油菜联合收获机种子籽粒脱粒装置结构及运行参数优化

2018-01-09关卓怀沐森林吴崇友

王 刚,关卓怀,沐森林,汤 庆,吴崇友

油菜联合收获机种子籽粒脱粒装置结构及运行参数优化

王 刚,关卓怀,沐森林,汤 庆,吴崇友※

(农业部南京农业机械化研究所,南京 210014)

为探究油菜联合收获机脱粒系统对油菜籽粒的收获效果,寻求较优的脱粒装置结构及运行参数,以喂入量、脱粒滚筒间隙、脱粒滚筒转速和脱粒元件型式种类为影响因素,油菜种子籽粒发芽率、脱粒损失为评价指标,开展油菜联合收获脱粒试验、发芽率试验及无损伤籽粒发芽率对比试验,探究了联合收获油菜籽粒的脱粒损伤机理。结果表明:影响油菜种子籽粒脱粒损伤的主次因素依次为脱粒元件型式、脱粒滚筒间隙、脱粒滚筒转速、喂入量;所选因素水平下,综合考虑脱粒损伤及损失,采用喂入量3.2 kg/s、脱粒滚筒间隙9 mm、脱粒滚筒转速856 r/min、全钉齿时为较优组合。分析表明:联合收获脱粒会对油菜种子籽粒造成损伤,影响脱粒损伤的直接因素为种子籽粒在滚筒内受打击次数及打击力大小;通过调整脱粒系统结构及运行参数,能够显著降低油菜的脱粒损伤及损失,本文为脱粒装置结构及运行参数的优化提供参考。

机械化;优化;农作物;油菜籽粒;脱粒损伤;联合收获;发芽率

0 引 言

油菜是重要的油料作物,是优质食用植物油的主要来源。油菜种子发芽率直接关系到油菜产量,是评价油菜种子优劣的重要指标之一。联合收获显著提高了收获效率,但是籽粒在机械脱粒过程中若受到过大的应力就会破裂或永久变形,破坏籽粒的生长点,产生裂纹的籽粒易受到微生物和昆虫的侵害,从而影响了籽粒的利用率和种子的发芽率[1-4],造成种子浪费、增加生产成本,同时也会影响到机械化精量播种质量,造成减产,降低经济效益。

机械化收获造成的籽粒损伤问题已经引起国内外学者的关注,并针对水稻、小麦、玉米、大豆等作物开展了研究,研究方法主要包括射线观察法[5]、发芽率判断法[6]、图像处理法[7-12]等。研究表明,收获损伤主要发生在脱粒环节,脱粒部件的冲击会造成籽粒裂纹从而导致了籽粒的损伤[13-19],改变脱粒装置结构和运行参数能有效降低籽粒损伤[20-23]。因此,研究油菜籽粒脱粒损伤,对油菜籽粒的利用具有重要意义。

为探究油菜联合收获机种子籽粒脱粒装置结构及运行参数,本文以喂入量、脱粒滚筒间隙、脱粒滚筒转速和脱粒元件型式种类为影响因素,以发芽率及损失率为评价指标,开展了油菜联合收获脱粒试验、发芽率试验及无损伤籽粒发芽率对比试验。为说明油菜种子籽粒损伤率和发芽率的相关性,排除其他因素对籽粒发芽率的干扰,以同时期、同品种、同地块及长势相同的人工收获的无损伤油菜籽粒的发芽率作为对照。通过对比和分析不同脱粒装置结构和运行参数下机收油菜籽粒的发芽率和损失率,探究脱粒装置结构和运行参数对油菜籽粒脱粒效果的影响。获得损伤率及损失率综合评价下的较优参数组合。以期探究油菜联合收获机脱粒系统的较优装置结构及运行参数,并为油菜联合收获机脱粒系统的设计和参数的优化提供参考。

