Sound absorption characteristic of micro-helix metamaterial by 3D printing

2018-05-19NanshaGaoHongHou

Nansha Gao*, Hong Hou

School of Marine Science and Technology, Northwestern Polytechnical University, Xi'an 710072, China

Acoustic metamaterial is artificial materials with purposely fabricated micro-structures that can achieve exotic sound physical phenomena in the last ten years, such as negative effective refraction index [1-4], negative effective density [5-7], negative effective modulus [8-10], omnidirectional sound absorption [11-13]. Corresponding studies have been the focus of the research hotspot. Great undertaking with respect to these excellent structures pointed out new concepts for the attenuation of low and medium frequency sound, challenging the sound absorption characteristic of traditional structures such as those using glass fibrous [14], mineral wool [15], porous foams [16], and microperforated panels [17]. In recent works, novel structures include membrane-type acoustic metamaterial [18-20] have been shown to absorb sound in the low frequency range experimentally. Peak

transmission loss frequency was tuned to specific values by varying the membrane properties and mass. But the stiffness of membrane is difficult to control and the assemble of central mass lump need to be precise, that prohibit the membrane type acoustic metamaterial application. Ren et al. [21] proposed the ultra-thin multi-slit metamaterial consisting of meso-slits in submillimeter scale and micro-slits in dozens of micrometers scale.The theoretical predictions agree with the numerical simulations, prove that ultra-thin multi-slit metamaterial has a superior absorption over a wide frequency range. But the absorption peak frequency exceeds 1500 Hz, corresponding noise reduction was not solved. Starkey et al. [22] presented a thin acoustic metamaterial absorber comprised of only rigid metal and air,results show that the strong absorption in this system is attributed to the thermo-viscous losses arising from a sound wave guided between the plate and the wall. Experiment results show that this kind of structure can only be effective in high frequency range, and a thickness of air layer is too small to processing. By additive manufacturing, Liu et al. [23] made a porous polycarbonate material. The study found that by adjusting the perforation angle and the airgap behind the sample, the significant absorption can be achieved at low frequency. Inspired by this idea,we designed and prepared a micro-helix metamaterial (MHM)in this paper. Compared with the straight hole and thin seam structure, micro-helix structure is more complicated and related factors of sound absorption are more. This paper study the sound absorption characteristic experimentally. Results and mechanism analysis are as follows.

