Rheological behavior of fresh cement pastes with a graphene oxide additive

2017-01-07WANGQinWANGJianLUChunxiangCUIXinyouLIShiyuWANGXi

WANG Qin, WANG Jian, LU Chun-xiang, CUI Xin-you, LI Shi-yu, WANG Xi

(1. Beijing Key Laboratory of Green Building and Energy Efficiency Technology, Beijing College Engineering Research Centre of EngineeringStructure and New Material, Beijing University of Civil Engineering and Architecture, Beijing100044, China;2. National Engineering Laboratory for Carbon Fiber Technology, Institute of Coal Chemistry, Chinese Academy of Sciences, Taiyuan030001, China)

Rheological behavior of fresh cement pastes with a graphene oxide additive

WANG Qin1, WANG Jian1, LU Chun-xiang2, CUI Xin-you1, LI Shi-yu1, WANG Xi1

(1.BeijingKeyLaboratoryofGreenBuildingandEnergyEfficiencyTechnology,BeijingCollegeEngineeringResearchCentreofEngineeringStructureandNewMaterial,BeijingUniversityofCivilEngineeringandArchitecture,Beijing100044,China;2.NationalEngineeringLaboratoryforCarbonFiberTechnology,InstituteofCoalChemistry,ChineseAcademyofSciences,Taiyuan030001,China)

The rheological properties and morphology of fresh cement pastes with different contents of graphene oxide (GO) were investigated by a rheometer and a laser confocal scanning microscope, respectively. The rheological data were fitted by the Modified-Bingham (M-B) model and Herschel-Bulkley (H-B) model. A mechanism for the effect of GO on the rheological properties is proposed. Results show that the cement particles are re-agglomerated and new flocculation structures are generated by the addition of GO. The new flocculation structures significantly alter the rheological properties of the pastes. The degree of re-agglomeration and the number of new flocculation structures increase with increasing GO content, leading to a sharp increase in the yield stress, plastic viscosity and the area of the hysteresis loop. GO can effectively reduce the degree of shear-thickening, and increase the critical shear rate and the stability of the pastes.

Graphene oxide; Cement paste; Rheological property; Flocculation structure

1 Introduction

With the advance in concrete construction technologies, researchers have paid more attention to not only the concrete strength and durability, but also the consistency, workability and rheological behavior of the cement paste. The suitable fluidity and viscosity of fresh cement slurry is key to assure the stability and workability to avoid aggregate segregation. Due to direct impact to consistency, workability, setting and hardening state of concrete, the rheological behavior of the fresh cement paste is crucial for achieving the desired properties of the finally solid concrete[1-5].

As the traditional cement has relatively simple composition, most of the studies focus on the effect of various additive including the water-reducing regents, fly ash, silica fume and slag on the rheological properties[6-10]. Recently, with the emerge of nano-materials in building materials, the focus has shifted to the effect of nano-materials on the rheological properties of cement paste, such as nano-SiO2, nano-TiO2, nano-ZnO and carbon nanotubes, etc.[11-14].

Graphene oxide (GO) is an exfoliation product of graphite oxide and the most important chemical derivative of graphene. The unique mechanical and chemical properties of GO make it an ideal candidate for reinforcement of composite materials[13-15]. The existence of abundant functional groups, such as hydroxyl, carboxyl and epoxy, makes GO highly chemically active and hydrophilic, which results in the homogeneous dispersion of the GO nanosheets in aqueous cement paste phase. GO nanosheets also affect the properties of cement hydration crystals, which in turn creates hardened cement pastes with increased flexural and compressive strength. According to the works reported by Lv[15], Pan[16]and Wang[17], the use of GO nanosheets offers a new mechanism to improve the compressive and flexural strength of concrete. It effectively minimizes the agglomeration and enhances the hydration reaction of cement. Nevertheless, with the addition of GO, the plastic viscosity of cement paste increases dramatically. Zhang[18]et al. demonstrated that graphene oxide encapsulated silica fume better improves the rheological properties of cement paste than single-doped GO due to the synergetic effect of the surface activity of GO and the dimentional effect of SF.

The thickening effect of GO in cement paste may become a disadvantage when applied practically; however, the improvement on the strength and toughness makes it beneficial, which thus has been the focus of many researchers. On the other hand studies to quantify the impact on the rheological properties are scarce. A solid understanding on the correlation between GO and the rheological behavior of cement paste is important to evaluate GO as a new additive, which is the focus of this study.