1 材料与方法

1.1 油菜联合收获试验

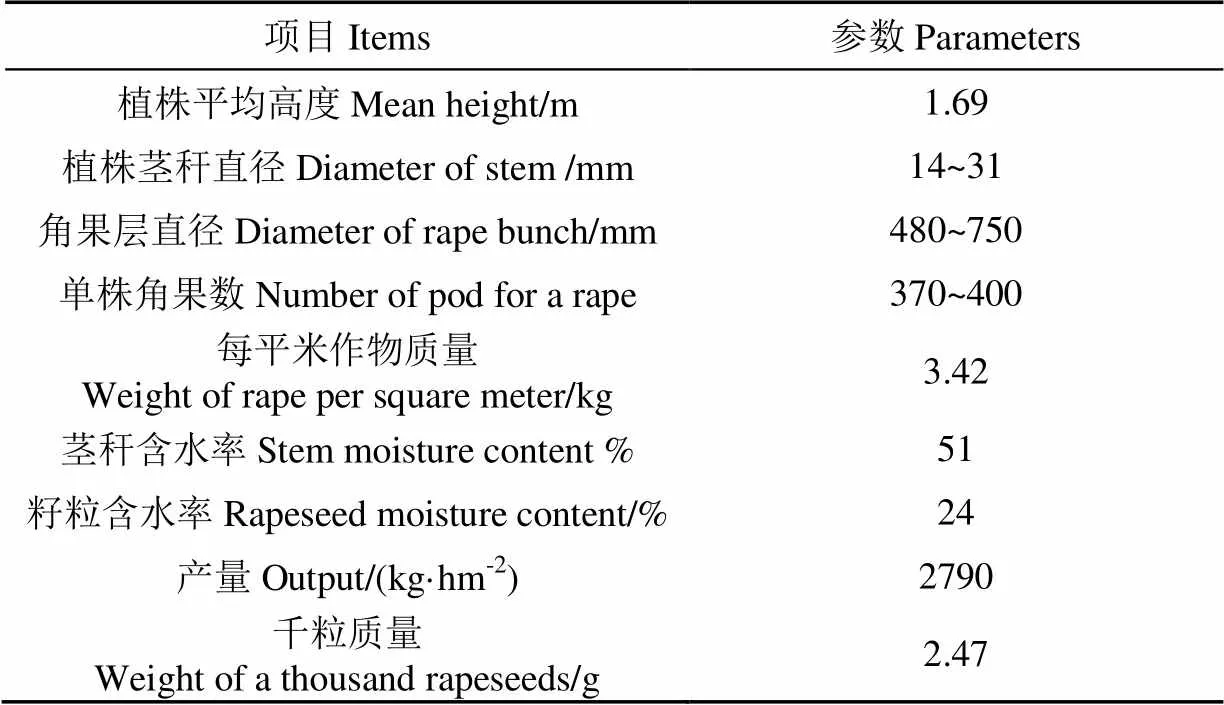

油菜联合收获试验于2016年6月5日至6月6日在江苏省东台市弶港镇进行,油菜品种为宁杂1818,种植方式为机械直播。按照GB/T 8097-2008《收获机械联合收割机试验方法》、NY/T12 31-2006《油菜联合收获机质量评价技术规范》的规定,进行作物的基本特性信息采集,结果如表1所示。

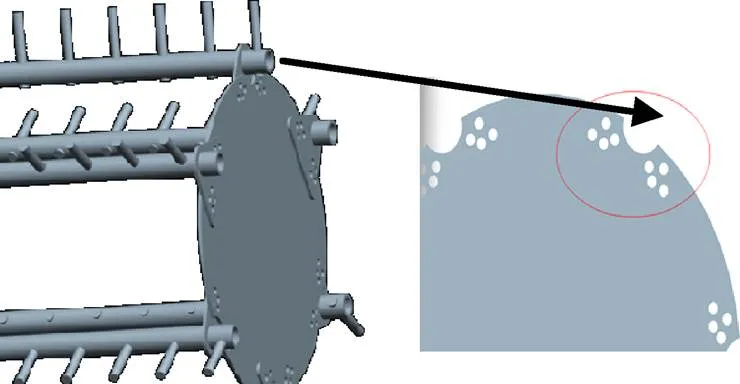

试验机具为农业部南京农业机械化研究所研制的NJS-2.2型移动式联合收获脱粒清选试验台,如图1所示。

表1 油菜基本特性参数

图1 NJS-2.2型移动式联合收获机脱粒清选试验台

根据已有研究,影响油菜联合收获脱粒效果的主要因素有喂入量、脱粒滚筒间隙、脱粒滚筒转速和脱粒元件型式种类[24-27]。根据文献所述,李耀明等[28]试制短纹杆-板齿脱粒滚筒并进行脱粒对比试验;宗望远等[29]分析滚筒转速对脱出物质量的影响[28-29]。选取常用的脱粒滚筒转速范围为760~1 010 r/min;移动试验台的脱粒滚筒由链轮传动,更换中间轴上的链轮可获得不同的转速。改变脱粒滚筒齿杆在脱粒滚筒幅板上安装位置可以调节脱粒间隙,如图2所示。通过前期研究,选取脱粒间隙调节范围为9~13 mm,当脱粒间隙大于13 mm时含杂率显著增加,当脱粒间隙小于9 mm时会提高功耗,且造成滚筒堵塞。

图2 脱粒间隙调节

目前油菜联合收获常用脱粒元件为钉齿式、纹杆式及组合式,采用全钉齿、全纹杆及半钉齿半纹杆组合3种形式进行试验,齿杆整体拆卸后替换。喂入量通过测定测区内收获的籽粒、茎秆和清选排出物的总量除以通过测区的时间进行计算。在满幅收割下改变联合收获机的前进速度从而改变喂入量。

