添加稻壳基陶瓷颗粒改善液体石蜡润滑特性

2017-07-07胡恩柱俞东瑞汤玉超胡坤宏胡献国宋汝鸿

胡恩柱,俞东瑞,汤玉超,吴 云,胡坤宏,胡献国,宋汝鸿

(1. 合肥学院化学与材料工程系,合肥 230601;2. 合肥工业大学机械工程学院,合肥 230009)

添加稻壳基陶瓷颗粒改善液体石蜡润滑特性

胡恩柱1,俞东瑞2,汤玉超1,吴 云1,胡坤宏1,胡献国2,宋汝鸿2

(1. 合肥学院化学与材料工程系,合肥 230601;2. 合肥工业大学机械工程学院,合肥 230009)

为了实现稻壳资源的综合利用,变废为宝,以稻壳和酚醛树脂为原料,高温碳化制备出稻壳基陶瓷颗粒(rice husk ceramic,RHC),将其作为润滑油功能添加剂,可缓解稻壳焚烧和储存给环境带来的危害。在四球机上探究不同温度(25、75和100 ℃)和司盘-80分散剂存在条件下,不同添加量(质量分数为0.01%、0.03%和0.05%)的RHC颗粒对液体石蜡(liquid paraffin,LP)润滑特性的影响,进而研究RHC颗粒的摩擦学行为。结果表明,25和75 ℃下,RHC颗粒在一定程度上改善了液体石蜡润滑性能,主要表现在钢球表面磨斑直径的降低,抗磨性增强,但并未明显降低摩擦系数;100 ℃下,RHC颗粒可明显改善液体石蜡的润滑特性,添加量为0.01%、0.03%和0.05%的油样与纯液体石蜡相比,平均摩擦系数从0.139(LP)分别降低到0.083、0.064和0.069;平均磨斑直径从0.389 mm(LP)分别降到0.314、0.311和0.318 mm。高温下摩擦诱导RHC颗粒组分参与边界润滑膜形成,起到抗磨减摩的功效。RHC颗粒可作为潜在的高温润滑油摩擦改进剂。

润滑;颗粒;摩擦;稻壳粉;陶瓷颗粒;液体石蜡;摩擦改进剂;抗磨减摩

胡恩柱,俞东瑞,汤玉超,吴 云,胡坤宏,胡献国,宋汝鸿. 添加稻壳基陶瓷颗粒改善液体石蜡润滑特性 [J]. 农业工程学报,2017,33(10):265-270. doi:10.11975/j.issn.1002-6819.2017.10.035 http://www.tcsae.org

Hu Enzhu, Yu Dongrui, Tang Yuchao, Wu Yun, Hu Kunhong, Hu Xianguo, Song Ruhong. Rice husk ceramic particles improving lubrication property of liquid paraffin[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(10): 265-270. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2017.10.035 http://www.tcsae.org

0 引 言

稻壳和秸秆作为农作物的副产品,大部分被堆积在农田中或直接焚烧掉,存在着严重的安全隐患和环境污染,因此稻壳和秸秆的综合利用技术成为国内外学者研究的热点。目前,稻壳可制备生物油[1-3]、生物吸附剂[4-5]、白炭黑[6]、固体成型燃料[7-8]和生物摩擦材料[9-11]等,其中稻壳基陶瓷颗粒(rice husk ceramic,RHC)的开发是稻壳综合利用的有效途径之一。

迄今为止,关于稻壳基陶瓷颗粒的研究已被广泛报道。Dugarjav等[12]将RHC颗粒压制成坯,考察不同摩擦副材料与RHC坯对摩时的干摩擦学性能,发现摩擦系数的降低归因于对摩件表面有转移膜的形成。此外,还研究了碳化温度对稻壳基陶瓷颗粒摩擦学性能的影响,发现 900 ℃下碳化的 RHC颗粒的摩擦学性能最佳[13]。Shibata等[14]研究了 RHC坯与氮化硅和碳化硅钢球对摩时的干摩擦学性能,发现氮化硅作为对摩件时,摩擦学性能最佳。在水基润滑条件下,Cu/C复合材料中加入稻壳秸秆基陶瓷颗粒(RBC)颗粒可明显改进材料的抗磨减摩性能[15]。此外,还研究了不同载荷下,Cu/C/RBC复合材料的磨损模型,并进行了磨损图的绘制[16-17]。Akiyama等[18-19]将RBC颗粒添加到5种热固性树脂当中,开发出了复合材料,并研究了这些材料在油润滑和干摩擦条件下的摩擦学性能,发现RBC颗粒的引入,明显降低了摩擦系数。综上所述,稻壳基陶瓷颗粒在一定的条件下,具有抗磨减摩的功效。然而,将其作为润滑油摩擦改进剂的研究较少,且随着重型机械的快速发展,对润滑油质量提出了较高的要求,其中,高温润滑油的开发成为目前研究的热点。能够作为润滑油摩擦改进剂的颗粒材料种类较多,如:片状石墨、二硫化钼、纳米二氧化硅、石墨烯和纳米金刚石等,均可在一定程度上改善润滑油的润滑特性。陶涛等[20]研究了片状石墨对聚α烯烃-4(PAO4)基础油摩擦学性能的影响,添加质量分数为 0.01%的片状石墨能够明显的增强润滑油的抗磨减摩特性。Xu等[21]研究了不同形态的二硫化钼对菜籽油润滑特性的影响,发现纳米球形二硫化钼可明显的改善菜籽油的润滑特性,而微米级片状二硫化钼对菜籽油润滑特性的改善不佳。王建华等[22]研究了水溶性二氧化硅颗粒作为水基添加剂的摩擦学性能,研究发现小颗粒水溶性纳米二氧化硅作为水基添加剂具有良好的抗磨减摩性能和极压性能,在摩擦过程中形成的沉积膜起到抗磨减摩的功效。乔玉林等[23]对石墨烯作为油基润滑油和水基润滑添加剂进行了综述,指出石墨烯表面可控修饰是今后石墨烯摩擦学研究的重点。张家玺等[24]发现纳米金刚石颗粒可改善普通发动机润滑油(15 W/30)润滑特性的功效,主要原因归于颗粒的纳米尺寸效应和摩擦诱导摩擦副界面形成固体膜。可见,碳材料和二氧化硅颗粒均可作为润滑油的摩擦改进剂,那么由稻壳炭化制备的陶瓷颗粒主要成分为碳和二氧化硅,应该可作为润滑油添加剂,尤其高温摩擦改进剂。因此设计了一系列的摩擦学试验,研究稻壳基陶瓷颗粒对液体石蜡摩擦学特性的影响,该工作的有效实施不仅为稻壳的综合利用开辟了新的途径,而且为高温润滑油摩擦改进剂的开发提供了基础的数据和理论指导。