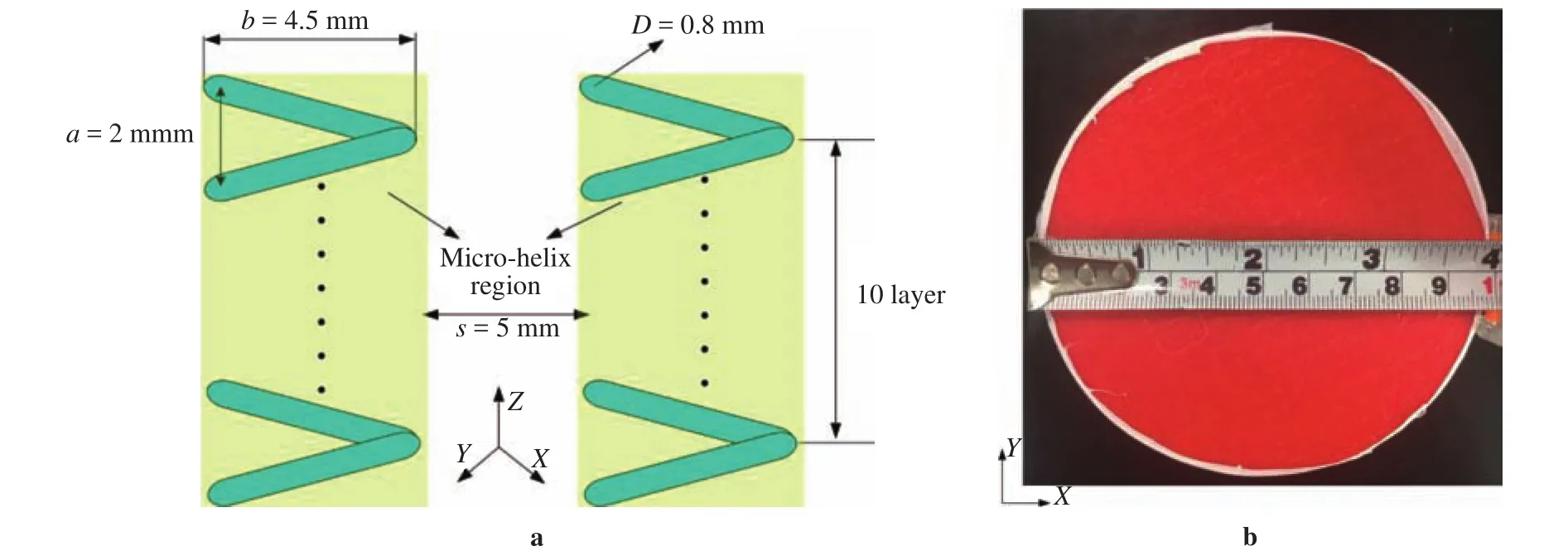

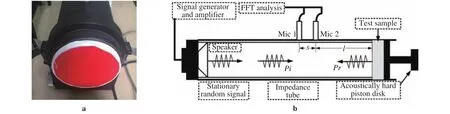

Matrix structure in this paper is single polylactide (PLA) material by 3-dimensional (3D) printed fabrication technique,“Maker Bot Replicator 2” equipment we used in this process can support minimum dimensional precision 0.1 mm. Micro-structure dimension diagram of MHM structure is shown in Fig. 1(a).Blue region is the hollow helix vestibule portion, and the faint yellow region is the micro-helix portion on the space. Distance s between neighboring unit is 5 mm, screw pitch a is 2 mm, diameter of circular helix vestibule D is 0.8 mm, and the external diameter of helix structure b is 4.5 mm. Helix hollow structures are arranged by quartet linear array at the XY plane. Number of piles is 5, shown in Fig. 1(b). The diameter of sample-1 is 99 mm,the white teflon tape was used for deterring sound leakage. Figure 2(a) is the measurement setup in the lab and Fig. 2(b) is twomicrophone impedance method schematic, corresponding method adopt ASTM E1050-12 standard [24]. In this method, the complex sound reflection coefficient R of a test sample is calculated from total acoustic field transfer function H12. According to Chung and Blaser’s [25] results, the complex sound reflection coefficient iswhere the wave numberl is the distance between Mic 2 (Fig. 2)and test sample, s is the distance between the two Mics,andNormal incidence sound absorption coefficientis obtained by, whereand c are the density and speed of sound in the air, respectively. Normal incidence sound absorption measurements for MHM structures were conducted using an impedance tube (Brȕel and Kjær 4206), two microphone (Brȕel and Kjær 4187) and data input acquisition module (Brȕel and Kjær 3560C). The sound absorption coefficient of the MHM structure was calculated using a transfer function method (PULSE software, Brȕel and Kjær). In order to investigate the effects of helix structure dimension and cavity(behind the samples) depth variation on the sound characteristics, we designed and made different samples, test experiment results and discussions are as follows.

Fig. 1. a Micro-helix metamaterial structure diagram; b 3D printed test sample-1.

Fig. 2. a Sound absorption experiment; b schematic of two-microphone impedance method.

