influences of pre-torsion deformation on microstructure and mechanical properties of pure titanium subjected to subsequent tension deformation

2018-04-21JieLIUFuguoLIHnCHEN

Jie LIU,Fuguo LI,Hn CHEN

aSchool of Aeronautics,Northwestern Polytechnical University,Xi’an 710072,China

bState Key Laboratory of Solidi fication Processing,School of Materials Science and Engineering,Northwestern Polytechnical University,Xi’an 710072,China

1.Introduction

Pure titanium and its alloys are widely used in the aviation industry due to their excellent properties such as low density and high specific intensity.1–3Besides,for its good biocompatibility,excellent corrosion resistance,and low modulus of elasticity,the use of pure titanium and its alloys for automotive and biological applications is increasing.4,5

Pure titanium is usually shaped by bulk forming where the material is actually subjected to large plastic deformation.It is well known that large plastic deformation can be used to prepare billets with desired shapes and excellent comprehensive properties.6,7A torsion test is an ideal means to provide large strain dominated by shear deformation.8In addition,a torsion test can achieve large uniform deformation without rupture or strain localization,and thus it can accumulate a higher plastic strain than tension and compression deformation.9,10Therefore,torsion deformation has been paid extensive attention to in recent years.The microstructures,mechanical properties,and deformation behaviors of materials during torsion have been studied by many scholars.10–18However,the accumulated plastic strain is limited in single torsion deformation,and thus the torsion deformation is often combined with other deformation modes to obtain a higher strain accumulation with the purpose of improving the comprehensive performance of materials,for instance,high pressure torsion(HPT)19,20and twist extrusion(TE).21,22Unfortunately,the applications of these severe plastic deformation processes are limited because of their higher costs,complicated manufacturing processes,and products with small sizes.6

Recently,a kind of simple and practical deformation process called combined tension and torsion has been proposed and studied by many scholars.23–25It has been shown that an introduction of pre-tension has important effects on microstructures and mechanical properties of materials subjected to later torsion deformation.It is because different loading patterns lead to different dislocation movements.25Thus it is reasonable to speculate that microstructures and mechanical properties have different trends of variation for tensile samples via pre-torsion deformation.26However,scarce special studies on microstructure evolution and mechanical properties of materials in tension deformation with pre-torsion strain have been conducted.Therefore,there is a detailed investigation of the impacts of pre-torsion on the microstructure evolution,mechanical properties,and fracture morphology of pure titanium subjected to subsequent tension deformation at room temperature in this paper.The detailed investigation may provide a new idea for improving materials’comprehensive performances by combining different deformation modes,which can provide theoretical and experimental supports to the preparation of materials with excellent high-tough-matching using traditional metal materials.

