颗粒密度对垃圾衍生燃料燃烧特性的影响

2017-12-20熊祖鸿房科靖熊培培

黎 涛,熊祖鸿,房科靖,鲁 敏,谢 森,熊培培

颗粒密度对垃圾衍生燃料燃烧特性的影响

黎 涛,熊祖鸿,房科靖,鲁 敏,谢 森,熊培培

(中国科学院广州能源研究所,广州 510640)

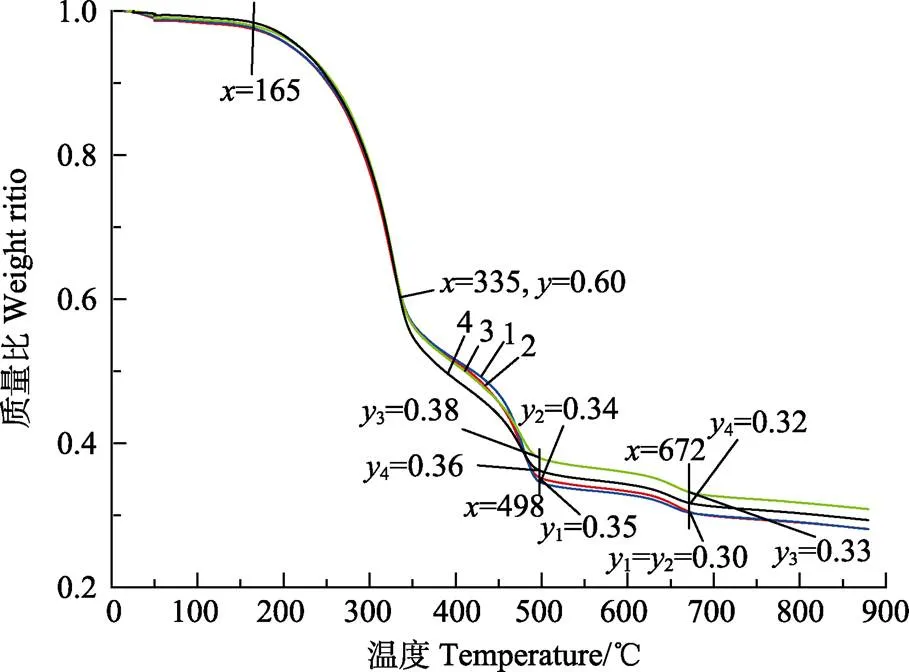

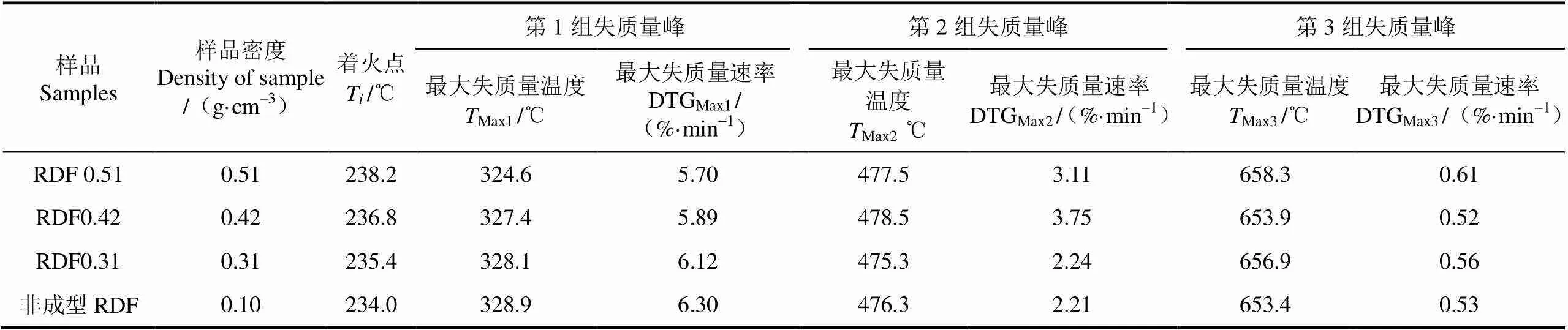

垃圾衍生燃料(RDF,refuse derived fuel)是垃圾焚烧发电的原料,该文研究RDF预加工的形态对其燃烧释放能量过程的影响。将RDF制备成不同密度等级的成型颗粒,通过热重、热值、灰分分析,同时参比与非成型的RDF和生物质秸秆燃料,观察RDF成型颗粒燃烧特性。研究结果表明,该组非成型RDF的着火点为234.0 ℃,3个最大失质量速率分别为6.30,2.21,0.53% min;高密度RDF的着火点为238.2 ℃,3个最大失质量速率分别为5.70,3.11,0.61%/min,表明较高密度RDF颗粒在燃烧过程中,着火点较高,燃烧速率较为均衡。该组高密度RDF比非成型RDF燃烧后的灰渣少6.7%,表明高密度RDF燃烧较为充分。在热值方面,方差显著性分析表明,RDF颗粒密度值对其燃烧产生的热值无明显影响。

垃圾;燃烧;生物质;RDF;密度;灰分

0 引 言

随着社会经济的发展、人口增长、农村城镇化加大、居民生活水平提高等,城市垃圾产量逐年增加,同时也必然导致全球范围的能源需求提高[1-8]。据统计,2014年,中国246个大、中城市生活垃圾产生量16 816.1万t,2016年增加到18 564.0万t,年增长率达5.20%。垃圾发电(waste to energy,WTE)是处理城市垃圾问题、缓解能源需求压力的优选方案。