In this paper, the effect of GO on the rheological parameters of cement paste is studied and the micro-morphology of cement paste is investigated using Laser confocal scanning microscope (LCSM). Based on the results, the effect of GO on the rheological properties are quantified and a mechanism is proposed.

2 Experimental

2.1 Raw materials

Pure Grade Portland Cement type PI 42.5 was used to eliminate the effect of mineral mixtures on the tests. The selected physical and chemical properties was shown in Table 1 and 2 as supplied by cement manufacture. GO in water dispersion with a solid content of 3 g/L was provided by Institute of Coal Chemistry, Chinese Academy of Sciences.The GO sample was characterized using AFM and TEM and the results are illustrated in Figs. 1(a) and 1(b). The oxygen-carbon groups of GO are confirmed with FTIR, as shown in Fig. 1(c). Polycarboxylate superplasticizer (PCE) with a solid content of 15 wt% is produced by Sika.

Table 1 Physical properties of the Portland cement.

Table 2 Mineralogical components of the Portland cement.

2.2 Preparation of cement paste

The W/C (water to cement ratio) of rheological testing cement paste in this paper is kept at 0.35. The dosage of water-reducing agent is 0.8 wt% of the cement. The graphene oxide dispersion is added accordingly to make sure the equivalent GO is 0.01 wt%, 0.03 wt% and 0.05 wt% of the cement. The formula is shown in Table 3. The cement paste is prepared according to the procedure in GB/T8077-2000 of China. Water and graphene oxide dispersion or water-reducing agent are weighed and premixed accordingly. The mixture is then added to the cement in a container with agitating. The sample is stirred at a low shear rate of 62 r/min for 2 min, placed under static condition for 10 s, and then stirred at a higher shear rate of 125 r/min for 2 min to assure the homogeneity of cement paste[19]. As soon as the mixing stops, the sample is poured into the sample cup to carry out the rheological measurement.

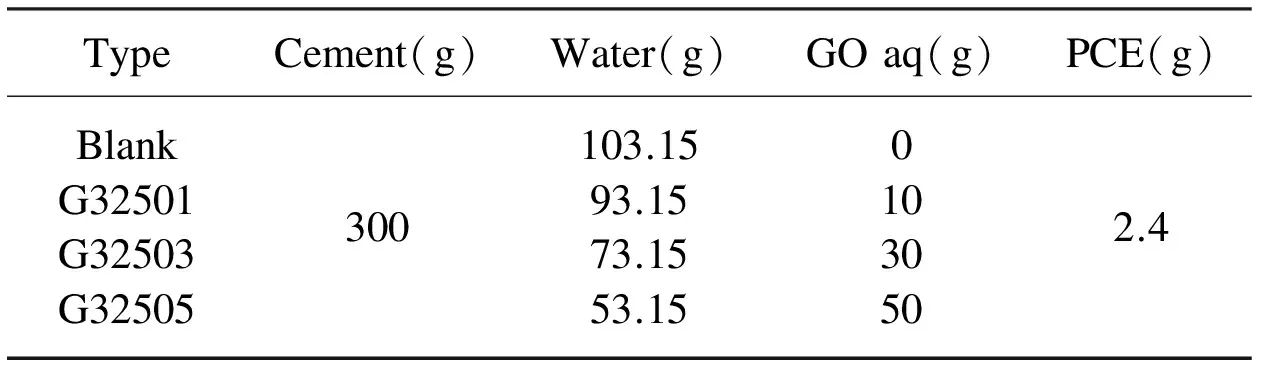

Table 3 Formulations of cement pastes.

2.3 Testing methods

2.3.1 Rheological measurements

The rheological parameters of cement paste were characterized by BROOKFIELD RST-CC rheometer from and the data was analyzed using the software RHE3000. The sample cup FTK-RST and spindle CC3-40 were used. 60 mL of the cement paste is poured to the sample cup. The selected spindle is then placed in it. They are attached to the rheometer together. After the spindle was tightened, the testing protocol was carried out. Controlling the shear rates (CSR) method wasemployed.During a test, the shear rate was increased from 5 to 150 s-1then back to 5 s-1with 16 speed intervals.

Currently, Bingham model is commonly used to characterize the rheological property of cement pastes. The plastic viscosity (ηp) and shear stress (τ0) can be obtained from the slop and intercept of the linear relationship between shear stress and rate as shown in the equation below:

τ=τ0+ηp·γ

(1)

whereτis the shear stress (Pa),ηpis the plastic viscosity (Pa·s),γis the shear rate (s-1), andτ0is the yield stress (Pa).

