Social Manufacturing for High-end Apparel Customization

2018-05-02XiuqinShangFeiYueWangGangXiongTimoNybergYongYuanShengLiuChaoGuoandSenBao

Xiuqin Shang,Fei-Yue Wang,Gang Xiong,Timo R.Nyberg,Yong Yuan,Sheng Liu,Chao Guo,and Sen Bao

I.INTRODUCTION

APPAREL industry is an important part of traditional manufacturing industries where labor requirement is high and product export volume is relatively large.According to the survey of Chinese apparel industry[1],most apparel manufacturing enterprises are original equipment manufacturer(OEM),where some adopt mass production(MP)mode which appears in 1760s,and few adopt the mass customization(MC)mode which appears in 1980s.Most of them have weak brands,own little original designs,and lack high-end products.Low product price is their strongest competence,which is ending with increasing labor cost,and fierce competition from other developing regions like Southeast Asia.To overcome such challenges,Chinese apparel industry has to apply a novel and competitive solution to upgrade their existing manufacturing modes.

Meanwhile,Chinese E-commerce is so popular that the daily turnover record of Tmall(an E-commerce platform of Alibaba)reached 91.2 billion RMB on Nov.11,2015[2],and increased to 254 billion RMB on Nov.11,2017.In fact,with the rapid development of internet technology,the millions even billions of people on the earth are connected together,more and more activities that were previously done in the real world can be executed online now,and a socalled networked society appears[3].In 2006,American Competitiveness Plan designated cyber physical system(CPS)as an important research project[4].In 2012,the concept of social manufacturing(SM)was proposed in the paper From social computing to social manufacturing:one coming industrial revolution[5].SM is a novel manufacturing mode,where precision customization can be realized online by using crowd-sourcing,and social resource can be allocated rationally and used efficiently through.

Since 2012,many researchers have focused on SM and published many papers.Prof.P.Y.Jiang and his team have analyzed SM and constructed its modeling for personalized production[6]-[9].Prof.X.F.Yao and his team have done much research on SM paradigm[10],[11].Prof.T.R.Nyberg and his team discussed and studied the economic value of SM[12],[13].

To realize SM mode,SM cloud is proposed to upgrade the apparel industry into high-end customization stage,and transform traditional apparel enterprise into a more competitive and intelligent enterprise.In fact,such apparel enterprises with socialized customization have appeared in China.For example,Hongling Company,headquartered at Qingdao,is able to execute one suit’s customization in about one week[14].

This paper is organized as follows:SM Cloud is designed to provide the customization service for apparel industry in Section II.The key technologies of SM for high-end apparel customization are discussed in Section III.The architecture,main functions,and one application case study of SM cloud for high-end apparel customization are given in Section VI.Finally,some conclusions are drawn in Section V.

II.SOCIAL MANUFACTURING CLOUD

A.Social Manufacturing

SM mode was proposed in 2012,and then researched by some experts[5],[15]-[21].It is a novel mode of distributed,collaborative,and intelligently customized production.Compared with the traditional manufacturing mode,its greatest feature is that consumers’demand can be directly reflected into a product,i.e., “From idea to products”,in which every consumer can participate in the whole process of product design,making and even marketing.Their participation behaviors enable them to gain more acceptance and satisfaction of their product.User experience can be enhanced through personalization,potential demand for products is released,and the production efficiency of customization is improved.The concept is from the customer-centric end users’view.

On the other hand,in the socialized producers’view,SM is various stakeholders owning socialized manufacturing resources(SMRs),including micro-/small-/medium-sized enterprises,smart factories,workshops,logistics service providers,and public warehouse providers,that make up a social mediabased community with manufacturer to collaborate for the crowdsourced or outsourced tasks.With the development of mobile internet and social networking,the interaction and information sharing among them become much easier.In the community,they are interconnected by contract relationships and production sequence relationships(upstream or downstream).The contract relationships are built between manufacturer and its partners,while the production sequence relationships are built among SMR providers[6]-[9].

An SM mode can be regarded as the further evolution from the latest MC mode.MC refers to module production,in which designers complete the product design,and some prede fined changes,like size,color and other negligible details,can be realized according to each customer’s demands.Obviously,MC cannot satisfy the customization demand fully in apparel industry.With the support of SM,more customization can be achieved,and product design can be finished fully according to a customer’s demands.Therefore,SM can provide better and more services than MC[6]-[13].

B.The Main Components of SM Cloud

SM mode can be realized only with the support of SM cloud,which involves all partners in the product life cycle.The partners mainly include consumers,manufacturers,designers and retailers,and the product life cycle covers measurement,E-business,design,supplying,logistics,after-sale service[10],[11].The main components of SM cloud for high-end apparel can be described as Fig.1.

1)For consumers,they can customize their own fashion clothes by using such technologies as the 3D fitting mirrors in stores near their homes or on the net.They can customize the styles,materials and sizes of the dress,or modify the customization online.All these services could transform a customer’s shopping into their convenient and comfortable entertainment experience.

2)For retailers,their service quality can be improved through combining online and offline sale together.On one hand,physical shops and stores,which distribute widely among all districts,can strengthen the customer’s perception for the products compared to online sales.On the other hand,combining physical shops and stores with the online sales,stocks and rent cost are decreased,and more customers can be attracted.Moreover,in each store,3D fitting mirror is supplied,in order to fit conveniently and help customers customize their dresses.Thanks to the high-tech new innovation-3D fitting mirrors,clothe fitting becomes more convenient and the customization becomes more accurate.Hence,for the retailers,the cost is decreased,and more specific,professional,and characteristic services can be provided to customers.