2.Experiments and methods

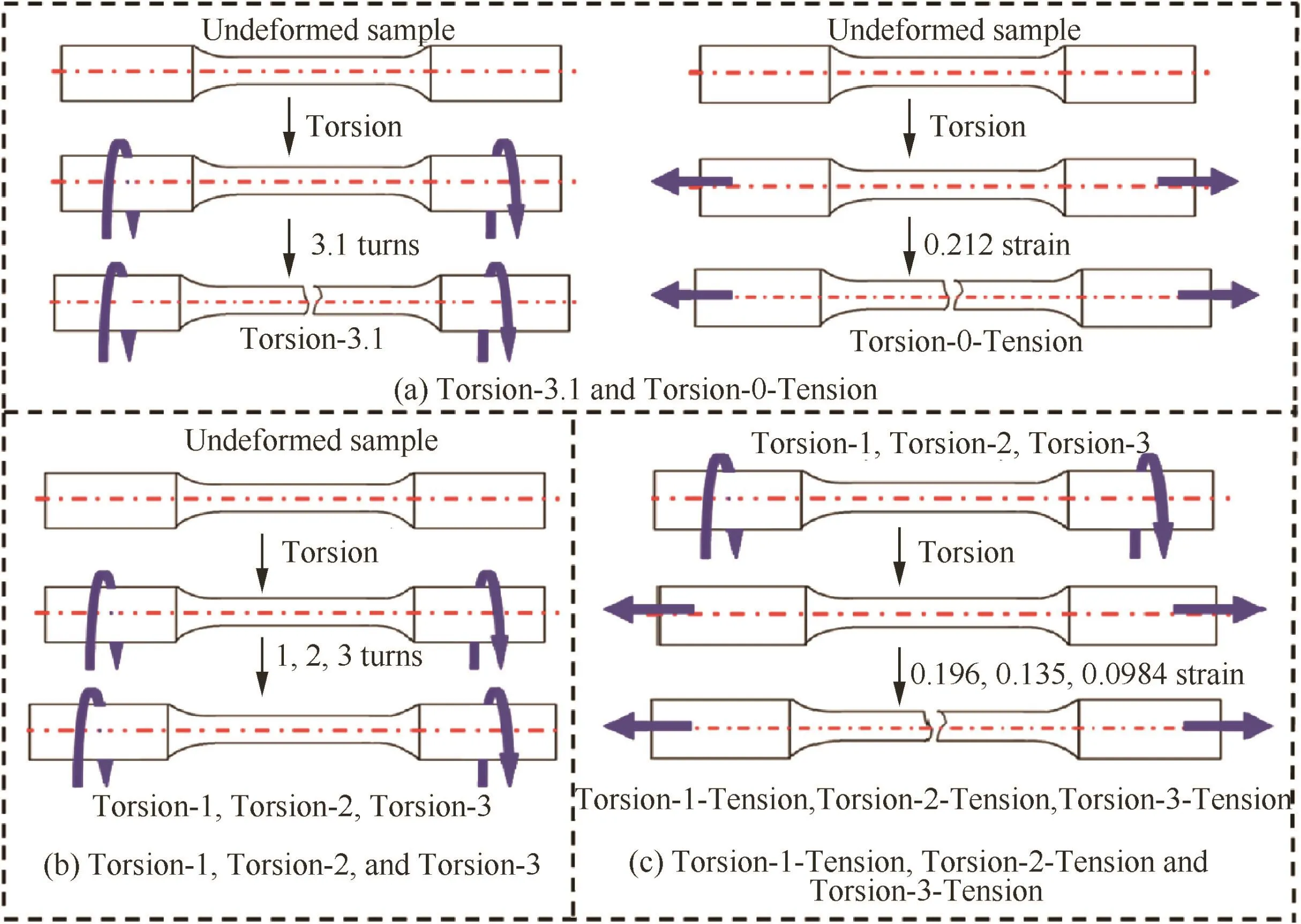

Pure titanium Ti-GR2(ASTM)rods were annealed at 823 K for 1 h in argon atmosphere and then cooled in air for removing residual stress.The rods after annealing were subjected to torsion and tension deformation,and the detailed dimensions about the samples are shown in Fig.1(a).Torsion and tension tests were carried out at room temperature using an XC-10 wire torsion testing machine and an Instron 3382 tension testing machine,respectively.The torsion speed and tension strain rate are 30 r/min and 10-3s-1,respectively.The first group of rods was subjected to tension deformation and torsion deformation separately,and the maximum tensile strain and torsion turns were 0.212(marked as Torsion-0-Tension)and 3.1 turns(marked as Torsion-3.1).A schematic diagram of the experimental procedure is shown in Fig.2(a).The second group of rods was subjected to single torsion deformation,and samples after twisting 1,2,and 3 turns were marked as Torsion-1,Torsion-2,and Torsion-3.A schematic diagram of the experimental process is shown in Fig.2(b).The third group of rods was firstly subjected to torsion deformation for 1,2,and 3 turns,and then the twisting samples were subjected to tension deformation until an occurrence of failure.The elongations were 19.6%,13.5%,and 9.84%,respectively,and the three deformed samples were marked as Torsion-1-Tension,Torsion-2-Tension,and Torsion-3-Tension.A schematic diagram of the technological process is shown in Fig.2(c).

Fig.1 Detailed dimensions of specimens and positions for micro hardness measurements on transversal and longitudinal sections as well as sampling locations for microstructure.

Fig.2 Schematic diagrams of different torsion and tension processes.