If the cement paste exhibits high pseudo-plastic or shear-thickening behavior, shear stress may not be calculated or the obtained value is lower than the actual one[20]. For this reason, the Bingham model is modified to better extrapolate the shear stress and plastic viscosity. The mathematic equation of the Modified-Bingham (M-B) model can be elaborated as below[21, 22].

τ=τ0+ηp·γ+c·γ2

(2)

whereτis the shear stress (Pa),ηpis the plastic viscosity (Pa·s),γis the shear rate (s-1),τ0is the yield stress (Pa), c is the constant.

In order to quantify the shear-thickening performance of cement paste, the shear stress and shear rate data are fitted using the Herschel-Bulkley (H-B) model usually[23, 24]. The model is given by:

τ=τ0+k·γn

(3)

whereτ0is the yield stress, k is the consistency, andnis the characteristic of the mixture’s behavior. The mixture is shear-thinning whenn<1 and shear-thickening whenn>1. Whenn>1, cement pastes were shear-thickening, and with the increase of the value ofn, the shear-thickening was more obvious.

2.3.2 Microstructures characterization

Nikon Ti-E Laser Confocal Scanning Microscope (LCSM) was used to investigate the morphology and microstructures of fresh cement paste. Rhodamine b was chosen as the fluorescence dye in this experiment. The mixed water is replaced by Rhodamine b solution with the concentration of 7×10-3g/L with the W/C ratio is 10. The cement paste is mixed for 30 s. After staying static for 30 s, a small amount of the suspension is placed on the glass slide for test[25-27].

3 Results and discussion

3.1 The effect of the GO on the strength and fluidity of the cement paste

Table 4 shows the effect of GO on the fluidity of fresh cement paste and the flexural and compressive strength of harden cement paste. The results show that the flexural strength and compressive strength increase by 90.5% and 40.3% at 28 days at a GO addition of 0.05 wt%, respectively. However, the fluidity of cement paste decreases significantly with the increase of GO dosage. It is obvious that the presence of GO changes the rheological properties of cement paste, which leads to a significant thickening effect. The fluidity of cement paste is closely correlated with the workability of concrete. Therefore, understanding the rheological behavior of the cement paste with GO is critical for the development of reliable GO cement composites.

Table 4 Effect of GO on paste fluidity and strength of harden cement pastes[17].

3.2 GO characterization

Fig. 1 GO characterization (a) nanosheet size and thickness of GO by AFM. (b) GO image by TEM and (c) Oxygen-containing functional groups of GO by FTIR.

3.3 The effect of the GO on the rheological properties

3.3.1 The effect of the GO on the shear stress and yield stress of the fresh cement paste

The shear stress-shear rate data are fitted using M-B model, and use this model to get the yield stress of cement paste. The effect of GO on the shear stress and yield stress of cement paste is shown in Fig. 2(a) and 2(b) respectively. Table 5 shows the rheological parameters and the fitted results by using the M-B model.

From Fig. 2(a), it can be seen that the shear stress of fresh cement paste increase with the shear rate at different GO dosage. And the more is the dosage of GO, the quicker is the increasing rate of shear stress. From Fig.2 (b), the plastic viscosity and yield stress of cement paste sharply increases with rising dosage of GO, especially when dosage higher than 0.01%. There exists a certain correlation between theτ0andηp, but theτ0is growing at a much higher rate thanηp. Theηpof the cement paste increases from 0.06 Pa·s to 0.10, 0.21 and 0.25 Pa·s and theτ0of the cement paste increases from 1.10 Pa to 1.48, 6.42 and 11.3 Pa when the dosage of GO increases from 0 to 0.05 wt%. Theτ0is the maximum stress to prevent cement paste occurring plastic deformation,ηpreflects the deformation speed of cement paste system. So with the increase of the GO, the deformation of cement paste becomes more difficult under the external force.

Fig. 2 Effect of GO addition on the (a) shear stress, (b) yield stress and (b) plastic viscosity of the fresh cement pastes. Table 5 Rheology parameters of fresh cement pastes fitted by M-B model.