焚烧可使垃圾质量减少80%,体积减少70%;有机物中大约65%~80%的能量可转化为热能,25%~30%可通过焚烧转化电能[9-13]。政府通过WTE方案妥善处理垃圾和降低垃圾容量,解决垃圾的污染、填埋问题,还贡献出可再生能源,缓解能源需求压力。目前,全球的垃圾产量为2.4万亿t/a,2025年将达到2.6万亿t/a[14]。中国也投入建设大量垃圾焚烧发电厂。通过焚烧垃圾产生热量发电,减轻日益增长的能耗负担,同时也大大减少垃圾的填埋场地的压力[15]。

垃圾经过分选、除铁、破碎、高压成型等过程,将垃圾中的可燃烧部分制备成垃圾衍生物颗粒燃料,简称RDF[16]。Hirunpraditkoon等[18-20]认为每千克RDF燃烧的有效热约为15.3 MJ;每18 kg干的RDF在燃烧完成后,产生1 kg CO[17]。Bosmans等[20]从动力学角度分析,RDF热解单方面的热能转换,也包括气化和燃烧过程。Younan等[21-22]认为RDF颗粒尺寸对其内部和外部传热有着很大的影响,小颗粒温度均匀,在反应器中的反应也是均匀的;但对于大颗粒,传热速度变慢,颗粒加大到一定的限度,就会导致颗粒内温度非均匀分布,降低反应的热效能。本文针对RDF成型颗粒,在不同挤压强度下制备不同密度等级的成型颗粒的燃烧特性进行探讨,探索RDF颗粒密度对其燃烧特性的影响。

1 试验部分

1.1 样品制备

本试验使用的生活垃圾来自佛山南海绿电再生能源有限公司厂区分选的可燃烧垃圾样品,包括废纸(18.17%)、草木(8.84%)、布碎(10.28%)、塑料和皮革(39.32%)、厨余(23.39%)等,经干燥、粉碎、混合、添加微量的黏合剂,通过挤压设备制备成4个密度等级的成型颗粒,同时取一未成型样品作为对照。样品原料的工业分析、元素分析含量见表1,样品密度分别为0.51、0.42、0.31 g/cm3,对照的非成型RDF密度为0.10 g/cm3。