3)For suppliers,business intelligence(BI)can be adopted to analyze market’s current requirements and future tendency in accordance with consumers’online and offline consumption records.Therefore,BI offers suppliers important information and helps them make right decisions.As a result,inventory level can be brought down,and the pressure of market competition can be reduced.

4)In manufacturing enterprises,an SM mode allows them to produce clothes with more varieties and smaller batches,brings the inventory level down,saves raw materials and improves production efficiency.At the same time,the information collected from 3D fitting mirrors(or dressing rooms)can be saved into SM cloud and fed back to manufacturers,which provides reference to new product design.This makes the new products succeed more easily,reduces operating risks and increases production efficiency.

In conclusion,SM cloud can improve efficiency of the whole industry,and realize the rational and effective utilization of social resources.Then,all partners like manufacturers,suppliers,retailers and customers of apparel production,can gain more benefits.Besides apparel industry,SM cloud are also useful for other manufacturing industries[18]-[30].

C.Main Research Topics

Based on latest information technologies like 3D fitting mirror technology,personalized design and customization,and service mode combining online and offline sales,SM cloud based total solution can be developed for the apparel industry.For realizing this novel SM mode,the main research topics are as follows:

1)Human-body big data acquisition technologies:3D model matching and 3D fitting mirror technology.It is essential for improving the customization precision and user experience.So,it will be discussed in the key technology of 3D technologies for apparel customization,and the 3D customization also is studied in the next section.

2)Collaborative management technology in an internet interactive cloud platform:As well known,SM is further distributed according to the customization demand compared with MC.Therefore,the collaborative management can realize the effective management of the distributed production.It is regarded as one key technology of SM.

3)Other supporting technologies,including cloud computing,evaluation,and E-commerce:In SM,the production is self organized through crowd-sourcing.The reasonable evaluation mechanism can ensure the effective execution of crowd-sourcing.So it will be the other key technology.

Fig.1.The main components of SM cloud for high-end apparel.

4)Big data based expert system of clothing customization in garment enterprises:It refers to the data mining and big data analysis algorithms,e.g.,deep learning,artificial neural network and expert system.In fact,Hongling Company has claimed that they have their own such basic expert system.However,it is a big research topic and a lot of work should be done,so we will further study it as the challenge in the future.

III.KEY TECHNOLOGIES OF SM FOR HIGH-END APPAREL CUSTOMIZATION

As mentioned above,three key technologies are studied in this paper.They are 3D technologies for apparel customization,information based collaborative management,suppliers’evaluation mechanism based on analysis hierarchy process(AHP).

A.3D Technologies for Apparel Customization

1)3D fitting mirror technology

Recently,3D fitting mirror technology continues to improve quickly.One of the most famous products is virtual fitting room from Russian AR DOOR Company.It projects a 3D image of the items of clothing onto the shopper as they stand before a screen.The company has used game-playing hardware to create the invention with an Xbox 360 console,complete with its Kinect motion-sensor,hooked up to a large video screen which resembles a full-length mirror.The Kinect camera is able to monitor customers’movements when they turn around in order to show them the back of the garment too.In the case above,3D fitting mirror is only used to enhance the user experience.

We try to improve the fitting mirror as the customization gateway through such technologies like computer aided design(CAD),virtual reality(VR),and augmented reality(AR).In the apparel industry,those technologies can collect a customer’s preferences,size,effect examination information,and feedback them to the designer,help the 2D garment cutting&sewing work such as inspections and garment manufacturing check.In virtual clothing stores,customers can achieve virtual fitting,customization,and decision support.The way to apply the 3D fitting mirror for clothing customization,can be described as Figs.2 and 3.

The Kinect plays an important role in the virtual fitting mirror.According to the depth information,the Kinect can build a 3D model quickly.Furthermore,the Kinect can capture customer’s motion,then update the 3D model in real time.By using the so-called motion sensing technology,customer can try on virtual clothes based on 3D body model,and merchants can get essential parameters from the 3D body model.

Fig.2. Main functions of a 3D fitting mirror.

Fig.3. A 3D fitting mirror.

To improve 3D modeling of human body shape,3D model matching approach is studied.A hybrid algorithm combining normal aligned radial feature(NARF)key point detector and fast point feature histogram(FPFH)descriptor are adopted for 3D model matching.NARF key point detector is able to accelerate the efficiency of the initial iteration while FPFH can reduce the calculation of matching process in light of the decrease of descriptors dimension.The experiment showed a great result.

2)3D customization

Based on 3D human body models,3D customization can be realized more easily,which can simplify the garment process and provide dressmaking efficiency.The existing garment’s processes consist of design,choosing fabrics,pattern,cutting,sewing,and ironing etc.For the design step,3D CAD has already been used,and there are many special design software in the garment industry.Besides,as the most important section,pattern means to decompose the clothing into pieces according to the design drawing,and then sewing them together,including body,sleeve and collar.After being checked,the fabric is cut according to the pattern of a contour cropping garment piece.Then,clothes can be made by sewing the pieces together.With the 3D technology,the effect of the ready-tomake clothes can be displayed virtually even before the clothes are made.In this way,the clothing play board process can be realized on the computers totally.