TypeFittingequationτ0/Paηp/(Pa·s)CorrelativecoefficientBlankτ=1.10+0.06·γ+2.97×10-4·γ21.100.060.99846G32501τ=1.48+0.10·γ+2.37×10-4·γ21.480.100.99937G32503τ=6.42+0.21·γ+4.02×10-4·γ26.420.210.99962G32505τ=11.30+0.25·γ+3.57×10-4·γ211.300.250.99946

3.3.2 The effect of the GO on the shear deformation of the fresh cement paste

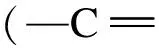

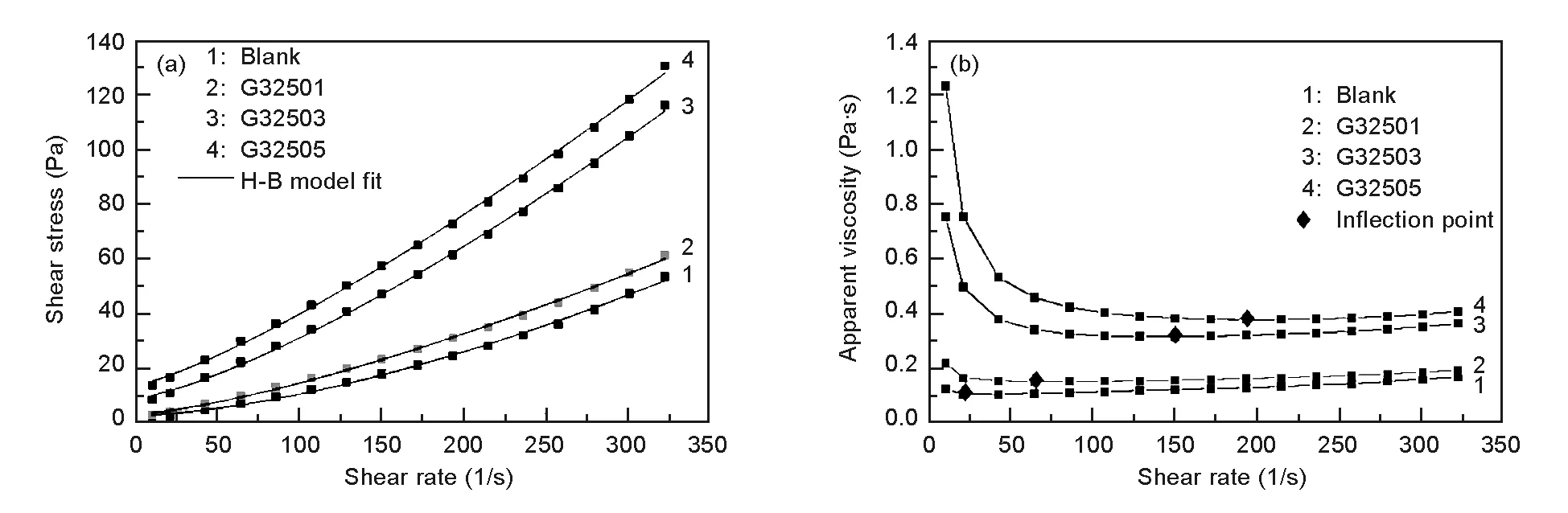

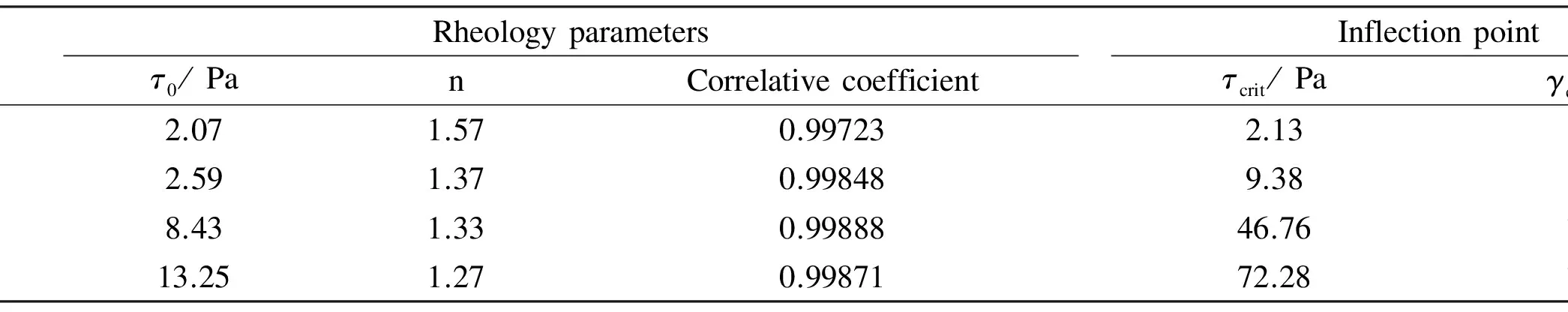

The shear deformation refers to the shear-thinning phenomenon and shear-thickening phenomenon of the cement paste. In this section, the effect of the GO on the shear deformation of the fresh cement paste was studied. Fig. 3(a) shows the fitted curves by H-B model, Table 6 shows the fitted results of shear rate-shear stress curves by H-B model and Fig.3(b) shows the effect of GO on the apparent viscosity of cement paste.

