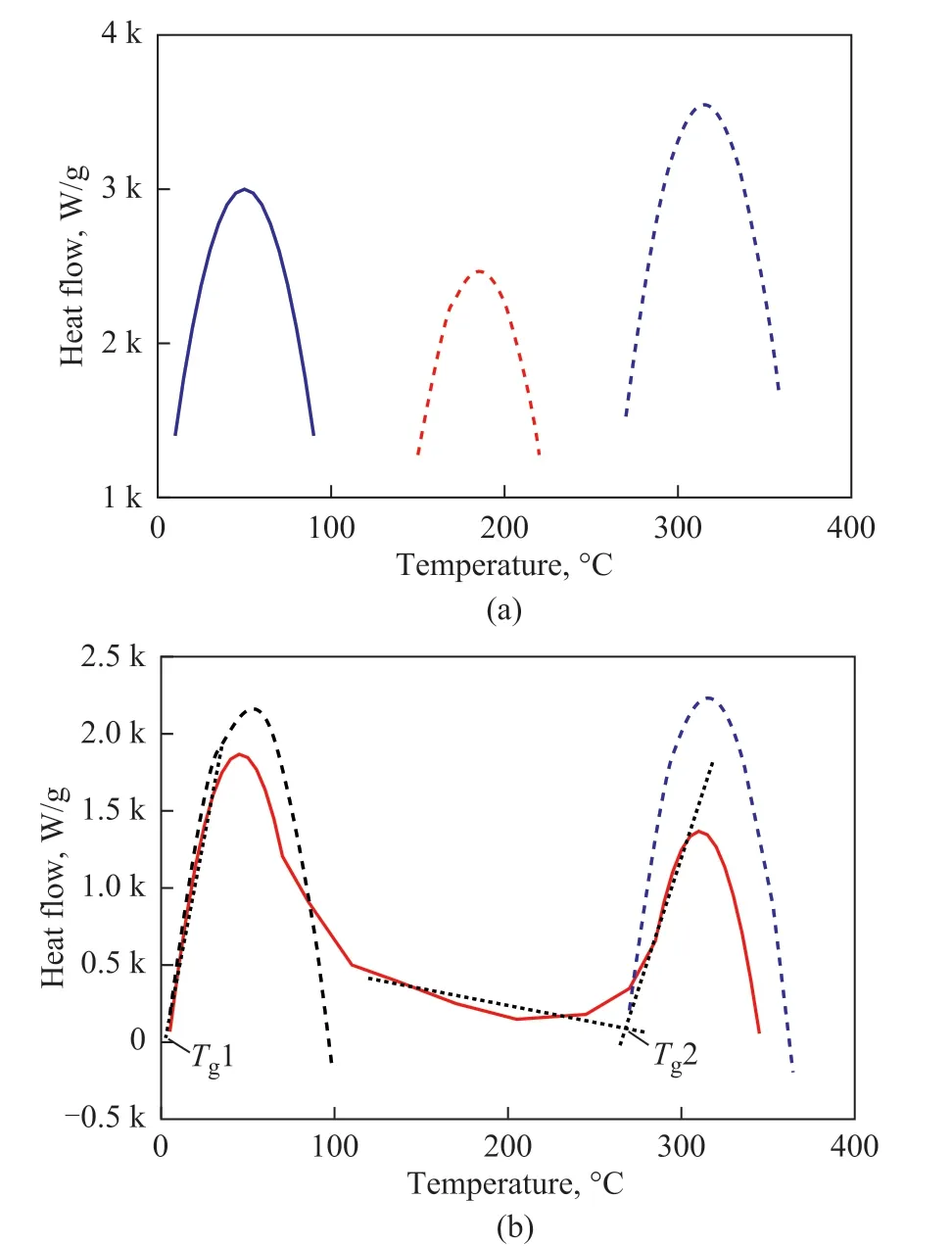

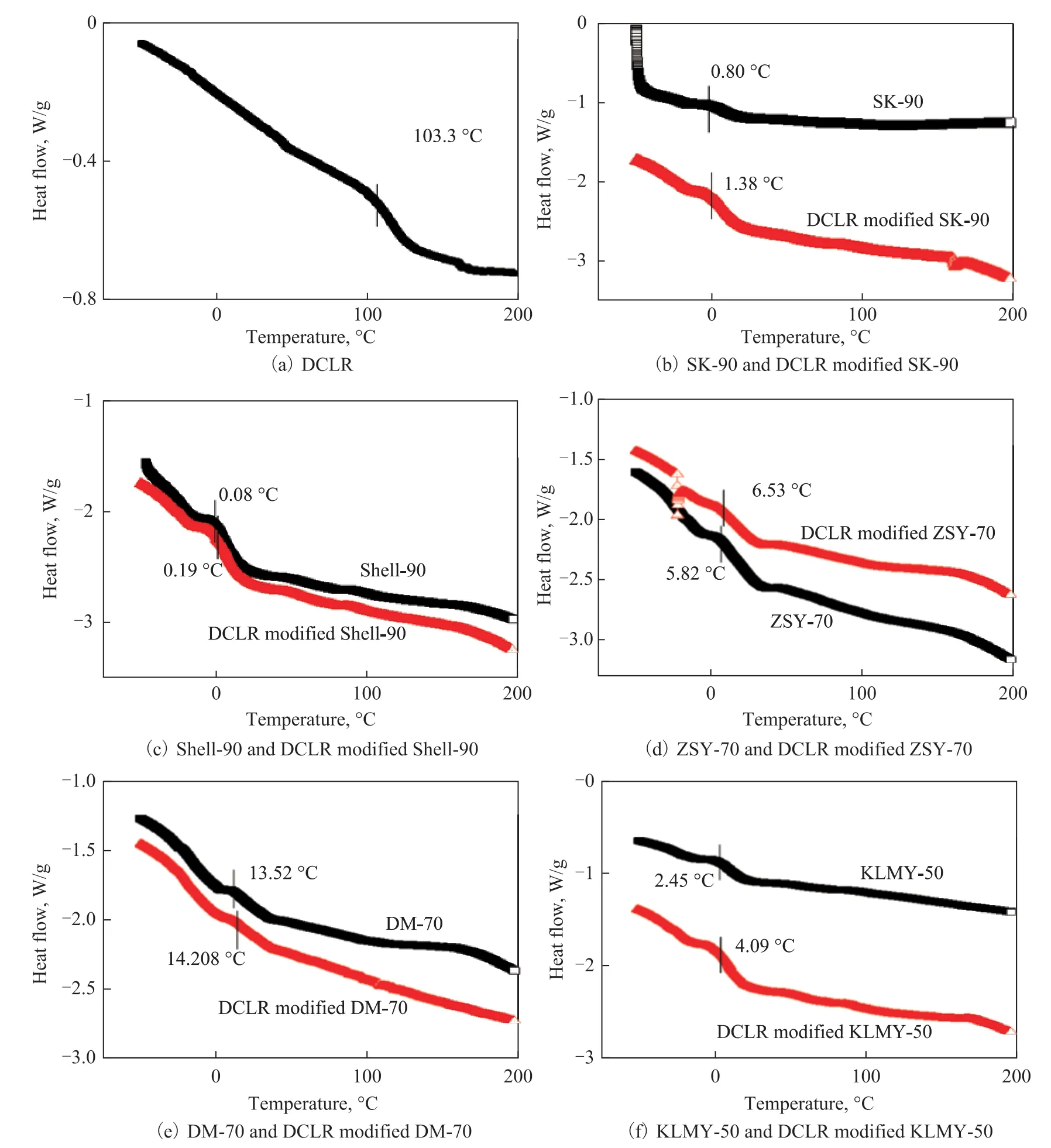

3.2 Glass transition temperature (Tg) approach

The glass transition of macromolecules shows a baseline shift on the DSC curve[24]. The Tgapproach intersection of the tangent to the curve with the baseline is taken as the Tg. Traditionally, if two or more substances are totally compatible, the system has only one Tg(Figure 3(a)). When two or more substances are incompatible,the Tgof their respective matrix materials is maintained in their respective phase regions and then two or more Tg(Figure3(b))[25-26]are supposed to exist. Hence, the compatibility between DCLR and bitumen can be evaluated by the Tgnumbers of their systems[26].

Figure 3 Heat folw-temperature relationships for two systems(a)—A;—AB-Compatible system;—B;(b)—A;—AB-Incompatible system;—B

3.3 Solubility parameter difference (SPD) method

The solubility parameter difference (SPD) between two substances has been used as an index to evaluate the compatibility of the blended systems. If two substances are compatible, their SPD value should be very small and vice versa. Hence, the compatibility between DCLR and bitumen can be estimated using the SPD method[29-30].

4 Results and Discussion

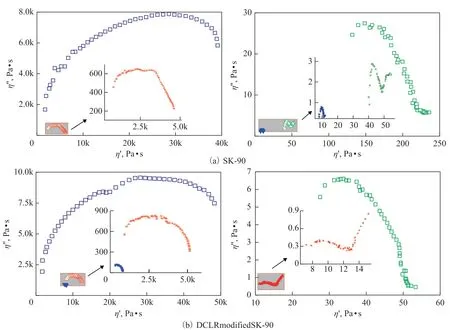

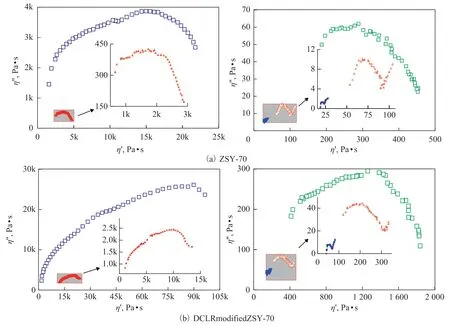

4.1 Cole-Cole plot

Figure 4 Cole-Cole plot of Shell-90 and DCLR modified Shell-90(a)□—30 C; ▲—40 C; □—50 C; △—60 C; ▼—70 C; (b)□—30 C; △—40 C; ▼—50 C; □—60 C; ●—70 C

Figure 5 Cole-Cole plot of SK-90 and DCLR modified SK-90(a)□—30 C; △—40 C; □—50 C; △—60 C; ▼—70 C; (b)□—30 C; △—40 C; ▼—50 C; □—60 C; ▲—70 C

Figure 6 Cole-Cole plot of ZSY-70 and DCLR modified ZSY-70(a)□—30 C; ▲—40 C; □—50 C; △—60 C; ▼—70 C; (b)□—30 C; ▲—40 C; □—50 C; ▲—60 C; ▼—70 C

Figure 7 Cole-Cole plot of DM-70 and DCLR modified DM-70(a)□—30 C; ▲—40 C; □—50 C; △—60 C; ▼—70 C; (b)□—30 C; ▲—40 C; □—50 C; △—60 C; ▼—70 C

The Cole-Cole plots of five kinds of pure bitumen samples and the DCLR modified bitumen samples are shown in Figures 4―8, with their CPST values listed in Table 4.

Table 4 CPST and CPSTD values of five kinds of purebitumen and DCLR modified bitumen samples

It can be seen from Figures 4―8 and Table 4 that the Cole-Cole curves are all smooth and perfect semi-circles and have no inflection points at testing temperatures in the range of 30 C, 40 C, and 50 C,respectively, regardless of whatever pure bitumen samples or DCLR modified bitumen samples.Compared to the corresponding pure bitumen samples, the CPST values of two kinds of DCLR modified bitumen samples (DM-70 and ZSY-70) are invariable, but for the other three DCLR modified bitumen samples (SK-90, Shell-90, and KLMY-50),the CPST values change conversely. For SK-90 and Shell-90, the CPST values of their DCLR modified bitumen samples increase, but for KLMY-50, the CPST value of its DCLR modified bitumen decreases.A higher CPST value means a better compatibility.Hence, the compatibility ranking of the five kinds of pure bitumen decreases in the following order: Shell-90=SK-90>DM-70=ZSY-70 > KLMY-50.

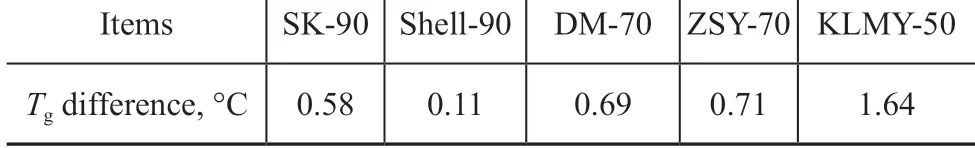

4.2 Tg analysis

The DSC curve and Tgof DCLR, pure bitumen and DCLR modified bitumen are shown in Figure 9. Meanwhile, the Tgdifference between pure bitumen and DCLR modified bitumen is presented in Table 4.

It can be observed from Figure 9 that the Tgvalue of DCLR is very high (103 C) and almost 7 times more compared to Tg value of the five kinds of pure bitumen (lower than 15 C). The higher asphaltenes content in DCLR may be the contributor, which is almost 7 times higher than the five kinds of pure bitumen. Generally, higher Tgdifference value means that the interaction forces between molecule inter-chain is stronger and the main molecule-chain flexibility is not smooth, which indicates that the compatibility is not good[27-28].

Figure 9 DSC curve and Tg of DCLR, pure bitumen and DCLR modified bitumen

It also can be calculated from Figure 9 and Table 5 that the KLMY-50 has the highest Tgdifference (1.64 C) and the Shell-90 has the lowest one (0.11 C). So, it can be suggested that the Shell-90 has the best compatibility with DCLR among the five kinds of pure bitumen. Then, the compatibility ranking of the five kinds of pure bitumen decreases in the following order: Shell-90 > SK-90>DM-70> ZSY-70> KLMY-50.

Table 5 Tg difference values of five kinds of pure bitumen and DCLR modified bitumen samples

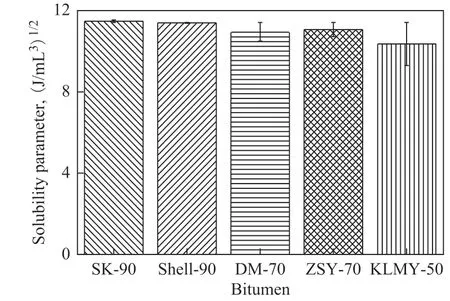

4.3 SPD analysis

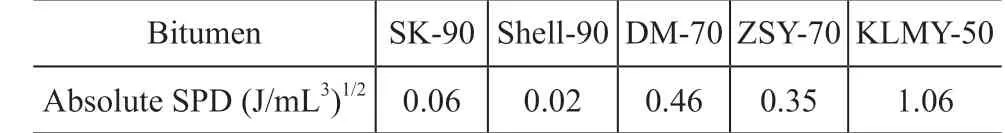

The SP of pure bitumen and SPD between DCLR and bitumen are shown in Figure 10 and Table 6.

Figure 10 SP values for five kinds of pure bitumen

Table 6 SPD values of DCLR and five kinds of pure bitumen

Generally, the pure bitumen and DCLR with lower SPD value denote the better compatibility. Judging from the SPD values, the compatibility ranking for the five kinds of pure bitumen decreases in the following order: Shell-90≈SK-90>ZSY-70≈DM-70>KLMY-50. Actually, this compatibility ranking is slightly different from one concluded from the Tgapproach and the Cole-Cole plot. However, it is noted from Table 6 that SPD values for DM-70 (0.46) and ZSY-70 (0.35) are pretty close, which can be considered that the compatibility of the two kinds of pure bitumen is almost identical and this difference can be ignored.

4.4 Comparison and analysis

It is well-known that the physical properties of bitumen are determined by its chemical composition. The SARA(saturates, aromatics, resins, and asphaltenes) fractions in the bitumen affect each other and can form a colloid system at the end, which can display the integrated performance. Hence, it is not easy to obtain a general conclusion regarding the influence of one single fraction on the compatibility. Fortunately, the colloid index (Ic)calculated from the SARA contents may be a good parameter to characterize the whole system. Bitumen with higher Icvalue indicates that the proportion between SARA fractions is not incongruous and the whole system is not stable. Additionally, it can be seen from Table 3 that the SARA fractions in DCLR consist of mostly asphaltenes (79.2%), so in this paper, the asphaltenes content and Icvalue were used as the main index and the secondary index, respectively, in order to evaluate the compatibility between DCLR and pure bitumen.

It can be found form Tables 1 and 4 that SK-90 and Shell-90 have lower asphaltenes content and Icvalue and higher CPST value. A higher CPST value means a better compatibility between pure bitumen and DCLR. So, it can be concluded that the SK-90 and Shell-90 bitumen samples have better compatibility with DCLR compared to the other three kinds of pure bitumen.

Meanwhile, Tables 1, 5, and 6 indicate that the DCLR modified Shell-90 has the smallest Tgdifference (0.11 C)and SPD value (0.02), since Shell-90 has the lowest asphaltenes content and Icvalue. But for KLMY-50, this remark is on the contrary. The lower Tgdifference and SPD value indicate a better compatibility. Hence, the Shell-90 bitumen has the best compatibility with DCLR and the KLMY-50 bitumen has the worst compatibility.

Since each method has its own working mechanism, the compatibility ranking for the DCLR and five kinds of pure bitumen is slightly different according to the three approaches, viz. the Cole-Cole plot, the Tgapproach,and the SPD method. However, because the difference is pretty close, sometimes it can be ignored. In generally,the asphaltenes content and Icvalue in pure bitumen can strictly affect its compatibility with DCLR. Then, based on the above analysis, the compatibility ranking of the five kinds of pure bitumen decreases in the following order: Shell-90≈SK-90> ZSY-70≈DM-70> KLMY-50.

5 Summary

Based upon the analysis and test results of this study, the major summaries can be drawn:

The Cole-Cole plot, the Tgapproach, and the SPD method can be utilized to assess the compatibility between the DCLR and pure bitumen. Since each method has its own working mechanism, the compatibility ranking for the DCLR and five kinds of pure bitumen is slightly different according to the outcome measured by the three approaches. But the difference is pretty close and sometimes can be ignored.

The asphaltenes content and Icvalue in pure bitumen has a great influence on its compatibility with DCLR. The bitumen with lower asphaltenes content and Icvalue has the better compatibility with DCLR. So, in this paper,Shell-90 has the best compatibility with DCLR compared to the other kinds of pure bitumen, while KLMY-50 has the worst compatibility. In general, the compatibility ranking of the five kinds of pure bitumen decreases in the following order: Shell-90≈SK-90> DM-70≈ZSY-70> KLMY-50.

This paper has just studied the five kinds of pure bitumen and their compatibility with DCLR. The test results are limited and some summaries may be only suitable for these materials. In the ongoing research, some other pure bitumen should be tested and some interesting conclusions may be found and further verified.

Acknowledgements:This study is sponsored by the National Natural Science Foundation of China (51478028 and 51778038)and the Program for Changjiang Scholars and Innovative Research Team in Universities (IRT-17R06). The authors also appreciate Mr. Gao Jinqi for his help in the experimentations.

杂志排行

中国炼油与石油化工的其它文章

- Novel NiMo Catalysts Supported on Sol-Gel Nanosized HY Zeolite-Alumina Composites for Hydrodesulfurization of Diesel

- Kinetic Model of Hydrogenation for Removal of Trace Olefins from Alkylation Mixture Formed during Linear Alkylbenzene Synthesis

- Influence of Cr3+ Concentration on SO2 Removal over TiO2 Based Multi-walled Carbon Nanotubes

- Phosphorous-Modified Carbon Nanotube-Supported Pt Nanoparticles for Propane Dehydrogenation Reaction

- Design, Optimization and Control of Extractive Distillation for Separation of Ethyl Acetate-Ethanol-Water Mixture Using Ionic Liquids

- Polycrystalline Phase WO3/g-C3N4 as a High Efficient Catalyst for Removal of DBT in Model Oil