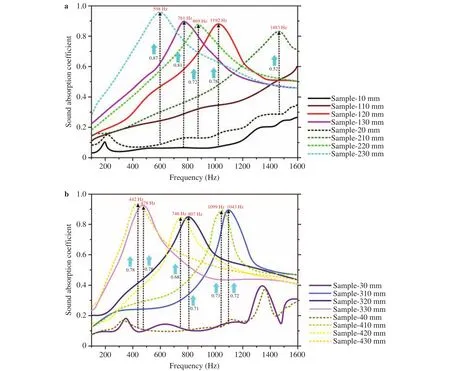

Figure 3 displays the effect results of different screw pitches on the sound absorption. Sample-1, sample-2, sample-3, and sample-4 correspond to the 4.0, 3.0, 2.5, and 2.0 mm respectively. As shown in the Fig. 3, different colors and line-types represent different sound absorption cavity depths. As the screw pitch decrease from 4 mm to 2 mm and the cavity depth is zero,the first sound absorption peak would move to the low frequency range slightly. When the screw pitch is 2.5 mm or 2.0 mm, the second sound absorption peak occurs in the range of 1300-1400 Hz. Introduction of cavity could improve the sound absorption coefficient greatly. When the cavity depths of the sample-1 are the 20 and 30 mm, sound absorption coefficients would have the increments of 0.78 and 0.81 at 1192 and 869 Hz.When the cavity depths of the sample-2 are the 10 mm, 20 mm and 30 mm, sound absorption coefficients would have the increments of 0.52, 0.72, and 0.87 at 1483, 869, and 598 Hz. Accompanied by the continuous increase of cavity depth, the sound absorption coefficient increment would increase. Compared to sample-1 and sample-2, effect of cavity depth increment will be more in sample-3 and sample-4, and corresponding sound absorption coefficients are all over 0.9 from Fig. 3(b). These can be concluded that the reduction of screw pitch and increment of cavity depth could bring about high sound absorption in MHM below 500 Hz. Structurally, the reduction of screw pitch leads to increase of sample porosity, then the acoustic mass of helix vestibule will be decreased, but the flowing air be increased, all these roles make the resonant frequency sound absorption peak move to the low frequency range. Due to the MHM structure in this paper belongs to micro-porous structure by artificial periodic arrangement, when sound wave enters into the helix vestibule,would cause the vibration of air particle. Friction and viscous effects happen among the air particle and helix vestibule, which lead to converting the portion of sound energy to thermal energy. If the screw pitch increases, sound wave cannot have two or more times to collide with each other, energy loss is less.Wave length in this paper is greater than the sample physical dimension, filler material PLA shows rigid, so more obvious effects of sound waves viscosity and thermal conductivity are,higher sound absorption coefficient is.

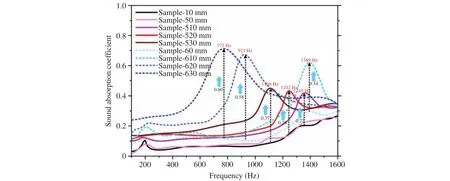

Next, this paper discusses the effects of the helix vestibule diameters variation, the experiment results are shown in Fig. 4.Diameter dimensions 1.2 mm and 0.6 mm correspond to sample-5 and sample-6 respectively. With cavity depth increasing, the sound absorption coefficient would be enhanced by 0.22, 0.28, and 0.37 increment at 1345, 1242, and 1108 Hz, the highest peak is no more than 0.5. When cavity depth of sample-6 is 30 mm, sound absorption coefficient is more than 0.7 at 772 Hz. Figure 4 illustrates the smaller helix vestibule diameters are,the better sound absorption coefficients are. Helix vestibule structure in this paper is analogous to “Capillary tube” model.“Capillary tube” diameter is too small, so this structure will affect air particle movement and produce thermal loss of sound propagation.

Fig. 3. Measurement results of MHM with different screw pitches.

Fig. 4. Measurement results of MHM with different helix vestibule diameters.