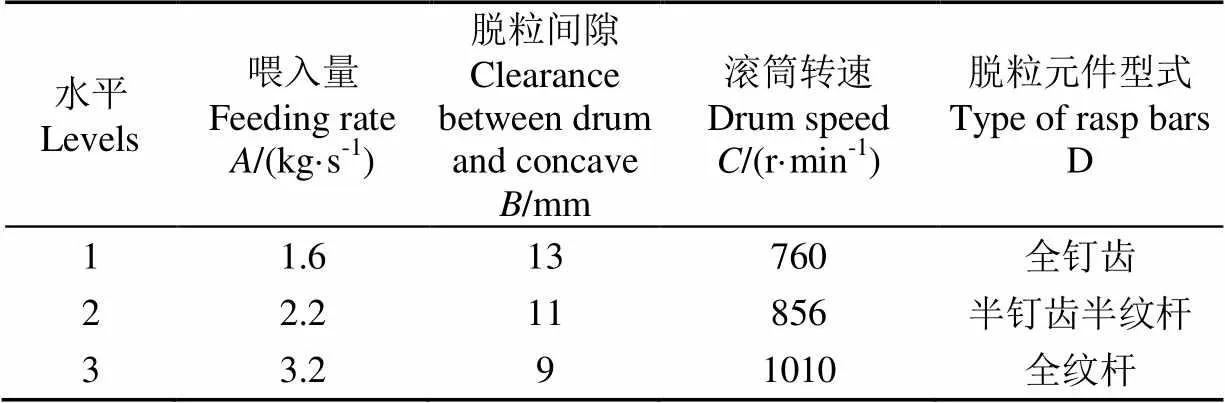

以脱粒滚筒脱粒元件型式、脱粒滚筒转速、脱粒间隙和喂入量为影响因素,每个影响因素选取3个水平开展正交试验L9(34),试验因素水平如表2所示。

表2 联合收获试验因素水平

选取长势均匀,密度、植株高度产量水平一致性较好的油菜进行联合收获试验。在作业地块中确定试验区域并分为准备区、测定区和停车区。准备区长度10 m,测定区长度20 m,停车区长度10 m,均不临地边。机具在准备区和测定区内满幅作业、割茬高度保持一致,试验过程中不改变工况。每次到达试验区前,先清空粮箱;试验结束后,人工将粮箱内的籽粒搅拌均匀,采用五点取样法,从每个点获取200 g籽粒,共1 kg,装入接样袋中保存并编号。联合收获试验共9组,每组试验重复4次,共36次,获得联合收获籽粒样本36袋。每次试验时收集滚筒脱出物料,筛选出物料内的油菜籽粒称重得出脱粒损失。

联合收获的同时,人工收获相同地块长势相同的油菜。进行人工割倒、晾晒,待角果干燥可以脱出籽粒时进行人工脱粒,每株全部角果脱粒干净,收集脱出籽粒并搅拌均匀,从籽粒中随即取出1 kg装入接样袋中保存编号。选取4块区域重复人工收获试验4次,获得籽粒样本4袋,收获试验共获得籽粒样本40袋。

1.2 油菜籽粒发芽试验

从每个接样带中随即选取400颗籽粒,分为2组,每组200颗,分别放入带有双层纸床的培养皿中并编号记录,共80组。将双层纸床吸足水分后沥去多余水分放置在编号的培养皿内,纸床pH值为6.0~7.5,种子籽粒均匀铺放在纸床上并保持一定距离。将培养皿放入人工气候箱中,按照国家经济作物种子发芽标准GB4407.2-2008进行发芽试验。气候箱内保持20°恒温,湿度为70%~80%,每天光照12 h,试验周期为7 d。

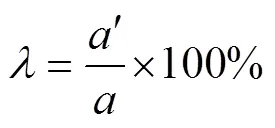

7 d后,从气候箱中取出培养皿,数出已发芽和未发芽的油菜籽粒数。设发芽率为,则

式中为未发芽的籽粒数,为发芽试验的籽粒总数。

在没有其他因素影响发芽率的情况下,损伤率可表达为

2 结果与分析

2.1 试验结果

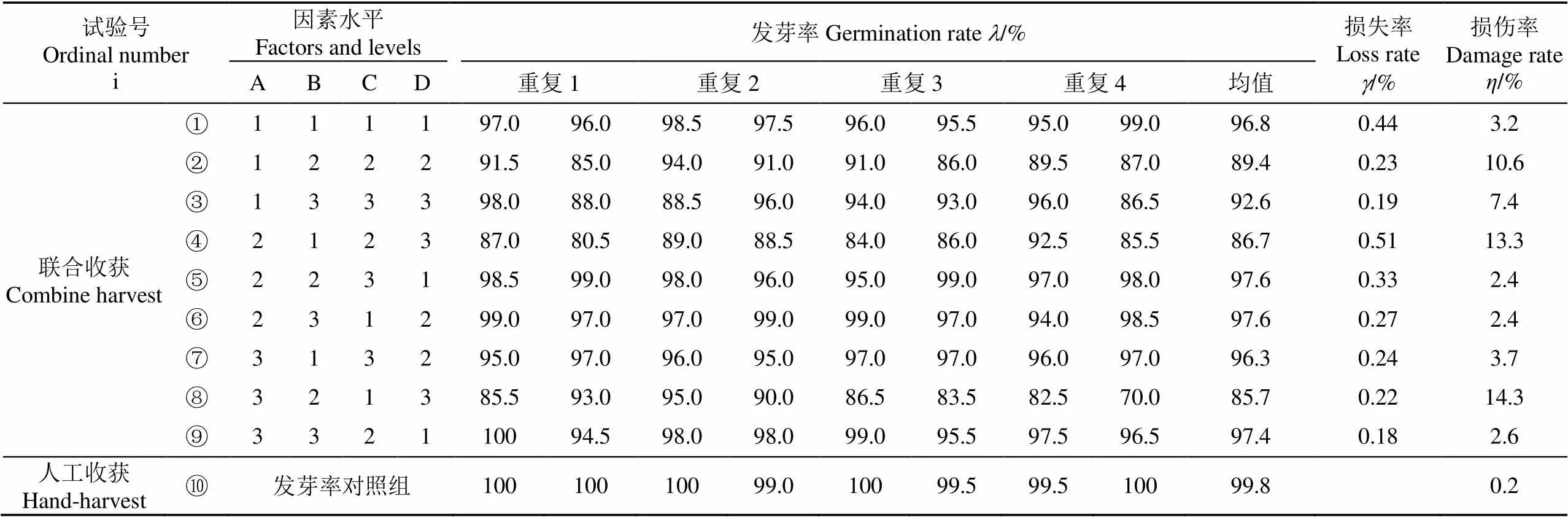

试验结果如表3所示。人工收割、脱粒的油菜种子籽粒发芽率为99.8%。机收籽粒发芽率范围为85.7%~97.6%,且变化较大。根据机收籽粒发芽率与无损籽粒的发芽率进行比较可以看出,机械化收获的油菜籽粒发芽率明显低于人工收获的无损伤油菜籽粒,脱粒装置结构及运行参数的差异会导致油菜种子籽粒不同的发芽率。脱粒损失率范围为0.18%~0.51%,在所选参数范围内脱粒损失都在较低水平[30]。