Vickers hardness tests were conducted on undeformed and deformed pure titanium with a load of 4.903 N and a dwell time of 15 s using an HMV micro hardness tester(SHIMADZU).The positions for micro hardness measurements are marked as red triangles in Fig.1(b)and(c),and the horizontal and longitudinal ordinates refer to radius(r)and height(h)on selected sections.For deformed samples by single torsion or tension,the shape of the transversal section is similar to a circle;for deformed samples by combined torsion and tension,the shape of the transversal section is like an ellipse.Their shapes can be seen from fracture appearance in Section 3.3.Microstructures were characterized on the transversal and longitudinal sections of deformed rods by using an optical microscope(OLYMPUS/PMG3),as shown in Fig.1(d).The chemical etchant used on the samples was a solution of 5 mL HNO3,10 mL HF,and 85 mL H2O.27The fracture surface morphology of deformed samples was observed by using a scanning electron microscope(SEM,MIRA3 TESCAN).

3.Results and discussion

3.1.Mechanical properties

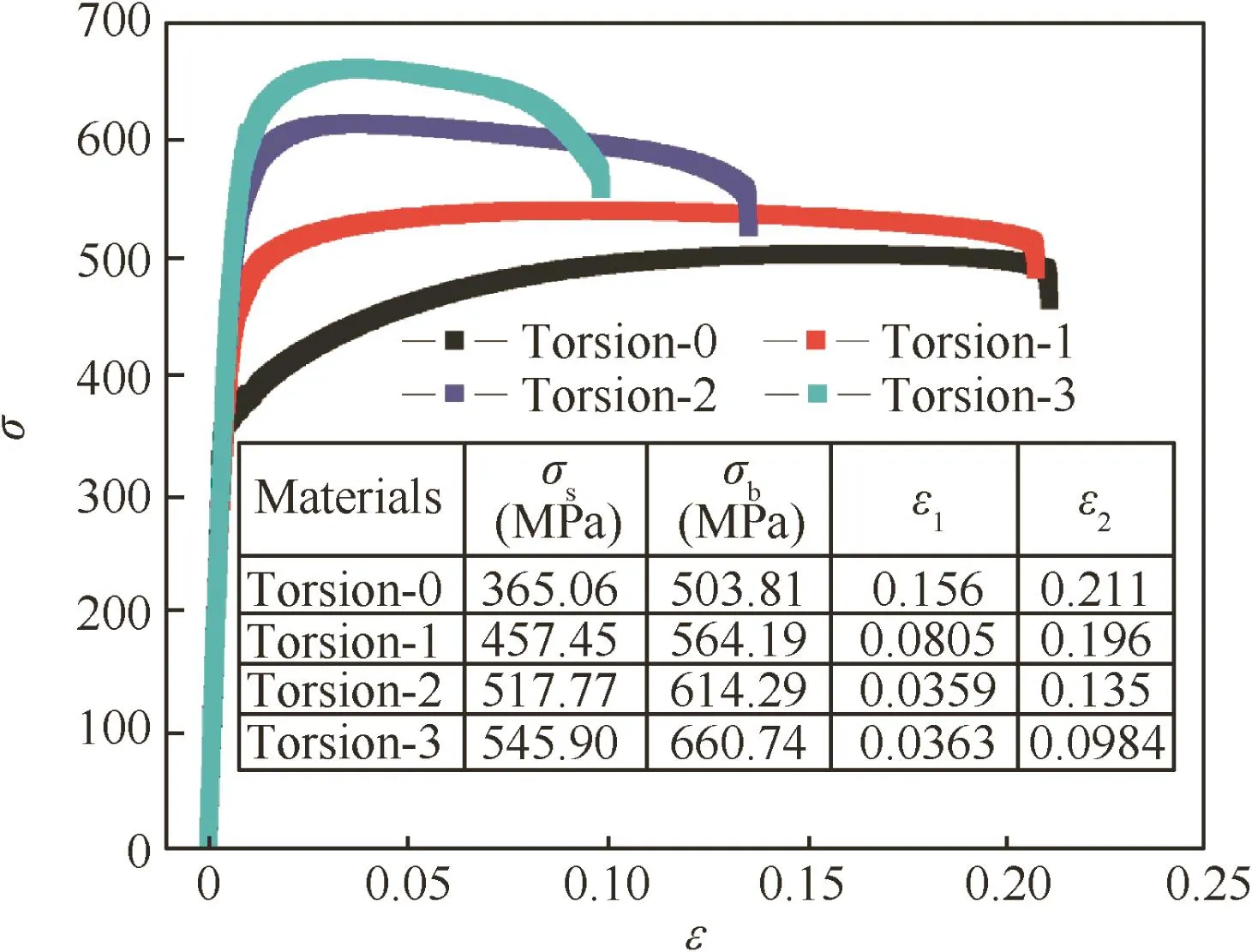

The engineering stress strain curves of samples after twisting different turns are shown in Fig.3.The yield strength σsand the ultimate tensile strength σbin Fig.3 refer to the yield and ultimate tensile strengths,respectively.ε1and ε2represent the engineering strains at the ultimate tensile strength stage and fracture,respectively.It is shown that the strength(σsand σb)increases dramatically(σs:365.06–545.90 MPa; σb:5 03.81–660.74 MPa),and plasticity (ε1:0.156–0.0363; ε2:0.211–0.0984)decreases evidently with increasing torsion turns.It can be seen that the necking phenomenon becomes more and more obvious with increasing deformation,which indicates that the percentage of non-uniform plastic deformation increases.28An increase of the percentage of non-uniform strain indicates that the toughness of the material increases to some extent.

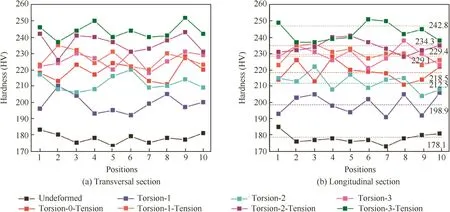

Hardness tests were conducted to investigate the variation trends of mechanical properties of samples after single deformation and combined deformation.From the observation of Fig.4,it indicates that the hardness of deformed samples by single tension or torsion deformation increases obviously,and the hardness increment caused by torsion deformation is about 50 HV,which is higher than that by tension deformation(about 40 HV).This phenomenon can be explained by the fact that the shear deformation by torsion can improve the strength better than that by tension or compression deformation.9,10For samples after combined torsion and tension deformation(Torsion-1-Tension, Torsion-2-Tension, and Torsion-3-Tension samples),it is found that the hardness increases further compared to the samples by single tension or torsion deformation.The increase increments are about 48,56,and 65,respectively,and the maximum increment(65)is higher than that by single torsion(50).This phenomenon is attributed to the fact that combined torsion and tension deformation can obtain a higher plastic strain accumulation.