1 材料与方法

1.1 试验材料与制备

稻壳粉(品种为:皖稻54,品种来源:88-22/T1003,颗粒大小为2.0 mm,安徽省蚌埠市宏发糠业有限公司),酚醛树脂(型号:3122,无锡明洋粘结材料有限公司),液体石蜡(liquid paraffin,分析级,天津富宇精细化工有限公司),司盘-80(Sp-80,分析级,天津市光复精细化工有限公司),四球机专用钢球为不锈钢钢球(直径为12.7 mm,洛氏硬度为61~63 HRC),甲醇和乙醇(AR500 ml,上海国药集团化学试剂有限公司)。

RHC颗粒制备过程如下:精确称取2.5 g酚醛树脂和7.5 g的稻壳粉,于50 ml小烧杯中充分搅拌约15 min,之后移取3 g混合物于石英舟中,将其放入管式炉(型号:OTF-1200X,合肥科晶材料技术有限公司)中,氮气氛围下,900 ℃下煅烧2 h,自然冷却,获取的颗粒利用立式方形行星式球磨机(型号:XQM-2,长沙天创粉末技术有限公司)球磨30 min后,获得细化颗粒即为稻壳基陶瓷颗粒,其颗粒平均尺寸约为10μm, RHC的形貌和组分见参考文献[25]。按照如下的比例[26]配制总质量均为30 g的液体石蜡油样:1号样,含2%(质量分数)Sp-80;2号样中含2% Sp-80和0.01%(质量分数)RHC;3号样含2% Sp-80和0.03% RHC;4号样含2% Sp-80和0.05%RHC,每组试样在磁力搅拌下搅拌2 h以便RHC颗粒均匀分散,摩擦试验前,再利用超声波清洗器(型号:JP-010S,厦门立本电子有限公司)超声分散20 min,尽量减小试验误差。

1.2 分析方法

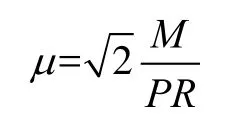

模拟发动机启动及高速运转下润滑油的温度,选择25、75和100 ℃为试验温度。在微机控制四球摩擦磨损试验机(型号为:MRS-10D,济南益华摩擦学测试技术有限公司)上,利用带有温控的模具控制试验温度,研究不同添加量(0.01%、0.03%和 0.05%)的稻壳基陶瓷颗粒对液体石蜡减摩和抗磨性能的影响,详细的四球机摩擦副见参考文献[26]。试验条件为载荷 200 N,转速1450 r/min,时间30 min,每组试验测试3次,取其平均值。摩擦系数按照如下的公式计算,反映RHC对液体石蜡减摩性的影响[26];

式中,μ为摩擦系数;M为摩擦力矩,N·m;P为法向载荷,N;R为钢球半径(6.35 mm)

利用摩擦试验机附带的光学显微镜观察试验后的下试样3个钢球的磨痕,测量出磨斑直径,计算出平均值,反映RHC对液体石蜡抗磨性能的影响。

利用扫面电子显微镜附带能谱(scanning electronic microscopy/energy dispersive spectrometer,SEM/EDS,型号:SU8020,日本日立公司)对摩擦后上试样钢球表面磨痕区域进行形貌、元素种类和含量分析,进而判断RHC颗粒所引起的摩擦形式。

利用 X射线光电子能谱仪(X-ray photoelectron spectroscopy,XPS,型号:ESCALAB250Xi,美国Thermo公司)对上试样钢球磨痕区域的元素化合价态进行定性定量分析[27-29],判断钢球表面摩擦膜的组成,进而揭示RHC颗粒的摩擦磨损机制。