表1 RDF样品的工业分析和元素分析

1.2 试验仪器与装置

试验仪器主要包括TGAQ50热重分析仪(美国TA公司)、Wvario EL cube元素分析(德国elementar仪器公司)、ZR-1T-CII微电脑自动热量计(长沙奔特仪器有限公司)、AL204电子天平(梅特勒-托利多仪器公司)、SX2-4-13N箱式电阻炉(上海一恒科技有限公司)、GZX- 9240 MBE数显鼓风干燥箱(上海博讯实业有限公司)。

1.3 试验方法

热重分析每次样品10 mg左右,天平净化流氮气30 mL/min,样品净化流氮气40 mL/min,空气气氛,升温速率10 ℃/min,从室温升至900 ℃。工业分析挥发分、灰分、固定碳项目参照GB/T212-2008,热值项目参照GB/T213-2008。

2 结果与分析

2.1 RDF各阶段燃烧趋势分析

图1为样品1~4的热重分析的TG曲线图。由图1可以看到,颗粒样品1~3与非成型样品4的燃烧趋势大致相同,分为4个燃烧阶段,即脱水、挥发物热解、挥发物燃烧与固定碳燃烧并存、固体碳的进一步燃烧[23],分别在165、165~335、335~498、498~672 ℃。在水分挥发阶段,1号样在最下端,4号样在最上方,表明这个阶段高密度颗粒水分溢出较慢,但差别并不太大,0.51 g/cm3比0.10 g/cm3的样品在同一温度点只有0.01%减幅。

样品在完成水分挥发后,进入挥发物热解,各样的TG曲线逐渐重叠,表明这个阶段的燃烧侧重热解,需要的氧气量不多,同物料不同颗粒密度的RDF燃烧速率在此阶段接近。值得注意的是,样品完成挥发物热解,质量已经减少了40%,如果除去RDF所含的不可燃烧的无机成分(灰分),该燃烧部分实际占样品原始质量的50%,说明RDF有一半的易燃物质在165~335 ℃温度段燃烧,为热值做出重大贡献。

注:样品1~4分别为成型RDF 0.51, 0.42, 0.32 g·cm-3, 非成型RDF。

在335 ℃后,RDF进入挥发物及固定碳燃烧。由图1的TG图可以看到,未成型的非颗粒样品4号RDF的失质量速度以绝对优势超过成型颗粒RDF1~3,结合DTG图更清晰地表现,4号样比1~3号更加剧烈地燃烧。可见,RDF在这个阶段的燃烧需要氧气的助燃,而密度大的RDF间隙少,接触空气面积小,氧气少,使其燃烧速度降低[24]。

2.2 RDF燃烧特征参数分析

系列样品1~4的TG和DTG整理出着火点T和最大失质量温度Max和最大失质量速率DTGMax,见表2。

表2 不同样品的着火点Ti,最大失质量温度TMax和最大失质量速率DTGMax

由表2看出,随着RDF颗粒密度的增加,着火点逐渐提高,从234.0 ℃升至238.2 ℃,表明着火点与物料接触到的空气面积密切相关。从另一角度看,物料密度直接影响着火点,挤压成型物料单元体积也会影响着火点。

为突出RDF的特点,本试验同时做了一个非成型的秸秆样品作为对照样。从图2看到,对照样的第一个失质量峰后的温度段,已经没有多少物质可以燃烧了,这就是生物质燃料与RDF的重大区别。由于RDF是混合物,有塑料、纸纤维、布纤维、植物纤维等组成,不同的物质具有不同的燃烧特征,使得本试验的RDF在DTG出现3组失质量峰。在第1组是失质量峰里,未成型RDF,密度为0.10 g/cm3,最大失质量温度TMax1最高,最大失质量速率DTGMax1也最高,随着RDF密度提高,Max1降低,DTGMax1也有所降低。有趣的是,在第2组的失质量峰里,未成型的RDF的TMax2降至第3,DTGMax2降至最末。2号成型RDF,密度为0.42 g/cm3,在第2组排第1。在第3组失质量峰里,未成型RDF的Max3、DTGMax3都降至最末;1号成型RDF,密度为0.51 g/cm3排位第1。可见,较高密度的RDF成型颗粒,有利于燃烧的持久性和均匀性。