Fig.3 Engineering stress stain curves of samples after twisting different turns.

Fig.4 Variation trends of the Vickers hardness of different deformation processes.

Taken together,an introduction of pre-torsion deformation could make the plasticity of samples decrease and improve their strength,and this phenomenon is attributed to dislocation strengthening.However,the toughness of materials is improved to a certain extent,for the percentage of nonuniform plastic strain increases and materials can still absorb a large amount of energy after necking.It indicates that materials present good comprehensive performance when they are subjected to torsion deformation and tension deformation subsequently.

3.2.Microstructure evolution

The microstructure of a metal material is the main factor deciding its mechanical properties and corresponding fracture behavior.The microstructure of undeformed pure titanium on the transversal section is shown in Fig.5(a),and the microstructure of a Torsion-0-Tension sample on the transversal section is shown in Fig.5(b).The average grain sizes are about 70 and 40 μm in Fig.5(a)and(b),respectively,which indicates that the grains are refined during tension deformation.Fig.6 shows the microstructure on the transversal section of deformed rods after single torsion(Torsion-1,Torsion-2,and Torsion-3 samples)and combined torsion and tension(Torsion-1-Tension, Torsion-2-Tension, and Torsion-3-Tension samples).The average grain sizes are about 60,50,and 40 μm in Fig.6(a),(b),and(c),respectively,which states that the grains are refined gradually when increasing the torsion turns.The red curves in Fig.6 refer to deformation twins,and it is found that the percentage of generated deformation twins increases with increasing deformation degree.It is inferred that the dislocation movement is impeded with increasing deformation,and as a result,deformation twins are activated to promote plastic deformation.29It is known that the appearance of deformation twins could change the crystal orientation and promote dislocation slip.The grains can be refined better under a combination of deformation twins and dislocation slip.17,18It can be seen from Fig.6(a)and(d)that the grains of a Torsion-1 sample are refined further when it is subjected to tension deformation.Similar results can be seen by comparing Fig.6(b)and(e)as well as comparing Fig.6(c)and(f).The average grain sizes are about 50,25,and 35 μm in Fig.6(d),(e),and(f).It is inferred that the refinement effect is attributed to an accumulated plastic strain,and combined deformation(Torsion-1-Tension,Torsion-2-Tension,and Torsion-3-Tension samples)with a higher plastic strain can ref i ne grains better.In addition,it is shown that the generated twins disappear,and it is because that the introduced twins by torsion deformation increase the chances of dislocation slip.Thus the produced twins disappear.