2 结果与分析

2.1 RHC对液体石蜡减摩性的影响

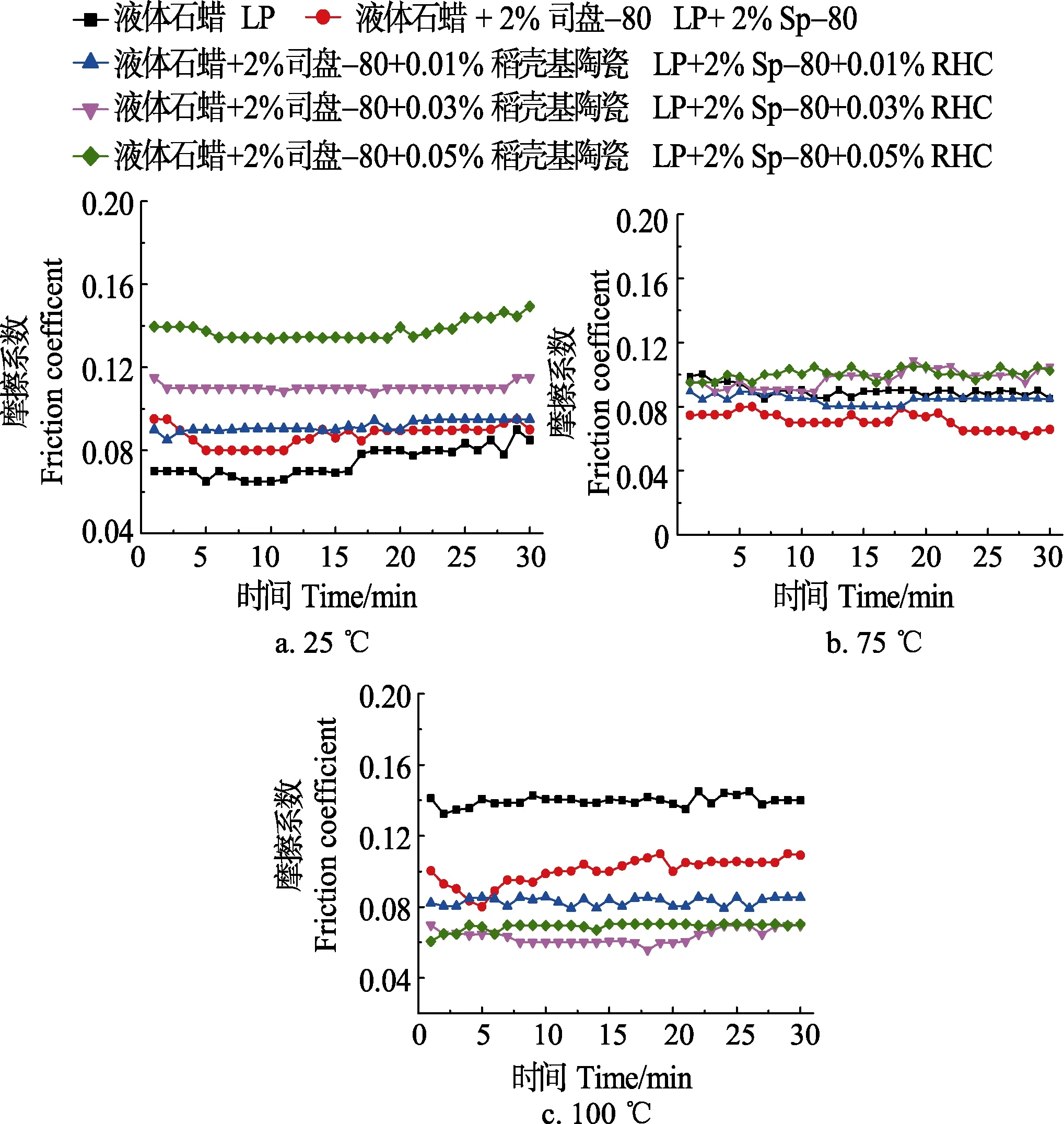

图1为不同油样和温度下,摩擦系数随时间的变化。

图1 不同油样和温度下摩擦系数的变化Fig.1 Variation of friction coefficients of different oil samples and test temperatures

图1a为25 ℃的摩擦系数曲线,添加质量分数为2%Sp-80 和不同量的RHC颗粒的油样,摩擦系数均高于纯液体石蜡,低温下添加剂引起液体石蜡减摩性变差,主要原因归于稻壳基陶瓷颗粒的磨粒磨损作用或由于磨粒阻碍润滑油进入摩擦副界面导致贫油磨损的发生[30]。当温度升高到 75 ℃,各油样的摩擦系数变化不大(见图1b),说明 75 ℃下添加剂的引入对润滑油减摩性的影响很小。当温度升高到100 ℃时,添加质量分数为2% Sp-80的液体石蜡平均摩擦系数明显降低,从 0.139降低到0.100;当添加稻壳基陶瓷颗粒时,平均摩擦系数分别降低到0.083(0.01% RHC),0.064(0.03% RHC)和0.069(0.05% RHC),主要原因归于高温下摩擦诱导摩擦副界面形成摩擦膜[31]。不同温度下,纯液体石蜡润滑时,摩擦系数随温度的升高逐渐增大,原因归于高温引起液体石蜡黏度的降低,油膜厚度降低,故润滑性能降低。添加不同量RHC颗粒的油样,摩擦系数随温度的升高逐渐的降低,与纯液体石蜡的摩擦系数呈现出相反的规律。100 ℃下,摩擦系数降低最为明显,主要的原因归于摩擦诱导RHC颗粒形成边界润滑膜,起到减摩的功效。可见,高温下RHC颗粒可明显改善液体石蜡的润滑性。

2.2 RHC对液体石蜡抗磨性的影响

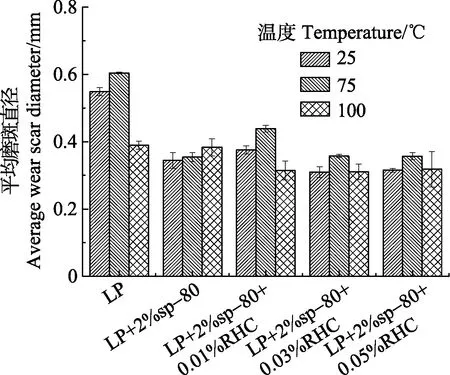

图 2为不同油样和温度下,磨斑直径的变化。

图2 不同温度和油样下平均磨斑直径的变化Fig.2 Variation of average wear scar diameters of different oil samples and test temperatures