In “Capillary tube” model, the distance from the wall to the tube axis is too small. Because the tube wall is connected to the matrix material, the temperature of that is constant. When the sound wave propagate in “Capillary tube”, heat conduction inside and outside the tube is quickly, so the sparse and dense process of sound wave can be regards as isothermal rather than adiabatic process. In light of this, conventional sound velocity c0is changed toIn “Capillary tube” model, sound absorption coefficientsound velocitywhereis specific heat ratio of airis shear viscosity coefficient of air; c0=340 m/s is air density,is air density,and

From 200 Hz to 1600 Hz, minimum helix vestibule diameter 0.6 mm is smaller thanso the “Capillary tube” model in this paper is feasible. Due to the Helix vestibule is too thin,sound absorption coefficient is very large, and sound velocity in tube is much smaller than in infinite spaceHence,structure absorption characteristics in this paper reflect the sound propagation characteristics of “capillary tube” model.Generally excellent sound absorbing material should satisfy two respects requirement: the one is characteristic impedance of material is as close as possible to medium, only if the incoming sound wave is allowed to penetrate into the material as much as possible; the other one is the material should have the strong intensive sound absorption. Helix vestibule structures in this paper all meet these two requirements, which are the physical mechanism behind the high sound absorption characteristics.

This paper designs and fabricates a kind of MHM structure by 3D printing, which has single matrix material and simple quick-processing method. By adjusting different geometrical dimensions of helix vestibule and cavity depth, MHM can get high sound absorption coefficient. Physical mechanism behind the experiment results depends on the friction and viscosity between the air and the helix vestibule. Due to the popularization of the increasing and different additive manufacturing (such as 3D printing, photosensitive resin molding), more micro-structure can be made, and corresponding abundant physical mechanism is the study pot. In the future work, we adopt more matrix material, such as resin, acrylonitrile-butadiene-styrene (ABS)plastic and metal. In this paper, matrix material filling ratio in the processing is 100 percent, if we decrease the filling ratio or change the printing type, micro-structure matematerial would has more closed cavity and the whole effective density decreases, researches on this subject will be the potential hot issues.

Acknowledgment

This work was supported by the National Natural Science Foundation of China (11704314 and 11474230) and the Fundamental Research Funds for the Central Universities(3102016QD056) for financial support. We thank the reviewers for their suggestions, which helped us to improve this paper to a great extent.

References

[1]D.M. Forrester, V.J. Pinfield, Shear-mediated contributions to the effective properties of soft acoustic metamaterials including negative index, Sci. Rep. 5 (2015) 18562.

[2]A. Alsaedi, B. Ahmad, D.P. Challa, et al., A cluster of many Dr.Durga Prasad Challa small holes with purely imaginary negative surface impedances may generate a negative refraction index, Math. Method. Appl. Sci. 39 (2016) 3607–3622.

[3]S.L. Zhai, X.P. Zhao, S. Liu, et al., Inverse Doppler Effects in Broadband Acoustic Metamaterials, Sci. Rep. 6 (2016) 32388.

[4]F. Lemoult, N. Kaina, M. Fink, G. Lerosey, Soda Cans Metamaterial: A Subwavelength-Scaled Phononic Crystal, Crystals. 6(2016) 82.

[5]H.C. Zeng, C.R. Luo, H.J. Chen, et al., Flute-model acoustic metamaterials with simultaneously negative bulk modulus and mass density, Solid. State. Commun. 173 (2013) 14–18.

[6]N. Cselyuszka, M. Sečcujski, V. Crnojević-Bengin, Novel negative mass density resonant metamaterial unit cell, Phys. Lett. A.379 (2015) 33–36.

[7]H. Chen, S. Zhai, C. Ding, et al., Meta-atom cluster acoustic metamaterial with broadband negative effective mass density,J. Appl. Phys. 115 (2014) 054905.

[8]H. Chen, H. Li, S. Zhai, et al., Ultrasound acoustic metamaterials with double-negative parameters, J. Appl. Phys. 119 (2016)204902.

[9]S. Zhai, H. Chen, C. Ding, et al., Double-negative acoustic metamaterial based on meta-molecule, J. Phys. D: Appl. Phys.46 (2013) 475105.