表3 发芽率试验方案与试验结果

2.2 油菜籽粒发芽率与籽粒损伤之间的关系

由表3可知,人工收获、脱粒的油菜籽粒发芽率为99.8%,说明油菜籽粒发芽试验所设置的环境条件合理,能够满足油菜发芽所需的外界条件。在当前发芽率试验条件下,人工收获、脱粒的无机械损伤油菜籽粒发芽率接近100%,排除了其他因素对油菜籽粒发芽率的影响。说明油菜籽粒发芽率与籽粒损伤之间呈正相关,可以用发芽率来评价油菜籽粒的损伤。

2.3 油菜联合收获与籽粒损伤之间的关系

由表3可知,联合收获的油菜籽粒发芽率为85.7%~97.6%,低于人工收获无损伤油菜种子籽粒的发芽率99.8%。通过人工收获无损伤油菜籽粒的对比试验已经排除了其他因素对发芽率的影响,所以机械化联合收获确实会对油菜籽粒造成损伤。这种损伤直接影响油菜籽粒的发芽率,并且损伤程度与脱粒装置结构及运行参数相关。在当前收获试验参数下,损伤率范围为2.4%~14.3%。

2.4 脱粒装置结构及运行参数与籽粒损伤之间的关系

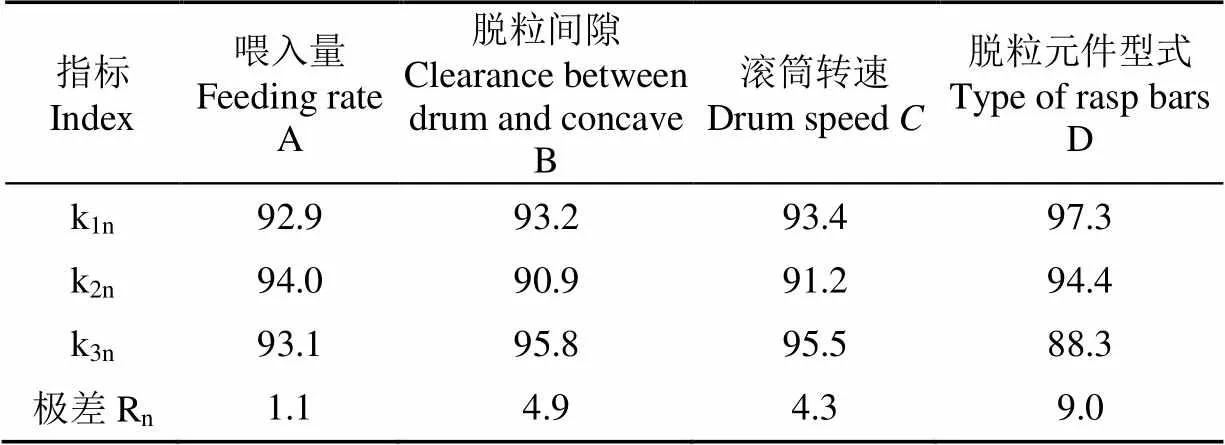

对联合收获的油菜籽粒发芽率结果进行极差分析,结果如表4所示。根据极差R的大小,可以判断影响油菜籽粒发芽率的主次因素依次为脱粒元件形式>脱粒间隙>滚筒转速>喂入量。依据试验指标k的大小可以判断损伤率较小的水平组合为脱粒元件为全钉齿,脱粒滚筒间隙9 mm,脱粒滚筒转速1 010 r/min,喂入量2.2 kg/s。

表4 发芽率极差分析

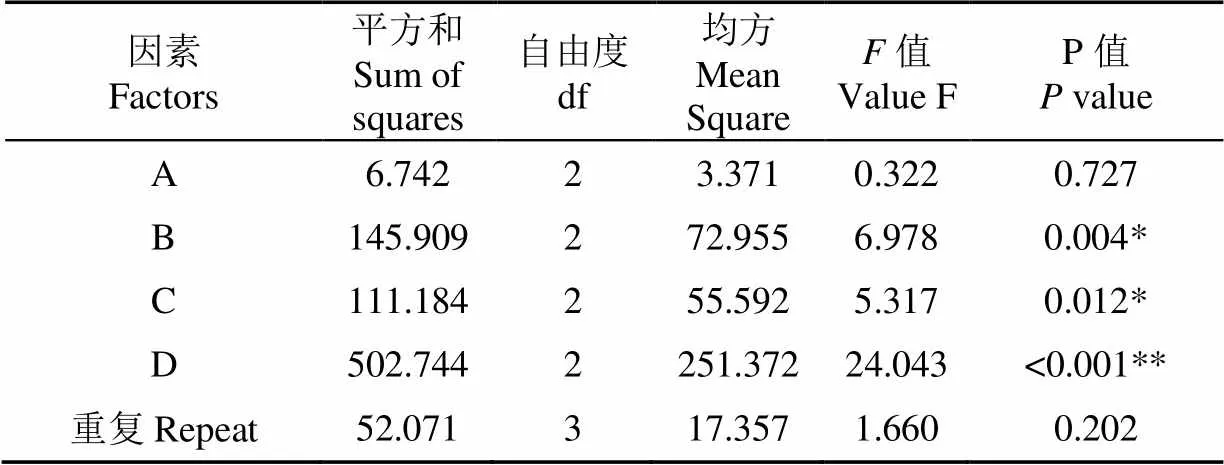

对联合收获的油菜籽粒发芽率结果进行方差分析,结果如表5所示。由方差分析可知,喂入量对试验结果影响不显著,脱粒滚筒间隙和元件型式对结果影响极其显著(<0.01),脱粒滚筒转速对结果影响显著(<0.05)。

表5 发芽率方差分析

注:<0.01(极显著,**),<0.05(显著,*)。

Note:<0.01(highly significant, **),<0.05(significant,*).