25 ℃下,不同油样润滑下,平均磨斑直径(average wear scar diameter,AWSD)的变化。纯液体石蜡润滑下,AWSD为 0.549 mm;添加质量分数为 2% Sp-80时,AWSD降为0.344 mm(降幅为37.3%);继续添加不同量(0.01%、0.03%和0.05%)的RHC颗粒于液体石蜡中时,平均磨斑直径分别为 0.375(降幅为 31.7%),0.310(降幅为43.5%)和0.315 mm(降幅为42.6%);说明稻壳基陶瓷颗粒进一步改善了润滑油的润滑特性,使其抗磨性能增强。温度升高到75 ℃时,纯液体石蜡润滑下,AWSD为0.605 mm;添加2% Sp-80时,AWSD降为0.354 mm,继续添加不同量(0.01%、0.03%和0.05%)的RHC颗粒时,平均磨斑直径分别降为0.438、0.358和0.357 mm。温度为100 ℃时,纯液体石蜡润滑下,AWSD为0.389 mm;添加2% Sp-80时,AWSD降为0.383 mm;继续添加不同量(0.01%、0.03%和0.05%)的RHC颗粒时,平均磨斑直径分别降为0.314(降幅为19.2%)、0.311(降幅为20%)和0.318 mm(降幅为18.2%)。综上可知,不同温度下,添加不同量(0.01%、0.03%和0.05%)的RHC颗粒于含Sp-80的液体石蜡润滑油中,平均磨斑直径均明显降低,说明润滑油的抗磨特性增强,主要原因归于RHC颗粒和Sp-80共同参与边界润滑膜形成。不同温度下,纯液体石蜡润滑时,磨斑直径随温度升高先增加后降低。75 ℃下,磨斑直径的增加归于液体石蜡运动黏度降低,油膜变薄;100 ℃下,磨斑直径反而降低归于高温摩擦诱导液体石蜡发生氧化,易于形成边界润滑膜;添加不同量的RHC颗粒的油样也具有类似的规律,说明高温下(100 ℃),摩擦更容易诱导RHC颗粒参与边界润滑膜的形成,进而起到很好的抗磨功效。