2.3 RDF残渣量分析

在实际生产中,RDF的燃烧产生大量的灰渣所涉及的废弃物处理是非常严峻的工作,尽量减少RDF的残渣量也是垃圾处理的解决方案之一[25-26]。仪器分析与实际焚烧的情况可能有出入,但系列条件样品平行比对的结果仍然具有参考价值。从图1的TG组图可以看到,RDF在672 ℃以后,基本上燃尽,密度较大的1号和2号样灰渣量几乎一致,比4号未成型样品低6.7%,而密度较小的3号样的灰渣量比4号样高3.1%。这组数据表明,增加RDF的成型颗粒密度,可燃物质分子之间的距离减小,燃烧过程原子活化能较高的获得能量释放离子;在距离较短的情况下,离子克服较少的位能即可与相邻的离子发生反应,释放反应能[27],因此,较大的密度有利于促进RDF在燃烧的后期进一步燃烧,燃烧后部分物质转化气体离开,相应减少灰渣量。

图2 样品1~4与秸秆的DTG曲线

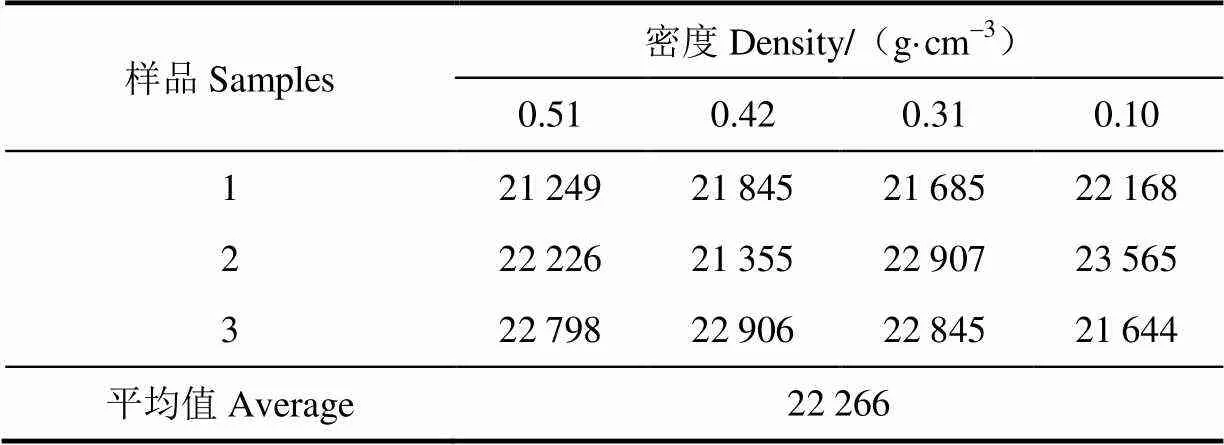

2.4 RDF热值分析

本试验的计算得为0.25,从分布表[28]查得0.05(3,8)=4.07,0.01(3,8)=7.59,<0.05<0.01,故RDF颗粒密度对热值无显著影响。

表3 样品1~4的热值

表4 颗粒密度对热值影响的方差分析表

Note:=0.25<0.05<0.01.