Fig.5 Microstructures on the transversal sections of undeformed pure titanium and Torsion-0-Tension samples.

Fig.6 Microstructures on the transversal sections of samples after torsion and combined deformation.

It can be seen that the refinement effect of a specimen with 2 turns pre-torsion(Torsion-2-Tension sample)strain is the best among all the combinations(from 70 to 25 μm),which is higher than those with single tension(from 70 to40 μm)and single torsion(from 70 to 40 μm).As illustrated in Fig.3,the Torsion-2-Tension sample is of good ductile performance,and thus it is speculated that the materials can possess better comprehensive performance(including microstructure and mechanical properties)by combining torsion and tension reasonably.Equiaxial grains are present on the transversal section in Fig.6(a),(b),a nd(c),while elongated grains are observed on the longitudinal section of a twisting specimen in Fig.7(a).It is related that the equiaxial grains are elongated by shear stress in torsion deformation.In addition,a large number of deformation twins occur on the selected section.The local amplification of generated twins is shown in Fig.7(b),and it is found that the twins are parallel to each other and distribute the grains.However,the grains are refined and equiaxial grains are always present on the longitudinal section of a specimen after combined torsion and tension,as illustrated in Fig.7(c).Therefore,we speculate that an introduction of subsequent tension stress can control grains’morphology.

Fig.7 Microstructures on the longitudinal sections of Torsion-3 and Torsion-3-Tension samples.

Fig.8 Fracture morphology of specimen after different torsion and tension processes.

In a word,grains are refined and elongated during torsion deformation,but the elongated effect is weakened or eliminated by latter tension deformation.Deformation twins formed during torsion deformation will disappear owing to the introduction of the subsequent tension stress.By contrasting Figs.6 and 7,the grains are refined most evidently for the specimen with 2 turns pre-torsion deformation(Torsion-2-Tension sample),and its morphology also changes obviously.It indicates that the refinement of grains and their appearances are controlled by both torsion and tension deformations.

3.3.Fracture analysis

The fracture appearances of specimens machined from different torsion and tension processes by SEM are shown in Fig.8.A dimple is the main microscopic characteristic of ductile fracture,which is caused by the micro-voids connected to each other after fracture.The macroscopic and microscopic fracture modes reflect different features with different enlargement levels.The macroscopic fracture analysis mainly shows the overall process of failure in essence,while the microscopic fracture mode reveals the formation of micro-voids and dimples in a local failure process.In this paper,dimples cover the fracture appearance and are the main characteristic of ductile fracture.30

The local amplification fractographs of the center and margin sections on the macroscopic fracture surface(the middle figure in Fig.8(a))of a Torsion-0-Tension sample are shown in locations A and B of Fig.8(a).Lots of equiaxial dimples with a similar size uniformly are distributed on the fracture surface,and the blue arrows in locations A,C,E,G,and I of Fig.8 refer to f i ne voids.It is inferred that the appearance of equiaxial dimples is related to the normal stress during tension deformation.Fig.8(b)shows the representative fractographs of a Torsion-3.1 sample.The middle figure in Fig.8(b)refers to the overall fracture morphology,and it is found that the overall fracture surface is flatter in contrast to that of Fig.8(a).Besides,torsion traces can be seen on the fracture appearance.It is known that a fracture caused by tension or torsion deformation is attributed to shear stress for ductile metal materials,and pure titanium suffers from a larger plastic strain accumulation during torsion.Unlike the fracture appearance by tension deformation,quantities of micro-voids and dimples with different types and sizes are distributed on the fracture section,as shown in locations C and D of Fig.8(b).1 and 3 in locations C and D refer to equiaxial and elongated dimples,and we speculate that elongated dimples are caused by the non-uniform shear stress during torsion deformation.In addition,it is found that a cleavage platform occurs on the fracture surface,marked as 2 in location D of Fig.8(b),which indicates that the fracture belongs to the range of brittle fracture.Fig.8(c),(d),and(e)shows the fracture appearances of specimens by combined torsion and tension deformation(Torsion-1-Tension, Torsion-2-Tension, and Torsion-3-Tension samples).A fracture appearance with an elliptical shape is observed,and an approximate parallelogram trace is present on the fracture surface,which are attributed to the introduction of combined shear and tension stress.