Therefore,compared with craft customization for smaller batches and more variety production,SM’s 3D customization with 3D human body models technology can reduce the cost of production design,making-board,and so on.

B.Information Based Collaborative Management

Based on SM cloud,the consumers,designers,and manufacturers are no longer the separated individuals,and all kinds of necessary collaborations can be executed among them.By applying advanced network and collaborative management,the information about business,affairs,and events can be shared,communicated and handled efficiently,and in an orderly and controllable manner among enterprises,departments,groups and individuals.Therefore,information based collaborative management can help all users build and keep the collaborative relationship online.In order to realize the information based collaborative management,SM cloud should provide the main functions including service infrastructure function,service bus layer and application function,and business entrance function.The more specific contents of those functions are shown in Fig.4.

Fig.4. Information collaborative management functions of SM.

For the coordinated dynamic netizen group(DNG)and coordinated production equipment,the research focuses on a collaborative model and modeling system,including a business model and modeling system in SM mode.DNG is defined as the groups who dynamically access the internet for the similar interests or purposes.Through DNG’s crowd-sourcing and distributed cooperative forms,network-based collaborative manufacturing services can be supplied for SM mode.

A collaborative model re fl ects the cooperative relationship among data,crowd-sourcing services,crowd-sourcing business process and DNG.The two parts,i.e.collaborative meta-model and collaborative modeling,are discussed further.

1)Collaborative meta-model:It is composed of crowd-sourcing business involved in DNG,a crowd-sourcing business process,crowd-sourcing services and data.Specifically,collaborative relationships can be classified as the relationships between crowd-sourcing business processes and business process,the relationships between crowd-sourcing business process and services,the relationships between crowd-sourcing services and services,the relationships between DNG and DNG,the relationships between DNG and crowd-sourcing business process/services,the relationships between data and data.A collaborative meta-model can abstract and translate the collaborative relationships in all levels of SM into the collaboration among businesses,data,and services,which constitute a collaborative meta-model of SM.

2)Collaborative modeling based on model mapping:An SM model with multiple views can reflect the information in all aspects of operating crowd-sourcing business.A collaborative model is established by using the extraction and mapping method of the related business views,which can help people obtain data,services,processes,and the related important information about the collaborative work.In this way,crowd-sourcing collaborative modeling can be improved in accuracy and efficiency.In an SM model,four elements of the related important collaborative operation are function view,crowd-sourcing process view,information view,and DNG view.

Based on a collaborative meta-model,the extraction and mapping methods of a manufacturing business view can be researched further.The service function definition is extracted according to business requirements and function view.The modeling of relationship between the services and the control processes of netizens collaboration is extracted by using the process view.The interface definition of crowd-sourcing services is extracted according to the information view.Based on the DNG view and its relationships with other views,the collaborative process description of DNGs can be established.

Based on a model driven architecture(MDA),the collaborative model can be transformed into the related collaborative model,which is supported by a business modeling tool.Model establishment and transformation are well integrated,and the business-driven model can support the business operation and monitor the implementation process.