2.3 摩擦后钢球表面分析

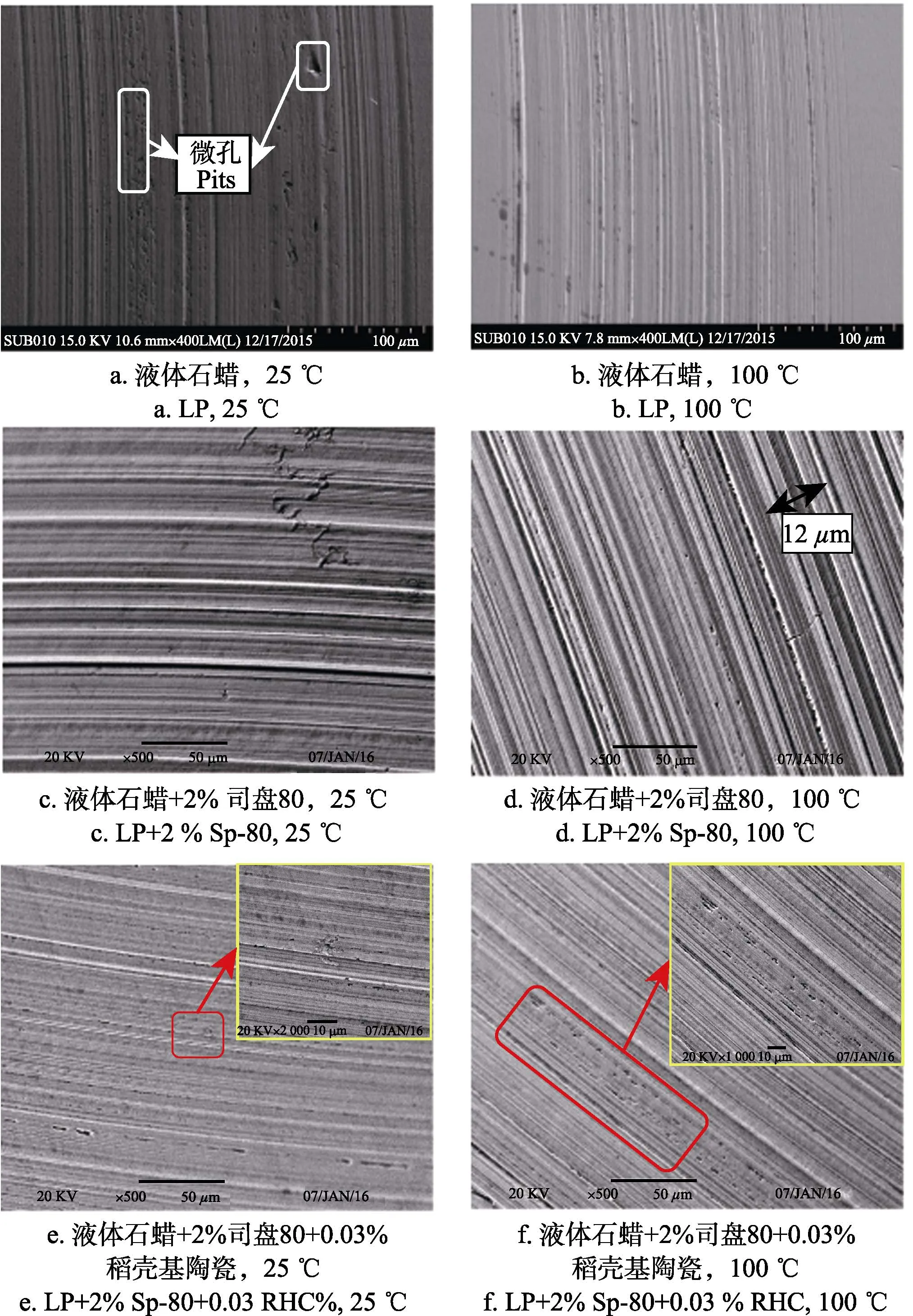

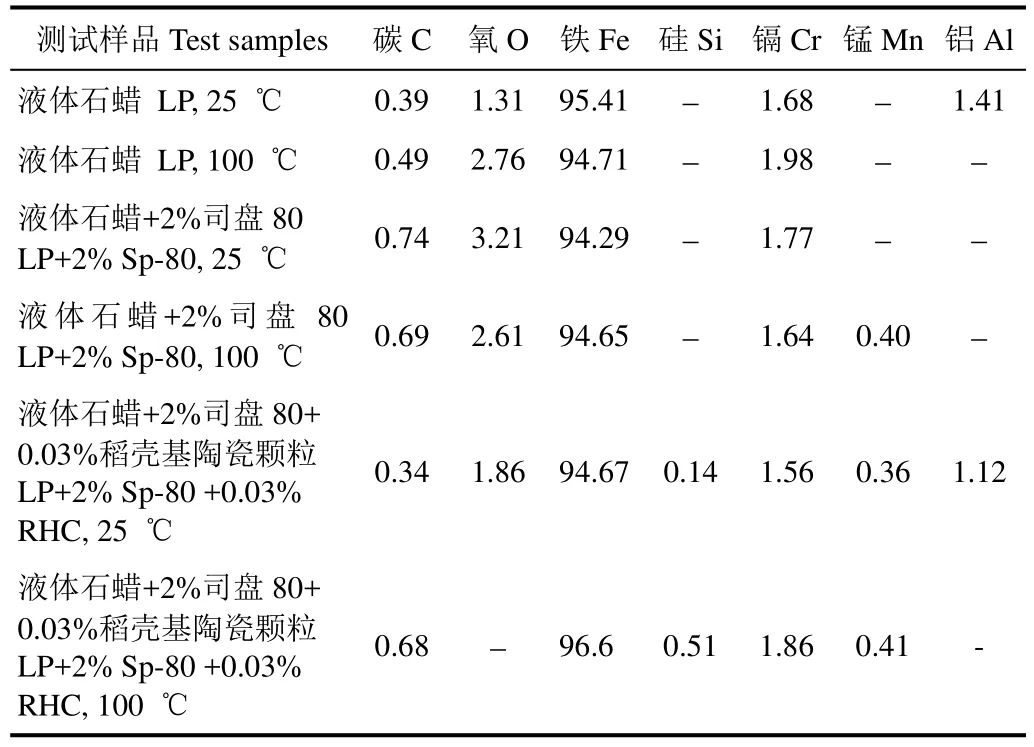

图3为25和100 ℃下,不同油样润滑下,磨痕区域的表面形貌。25 ℃下,纯液体石蜡润滑,钢球表面犁沟较为明显,有明显的微坑存在(图3a中矩形框所示);当温度升高到 100 ℃下,纯液体石蜡润滑下的钢球表面犁沟和微坑也明显减少(见图3b)。添加2% Sp-80时,25或 100 ℃下,钢球表面犁沟清晰可见,且局部有润滑膜形成,犁沟宽度局部达到 12μm(见图 3d)。继续添加RHC颗粒于液体石蜡中时,25和100 ℃下的钢球表面的犁沟明显减少,犁沟宽度也相应减小,表面有一层润滑膜存在(见图3(e和f中的放大部分)。为了验证表面是否有润滑膜,对磨痕区域进行了能谱分析,发现添加RHC颗粒的液体石蜡,无论在 25或 100 ℃下,表面均存在Si元素(见表1),其来源于RHC颗粒中的组分二氧化硅,这也表明 RHC颗粒参与了边界润滑膜的形成。未添加RHC颗粒的液体石蜡油表面元素大致相似,均含有C、O、Fe、Cr等元素。

图3 不同油样和温度下钢球磨痕区域的SEM图Fig.3 SEM images of worn traces of different oil samples and test temperatures

2.4 RHC颗粒摩擦磨损机制分析

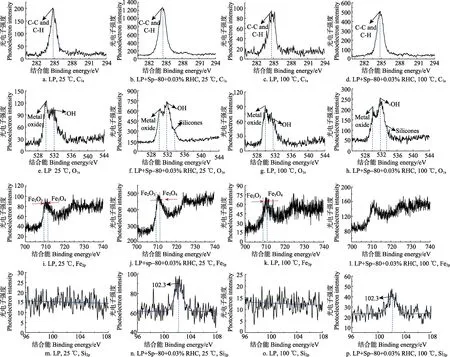

纯液体石蜡润滑时,升高温度会降低油品的黏度,油膜厚度降低,致使摩擦系数和平均磨斑直径呈现不同规律的变化。25 ℃下,RHC添加于含2% Sp-80液体石蜡时,摩擦诱导Sp-80和RHC颗粒形成的润滑膜减摩效果小于稻壳基陶瓷的磨粒磨损作用,且颗粒的团聚致使贫油磨损的发生,故摩擦系数增加;然而部分颗粒或形成的局部摩擦膜起到抗磨的功效,故使液体石蜡抗磨性增强。当温度升高到75 ℃时,纯液体石蜡的油膜厚度随黏度降低而降低,故摩擦系数和平均磨斑直径增大;添加Sp-80时,摩擦诱导Sp-80分解参与润滑膜形成,故摩擦系数减小和磨损量降低;继续添加不同量的RHC颗粒时,稻壳基陶瓷颗粒在摩擦副界面并未因温度升高而发生明显的变化,仍表现为磨粒磨损,此时,温度的升高也致使油膜厚度降低,共同致使摩擦系数呈现波动性变化。当温度升高至100 ℃下,液体石蜡黏度会进一步降低,高温也会加剧液体石蜡的氧化,与Sp-80和稻壳基陶瓷颗粒共同参与润滑膜的形成,故摩擦系数和平均磨斑直径均表现出明显的降低。为了验证该结论,利用 XPS(X-ray photoelectron spectroscopy)对25和100 ℃下,纯液体石蜡和添加2%Sp-80+0.03% RHC颗粒的油样润滑下的磨痕表面元素价态进行分析。图4为不同温度和油样下,钢球表面磨痕区域的C1s、O1s、Fe2p和Si2p谱图。