通过对试验结果极差分析和方差分析可知:

1)脱粒元件为全钉齿时发芽率为97.3%,全纹杆时发芽率为88.3%。在采用不同的脱粒元件时,油菜的发芽率相差达9个百分点,脱粒元件型式对油菜籽粒的收获损伤影响极大。根据文献[9]的研究,籽粒的损伤率与其和脱粒元件碰撞时所吸收能量成正比,表面自由能越大,损伤越严重,圆形断面的脱粒零件比矩形断面的脱粒零件产生的表面自由能小,更不容易造成籽粒的损伤。所以在进行油菜收获时,钉齿比纹杆对油菜种子籽粒的碰撞损伤小。应尽量选择钉齿作为脱粒元件。

2)在不同的脱粒间隙下,油菜籽粒的发芽率相差4.9个百分点,脱粒间隙对油菜籽粒的收获损伤有较大的影响。在当前试验参数下,随着脱粒间隙的增大,发芽率先减小后增大,损伤率先增大后减小,与文献[3]中的试验结果一致。根据文献[9]的研究,籽粒损伤与其所受打击力的大小和次数有关。打击力越大、次数越多,越容易损伤。脱粒间隙越小,籽粒受到的打击力越大,同时籽粒也更容易脱出离开脱粒系统,受到打击的次数越少。脱粒间隙为9 mm时,由于滚筒内空间小,物料在滚筒内的揉搓作用明显,籽粒更容易从荚果中脱出,脱出的籽粒从滚筒内筛出后不再受到滚筒的打击,籽粒受打击次数少,所以损伤低,发芽率高。油菜籽粒的损伤率与脱粒间隙之间并非正相关,需要进一步的研究才能定性说明。在当前试验参数下,脱粒间隙的较优水平为9 mm。

3)在不同的滚筒转速下,油菜籽粒的发芽率相差4.3个百分点。脱粒滚筒转速对油菜籽粒的收获损伤有较大的影响。在当前试验参数下,随着滚筒转速的升高,发芽率先减小后增大,损伤率先增大后减小,与文献[3]中的试验结果一致。根据文献[17]的能量理论和文献[18]的加载理论,滚筒转速越快,脱粒元件和籽粒之间碰撞的产生的表面能越大,籽粒越容易损伤;但是滚筒转速越快,籽粒离开脱粒系统的速度越快,受到打击的次数越少。滚筒转速为1 010 r/min时,打击力较大,籽粒从荚果中更容易脱出,脱出的籽粒从滚筒内筛出后不再受到滚筒的打击,籽粒受打击次数少,所以损伤率低,发芽率高。所以,油菜籽粒的损伤率与滚筒转速之间也非正相关,需要进一步的研究才能定性说明。在当前试验参数下,脱粒滚筒转速的较优水平为1 010 r/min。

4)在不同的喂入量下,发芽率的变化范围在1.1个百分点以内。根据文献[23],在不同的喂入量下,脱粒元件的扭矩变化并不大。所以在其他条件不变的情况下,喂入量几乎不影响脱粒元件对籽粒的打击力、打击次数和籽粒的表面能。所以,相较于其他因素,喂入量对油菜籽粒损伤的影响较小。

2.5 脱粒损失及脱粒损伤综合分析

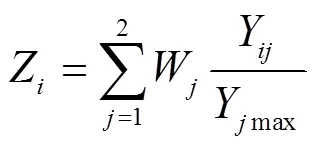

前文分析了不同参数下籽粒脱粒损伤情况,得出了损伤率较小的参数组合,为了兼顾脱粒损失及损伤2种指标,使脱粒效果达到最优,采用加权评分法对表3中损伤及损失试验结果进行分析。以100分为总权重,通过加权综合指标Z来进行评分,其计算公式如式(3)所示。

式中Z为表3中第号试验所得计算值(加权评分指标,较小为优),=1,2,3,…,9;W为第个指标的“权”值,=1,2;Y为第个试验中第个指标;Ymax为所有9组试验中,第个指标的最大值。

若所收油菜籽粒作为种子源,为保证种子出苗率,则以损伤率为重,将损伤率定为1=70分,损失率2=30分,最优结果为加权综合指标9=23.3分,最优组合为正交试验第9组3321;若所收油菜用于食用或加工,损伤则为次要因素,以损失率为重,将损伤率定为1=30分,损失率2=70分。最优结果为加权综合指标9=30.2分,最优组合亦为正交试验第9组3321。

由表3可知,在所选因素水平内损失率变化范围0.18%~0.51%相较于损伤率处于较低水平,对综合评价结果影响较小。在加权评价方法下损失率权重从30分至70分范围内最优组合皆为第9组。此时损失率为0.18%,损伤率为2.6%,机器在此参数下作业喂入量大,收获效率高、籽粒损失及损伤在较低水平、机器功耗也较低。