Compared to the fracture morphology caused by single torsion,dimples with larger sizes and depths are distributed uniformly on the fracture appearance for combined samples,as shown in locations F,H,and J of Fig.8(c),(d),and(e).An obvious slip is traced,marked as 6,7,8,and 9 in locations G and I of Fig.8(d)and(e).In addition,elongated and equiaxial dimples appear,marked as 4 and 5 in location F of Fig.8(c).Lots of micro-voids disappear,and it may be that a part of micro-voids formed in the torsion test are covered in subsequent tension deformation.The depth and size of dimples on fracture by combined torsion and tension are larger than those by single tension.The appearance of elongated dimples is related to the shear stress,and it is inferred that an introduction of pre-torsion deformation could improve materials’toughness compared to that of single tension deformation.

4.Conclusions

The mechanical properties,microstructure,and fracture analysis of pure titanium with pre-torsion strain subjected to subsequent tension deformation were investigated by experiments.It is found that an introduction of pre-torsion deformation has significant effects on microstructure,mechanical properties,and fracture appearance.Some conclusions can be obtained as follows:

(1)Single torsion or tension deformation can improve the materials’strength,but tension deformation with pretorsion can improve the materials’strength further.The maximum hardness increment of 65 HV by combined torsion and tension deformation is higher than those by single tension deformation(40 HV)and single torsion deformation(50 HV).

(2)An introduction of pre-torsion strain can re fine grains better by combining later tension deformation.The grains are re fined most evidently for samples with 2 turns pre-torsion strain(from 70 to 25 μm),which are finer than those by single tension(from 70 to 40 μm)and single torsion(from 70 to 40 μm).Moreover,the grain morphology can be controlled by combined torsion and tension deformation.

(3)An introduction of pre-torsion strain can change dimples’type,size,and depth.It is shown that the materials after combined torsion and tension deformation can present good toughness performance based on fracture analysis.

Acknowledgements

The authors are very grateful for the supports received from the National Natural Science Foundation of China(No.51275414),the Aeronautical Science Foundation of China(No.2011ZE53059),the Research Fund of the State Key Laboratory of Solidification Processing(NWPU)of China(No.130-QP-2015),and the National College Students Innovation Experiment Program(No.201610699287).

1.Banerjee D,Williams JC.Perspectives on titanium science and technology.Acta Mater2013;61(3):844–79.

2.Qu NS,Fang XL,Wei L,Zeng YB,Di Z.Wire electrochemical machining with axial electrolyte f l ushing for titanium alloy.Chinese J Aeronaut2013;26(1):224–9.

3.Sun ZQ,Huang MH.Fatigue crack propagation of new aluminum lithium alloy bonded with titanium alloy strap.Chinese J Aeronaut2013;26(3):601–5.

4.Song FF,Yang H,Li H,Zhan M,Li GJ.Springback prediction of thick-walled high-strength titanium tube bending.Chinese J Aeronaut2013;26(5):1336–45.

5.Kar A,Nath R,Barik A.Ion implantation of titanium based biomaterials.Prog Mater Sci2011;56(8):1137–77.

6.Valiev RZ,Islamgaliev RK,Alexandrov IV.Bulk nanostructured materials from severe plastic deformation.Prog Mater Sci2000;45(2):103–89.

7.Valiev RZ,Estrin Y,Horita Z,Langdon TG,Zechetbauer MJ,Zhu YT.Producing bulk ultraf i ne-grained materials by severe plastic deformation.JOM2006;58(4):33–9.

8.Kang JY,Bacroix B,Brenner R.Evolution of microstructure and texture during planar simple shear of magnesium alloy.Scripta Mater2012;66(9):654–7.

9.Unga´r T,To´th LS,Illy J,Kova´cs I.Dislocation structure and work hardening in polycrystalline OFHC copper rods deformed by torsion and tension.Acta Metall1986;34(7):1257–67.

10.Wang CP,Li FG,Li JH,Dong JZ,Xue FM.Microstructure evolution,hardening and thermal behavior of commercially pure copper subjected to torsion deformation.Mater Sci Eng A2014;598(6):7–14.

11.Zhao TZ,Zhang SH,Zhang GL,Song HW,Cheng M.Hardening and softening mechanisms of pearlitic steel wire under torsion.Mater Des2014;59(7):397–405.