Fig. 3 Effect of GO dosage on the shear deformation of the fresh cement pastes: (a) shear rate- shear stress curves and (b) shear rate- apparent viscosity curves.

As can be seen in Fig.3(a) and Table 6, the pseudoplastic index (n) of cement pastes decreases from1.57 to 1.37, 1.33 and 1.27 when the dosage of GO increases from 0 to 0.01, 0.03 and 0.05 wt%. The flow curves obtained at low dosage of GO exhibited higher shear-thickening response than those obtained at higher dosage of GO. Fig. 3(b) show that the apparent viscosity decrease firstly and then slowly increase and there are inflection points in apparent viscosity-shear rate curves when shear rate increases. The corresponding parameters of the inflection point are critical shear rate (γcrit), critical shear stress (τcrit) and minimum viscosity (ηmin), respectively. This indicated that the cement paste is divided into two stages by inflection point, shear-thinning stage (left sides) and shear-thickening stage (right sides)[29, 30]. With the increase of the GO dosage from 0 to 0.01, 0.03 and 0.05 wt%, theγcritof cement paste increases significantly from 21.5 s-1to 64.4,150.4 and 193.3 s-1.This suggest that the cement paste with higher GO exhibits the shear-thinning effect at the higher shear rate. These results are absolutely different from those obtained from other admixtures, such as PCE[22]and fly ash[29]. Previous research has shown that the cement paste incorporating PCE exhibit a higher degree of pseudoplastic properties compared to conventional paste[23, 28].Some researchers think that the PCE acting by steric effect exhibited high shear-thickening response, and this behavior is more pronounced for paste made with Portland cement and low W/C[24]. On the basis of the above analysis, the results indicate that the GO can effectively reduce the degree of shear-thickening, improve the critical shear rate and increase the stability of the fresh cement paste.

Table 6 Rheology parameters of fresh cement pastes fitted by H-B model.

3.3.3 The effect of the GO on the thixotropic property of the fresh cement paste

The thixotropic properties of the fresh cement paste are closely related to the micro-structures of the cement paste. The effect of GO addition on the thixotropic property of the fresh cement paste is shown in Fig. 4.

From Fig.4 (a), a loop is observed between the ascent curve and the descent curve. The integrated hysteresis loop area represents the degree of thixotropy. The integration method is shown below. Through the polynomial fitting, the mathematic functions of the curves of the ascent stage and descent stage can be obtained. And the area of hysteresis loop can be calculated using the integral equation below.

(4)

whereSis the area of hysteresis loop (Pa/s);x1andx2are the initial shear rate and final shear rate, respectively;Y1andY2are the functional relationship of the curves of ascent stage and descent stage. The areas of hysteresis loop of the samples are listed in Fig. 4(b).

Fig. 4 Effect of GO dosage on the thixotropic property of the fresh cement paste.

The samples exhibit thixotropic properties, which indicate possible structures changes in cement paste. In the ascent stage, the cement paste contains a large quantity of flocculated structures, which is hard to be broken and then results in a higher shear stress at a lower shear rate. In the descent stage, due to most of the flocculation structures has been broken at the ascent stage, a large number of free cement particles and smaller flocculation structures form, and then reduce the internal friction of the paste which results in a lower shear stress at same shear rate compared with the ascent stage. Thus, the more are the number of flocculated structures, the larger are the area of hysteresis curve encircles which indicates the fresh cement paste has a higher thixotropic property.

In Fig.4, as the thixotropic effect is time dependent, the shear stress recovers when the shear is removed as shown in the curves where the loops close when back to lower shear rate. It can also be seen that the area of hysteresis loop increases with dosage of GO. According to the integral calculated result, the loop area with 0.01 wt%, 0.03 wt% and 0.05 wt% of GO is 101%, 186% and 289% of that of the blank sample, which is attributed to the abundant flocculation structures in the fresh cement paste. The higher the GO dosage, the more it is flocculated.