3 结论与讨论

1)油菜籽粒发芽率与籽粒损伤之间呈正相关,可以用发芽率来评价油菜籽粒的损伤。机械化脱粒会对油菜籽粒造成损伤,在试验所选的参数范围内,脱粒损伤率为2.4%~14.3%。影响油菜籽粒损伤的主次因素依次为脱粒元件型式、脱粒滚筒间隙、脱粒滚筒转速、喂入量。

2)在试验所选的参数范围内,综合考虑脱粒损伤及损失情况下,采用喂入量3.2 kg/s、滚筒间隙9 mm、滚筒转速856 r/min、全钉齿时为较优组合。此时损失率为0.18%,损伤率为2.6%,喂入量较大,收获效率高、机器功耗较低。通过调整脱粒系统结构及参数,能够达到较好的收获脱粒效果。

影响脱粒损伤的直接因素为籽粒在滚筒内受打击次数及打击力大小。由于试验次数、参数水平的限制,要明确脱粒滚筒转速、脱粒间隙与油菜种子籽粒损伤之间的关系还需要更加深入的研究。

[1] 吴明亮,官春云,方耿,等. 挤压及剪切作用对油菜籽粒发芽率的影响[J]. 湖南农业大学学报,2009,35(3):329-330.

Wu Mingliang, Guan Chunyun, Fang Geng, et al. Influence of extrusion and shear force on rate of rapeseed germination[J]. Journal of Hunan Agricultural University, 2009, 35(3): 329-330. (in Chinese with English abstract)

[2] 徐立章,李耀明,王显仁. 谷物脱粒损伤的研究进展分析[J]. 农业工程学报,2009,25(1):303-307.

Xu Lizhang, Li Yaoming, Wang Xianren. Research development of grain damage during threshing[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2009, 25(1): 303-307. (in Chinese with English abstract)

[3] 李心平,马福丽,高连兴. 玉米种子的机械损伤对其发芽率的影响[J]. 农机化研究,2009,31(3):34-35.

Li Xinping, Ma Fuli, Gao Lianxing. Impact of mechanical damage of corn seed to it’s germination percentage[J]. Journal of Agricultural Mechanization Research, 2009, 31(3): 34-35. (in Chinese with English abstract)

[4] 高连兴,李晓峰,接鑫,等. 大豆内部机械损伤对发芽的影响[J]. 农业机械学报,2010,41(10):63-66.

Gao Lianxing, Li Xiaofeng, Jie Xin, et al. Inner mechanical damage impact to germination of soybean kernels[J]. Transactions of the Chinese Society for Agricultural Machinery, 2010, 41(10): 63-66. (in Chinese with English abstract)

[5] Gunasekaran S, Paulsen M R, Shove G C. A laser optical method for detecting corn kernel defects[J]. Transactions of the Asae, 1986, 29(1): 0294-0298.

[6] 栾玉娜,梁明. 花生米机械损伤特征及其对发芽的影响[J]. 农业科技与装备,2013,31(2):24-25.

Luan Yu’na, Liang Ming. Internal mechanical damage of peanut seed and the influence on the germination[J]. Agricultural science & technology & equipment, 2013, 31(2): 24-25. (in Chinese with English abstract)

[7] 李晓峰,接鑫,张永丽,等. 玉米种子内部机械裂纹检测与机理研究[J]. 农业机械学报,2010,41(12):143-147.

Li Xiaofeng, Jie Xin, Zhang Yongli, et al. Detecting and research on characteristics and mechanism of inner mechanical cracks of corn seed kernels[J]. Transactions of the Chinese Society for Agricultural Machinery, 2010, 41(12): 143-147. (in Chinese with English abstract)

[8] Junior M B, Luiz H. Avaliaco do relacionamento entre danos mecanicos e vigor, em sementes de milho, por meio da análise de imagens[J]. Revista Brasileira De Sementes, 2003, 25(1): 29-36.

[9] 张新伟,赵学观,张健东,等. 基于数据融合的玉米种子内部机械裂纹检测方法[J]. 农业工程学报,2012,28(9):136-141.

Zhang Xinwei, Zhao Xueguan, Zhang Jiandong, et al. Detection of internal mechanical cracks in corn seeds based on data fusion technology[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(9): 136-141. (in Chinese with English abstract)

[10] 王艳春,迟胜起,郑长英. 基于数学形态学滤波算子的黄顶菊种子图像边缘检测[J]. 农机化研究,2011,33(3):39-42.

Wang Yanchun, Chi Shengqi, Zheng Changying. The edge detection of flaveria bidentis seed image based on mathematics morphological filtering operators[J]. Journal of Agricultural Mechanization Research, 2011,33 (3): 39-42. (in Chinese with English abstract)

[11] Ni B, Paulsen M R, Reid J F. Corn kernel crown shape identification using image processing[J]. Transactions of the Asabe, 1997, 40(3): 83-88.

[12] Vanutrecht D, Bernc C J, Rukunudin I H. Soybean mechanical damage detection[J]. Applied Engineering in Agriculture, 2000, 16(2): 137-141.

[13] 高连兴,李晓峰,接鑫,等. 大豆机械脱粒损伤特征及损伤率研究[J]. 沈阳农业大学学报,2010,41(1):55-58.