3 结 论

垃圾的易燃部分经破碎混合后再经过挤压制备RDF颗粒。对一系列不同密度的RDF颗粒的热性能分析,得出以下结论:

1)高密度RDF颗粒在燃烧过程中,着火点较高,燃烧剧烈程度小于低密度颗粒。但高密度颗粒在燃烧过程的几个阶段,其燃烧速率较为均衡,有利于热量吸收。

2)高密度RDF颗粒在后期的进一步燃烧较为充分,燃烧后的灰渣含量比低密度和非颗粒的RDF少7%左右,有利于减少灰渣含量,对减少固体废弃物排放有着重要的意义。

3)试验数据分析,RDF颗粒密度大小对燃烧过程释放的热量值无直接影响。

除了技术上的因素,RDF在实际生产中的工艺受到诸多因素的制约,如场地、设备、运输,以及生产过程中能耗;另外,垃圾焚烧炉空间大,温度分布不均匀,导致灰渣量增加、灰渣成分复杂等等情况。RDF的研究需要从每一个环节入手,在细节上考虑优化生产工艺;同时,开辟其他能提高其RDF附加值的产品,如对灰渣进行资源化利用也值得深入研究。

[1] 袁振宏,吴创之,马隆龙. 生物质能利用原理与技术[M]. 北京:化学工业出版社,2005.

[2] 段佳,罗永浩. 生物质燃料再燃研究进展[J]. 热能动力工程,2006,21(3):227-230; Duan Jia, Luo Yonghao. Recent advances in the study of biomass fuel reburning[J]. Journal of Engineering for Thermal Energy &Power, 2006, 21(3): 227-230. (in Chinese with English abstract)

[3] 何品晶,陈淼,杨娜,等. 我国生活垃圾焚烧发电过程中温室气体排放及影响因素[J]. 中国环境科学,2011,31(3):402-407. He Pinjing, Chen Miao, Yang Na, et al. GHG emissions from Chinese MSW incineration and their influencing factors [J]. China Environmental Science, 2011, 31(3): 402-407. (in Chinese with English abstract)

[4] Gallardo A, Carlos M, Bovea M D, et al. Analysis of refuse-derived fuel from the municipal solid waste reject fraction and its compliance with quality standards[J]. Journal of Cleaner Production, 2014, 83: 118e125;

[5] Rotheut M, Quicker P. Energetic utilisation of refuse derived fuels from landfill mining[J]. Waste Management, 2017, 62: 101-117.

[6] Kabalina N, Costa M, Yang W, et al. Energy and economic assessment of a polygeneration district heating and cooling system based on gasification of refuse derived fuels[J]. Energy, 2017: 1e10.

[7] Edo M, Budarin V, Aracil I, et al. The combined effect of plastics and food waste accelerates the thermal decomposition of refuse-derived fuels and fuel blends[J]. Fuel, 2016: 180: 424-432.

[8] Zhou X, Liu W, Zhang P, et al. Study on heavy metals conversion characteristics during refused derived fuel gasification process[J]. Procedia Environmental Sciences, 2016, 31: 514-519.

[9] W A Wan Ab Karim Ghani, Alias A B, Savory R M, et al. Co-combustion of refuse derived fuel with coal in a fluidised bed combustor[J]. Journal of Engineering Science and Technology, 2009, 4 (1): 122-131.

[10] 胡谢利,云斯宁,尚建丽. 生物质燃料压缩成型技术研究进展[J]. 化工新型材料,2016,44(9):42-44. Hu Xieli, Yun Sining, Shang Jianli. Research progression of briquetting technology for biomass fuel[J]. New Chemical Materials, 2016, 44 (9): 42-44. (in Chinese with English abstract)

[11] 成伟,陈汉平,杨海平,等,棉秆燃烧过程中的颗粒物排放特性[J]. 农业工程学报,2017,33(19):223-228. Cheng Wei, Chen Hanping, Yang Haiping, et al. Emission characteristics of particulate matter during combustion of cotton stalk[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(19): 223-228. (in Chinese with English abstract)

[12] Carroll J, Finnan J. Emissions and efficiencies from the combustion of agricultural feedstock pellets using a small scale tilting grate boiler[J]. Biosystems Engineering, 2013, 115(1): 50-55.