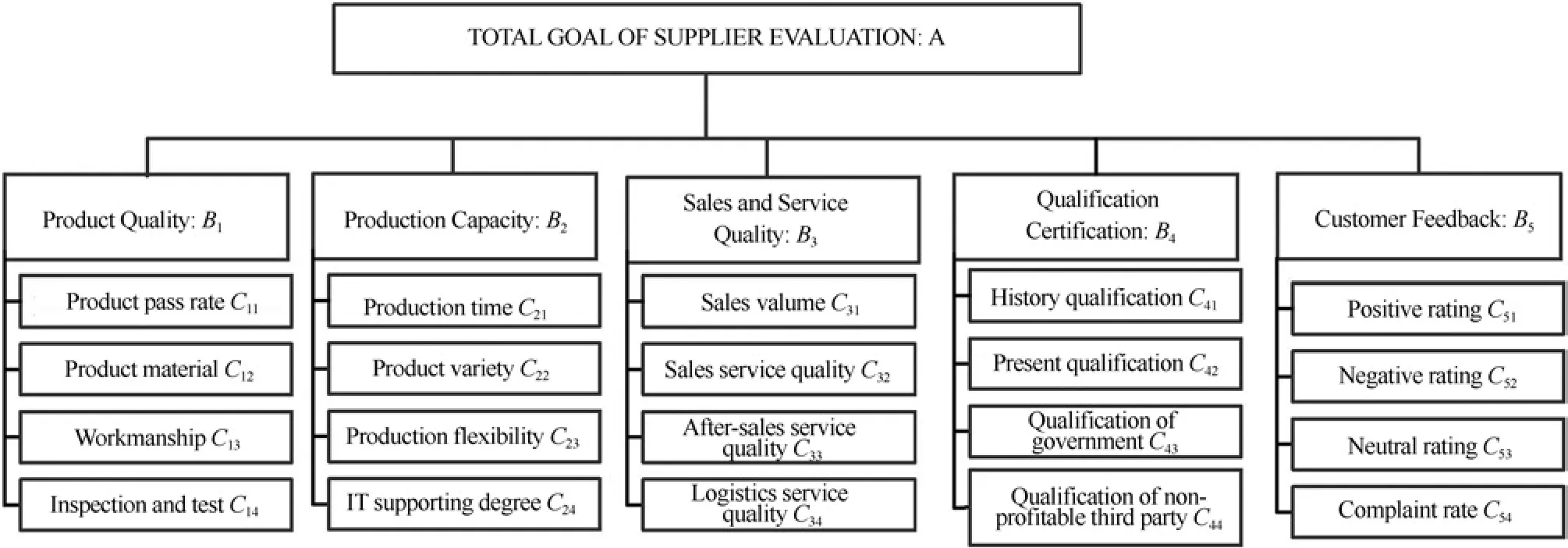

C.Supplier Evaluation Mechanism Based on AHP

In SM mode,the customers must face many suppliers to make decision and choices,so a supplier evaluation mechanism is necessary.In accordance with a supplier’s characteristics under SM,the hybrid method combining AHP and fuzzy analysis is adopted under SM mode[31]-[35].The two-level indicators are constructed under the total evaluation goal.The first level indicators are established through investigating several garment enterprises in South China’s Dongguan City.For the second level,the indicators areBi,i∈{1,2,...,5},including:1)product quality;2)production capacity;3)sales and service quality;4)qualification certification;and 5)customer feedback.The third level is(Cij)5×4,as shown in Fig.5.

Fig.5. Hierarchy of the supplier evaluation in three level indicators.

1)Judgment matrices

In AHP,a hierarchic or network structure is needed to represent the problem and pairwise comparisons to establish relations within the structure[31].Based on the 1-9 scaling method given in[32]-[35],we use the consistent matrix method to construct the judgment matrix according to the comparison results.The judgment matrix is a relative importance comparison of all factors in this level with respect to any factor in the next higher level.The judgment matrixA-Bi=(bij)n×n,wherebij>0,andbii=1.Here the elementsbijof judgment matrix are given by the 1-9 scaling method.

2)Relative weights and consistent computing

Based on the judgment matrix,the relative weightwiofBiare computed by the normalized eigenvector creating correspondence betweenWto the maximal eigenvalueλmaxof the judgment matrix.Besides,the geometric method of approximate algorithm is given as

When comparing the importance of three items,i.e.,a,bandc,the consistency judgment is needed for those conflicting cases,likeais more important thanb,andbis more important thanc,butcis more important thana.the consistency judgment is necessary to fine the possible single hierarchical sorting answer for the conflicting problem.whereCIis the consistency index;λmaxis the largest eigenvalue of a judgment matrix;andnis the order of the judgment matrix.

In AHP,the more factors in pairwise comparisons,the lower the consistency requirements.To measure the consistency of a judgment matrix in different orders,average random consistency indexIRof thenth order is introduced.Random consistency indexIRcan be found in Table I.

TABLE IRANDOM CONSISTENCY INDEXIR

whereCRis the consistency ratio;IRis the random consistency index;IfCR<0.1,inconsistent degree is considered within the allowable range and has a satisfying consistency.Otherwise,it needs to reconstruct pairwise judgment matrix.

3)Fuzzy evaluation

When one supplier is evaluated corresponding to certain factors,all the possible evaluation results are obtained and collected,the collection is called an evaluation set,denoted byG.The multi-factor fuzzy evaluation matrix is obtained according to the single factor evaluation vector scored with the expert scale.Experts evaluate each factor in a factor set,and map the evaluation results into the factor set to derive an overall evaluation MatrixR.The weight of each factor for the total target is obtained via hierarchical analysis,denoted asW.

Known factors set weight vectorWand evaluation matrixR.The fuzzy comprehensive method is used to evaluate complex systems.The mathematical model is shown as follows:

Then,Mis given normalized treatment,thus resulting inM.The last evaluation resultVis shown as follows:

De fine consistency ratioCRas follows:

Fig.6.The architecture of the social manufacturing cloud.

The system uses the method that combines AHP and fuzzy comprehensive method to evaluate suppliers,reducing the impact of human’s subjective preferences on evaluation.The system correctness and feasibility are verified by suppliers’strength of garment enter-prises.

IV.CONSTRUCTING THE SOCIAL MANUFACTURING CLOUD

A.Architecture of Social Manufacturing Cloud

Based on the above key technologies,the architecture of SM cloud is designed with five layers,i.e.Service resource,Service support,Coordinated running environment,Business support,and Business application,shown as Fig.6.They are further described as follows:

1)Service resource layer

This layer includes all kinds of production and services resources,which can form a social resource network.Specially,the resources include manufacturing equipment,production(e.g.,3D printers),information network using 3D intelligent terminals,modern logistics network,and heterogeneous operating system.In this layer,3D intelligent terminals’perception function and interactive function can be provided;the modern logistics network offers logistics capability;additionally,the networks provide all kinds of physical connection,and provides transparent information communicating services.This layer plays an important role of terminal perception and information communication,production service and product logistics.

2)Service support layer

This layer contains service module encapsulation,service registration,service discovery,service data management,service management,middle ware management.With the help of service registration and service discovery modules,the information of the enterprises can be transferred accurately,efficiently and safely in accordance with user requests.

a)Service module encapsulates the current application system’s function,data and staff integrally through adapter,and converts them into the service that can be accessed by applicants in a standard mode.

b)Service registration module classifies and publishes the current service using the universal description,discovery and integration(UDDI)protocol.There are three services in this module,namely,business services,business function services and technical function services.With the help of the service registration module,the services can be published by service providers,then users can search available services.

c)Service discovery module is based on the classification information and the functional description of a service in the registration module.This module helps search relevant services for specific demands that come from customers and the service bus.

d)Service data management module provides accessing and management of heterogeneous data in the framework of service oriented architecture(SOA),which comprises accessing and mapping to relational databases as well as accessing and operation of business objects.

e)Service management module includes version management and product lifecycle management.

f)Middle ware management administrates various adapter interfaces uniformly,and realizes more value-added services by integrating current applications and information.

g)Security service and other standard services guarantee the loose coupling between APPs(applications)and service providers,and make them interact in dynamic ways that are safe and efficient.