[10]Z. Hou, B.M. Assouar, Tunable solid acoustic metamaterial with negative elastic modulus, Appl. Phys. Lett. 106 (2015) 251901.

[11]N. Jiménez, W. Huang, V. Romero-García, et al., Ultra-thin metamaterial for perfect and quasi-omnidirectional sound absorption, Appl. Phys. Lett. 109 (2016) 121902.

[12]Q. Wei, Y. Cheng, X.J. Liu, Acoustic omnidirectional superabsorber with arbitrary contour, Appl. Phys. Lett. 100 (2012)094105.

[13]A. S. Elliott, R. Venegas, J.P. Groby, et al., Omnidirectional acoustic absorber with a porous core and a metamaterial matching layer, J. Appl. Phys. 115 (2014) 204902.

[14]H.F. Xiang, D. Wang, H.C. Liu, et al., Investigation on sound absorption properties of kapok fibers, Chinese. J. Polym. Sci. 31(2013) 521–529.

[15]C. Van der Kelen, P. Goransson, Identification of the full anisotropic flow resistivity tensor for multiple glass wool and melamine foam samples, J. Acoust. Soc. Am. 134 (2013)4659–4669.

[16]K., Subwavelength structure for sound absorption from graphene oxide-doped polyvinylpyrrolidone nanofibers, Appl.Phys. A-mater. 122 (2016) 788.

[17]X.F. Shi, C.M. Mak, Sound attenuation of a periodic array of micro-perforated tube mufflers, Appl. Acoust. 115 (2017) 15–22.

[18]Z. Yang, H.M. Dai, N.H. Chan, et al., Acoustic metamaterial panels for sound attenuation in the 50-1000 Hz regime, Appl.Phys. Lett. 96 (2010) 041906.

[19]C. J. Naify, C. M. Chang, G. McKnight, et al., Transmission loss and dynamic response of membrane-type locally resonant acoustic metamaterials, J. Appl. Phys. 108 (2010) 114905.

[20]C. J. Naify, C. M. Chang, G. McKnight, et al., Scaling of membrane-type locally resonant acoustic metamaterial arrays, J.Acoust. Soc. Am. 132 (2012) 2784–2792.

[21]S.W. Ren, H. Meng, F.X. Xin, et al., Ultrathin multi-slit metamaterial as excellent sound absorber: Influence of micro-structure,J. Appl. Phys. 119 (2016) 014901.

[22]T.A. Starkey, J.D. Smith, A.P. Hibbins, et al., Thin structured rigid body for acoustic absorption, Appl. Phys. Lett. 110 (2017)041902.

[23]Z. Liu, J. Zhan, M. Fard, et al., Acoustic properties of a porous polycarbonate material produced by additive manufacturing,Mater. Lett. 181 (2016) 296–299.

[24]E. ASTM, 1050-12, Standard Test Method for Impedance and Absorption of Acoustical Materials Using a Tube, Two Microphones and a Digital Frequency Analysis System, American National Standards Institution, New York, 2012.

[25]J.Y. Chung, D.A. Blaser, Transfer function method of measuring in-duct acoustic properties, Theory I., J. Acoust. Soc. Am. 68(1980) 907–913.

[26]H. Koruk, An assessment on the performance of impedance tube method, Noise Contr. Eng. J. 62 (2014) 264–274.

杂志排行

Theoretical & Applied Mechanics Letters的其它文章

- Graphical Abstract

- An analysis of dynamic stability of an elastic column

- Local buckling of thin plate on tensionless elastic foundations under interactive uniaxial compression and shear

- Quantitative characterization of deformation and damage process by digital volume correlation: A review

- Forced vibration analysis of nano-composite rotating pressurized microbeam reinforced by CNTs based on MCST with temperature-variable material properties

- A new equivalent method to obtain the stoichiometric fuel-air cloud from the inhomogeneous cloud based on FLACS-dispersion