3.4 Effect of GO on the morphology of flocculation structures of the fresh cement paste

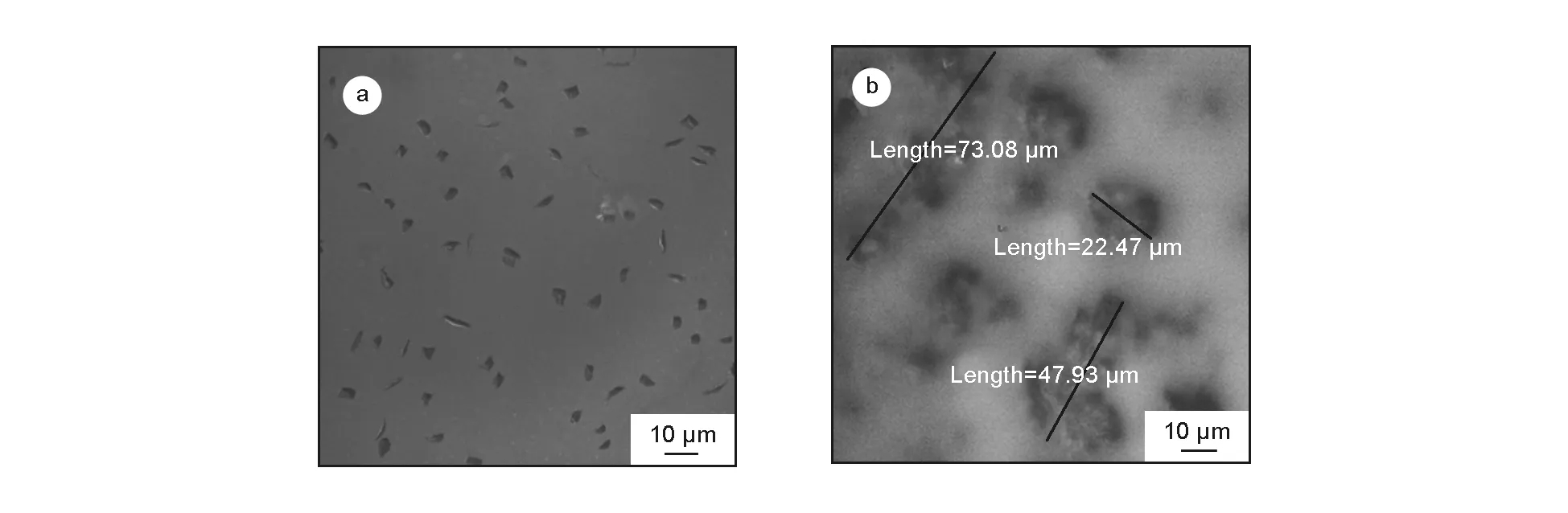

The morphology and inter structures of the different types of fresh cement paste were characterized by LCSM, shown in Fig. 5 and Fig.6. To show the effect of GO on the flocculation structures of cement paste, three types of cement paste were chosen to be investigated (1) without PCE (2) with PCE and (3) with PCE and GO.

At a water/cement ratio 10, the existence stage of the hydrated cement particles without any admixtures was illustrated in Fig. 5. The red background presents water, as Rhodamine B is employed as the fluorescent agent. When a water-reducing agent is absent, the cement paste particles will sediment as soon as agitation is removed. The majority of cement particles settle on the bottom of the container with particles smaller than 10 μm suspended in supernatant. The image of the supernatant suspension by CLSM is illustrated in Fig.5a. The image of the settled particles is illustrated in Fig.5b. From Fig.5a, it can be seen that the cement particles with the smaller size uniformly dispersed in water, without flocculation, while abundant irregular flocculated aggregations are seen on the bottom of the paste.

Fig. 5 The existence stage of the hydrated cement particles without admixtures: (a) supernatant suspension and (b) settled particles.

Fig. 6 Effect of GO dosage on the morphology and inter structures of the fresh cement pastes: (a) 0%, (b) 0.01%, (c) 0.03% and (d) 0.05%.

When the addition of water-reducing agent is added, the flocculation structures of the cement paste is retarded and the cement paste exhibits an excellent stability. After static aging for 30 s, no evident solid/liquid separation was observed. From Fig. 6(a), it can be seen that with water-reducing agent, large particle aggregations are scarce.The particles are homogenously dispersed except a few agglomerations as circled in the image.