表1 25和100 ℃,不同油样磨痕区域能谱分析Table 1 Energy spectrum analysis of worn zones of different oil samples at 25 and 100 ℃ %

图4 纯液体石蜡与添加2% Sp-80和0.03% RHC油样润滑下,25和100 ℃时磨痕区域的C1s、O1s、Fe2p和Si2p谱图Fig.4 C1s, O1s, Fe2pand Si2pspectra of worn zones lubricated with pure LP and LP+2% Sp-80+0.03% RHC at 25 and 100 ℃

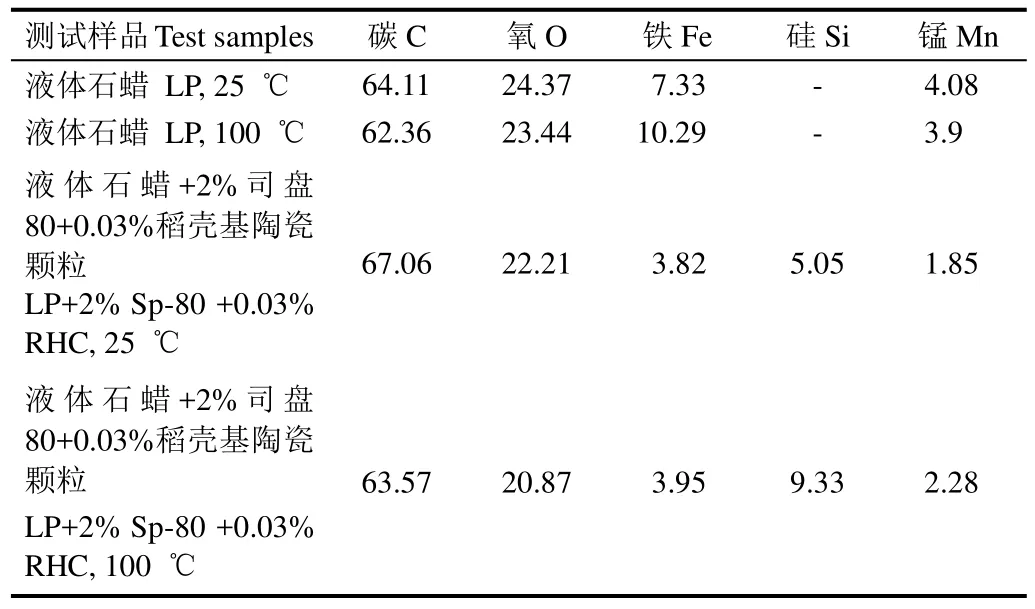

图4a、4b,4c和4d为不同温度和油样下,磨痕区域的C1s谱图,波峰位于284.7 eV为C-C或C-H,对比4张图可知碳元素化合价变化不大;图4e、4f,4g和4h为O1s的谱图,纯液体石蜡润滑下,表面氧的化合价峰位分别位于530.4和531.9 eV,归属于金属氧化物和C-OH。当添加Sp-80和RHC颗粒时,氧元素的化合价峰为530.4、531.9和533.2 eV(新峰尖),分别归属于金属氧化物、C-OH和硅烷类化合物,其中C-OH键含量明显增多,说明高温下,摩擦诱导RHC颗粒参与边界润滑膜形成。图4i、4j、4k和4l为铁元素(F2p)的化合价谱图。25 ℃下,不同油样润滑下,表面铁元素的峰形强度较高,709~711.2 eV之间属于Fe2O3和Fe3O4。温度为100 ℃时,添加Sp-80和RHC颗粒的油样,磨痕表面,铁元素峰尖明显变弱,说明铁元素的含量降低(见图4l),说明100 ℃下,摩擦诱导Sp-80和RHC颗粒形成的润滑膜厚度大于25 ℃下的润滑膜,可间接证明25 ℃下摩擦系数增加的原因。此外,图4m、4n、4o和4p为硅元素(Si2p)的化合价谱图。纯液体石蜡润滑下,表面无硅元素化合价的特征峰。当液体石蜡中添加RHC时,表面Si2p峰(102.3 eV)出现,相应的元素原子含量分别5.05%和9.33%,见表2。以上结论说明摩擦诱导稻壳基陶瓷颗粒参与了润滑膜的形成,也为高温下,摩擦系数和平均磨斑直径的降低给予充分的证明[32]。

表2 不同油样和温度下磨痕区域表面元素的原子含量Table 2 Element atom contents of worn zones of different oil samples and test temperatures %

3 结论

在25和75 ℃下,稻壳基陶瓷颗粒在一定程度上改善了液体石蜡润滑性能,主要表现在钢球表面磨斑直径的明显降低,抗磨性增强。

在 100 ℃下,稻壳基陶瓷颗粒可明显改善液体石蜡的润滑性能,摩擦系数和平均磨斑直径均降低,特别是平均摩擦系数降幅最大。当添加不同质量分数(0.01%、0.03%和 0.05%)的 RHC颗粒于液体石蜡时,平均摩擦系数与纯液体石蜡(0.139)相比,分别降低到0.083、0.064和0.069,说明稻壳基陶瓷颗粒可作为润滑油的一种高温摩擦改进剂。

高温摩擦下,添加 0.03%RHC的液体石蜡摩擦后,摩擦膜中硅原子含量为 9.33%,说明摩擦容易诱导 RHC颗粒组分参与边界润滑膜形成,致使摩擦系数和平均磨斑直径的降低,进而提升了液体石蜡的润滑性能。

[1]Ikura M, Stanciulescu M, Hogan E. Emulsification of pyrolysis derived bio-oil in diesel fuel[J]. Biomass and Bioenergy. 2003, 24: 221-232.