Gao Lianxing, Li Xiaofeng, Jie Xin, et al. Inner mechanical damage impact to germination of soybean kernels[J]. Transactions of the Chinese Society for Agricultural Machinery, 2010, 41(1): 55-58. (in Chinese with English abstract)

[14] 李心平. 种子玉米脱粒损伤机理及5TYZ-1型定向喂入式脱粒机研究[D]. 沈阳:沈阳农业大学,2007.

Li Xinping. Study on Threshing-damage Mechanism and 5TYZ-1 Type Directional-feeding Thresher of Seed corn[D]. Shenyang: Shenyang Agricultural University, 2007. (in Chinese with English abstract)

[15] 耿爱军,杨建宁,张姬,等. 玉米摘穗收获机械损伤影响因素分析[J]. 农业工程学报,2016,32(22):56-62.

Geng Aijun, Yang Jianning, Zhang Ji, et al. Influence factor analysis of mechanical damage on corn ear picking[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(22): 56-62. (in Chinese with English abstract)

[16] 范国昌,王惠新,籍俊杰,等. 影响玉米摘穗过程中籽粒破碎和籽粒损失率的因素分析[J]. 农业工程学报,2002,18(4):72-74.

Fan Guochang, Wang Huixin, Ji Junjie, et al. Analysis of influence factor on seed damage rate and loss rate during picking corn cob[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2002, 18(4): 72-74. (in Chinese with English abstract)

[17] 李耀明,王显仁,徐立章. 基于能量平衡的水稻谷粒脱粒损伤[J]. 机械工程学报,2007,43(3):160-164.

Li Yaoming, Wang Xianren, Xu Lizhang. Threshing injury to rice grain based on the energy conservation[J]. Chinese Journal of Mechanical Engineering, 2007, 43(3): 160-164. (in Chinese with English abstract)

[18] 李耀明,王显仁,徐立章. 加载/卸载作用次数对水稻谷粒机械损伤的影响[J]. 农业机械学报,2007,38(10):61-63.

Li Yaoming, Wang Xianren, Xu Lizhang. Study on rice grain injury under repeated loads[J]. Transactions of the Chinese Society for Agricultural Machinery, 2007, 38(10): 61-63. (in Chinese with English abstract)

[19] 李耀明,李洪昌,徐立章. 短纹杆-板齿与钉齿脱粒滚筒的脱粒对比试验研究[J]. 农业工程学报,2008,24(3):139-142.

Li Yaoming, Li Hongchang, Xu Lizhang. Comparative experiment on threshing performance between short-rasp-bar tooth cylinder and spike tooth cylinder[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2008, 24(3): 139-142. (in Chinese with English abstract)

[20] 周旭,李心平,高连兴,等. 两种脱粒滚筒的玉米籽粒损伤试验研究[J]. 沈阳农业大学学报,2005,36(6):756-758.

Zhou Xu, Li Xinping, Gao Lianxing, et al. Comparison of corn kernel damage using two types of threshing cylinders[J]. Journal of Shenyang Agricultural University, 2005,36(6): 756-758. (in Chinese with English abstract)

[21] Špokas L, Steponavičius D, Petkevičius S. Impact of technological parameters of threshing apparatus on grain damage[J]. Agronomy Research, 2008,33(6): 367-376.

[22] 王显仁,李耀明,徐立章. 水稻谷粒的机械损伤机理及试验[J]. 农机化研究,2007,29(12):141-143.

Wang Xianren, Li Yaoming, Xu Lizhang. Mechanical injury mechanism of rice grain and experiments[J]. Journal of Agricultural Mechanization Research, 2007, 29(12): 141-143. (in Chinese with English abstract)

[23] 谢方平,罗锡文,苏爱华,等. 刚性弓齿与杆齿及柔性齿的脱粒对比试验[J]. 湖南农业大学学报,2005,31(6):648-651.

Xie Fangping, Luo Xiwen, Su Aihua, et al. Contrastive experiment on threshing by using rigid wire-loop,rigid pole tooth and flexible pole tooth[J]. Journal of Hunan Agricultural University, 2005, 31(6): 648-651. (in Chinese with English abstract)

[24] 吴崇友,丁为民,石磊,等. 油菜分段收获捡拾脱粒机捡拾损失响应面分析[J]. 农业机械学报,2011,42(8):89-93.

Wu Chongyou, Ding Weimin, Shi Lei, et al. Response surface analysis of pickup losses in two-stage harvesting for rapeseed[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(8): 89-93. (in Chinese with English abstract)

[25] Bansal N K, Lohan S K. Design and development of an axial flow thresher for seed crops[J]. Journal of Agricultural Engineering, 2009, 46(1): 1-8.

[26] Harrison H P. Grain separation and damage of an axial-flow combine [J]. Canadian Agricultural Engineering, 1992, 34(1): 49-53.

[27] 宗望远,廖庆喜,陈立,等. 完熟期油菜果荚不同脱粒方式的脱粒效果[J]. 农业工程学报,2012,28(9):29-34.

Zong Wangyuan, Liao Qingxi, Chen Li, et al. Threshing effect of ripe rape by different methods[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(9): 29-34. (in Chinese with English abstract)

[28] 李耀明,周金芝,徐立章,等. 油菜联合收割机脱粒分离装置的试验[J]. 江苏大学学报:自然科学版,2005,26(4):281-284.

Li Yaoming, Zhou Jinzhi, Xu Lizhang, et al. Experimental study on threshing and separating unit of rape combine[J]. Journal of Jiangsu University, 2005,26 (4): 281-284. (in Chinese with English abstract)

[29] 宗望远,黄鹏,李海同,等. 完熟期油菜的脱粒特性与分析[J]. 华中农业大学学报,2013,32(2):128-133.