[13] Zhou Chunguang, Yang Weihong. Effect of heat transfer model on the prediction of refuse-derived fuel pyrolysis process[J]. Fuel, 2015, 142: 46-57.

[14] Ouda O K M, Raza S A, Nizami A S, et al. Waste to energy potential: A case study of[J]. Renewable and Sustainable Energy Reviews, 2016, 61: 328-340.

[15] Niu M, Huang Y, Sun Y, et al. Enriched-air gasification of refuse-derived fuel in a fluidized bed: Effect of gasifying conditions and bed materials[J]. Effect of Gasifying Conditions and Bed Materials, 2014, 37 (10): 1787-1796.

[16] 刘军伟,雷廷宙,杨树华,等. 浅议我国垃圾焚烧发电的现状及发展趋势[J]. 中外能源,2012(17):29-34. Liu Junwei, Lei Tingzhou, Yang Shuhua, et al. Garbage-fired power generation in china today and development trends[J]. Sino-global Energy, 2012(17): 29-34. (in Chinese with English abstract)

[17] Sibel Bas, Hilal Aydemir. Pyrolysis of olive pomace and copyrolysis of olive pomace with refuse derived fuel[J]. Environmental Progress & Sustainable Energy, 2014, 33(2): 649-656.

[18] Hirunpraditkoon S, Dlugogorski B Z, Kennedy E M. Fire properties of surrogate refuse-derived fuels[J]. Fire and Materials Fire Mater, 2006, 30: 107-130.

[19] Schwarzböck T, Aschenbrenner P, Rechberger H. Effects of sample preparation on the accuracy of biomass content determination for refuse-derived fuels[J]. Fuel Processing Technology, 2016, 153: 101-110.

[20] Bosmans A, Dobbelaere C D, Helsen L. Pyrolysis characteristics of excavated waste material processed into refuse

derived fuel[J]. Fuel, 2014, 122: 198-205.

[21] Sibel Bas, Hilal Aydemir. Pyrolysis of olive pomace and copyrolysis of olive pomace with refuse derived fuel[J]. Wiley Online Library (wileyonlinelibrary. com). DOI 10. 1002/ep. 11827.

[22] Younan Y, Goethem M W M V, Stefanidis G D. A particle scale model for municipal solid waste and refuse-derived fuels pyrolysis[J]. Computers and Chemical Engineering, 2016, 86: 148-159

[23] Robinson T, Bronson B, Gogolek P. Sample preparation for thermo-gravimetric determination and thermo-gravimetric characterization of refuse derived fuel[J]. Waste Management, 2016, 48: 265-274

[24] 罗娟,侯书林,赵立欣,等. 典型生物质颗粒燃烧特性实验[J]. 农业工程学报,2010,26(5):220-226. Luo Juan, Hou Shulin, Zhao Lixin, et al. Experimental study on combustion and emission characteristics of biomass pellets[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2010, 26(5): 220-226. (in Chinese with English abstract)

[25] 刘恩海,刘圣勇,白冰,等. 玉米秸秆打捆燃料燃烧动力学模型[J]. 农业工程学报,2013,29(24):218-225. Liu Enhai, Liu Shengyong, Bai Bing, et al. Development of dynamic model of cornstalk bale combustion[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(24): 218-225. (in Chinese with English abstract)

[26] Ishii K, Furuichi T. Influence of moisture content, particle size and forming temperature on productivity and quality of rice straw pellets[J]. Waste Management, 2014, 34(12): 2621-2626.

[27] Krüger B, Mrotzek A, Wirtz S. Separation of harmful impurities from refuse derived fuels (RDF) by a fluidized bed[J]. Waste Management, 2014, 34: 390-401.

[28] Kaliyan N, Morey R V. Densification characteristics of corn cobs[J]. Fuel Processing Technology, 2010, 91(5): 559-565

[29] 李云雁,胡传荣. 实验设计与数据处理 [M]. 第二版. 北京:化学工业出版社,2008.