[2]何玉凤,钱文珍,王建凤,等. 废弃生物质材料的高附加值再利用途径综述[J]. 农业工程学报,2016,32(15):1-8.He Yufeng, Qian Wenzhen, Wang Jianfeng, et al. High value-added reutilization approach for waste biomass materials[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016,32(15): 1-8. (in Chinese with English abstract).

[3]何文修,张智亮,计建炳. 稻壳生物质资源利用技术研究进展[J]. 化工进展,2016,35(5):1366-1376.He Wenxiu, Zhang Zhiliang, Ji Jianbing. Research progress of rice husk utilization technologies[J]. Chemical Industry and Engineering Progress, 2016, 35(5): 1366-1376. (in Chinese with English abstract).

[4]Chuah T G, Jumasiah A, Azni I, et al. Rice husk as a potentially low-cost biosorbent for heavy metal and dye removal: an overview[J]. Desalination. 2005, 175: 305-316.

[5]张继义,蒲丽君,李根. 秸秆生物碳质吸附剂的制备及其吸附性能[J]. 农业工程学报,2011,27(2):104-109.Zhang Jiyi, Pu Lijun, Li Gen. Preparation of biochar adsorbent from straw and its adsorption capability[J].Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(2): 104-109. (in Chinese with English abstract).

[6]Carmona V B, Oliveira R M, Silva L, et al. Nanosilica from rice husk: Extraction and characterization[J]. Industrial Crops and Products. 2013, 43: 291-296.

[7]张永亮,赵立欣,姚宗路,等. 生物质固体成型燃料燃烧颗粒物的数量和质量分布特性[J]. 农业工程学报,2013,29(19):185-192.Zhang Yongliang, Zhao Lixin, Yao Zonglu. et al.Distribution characteristics of number and mass for particulate emission of biomass solid fuel combustion[J].Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(19):185-192. (in Chinese with English abstract).

[8]Li P, Kanda H, Makino H. Simultaneous production of bio-solid fuel and bio-crude from vegetal biomass using liquefied dimethyl ether[J]. Fuel. 2014, 116: 370-376.

[9]Soltani N, Bahrami A, Pech-Canul M I, et al. Review on the physicochemical treatments of rice husk for production of advanced materials[J]. Chemical Engineering Journal. 2015,264: 899-935.

[10]Matsuo Y, Tsuruda T, Kumagai S. Sliding properties of rice husk-derived Carbon/Silica composite[J]. Journal of the Society of Materials Engineering for Resources of Japan.2012, 24: 31-35.

[11]Jenkins B M. Global Agriculture: Industrial feedstocks for energy and materials[M]. Oxford: Academic Press, 2014,461-498.

[12]Dugarjav T, Yamaguchi T, Shibata K, et al. Friction and wear properties of rice husk ceramics under dry condition[J].Journal of Mechanical Science and Technology. 2010, 24:85-88.

[13]Dugarjav T, Yamaguchi T, Katakura S, et al. The effect of carbonizing temperature on friction and wear properties of hard porous carbon materials made from rice husk[J].Tribology Online. 2009, 4: 11-16.

[14]Shibata K, Yamaguchi T, Hokkirigawa K. Tribological behavior of RH ceramics made from rice husk sliding against stainless steel, alumina, silicon carbide, and silicon nitride[J].Tribology International. 2014, 73: 187-194.

[15]Shibata K, Yamaguchi T, Hokirrigawa K. Wear and friction properties of copper/carbon/rich bran ceramics composite under water lubricated-condition[J]. Tribology Online. 2010,6: 180-184.

[16]Shibata K, Yamaguchi T, Urabe T, et al. Experimental study on microscopic wear mechanism of copper/carbon/rice bran ceramics composites[J]. Wear. 2012, 294-295: 270-276.

[17]Shibata K, Yamaguchi T, Yao Y, et al. Friction and wear properties of Copper/Carbon/RB ceramics composite under electrical current[J]. Tribology online. 2009, 4: 131-134.

[18]Akiyama M, Yamaguchi T, Matsumoto K, et al. Polymer composites filled with RB ceramics particles as low friction and high wear resistant filler[J]. Tribology online. 2010, 5:19-26.

[19]Akiyama M, Yamaguchi T, Matsumoto K, et al. Friction and wear of polyamide 66 composites filled with RB ceramics particles under dry condition[J]. Tribology Online. 2010, 5:87-91.

[20]陶涛,张祖川,张旭,等. 纳米石墨粉和柴油烟炱作为润滑油添加剂的摩擦磨损行为研究[J]. 润滑与密封,2016,41(2):90-95.Tao Tao, Zhang Zuchuan, Zhang Xu, et al. Comparative research on tribological behavior of nano-graphite and diesel soot as lubricant additives[J]. Lubrication engineering, 2016,41(2): 90-95. (in Chinese with English abstract).

[21]Xu Zeyin, Hu Kunhong, Han Chengliang. Morphological influence of molybdenum disulfide on the tribological properties of rapeseed oil[J]. Tribology Letters, 2013, 49:513-524.

[22]王建华,宋敏,李金龙,等. 水溶性纳米二氧化硅添加剂的制备及摩擦学性能研究[J]. 摩擦学学报,2011,31(2):118-123.Wang Jian hua, Song Min, Li Jinlong, et al. The preparation and tribological properties of water soluble nano-silica particales[J]. Tribology, 2011, 31(2): 118-123. (in Chinese with English abstract).

[23]乔玉林,赵海朝,臧艳,等. 石墨烯的功能化修饰及作为润滑添加剂的应用研究进展[J]. 化工进展,2014,33(增刊1):216-223.Qiao Yulin, Zhao Haichao, Zang Yan, et al. Research progress of functionalization modifition and applications of graphene as lubrication additive[J]. Chemical Industry and Engineering Progress, 2014, 33(Supp 1): 216-223. (in Chinese with English abstract).