Zong Wangyuan, Huang Peng, Li Haitong, et al. Threshing characteristic and analysis of full ripeness period rape[J]. Journal of Huazhong Agricultural University, 2013, 32(2): 128-133. (in Chinese with English abstract)

[30] 李耀明,孙韬,徐立章. 油菜多滚筒脱粒分离装置的性能试验与分析[J]. 农业工程学报,2013,29(8):36-43.

Li Yaoming, Sun Tao, Xu Lizhang. Performance test and analysis of rape multi cylinder threshing and separating device[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(8): 36-43. (in Chinese with English abstract)

Optimization of operating parameter and structure for seed thresher device for rape combine harvester

Wang Gang, Guan Zhuohuai, Mu Senlin, Tang Qing, Wu Chongyou※

(210014,)

Rapeseed germination rate is directly related to rapeseed yield, which is one of the most important indices to evaluate the rapeseed quality. Combine harvesters have greatly improved the harvest efficiency, but rapeseeds would be damaged by the mechanical threshing equipment during harvesting, and mechanical damage extent of rapeseeds was directly correlated to the design characteristics of the threshing apparatus, such as the movement speed of rasp bars, feeding rate, clearance between the drum and the concave. The rapeseed damage caused by mechanized harvest has aroused the concern of scholars, but there is no study on the rape harvest. In order to explore the damage of rapeseed caused by combine harvester during threshing process and the superior parameters of the threshing mechanism, rape combine harvest comprehensive experiment and germination rate experiment were carried out. Germination rate was used as an index to evaluate the damage. The type of rasp bars, the movement speed of rasp bars, the clearance between the drum and the concave and the feeding rate were taken as the influencing factors in the rape combine harvest comprehensive experiment and each factor had 3 levels. The evaluation indices were the germination rate and loss rate, the undamaged rapeseeds grown in the same plots were used as the comparison. The germination of mechanically harvested rapeseeds and hand harvested rapeseeds was tested in the same environment. The parameters of threshing apparatus with the highest germination rate (lower damage rate) were obtained through the comparison of germination rates between undamaged rapeseeds and mechanically harvested rapeseeds. The results showed that the germination rate of hand harvested rapeseeds was 99.8%, and the highest germination rate for mechanically harvested rapeseeds was 97.6% and the lowest was 85.7%. Therefore, mechanized harvest did cause damage to rapeseed and the damage rate was 2.4%-14.3% within the range of parameters selected. Through the range analysis of germination rate experiment, the factors affecting the damage of rapeseed were the threshing component form, the clearance between the drum and the concave, the movement speed of rasp bars and the feeding rate in turn. Through the variance analysis of germination rate experiment, the feeding rate (=0.727) had no significant effect on the test results, the threshing gap (=0.004) and threshing component form (0.001) had highly significant effect on the results, the drum speed (=0.012) had a significant effect on the results, and the repeated experiment error (=0.202) had no significant effect on the test results, and the test results were reliable. The threshing component form had a great influence on the harvest damage of rapeseed. The germination rate was 88.3% when using striped rod and was 97.3% when using full nailed tooth, which had 9 percentage points difference. For the rapeseed, striped rod was more likely to cause threshing damage than nails. Due to the limitation of the number of experiments, the relationship among drum rasp bars speed, clearance between the drum and the concave and rapeseed damage couldn’t be concluded. But the optimal parameters should exist between drum rasp bars speed and clearance between the drum and the concave. It needed further research to clarify the relationship among drum rasp bars speed, clearance between the drum and the concave and rapeseed damage. The effect of feeding rate was not significant. The change range of germination rate was less than 1.1 percentage points under different feeding rates. The optimal combination of threshing parameters was: nailed tooth, threshing drum clearance of 9 mm, drum rasp bars speed of 856 r/min, and feeding rate of 2.2 kg/s, and the damage rate was lower. In order to verify the accuracy of the combination of superior parameters, the artificially harvested rapeseed was threshed by experiment bench and different combinations of parameters were used for the comparison. The germination rate under the optimum parameters combination was 97.4%, which was the highest. Combine harvest damage could be reduced to a very small extent through adjusting the threshing system parameters. The study provides a reference for the design of combine harvester threshing system.

mechanization; optimization; crops; rapeseed; threshing damage; combine harvest; germination rate

10.11975/j.issn.1002-6819.2017.24.007

S225.31

A

1002-6819(2017)-24-0052-06

2017-06-09

2017-11-03

国家重点研发计划(2016YFD0702101):油菜智能化低损失收获技术与装备研究

王 刚,安徽阜阳人,助理研究员,主要从事收获机械的研究。Email:421404047@qq.com

吴崇友,研究员,博士,博士生导师,国家油菜产业技术体系收获机械化岗位专家,主要从事耕作与收获机械的研究。 Email:542681935@qq.com

王 刚,关卓怀,沐森林,汤 庆,吴崇友. 油菜联合收获机种子籽粒脱粒装置结构及运行参数优化[J]. 农业工程学报,2017,33(24):52-57. doi:10.11975/j.issn.1002-6819.2017.24.007 http://www.tcsae.org

Wang Gang, Guan Zhuohuai, Mu Senlin, Tang Qing, Wu Chongyou. Optimization of operating parameter and structure for seed thresher device for rape combine harvester[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(24): 52-57. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2017.24.007 http://www.tcsae.org