3)Coordinated running environment layer

This layer contains computing environment,coordinated operation environment,cooperative monitoring management,information analysis environment and optimization environment.

a)Coordinated running environment:process driving,process navigation,and task management.

b)Coordinated monitoring environment:process state control,process state display,and process optimization.

c)Information analysis environment:the information filtering and information mining.

d)Optimization and decision environment:it includes the artificial system and computing experiment.The artificial system can support the models for the optimization and decision.The computing experiment can support the optimization methods,and provide the tools for optimization and decision.

4)Business support layer

This layer consists of physical clothing stores,internet-based clothing stores,social media information platform,data acquisition and analysis platform,business intelligence platform,collaborative manufacturing management platform,logistics supervising platform,and all kinds of management tools for user management,right control,safety management,running monitoring,computing resource scheduling and exception handling.

5)Business application layer

This layer consists of the portals of SM cloud platform as well as the interfaces to integrate those existing information systems,like manufacturing execution system(MES),enterprise resource planning(ERP),and office automation(OA).They are social network application,enterprise-level APP,community-level APP,big data analysis application,and integrated existing application.Therefore,both enterprises and community customers can access the system in different ways,and are allowed to accomplish specific settings and con figurations.This layer realizes content aggregation,customized views,customization,collaboration features,internationalization,big data analysis,integrated existing application,support of various web browsers,personal digital assistant(PDA).

B.Application Cloud for High-End Apparel Customization

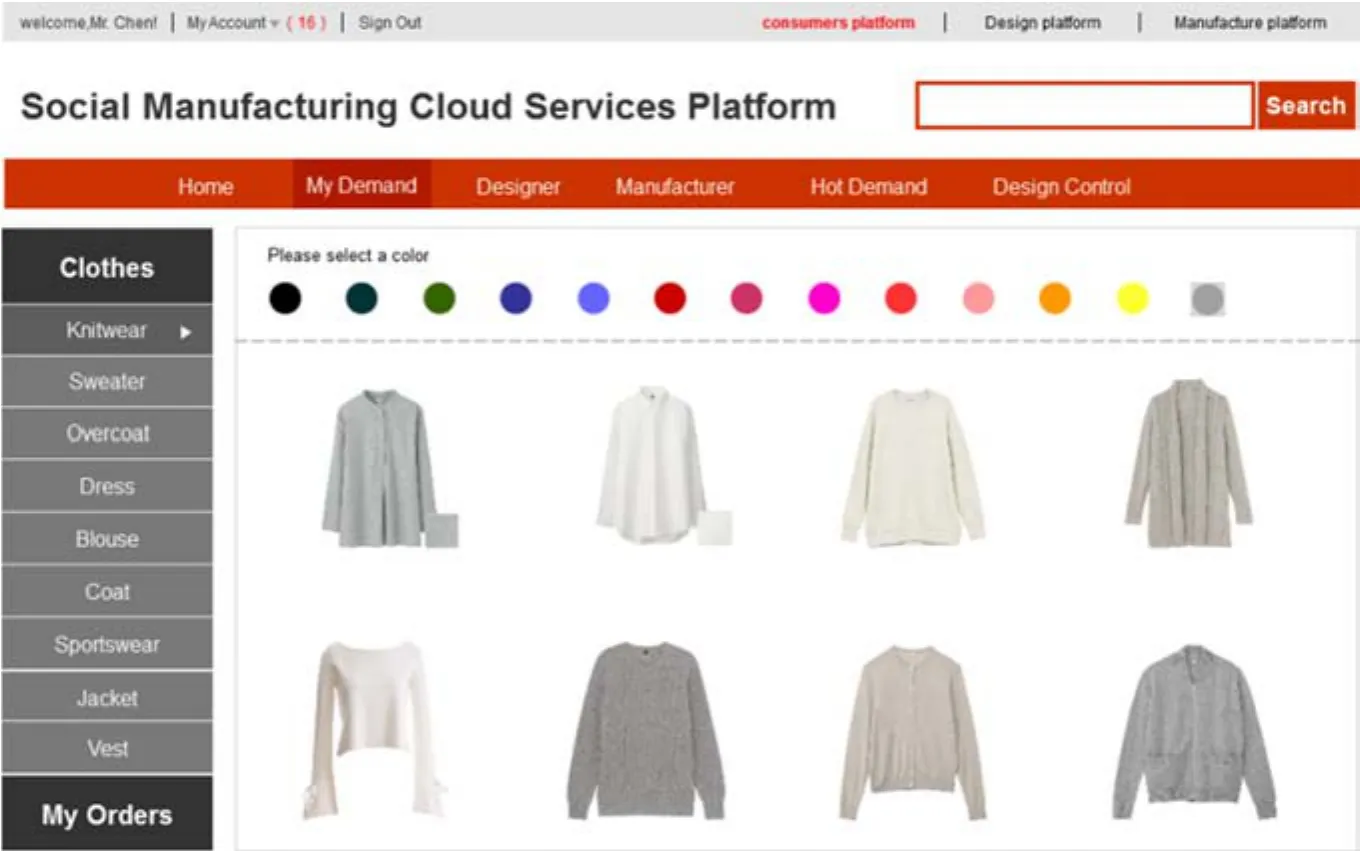

Based on the previous SM cloud platform,the application cloud especially for high-end apparel customization case study is developed,including customization subsystem,design subsystem,and manufacturing subsystem,shown in Figs.7-9.For consumers,they can choose a variety of factors to achieve the customization according to their habit,such as materials,colors,styles,designers and other clothing design elements,to customize their clothing independently.When

Fig.7. Application cloud interface for consumers.