[24]张家玺,刘琨,胡献国. 纳米金刚石颗粒对发动机润滑油摩擦学特性的影响[J]. 摩擦学学报,2002,22(1):44-48.Zhang Jiaxi, Liu Kun, Hu Xianguo. Effect of ultra-dispersed diamond nanoparticles as additive on the tribological properties of 15W/30 engine oil[J]. Tribology, 2002, 22(1):44-48. (in Chinese with English abstract).

[25]Hu E, Hu K, Xu Z, et al. Investigation into the morphology,composition, structure and dry tribological behavior of rice husk ceramic particles[J]. Applied Surface Science. 2016,366C: 372-382.

[26]汪向阳,陈金思,徐玉福. 棉籽油生物柴油和柴油混合燃料的润滑特性[J]. 农业工程学报,2010,26(3):272-276.Wang Xiangyang, Chen Jinsi, Xu Yufu. Lubrication characteristics of mixed fuel between cottonseed oil biodiesel and diesel[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2010,26(3): 272-276. (in Chinese with English abstract).

[27]Hu E, Hu X, Liu T, et al. Role of TiF3catalyst in the tribological properties of biofuel soot-contaminated liquid paraffin[J]. Tribology International. 2014, 77: 122-131.

[28]Hu E, Hu X, Liu T, et al. Investigation of morphology,structure and composition of biomass-oil soot particles[J].Applied Surface Science. 2013, 270: 596-603.

[29]http://www.lasurface.com/database/elementxps.php.

[30]Hu E, Hu X, Liu T, et al. The role of soot particles in the tribological behavior of engine lubricating oils[J]. Wear.2013, 304: 152-161.

[31]Peng D X, Chang S Y, Kang Y, et al. Size effects of SiO2nanoparticles as oil additives on tribology of lubricant[J].Industrial Lubrication & Tribology. 1948, 62: 111-120.

[32]Qi X, Jia Z, Yang Y, et al. Characterization and auto-restoration mechanism of nanoscale serpentine powder as lubricating oil additive under high temperature[J].Tribology International. 2011, 44: 805-810.

Rice husk ceramic particles improving lubrication property of liquid paraffin

Hu Enzhu1, Yu Dongrui2, Tang Yuchao1, Wu Yun1, Hu Kunhong1, Hu Xianguo2, Song Ruhong2

(1. Department of Chemical and Materials Engineering, Hefei University, Hefei230601, China;2. Schoole of Mechanical Engineering, Hefei University of Technology, Hefei230009, China)

Comprehensive utilization of rice husk resource is important in resolving serious environmental pollutions induced by arbitrary burning and storage of rice husk. Rice husk ceramic (RHC) particles can be a functional addition in developing high-quality and high-performance engine lubricating oils and comprehensively utilizing rice husk resource. In this study,coarse RHC particles were prepared via co-carbonization of rice husk and phenolic resin with a mass ratio of 3:1 for 2 h at 900℃ under N2atmosphere. Then, the particles were ground in a planetary ball mill for 30 min to obtain fine RHC particles. Test oil samples including different contents (0.01%, 0.03%, and 0.05%) of RHC particles were prepared using a conventional magnetic stirring method until particles were uniformly dispersed in liquid paraffin (LP). Effects of different contents of RHC particles on lubrication property of LP including 2% Span-80 were investigated using a four-ball tribometer at 200 N load and 1450 r/min rotation speed for 30 min. Test temperatures of 25, 75, and 100 ℃ were selected to simulate the real engine conditions of initial and high-speed operation. Variations in friction coefficient and average wear scar diameter (AWSD)reflected the anti-friction and anti-wear properties of the different oil samples. Scanning electron microscopy/energy dispersive spectroscopy were used to observe the morphologies of wear traces and detect element contents in the wear zones for the different samples, thereby reflecting the wear form of RHC particles on the surface of friction pairs. X-ray photoelectron spectroscopy was used to detect the variations in the element chemical valence and the element’s atom contents in wear zones,and clarify the friction and wear mechanisms of RHC particles in LP under different test conditions. Results showed that friction coefficients did not obviously decrease in comparison with the pure LP, however, all AWSD decreased when different contents (i.e. 0.01%, 0.03%, and 0.05 %) of RHC particles were added into LP at 25 and 75 ℃. Therefore, the anti-wear property of LP was modified at a certain extent. When the temperature was 100 ℃, all average friction coefficients of different contents of RHC particles in LP decreased from 0.139 (LP) to 0.083, 0.064, and 0.069, respectively, and all AWSD decreased from 0.389 to 0.314, 0.311, and 0.318 mm, respectively. The anti-wear and anti-friction properties of the different contents of RHC particles in LP were obviously better than those of oil samples at 25 and 75 ℃. The Si element contentt in the wear zones of different oil samples lubricated with LP + 2% Sp-80 + 0.03% RHC at 100 ℃ was 0.51%, respectively. The Si came from the composition of RHC particles. These results indicate that friction induces RHC particles to participate in the formation of boundary lubricating film under high-temperature condition. The RHC particles can be used as a high-temperature friction-modified additive.

lubrication; particulates; friction; rice husk power; ceramic particle; liquid paraffin; frictional modifier; wear resistance and friction reduction

10.11975/j.issn.1002-6819.2017.10.035

TH117

A

1002-6819(2017)-10-0265-06

2016-10-22

2017-04-13

国家自然科学基金资助项目(51505121);安徽省自然科学基金资助项目(1608085QE119,1508085J10);安徽省教育厅自然科学基金资助项目(KJ2017A536)

胡恩柱,男(回族),安徽淮南人,讲师,博士,研究方向:生物质资源化利用,生物摩擦学。合肥,合肥学院化学与材料工程系,Email:huez@hfuu.edu.cn,huenzhu7@163.com