黎 涛,熊祖鸿,房科靖,鲁 敏,谢 森,熊培培.颗粒密度对垃圾衍生燃料燃烧特性的影响[J]. 农业工程学报,2017,33(23):241-245. doi:10.11975/j.issn.1002-6819.2017.23.031 http://www.tcsae.org

Li Tao, Xiong Zuhong, Fang Kejing, Lu Min, Xie Sen, Xiong Peipei.Effect of particle density on combustion characteristics of refuse derived fuel [J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(23): 241-245. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2017.23.031 http://www.tcsae.org

Effect of particle density on combustion characteristics of refuse derived fuel

Li Tao, Xiong Zuhong, Fang Kejing, Lu Min, Xie Sen, Xiong Peipei

(510640,)

Waste to energy (WTE) plants have been built more and more worldwide nowadays. It is one of the most successful types to resolve the impact of city rubbish on environment. Refuse derived fuel (RDF) is the fuel of WTE plant, which is made of combustible refuse such us cardboard, paper, various plastics, textile and wood. According to literature, the incineration process has the advantage of reducing waste weight by 80% and volume by 70%, and around 25%-30% energy within RDF can be obtained through conversion of power facilities. Combustible refuse can be processed into pellets with physical density of more than 0.3 g/cm3through extrusion forming after separating, crushing, and drying procedure. In this paper, pelleted RDF with different densities of 0.51, 0.42, and 0.31 g/cm3was adopted in this experiment, and their combustion characteristics from 30 to 900 ℃were investigated by means of thermogravimetric (TG), calorific value, and ash content analysis. Meanwhile, pelleted RDF was compared with non-pelleted RDF and straw which represented biomass fuel. By comparing TG of pelleted RDF and non-pelleted RDF, the results indicated that non-pelleted RDF was faster in burning, showing pelleted RDF can release energy slower, which is good for boiler equipment to absorb energy more efficiently. By comparing DTG of pelleted RDF and non-pelleted RDF, the ignition point of the non-pelleted RDF (0.10 g/cm3) was 234.0 ℃, and 3 maximum mass loss rates were 6.30, 2.21 and 0.53 percentage points per minute, respectively; While for the highest density of pelleted RDF (0.51 g/cm3), the ignition point was 238.2 ℃, and 3 maximum mass loss rates were 5.70, 3.11, and 0.61 percentage points per minute, respectively, showing that the higher density, the higher ignition point, and the higher burning rate got more balance. DTG data also show that pelleted RDF is more suitable for the boiler to absorb heat efficiently. After finishing burning, the content of combustion ash coming from the highest density pelleted RDF sample in this experiment was 6.7% less than that of the non-pelleted one, showing that procession of extrusion forming will help to reduce weight and volume of RDF ash, thus relieving the pressure of landfill, which is the most serious problem to our environment. For the burning calorific value, and the data from pelleted RDF and non-pelleted RDF checked by calorimeter, each sample was checked 3 times. By calculating all sample values with the method of variance analysis,value was 0.25, whilevalues between groups and within group were 3 and 8, respectively, the final0.05(3, 8) value was 4.07, and0.01(3, 8) value was 7.59, thus<0.05<0.01.The results of variance analysis show that calorific value difference between pelleted RDF and non-pelleted RDF is not obvious. Though pelleted RDF has some advantage for equipment to absorb energy, its procession is limited by many factors, such us space, equipment structure, transportation, moreover, investment cost and energy cost are also included in the consideration. On other hand, we also can make use of RDF ash as product material, so there are still many researching works to be done.

wastes; combustion; biomass; refuse derived fuel; RDF density; ash

10.11975/j.issn.1002-6819.2017.23.031

TK16

A

1002-6819(2017)-23-0241-05

2017-07-27

2017-10-28

广州市民生科技攻关计划项目(705272504057)

黎 涛,广东湛江人,高级工程师,从事固体废弃物资源化利用。Email:litao@ms.giec.ac.cn