The morphology of the cement particles are illustrated in Fig. 6(b)-6(d), when both the water reducing and GO are presented. With an addition of 0.01 wt% of GO, slight aggregation of cement particles is seen in Fig. 6(b). When the dosage of GO is increased to 0.03 wt% (Fig.6(c)) or 0.05 wt%(Fig.6 (d)), agglomeration of cement particles becomes more popular. Particularly, when the GO addition reaches 0.05 wt%, a large quantity of flocculation structures is seen and individually dispersed cement particles are very scarce. It also can be seen that the flocculation structures with GO is more packed than that of blank sample where no water reducing agent is used.

It is evident that the presence of GO alters the flocculation structures and the flocculation structures are much looser and easily to be broken, which is very different from that of the cement paste without PCE. And this is also accordance with the afore-mentioned results that the Bingham fluid model can't be applied to calculate the shear stress at the existence of GO. The addition of GO increases the re-arrangement of flocculation structures and improves the pseudo-plastic property of the fluid.

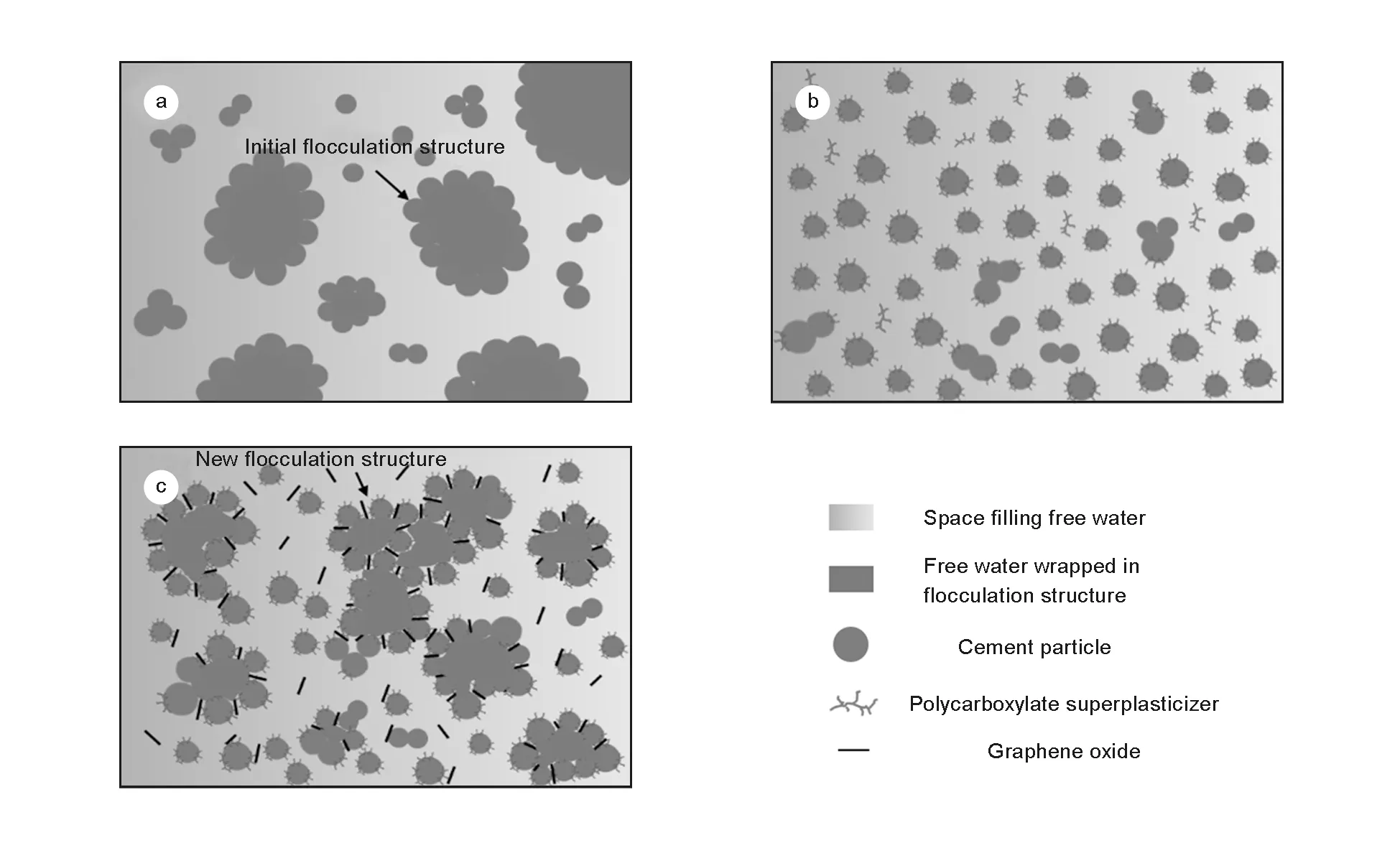

3.5 The mechanism of effect of GO on the rheological properties of the cement paste

Considering the results obtained from the rheological behavior and the images obtained by LCSM. The mechanism of effect of GO on the rheological property of the fresh cement paste is illustrated in Fig. 7.

Fig. 7 Schematic illustration of the formation of flocculation structures (a) cement paste without PCE, (b) cement paste with PCE and (c) cement paste with PCE and GO.

The re-arrangement of the flocculation structures leads to the unique rheological properties of the cement paste. With the increase of GO, the number of new flocculation structures increase, leading to a sharp increases in the yield stress, plastic viscosity and the area of the hysteresis loop of cement paste, as illustrated in Fig.2 and 4. Due to the loose structures and weak intermolecular forces of the new agglomeration of cement particles, with the increase the shear rate, the apparent viscosity of cement paste exhibits a firstly abrupt decline, and then a plateau and ultimately a slow increase, as illustrated in Fig.3 (b). With the increase of shear rate, the flocculation structures have been destroyed by the rotor, result in the decrease ofthe apparent viscosity. The cement paste shows the shear-thinning behavior. In the same time, the more is the number of the new flocculation structures, the higher is the critical shear rate. When the increase of shear rate exceed the critical shear rate (γcrit), the cement paste with a more loosen and smaller flocculation structures exhibits a shear-thickening behavior, which is similar to the result obtained from the cement paste with only PCE[22]. This results are different with the cement paste with initial flocculation structures which only exhibits a shear-thinning behavior[23]. At a higher shear rate, the new flocculation structures of cement paste are divided into smaller flocculation structures which contribute to the stability of the cement paste. This phenomenon is elaborated by the theory of "order-disorder transition" in the literature[32]. With the increase of GO, the degree of shear-thickening of cement paste is reduced and the stability of the cement paste increased.