Fig.8. Application cloud interface for designers.

Fig.9. Application cloud interface for manufacturers.

one consumer completes and saves his/her customized clothing independently into the application cloud,he/she can see and edit clothing effect,as shown in Fig.7.Besides,they can use 3D fitting mirror to display fitting effect,as shown in Fig.3.

For designers,according to the customization information from the customers,they can integrate all the information,make the necessary processing,supply the design scheme,and feedback the scheme to customers.Through crowd-sourcing,the designer,who can supply the most suitable design scheme to satisfy the customers demand,is chosen as the final designer.The system can help all the designers to evaluate their schemes by big data computation and analysis.By using the application cloud,designers can design new clothes rapidly and easily for consumers to choose and test,as shown in Fig.8.

For manufactures,they can arrange the final processing tasks in the application cloud.The design subsystem can push production data into the manufacturing subsystem.Through collaborative management technology,the production tasks are optimized,and then are assigned to each workstation.Within the shortest time,the manufacturing task can be finished by the collaborative and distributed management.The production plan of one order is shown in Fig.9.In this way,the rapid,efficient,and low-cost production is possible.

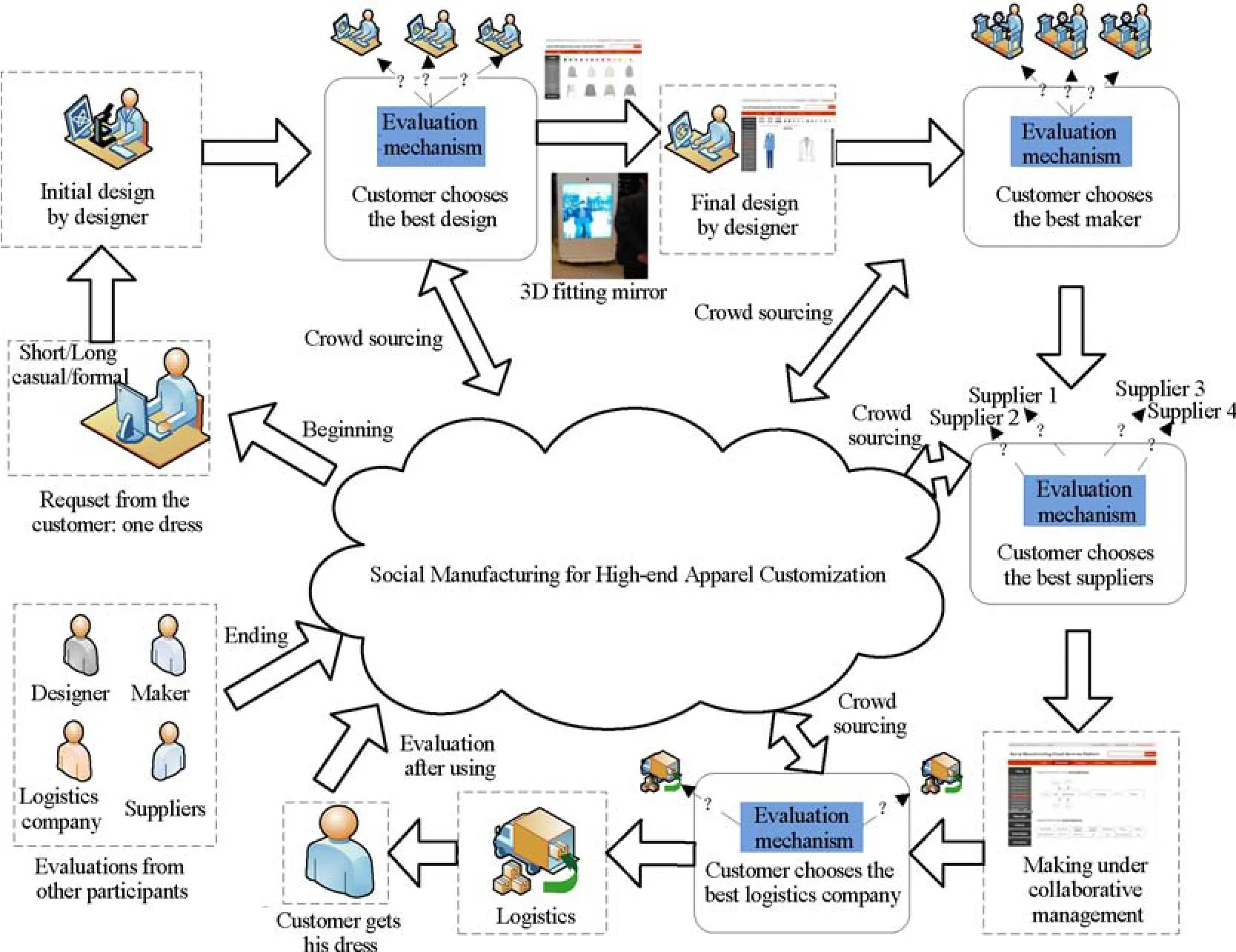

C.Application Case

A demonstrative case is given to verify how SM can be applied to high-end apparel.If a customer wants to customize his clothes in SM cloud,he will go through these steps,as shown in Fig.10.

Fig.10. One demonstrative case of SM for high-end apparel.

First of all,when he wants one customized dress,he must describe his request.Secondly,designers can offer their initial design if they are interested in the request.Thirdly,the customer can choose the best design scheme from all the ones according to the supplier evaluation mechanism,and he must scan his body and send the 3D body data to the selected designer for precise customization.Fourthly,the designer gives the final design according to 3D body model.After that,the customer gets the design scheme and go on to choose the makers,suppliers,logistics companies for his dress,who can work under collaborative management.After he gets it,he needs to evaluate the other collaborators of designer,maker and so on,while they also evaluate him.In the case,the customer can participate in the whole process of product design,making and even marketing,and the other participators can be managed collaboratively.

V.CONCLUSION

In this paper,SM mode is proposed and SM cloud is constructed for high-end apparel customization,and the key technologies thereof are studied,including 3D apparel customization,collaborative management,and suppliers evaluation mechanism.

With SM cloud,a distributed,collaborative and intelligent manufacturing mode is established.Compared with the existing craft customization and mass customization,SM can release more potential demand for products,enhance user experience and improve efficiency and precision of customization production,so that the traditional apparel enterprise can be upgraded into intelligent one.The new SM mode of manufacturing and service will transform the apparel industry,and break through traditional apparel industry’s structure.It will lead to the new trend of fashion garment production,making,and also promote the sustainable growth of garment industry.

This paper provides the possible scheme to deal with high-end apparel customization.However,there is still some work to do,such as self-study mechanism and expert system to improve customization precision and intelligence,3D fitting mirror to enhance user experience,and conflict and balance between information resources sharing and trade secret protection for enterprises.

[1]J.L.Zhao and L.Li,“The impact of outsourcing on local industry upgrading:a case of China from a global value chain perspective,”J.Donghua Univ.,vol.28,no.3,pp.261-266,Jun.2011.(in Chinese)

[2]www.chinabgao.com,[Online],Available:http://www.chinabgao.com/freereport/69794.html.Accessed on:Nov.28,2015.

[3]P.Sobkowicz,“Effect of leaders strategy on opinion formation in networked societies with local interactions,”Int.J.Mod.Phys.C,vol.21,no.6,pp.839-852,Jun.2010.

[4]E.A.Lee, “Cyber physical systems:Design challenges,”inProc.11th IEEE Int.Symposium on Object Oriented Real-Time Distributed Computing,Orlando,USA,2008,pp.363-369.

[5]F.Y.Wang,“From social computing to social manufacturing:the coming industrial revolution and new frontier in cyber-physical-social space,”Bull.Chinese Acad.Sci.,vol.27,no.6,pp.658-669,2012.(in Chinese)

[6]P.Y.Jiang,K.Ding,and J.W.Leng,“Towards a cyber-physicalsocial-connected and service-oriented manufacturing paradigm:Social Manufacturing,”Manuf.Lett.,vol.7,pp.15-21,Jan.2016.

[7]P.Y.Jiang and K.Ding,“Analysis of personalized production organizing and operating mechanism in a social manufacturing environment,”Proc.Inst.Mech.Eng.B:J.Eng.Manuf.,to be published.doi:10.1177/0954405417699016.

[8]K.Ding,P.Y.Jiang,J.W.Leng,and W.Cao,“Modeling and analyzing of an enterprise relationship network in the context of social manufacturing,”Proc.Inst.Mech.Eng.B:J.Eng.Manuf.,vol.230,no.4,pp.752-769,Apr.2016.

[9]J.W.Leng and P.Y.Jiang,“A deep learning approach for relationship extraction from interaction context in social manufacturing paradigm,”Knowl.-Based Syst.,vol.100,pp.188-199,May 2016.

[10]X.F.Yao and Y.Z.Lin,“Emerging manufacturing paradigm shifts for the incoming industrial revolution,”Int.J.Adv.Manuf.Technol.,vol.85,no.5-8,pp.1665-1676,Jul.2016.

[11]X.F.Yao,H.Jin,and J.Zhang,“Towards a wisdom manufacturing vision,”Int.J.Comput.Integrat.Manuf.,vol.28,no.12,pp.1291-1312,Dec.2015.

[12]B.Mohajeri,T.Nyberg,J.Karjalainen,T.Tukiainen,M.Nelson,X.Q.Shang,and G.Xiong,“The impact of social manufacturing on the value chain model in the apparel industry,”in2014 IEEE Int.Conf.Service Operations and Logistics,and Informatics,Qingdao,China,2014,pp.378-381.

[13]B.Mohajeri,“Paradigm shift from current manufacturing to social manufacturing,”M.S.thesis,Aalto University,Finland,2015.

[14]www.ce.cn,[Online],Available:http://www.ce.cn/xwzx/gnsz/gdxw/201507/07/t20150707-5856343.shtml.Accessed on:Jul.7,2015.

[15]F.Y.Wang,X.C.Li,W.J.Mao,and T.Wang,Social Computing Methods and Applications(Second edition).Zhejiang,China:Zhejiang University Press,2013.(in Chinese)

[16]M.E.Porter,Competitive Advantage.New York:Free Press,2004.

[17]F.Y.Wang and T.Shunning,“Arti ficial societies for integrated and sustainable development of metropolitan systems,”IEEE Intell.Syst.,vol.19,no.4,pp.82-87,Jul.-Aug.2004.

[18]F.Y.Wang,“Agent-based control for networked traffic management systems,”IEEE Intell.Syst.,vol.20,no.5,pp.92-96,Sep.-Oct.2005.

[19]F.Y.Wang,“Toward a Paradigm Shift in Social Computing:The ACP Approach,”IEEE Intell.Syst.,vol.22,no.5,pp.65-67,Sep.-Oct.2007.

[20]F.Y.Wang,K.M.Carley,D.Zeng,and W.J.Mao,“Social computing:From social informatics to social intelligence,”IEEE Intell.Syst.,vol.22,no.2,pp.79-83,Mar.-Apr.2007.

[21]F.Y.Wang,“The emergence of intelligent enterprises:from CPS to CPSS,”IEEE Intell.Syst.,vol.25,no.4,pp.85-88,Jul.-Aug.,2010.

[22]Y.J.Lu and J.Cecil,“An Internet of Things(IoT)-based collaborative framework for advanced manufacturing,”Int.J.Adv.Manuf.Technol.,vol.84,no.5-8,pp.1141-1152,May 2016.

[23]J.G.Mai,L.Zhang,F.Tao,and L.Ren,“Customized production based on distributed 3D printing services in cloud manufacturing,”Int.J.Adv.Manuf.Technol.,vol.84,no.1-4,pp.71-83,Apr.2016.

[24]X.Li,J.D.Song,and B.Q.Huang,“A scientific work flow management system architecture and its scheduling based on cloud service platform for manufacturing big data analytics,”Int.J.Adv.Manuf.Technol.,vol.84,no.1-4,pp.119-131,Apr.2016.

[25]Y.P.Xu,G.X.Chen,and J.L.Zheng,“An integrated solution-KAGFM for mass customization in customer-oriented product design under cloud manufacturing environment,”Int.J.Adv.Manuf.Technol.,vol.84,no.1-4,pp.85-101,Apr.2016.

[26]G.Xiong,D.Fan,S.Liu,T.R.Nyberg,and F.Y.Wang,“Mass customization manufacturing solution for cell phone production,”inProc.IEEE Int.Conf.Automation and Logistics,Hong Kong,China 2010,pp.518-523.

[27]X.Q.Shang,X.W.Liu,G.Xiong,C.J.Cheng,Y.H.Ma,and T.R.Nyberg,“Social manufacturing cloud service platform for the mass customization in apparel industry,”inProc.2013 IEEE Int.Conf.Service Operations and Logistics,and Informatics,Dongguan,China,2013,pp.220-224.

[28]A.Greasley and Y.C.Wang,“Building the hybrid organisation through ERP and enterprise social software,”Comput.Ind.,vol.82,pp.69-81,Oct.2016.

[29]J.T.Ye,G.H.Ma,L.G.Jiang,L.Chen,J.T.Li,G.Xiong,X.P.Zhang,and M.Tang,”A unified cloth untangling framework through discrete collision detection,”Comput.Graph.Forum,vol.36,no.7,pp.217-228,Oct.2017.

[30]X.Q.Shang,B.L.Su,X.W.Liu,G.Xiong,and Z.B.You.“Social manufacture cloud mode in high-end apparel,footwear and hats”,inProc.11th World Congress on Intelligent Control and Automation,Shenyang,China,2014,pp.5264-5269.

[31]R W Saaty,“The analytic hierarchy process-what it is and how it is used,”Math.Modell.,vol.9,no.3-5,pp.161-176,1987.

[32]T.L.Saaty,The Analytic Hierarchy Process:Planning,Priority Setting,Resource Allocation.New York:McGraw-Hill,1980.

[33]D.Y.Chang,“Applications of the extent analysis method on fuzzy AHP,”Eur.J.Oper.Res.,vol.95,no.3,pp.649-655,Dec.1996.

[34]O.S.Vaidya and S.Kumar,“Analytic hierarchy process:An overview of applications,”Eur.J.Oper.Res.,vol.169,no.1,pp.1-29,Feb.2006.

[35]R.Hand field,S.V.Walton,R.Sroufe,and S.A.Melnyk,“Applying environmental criteria to supplier assessment:A study in the application of the Analytical Hierarchy Process,”Eur.J.Oper.Res.,vol.141,no.1,pp.70-87,Aug.2002.

杂志排行

IEEE/CAA Journal of Automatica Sinica的其它文章

- Letter to the Editor Re“Fractional Modeling and SOC Estimation of Lithium-ion Battery”

- Relationship Between Integer Order Systems and Fractional Order Systems and Its Two Applications

- A Novel Approach for Enhancement of Geometric and Contrast Resolution Properties of Low Contrast Images

- An Exploration on Adaptive Iterative Learning Control for a Class of Commensurate High-order Uncertain Nonlinear Fractional Order Systems

- Robust H∞Load Frequency Control of Multi-area Power System With Time Delay:A Sliding Mode Control Approach

- Cyber Attack Protection and Control of Microgrids