12.Khamsuk S,Park N,Adachi H,Terada D.Evolution of ultraf i ne microstructures in commercial purity aluminum heavily deformed by torsion.J Mater Sci2012;47(22):7841–7.

13.Böhlke T,Bertram A,Krempl E.Modeling of deformation induced anisotropy in free-end torsion.Int J Plasticity2003;19(11):1867–84.

14.Ducheˆne L,Houdaigui FE,Habraken AM.Length changes and texture prediction during free end torsion test of copper bars with FEM and remeshing techniques.IntJPlasticity2007;23(8):1417–38.

15.Sanchez P,Pochettino A,Chauveau T,Bacroix B.Torsion texture developmentofzirconium alloys.JNuclMater2001;298(3):329–39.

16.Biswas S,Beausir B,Toth LS,Suwas S.Evolution of texture and microstructure during hot torsion of a magnesium alloy.Acta Mater2013;61(14):5263–77.

17.Chen H,Li FG,Li JH,Ma XK,Li J,Wan Q.Hardening and softening analysis of pure titanium based on the dislocation density during torsion deformation.MaterSciEngA2016;671:17–31.

18.Chen H,Li FG,Li JH,Zhao Z,Zhou SS,Wan Q.Experimental study on pure titanium during the positive-torsion and positivenegative-torsion.Mater Sci Eng A2016;674:552–68.

19.Zhilyaev AP,Langdon TG.Using high-pressure torsion for metal processing:Fundamentals and applications.Prog Mater Sci2008;53(6):893–979.

20.Yang C,Song M,Liu Y,Ni S,Sabbaghianrad S,Langdon TG.Evidence for a transition in deformation mechanism in nanocrystalline pure titanium processed by high-pressure torsion.Philos Mag2016;96(16):1–11.

21.Zendehdel H,Hassani A.influence of twist extrusion process on microstructure and mechanical properties of 6063 aluminum alloy.Mater Des2012;37:13–8.

22.Wang CP,Li FG,Lu HY,Yuan ZW,Chen B.Optimization of structural parameters for elliptical cross-section spiral equalchannel extrusion dies based on grey theory.Chinese J Aeronaut2013;26(1):209–16.

23.Wang CP,Li FG,Wei L,Yang YJ,Dong JZ.Experimental microindentation of pure copper subjected to severe plastic deformation by combined tension–torsion.Mater Sci Eng A2013;571(4):95–102.

24.Li JH,Li FG,Hussain MZ,Wang CP,Wang L.Micro-structural evolution subjected to combined tension–torsion deformation for pure copper.Mater Sci Eng A2014;610(29):181–7.

25.Chen H,Li FG,Zhou SS,Li JH,Zhao C,Wan Q.Experimental study on pure titanium subjected to different combined tension and torsion deformation processes.MaterSciEngA2017;680:278–90.

26.Guo N,Song B,Guo CF,Xin RL,Liu Q.Improving tensile and compressive properties of magnesium alloy rods via a simple pretorsion deformation.Mater Des2015;83:270–5.

27.Chen H,Li FG,Liu J,Li JH,Ma XK,Wan Q.Microstructure and microtexture evolution of pure titanium during single direction torsion and alternating cyclic torsion.Metall Mater Trans A2017;48(5):2396–409.

28.Courtney TH.Mechanical behavior of materials.2nd ed.Beijing:China Machine Press;2004.p.404–50.

29.Smith WF,Hashemi J.Foundations of materials science and engineering.5th ed.Beijing:China Machine Press;2011.p.240–59.

30.Bathini U,Srivatsan TS,Patnaik A,Quick T.A study of the tensile deformation and fracture behavior of commercially pure titanium and titanium alloy:influence oforientation and microstructure.J Mater Eng Peform2010;19(8):1172–82.

杂志排行

CHINESE JOURNAL OF AERONAUTICS的其它文章

- Extension of analytical indicial aerodynamics to generic trapezoidal wings in subsonic flow

- Time-varying linear control for tiltrotor aircraft

- Global aerodynamic design optimization based on data dimensionality reduction

- Mesh deformation on 3D complex configurations using multistep radial basis functions interpolation

- Stagnation temperature effect on the conical shock with application for air

- Transient simulation of a differential piston warm gas self-pressurization system for liquid attitude and divert propulsion system