4 Conclusions

The effects of GO on the rheological parameters of cement paste was investigated in this paper. Rheological measurement and CLSM are used to investigate the physical properties and flocculation structures of cement paste. The specific findings are summarized below:

With the increase of the GO dosage, the shear stress of fresh cement paste increase with the shear rate at different GO dosages. And the more is the dosage of GO, the quicker is the increasing rate of shear stress. The plastic viscosity and yield stress of cement paste sharply increases with rising dosage of GO, especially when dosage higher than 0.01 wt%. The dosage of GO has a noticeable thickening effect.

The pseudo-plastic index of cement pastes decreases when the dosage of GO increases. The flow curves obtained at low dosage of GO exhibited higher shear-thickening response than that obtained at higher dosage of GO. The GO can effectively reduce the degree of shear-thickening, improves the critical shear rate and increases the stability of the fresh cement paste.

With the increase of the dosage of GO, the cement paste becomes more thixotropic, which indicates that the presence of GO enhances the formation of flocculated structures. The presence of GO alters the flocculation structures and the flocculation structures is much looser and easily to be broken, which is very different from that of the cement paste without PCE.

It can also be observed from CLSM that the addition of GO result in a significant growth of the flocculation structures, which is accordant with the results from the rheological data. In conclusion, the addition of GO results in the re-arrangement of flocculation structures, which is attributed to the high specific surface area and the abundant quantity of oxygen-containing functional groups of GO. The new flocculation structures are bonded by intermolecular force.The new flocculation are smaller in size, more quantity, lower free water be packed and the whole structures is relatively loose,compared to the initial flocculation structures. This provides a novel way to control the cement paste properties and a quantitative understanding of the potential use of graphene oxide in cement industry.

[1] S Girish, R V Ranganath, Jagadish Vengala. Influence of powder and paste on flow properties of SCC[J]. Construction and Building Materials, 2010, 24(12): 2481-2488.

[2] S K Ling, A K H Kwan. Adding ground sand to decrease paste volume, increase cohesiveness and improve passing ability of SCC[J]. Construction and Building Materials, 2015, 84: 46-53.

[3] Gonzalo Barluenga, Irene Palomar, