Adaptive Proportional-Derivative Sliding Mode Control Law With Improved Transient Performance for Underactuated Overhead Crane Systems

2018-08-11MenghuaZhangXinMaRuiSongXuewenRongGuohuiTianXinchengTianandYibinLi

Menghua Zhang,Xin Ma,Rui Song,Xuewen Rong,Guohui Tian,Xincheng Tian,and Yibin Li

Abstract—In this paper,an adaptive proportional-derivative sliding mode control(APD-SMC)law,is proposed for 2D underactuated overhead crane systems.The proposed controller has the advantages of simple structure,easy to implement of PD control,strong robustness of SMC with respect to external disturbances and uncertain system parameters,and adaptation for unknown system dynamics associated with the feedforward parts.In the proposed APD-SMC law,the PD control part is used to stabilize the controlled system,the SMC part is used to compensate the external disturbances and system uncertainties,and the adaptive control part is utilized to estimate the unknown system parameters.The coupling behavior between the trolley movement and the payload swing is enhanced and,therefore,the transient performance of the proposed controller is improved.The Lyapunov techniques and the LaSalle’s invariance theorem are employed in to support the theoretical derivations.Experimental results are provided to validate the superior performance of the proposed control law.

I.INTRODUCTION

OVERHEAD cranes have recently become a focus of research in modern industrial fields.To increase productivity,the overhead crane transports the payload as fast as possible to its destination.However,crane acceleration,deceleration and external disturbances,such as winds,lead the payload to sway[1]−[2].The unwanted payload swing affects the payload’s positioning precision and thus decreases the overall control performance.Moreover,it may result in accidents and damages to the surroundings[3].Therefore,to achieve safety and effectiveness of overhead crane operations,high-performance control schemes are required[4].Several control methods have previously been proposed to address the aforementioned issues,which can be roughly divided into open-loop and closed-loop control methods[5]−[6].

The open-loop control method can eliminate the overhead crane system’s oscillation by altering the command input signal,while the closed-loop control method uses the system’s states for tracking and regulation control[7].It is well known that the open-loop control method needs no measurement of payload swing angles,it is simple,feasible,easy to implement,and of low cost[8].By using the finite impulse response(FIR)filters[9]and the infinite impulse response(IIR) filters[10],a number of controllers have been proposed for overhead cranes.Another form of open-loop controller is command smoothing,which can suppress the system’s vibration by estimating the system’s natural frequency and damping ratio[11].The most popular open-loop method is the input shaping approach,which is implemented online by convolving a command input signal with a sequence of impulses that are designed based on the natural frequency and the damping ratio of the overhead crane system[12]−[14].Additionally,motion planning methods are also proposed for the crane systems.In[6],[15]−[16],an S curve trajectory,which satisfies physical constraints of the overhead crane system,is proposed and combined with antiswing parts to guarantee both positioning and payload swing elimination control.In[17],an off-line trolley trajectory is proposed by fully considering the constraints such as maximum allowable trolley acceleration/velocity,payload swing amplitude,and so on.The main drawback of the open-loop control method is that it is sensitive to external disturbances and parameter variations[18].

Closed-loop control methods use the measurement and estimation of the system states to suppress and eliminate the payload swing and obtain accurate trolley positioning.So,the closed-loop control schemes are insensitive to external disturbances and parameter variations[19].In the past decades,the closed-loop control for overhead crane systems has received considerable attention.More precisely,Yang and Xiong[20]apply the linear quadratic regulator(LQR)method for the antisway control of an overhead crane.Zhang et al.[21]propose an error tracking controller with which the error trajectories of the trolley and the payload swing can be pre-specified.More-over,it does not require the condition that the initial payload swing angle remains zero.A series of energy-based nonlinear controllers are designed to realize accurate trolley positioning and fast payload swing elimination[22]−[23].Owing to advantages in dealing with constraints,capacity of utilizing simple models,robustness against parametric uncertainties,model predictive control(MPC)methods have been proposed for crane systems[24]−[25].MPC-based methods for a constrained payload swing angle are also designed in the recent literatures[26].Adaptive control methods have the capability of estimating system parameter uncertainties and,therefore,have been widely investigated by researchers in[5],[27]−[28]for overhead crane systems.Uchiyama[29]proposes a partial state feedback controller on the basis of a linearized crane dynamic model.In addition to the aforementioned model-based methods,some intelligent control methods[30]−[33],including neural network and fuzzy logic controllers,have been applied to crane systems,improving the control performance of trolley positioning and payload swing reduction.

It is well known that the key characteristic of SMC is strong robustness.The sliding mode behavior is insensitive to unknown system parameters and external disturbances.Therefore,a series of SMC methods are proposed for overhead crane systems[34]−[38].However,there are two drawbacks for the SMC law,including chattering phenomenon and requirements for certain knowledge of the overhead crane system parameters when calculating the equivalent control part of the SMC law[39]−[40].Adaptive SMC law needs no knowledge of system parameters,and has been successfully applied to linear motor drive systems[41]−[42].Moreover,owing to the underactuated nature,the payload swing can merely be damped out by the trolley motion.Inspired by this fact and motivated by the desire to achieve an improved control performance,we think that the coupling behavior between the trolley movement and the payload swing should be enhanced.

This paper proposes an APD-SMC method with improved transient performance that combines the PD control,SMC,and the adaptive control.In the designed controller,the PD control part is used to stabilize the nominal model,the SMC part is designed to provide the robustness,and the adaptive part is utilized to estimate the uncertain system dynamics.Moreover,coupling behavior between the trolley displacement and the payload swing is enhanced,which leads to an improved transient performance.The Lyapunov techniques and the LaSalle’s invariance theorem are utilized to prove the convergence and stability of the closed-loop system.Experimental results are presented to verify the superior performance of the proposed controller.The advantages of the controller proposed in this paper are as follows:

1)It has a PD-like simple form,which is easy for practical implementation.

2)It is characterized by high-robustness,which is validated by experimental results.

3)As verified by experimental results,an increased transient performance is achieved.

4)It needs no knowledge of the system parameter associated with a standard SMC.

The rest of this paper is outlined as follows.In Section II,the model of 2D overhead crane systems is described.In Section III,the main results,including the APD-SMC law design and closed-loop stability analysis,are given.To verify the superior performance of the proposed method,some experimental results are given in Section IV.In Section V,we draw the conclusion of this paper.

II.2D OVERHEAD CRANE SYSTEM MODEL

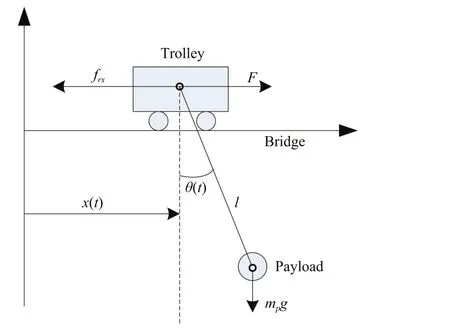

The dynamic equations of a 2D overhead crane system(as shown in Fig.1)can be described as follows[21],[23]:

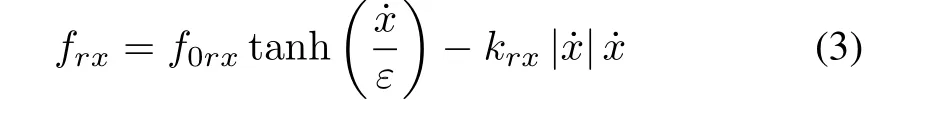

where mxand mprepresent the trolley mass and the payload mass,respectively,l and g stand for the cable length and the gravitational constant,respectively,x(t)and θ(t)are the trolley displacement and the payload swing,respectively,F is the control input,and frxdenotes the friction,which is of the following form[5],[15]−[16]:

with f0rx,ε,krx∈ R1being the friction-related parameters.

Fig.1.Model of 2D overhead crane systems.

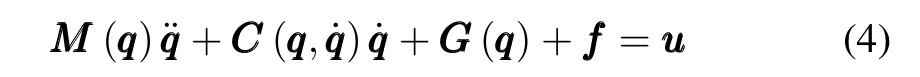

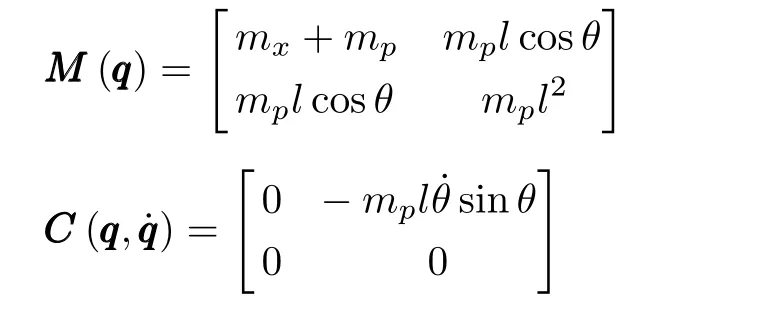

To facilitate the analysis,(1)is rewritten as follows:

where MMM( qqq) ∈ R2×2, CCC( qqq , qqq˙ ) ∈ R2×2,and GGG( qqq) ∈ R2×1are the inertia matrix,the centripetal-Coriolis matrix,and the gravity vector,respectively, qqq∈ R2×1denotes the state vector,fff ∈ R2×1stands for the friction,and uuu ∈ R2×1is the control input vector.They are explicitly defined as

The properties and assumption of the overhead crane system are described as follows:

Property 1:The inertia matrix MMM( qqq )is symmetric positive definite,i.e.,MMM( qqq)>0.

Property 2:The matrix( qqq)/2− CCC ( qqq ,˙)is skew symmetric,i.e.,

Assumption 1:During the transportation process,the payload swing angle always remains in the interval between−π/2 and π/2,i.e.,

III.MAIN RESULTS

In this section,an APD-SMC method is proposed and the stability analysis is presented.

A.APD-SMC Law

To improve the control performance of the underactuated overhead crane systems,the coupling behavior between the trolley displacement x(t)and the payload swing θ(t)should be enhanced.The following composite signal is introduced[23]

where γ∈R+represents a positive control parameter.

Taking the first and second derivatives of(7)with respect to time,one has

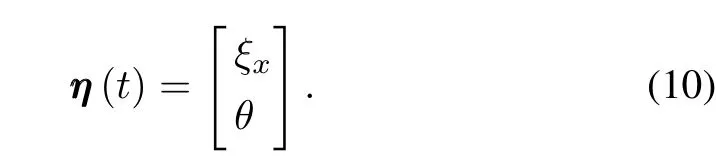

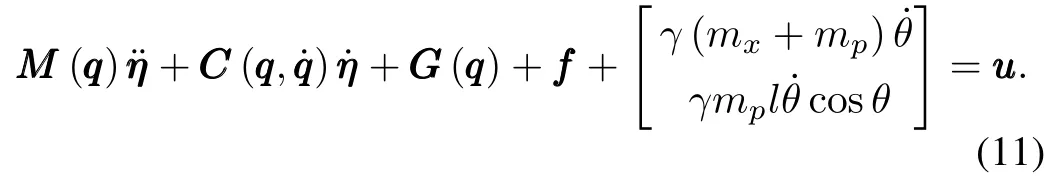

Accordingly,a new state vector η (t) ∈ R2×1is provided with:

According to(1)−(2),and(7)−(9),the dynamic equation with the new state vector can be described as

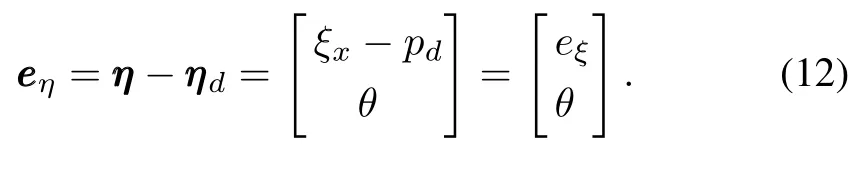

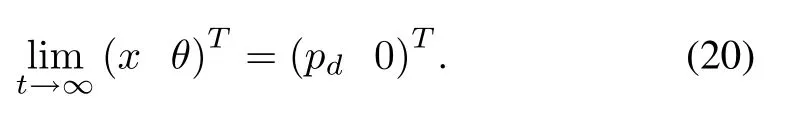

Define ηd=(pd0)Tas the desired trajectory of η(t),with pddenoting the trolley desired location.Let the error signal be defined as

The following sliding surface is used in this study:

where α∈R+denotes the sliding constant.

Define the following function as:

with PPP being a vector of unknown system parameters,ϖT( qqq,˙)standing for a qqq, qqq˙ -related vector,which can be calculated online.The detailed expressions for ϖT( qqq, q˙)and PPP are given as follows:

with P1,P2,P3∈R1being auxiliary functions.

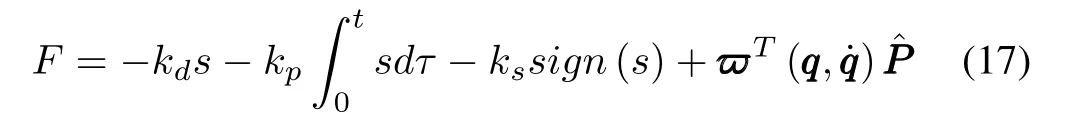

For overhead crane systems,an APD-SMC method is proposed as follows:

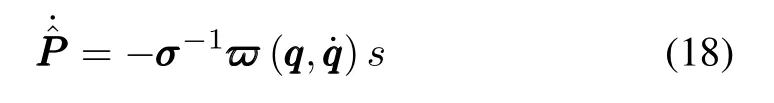

where kpand kd∈R+are the proportional and derivative control gains,ks∈R+denotes the SMC gain,is the estimation of PPP ,which is generated by the following update law:

with σ ∈ R3×3representing a diagonal,positive definite,update gain matrix.

To avoid the chattering problem associated with the SMC method,a hyperbolic tangent function is introduced and(17)can be modified as follows:

B.Stability Analysis

Theorem 1:Under the proposed APD-SMC method(18)−(19),the trolley can be driven to the desired location while the payload swing can be suppressed and eliminated in the sense that:

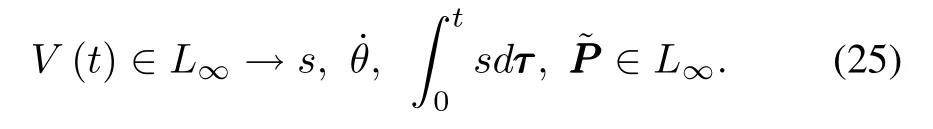

Proof:To prove Theorem 1,a non-negative function is selected as follows:

Taking the time derivative of(22),we obtain that

Differentiating(21)with respect to time,and substituting(11),(18)−(19),and(21)−(22)into it,one has

Therefore,the closed-loop system is Lyapunov stable at the desired equilibrium point[43],and

From(13),(15),(19),and(25),it can be obtained that:

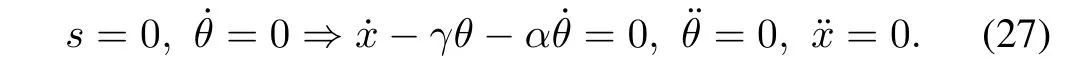

Let Ω={(s,˙s,θ,˙θ)|˙V(t)=0},and then define Ξ as the largest invariant set contained in Ω.Thus,it can be concluded that in Ξ

Substituting(27)into(2),we have that:

Based on(1),(19),and(27)−(28),the following can be obtained:

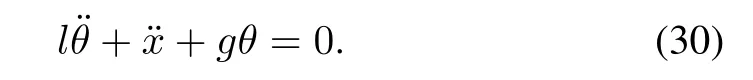

For overhead cranes,the approximations of sinθ≈ θ,cosθ≈ 1 are usually utilized[5]−[6],[21],[23],[44]−[45].Thus,(2)can be rewritten as

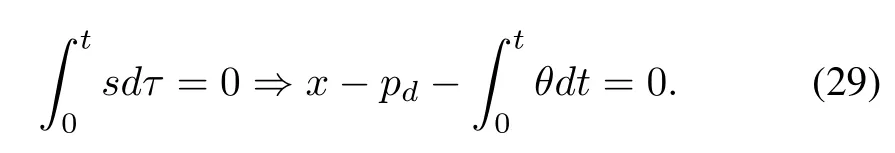

Integrating(30)with respect to time,one has

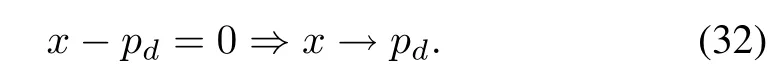

It follows from(29)and(31)that

By collecting the conclusions of(27)−(28)and(32),it can be obtained that only the equilibrium point[x˙x θ˙θ]T=[pd0 0 0]T.Therefore,by using the LaSalle’s invariance theorem[41],Theorem 1 is proven. ■

IV.EXPERIMENTAL RESULTS

In this section,some actual experiments are conducted in a self-built scaled crane testbed[46](as shown in Fig.2)to verify the superior performance of the proposed controller.

Fig.2.Self-built scaled crane testbed.

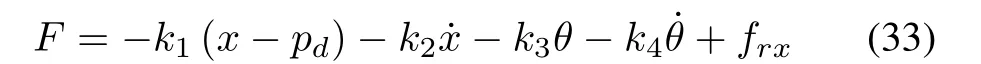

By comparing the proposed APD-SMC law with the LQR[20]and the enhanced coupling controllers[23],the practical control performance of the designed controller is validated.For literature completeness,the expressions of the LQR and the enhanced coupling controllers are given as follows:

1)LQR controller

with k1,k2,k3,and k4∈R+being control gains.

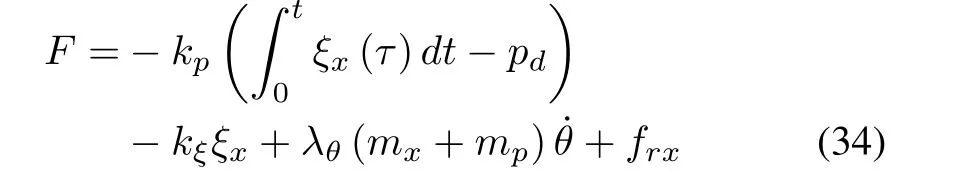

2)Enhanced coupling controller

where kp,kξ,and λθ∈ R+stand for the positive control gains,ξxis defined in the following form:

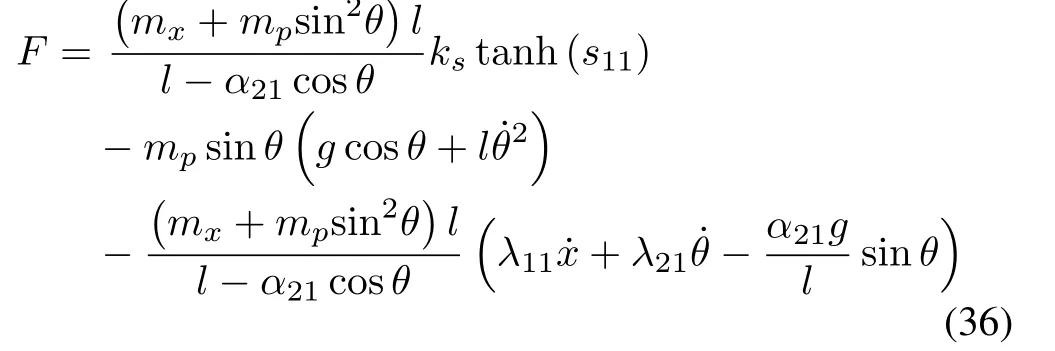

3)SMC controller

where s11=+λ11(x−pd)+α21˙θ+λ21θ represents the sliding surface,and λ11,λ21,α21,ksare control gains.

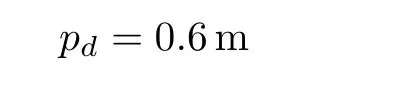

For the comparative experiment,the desired trolley position is set as

the system parameters of the testbed are selected as follows:

and the friction parameters in(3)are identified as

The initial online estimation ofis set as 0,i.e.,

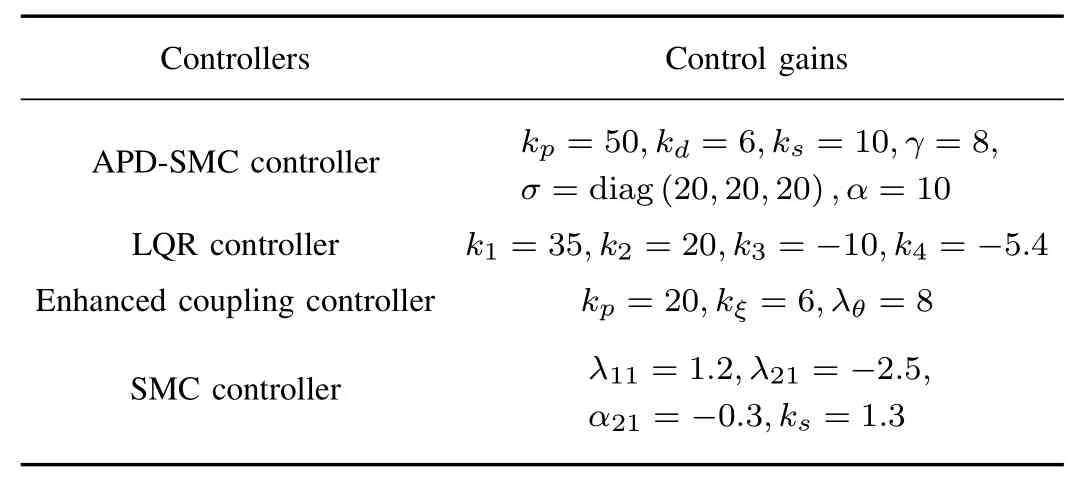

By trial and error,the control gains for the proposed controller,the PD controller,the enhanced coupling controller and the SMC controller are tuned as shown in Table I.

TABLE ICONTROL GAINS

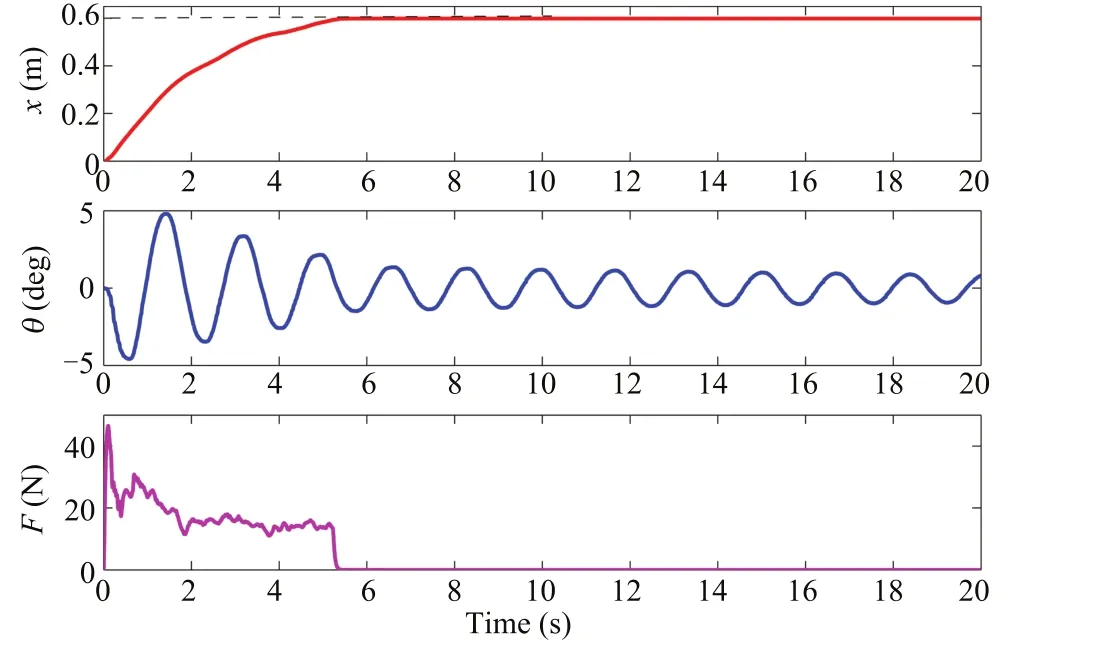

Fig.3.Results of the proposed controller.

Fig.4.Results of the LQR controller.

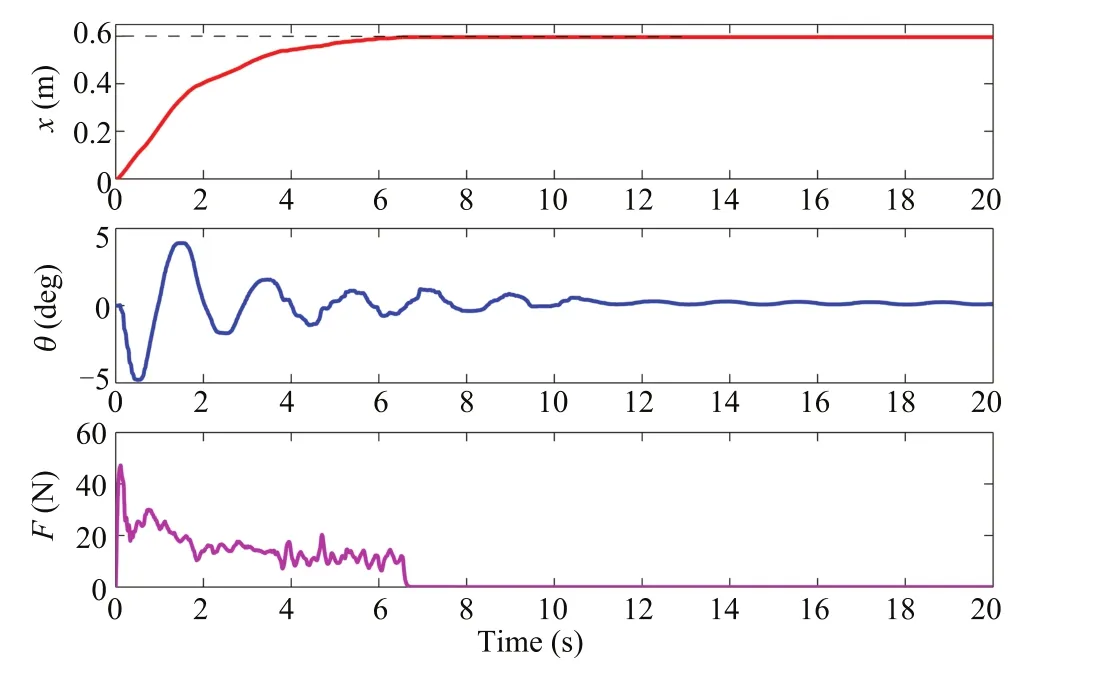

Fig.5.Results of the enhanced coupling controller.

Fig.6.Results of the SMC controller.

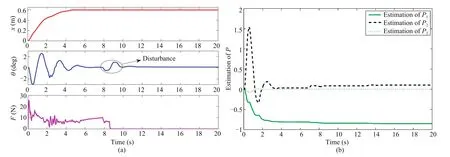

Figs.3−6 depict the behavior of the proposed APD-SMC law,the LQR controller,the enhanced coupling controller,and the SMC controller.It is obvious that the proposed APD-SMC law has better transient performances than those of the other three controllers.More precisely,all the four controllers can push the trolley to reach the destination in about 6s,yet the payload swing amplitude of the proposed APD-SMC law is smaller than those of the LQR controller,the enhanced coupling controller,and the SMC controller.Moreover,there exists almost no residual payload swing as the trolley stops moving for the APD-SMC law while residual payload swing occurs for the other two controllers.The system parameters estimation is shown in Fig.3(b),which clearly depicts that all the estimations converge in about 6s.

To further verify the adaptability and robustness of the designed controller for different working conditions and external disturbances,the following three working conditions are considered:

Fig.7.Results of the proposed controller with respect to Case 1.

Fig.9.Results of the proposed controller with respect to Case 3.

Case 1:Different payload masses:the payload mass is changed from 1.025kg to 2.05kg,whereas the control gains are kept the same as those in Table I.

Case 2:Different cable lengths:the cable length is changed from 0.75m to 0.6m,whereas the control gains are kept the same as those in Table I.

Case 3:External disturbances:some external disturbances with an amplitude of about 1 degree are added to the payload swing between about 8s and 9s,whereas the control gains are kept the same as those in Table I.

The derived results with respect to the three cases are provided in Figs.7−9.As can be seen from Figs.7 and 8 that the overall control performance,including positioning and payload swing elimination,is not affected much by the change of the system parameters,implying that the proposed APDSMC law is insensitive to these uncertainties of payload mass and cable length.From Fig.9,the external disturbances are rapidly suppressed and eliminated by the proposed controller.The aforementioned results evidently prove the adaptiveness and robustness of the proposed method.

V.CONCLUSION

In this paper,an APD-SMC method is proposed for an underactuated overhead crane system,which achieves efficient positioning and rapid payload swing elimination.The control structure of the proposed controller is simpler,and it can achieve increased control performance with strong robustness.Lyapunov techniques are used to support the theoretical derivations.It is proven that the proposed controller can obtain superior transient performance by comparing it with the LQR controller and the enhanced coupling controller.The adaptiveness and robustness of the proposed controller are validated by the experimental study by changing the system parameters and adding external disturbances with the same control gains.In our future work,we will target to give some discussion on the transient performance theoretically.

杂志排行

IEEE/CAA Journal of Automatica Sinica的其它文章

- Advances in Vision-Based Lane Detection:Algorithms,Integration,Assessment,and Perspectives on ACP-Based Parallel Vision

- Deep Scalogram Representations for Acoustic Scene Classification

- A Mode-Switching Motion Control System for Reactive Interaction and Surface Following Using Industrial Robots

- On“Over-sized"High-Gain Practical Observers for Nonlienear Systems

- H∞Tracking Control for Switched LPV Systems With an Application to Aero-Engines

- Neural-Network-Based Terminal Sliding Mode Control for Frequency Stabilization of Renewable Power Systems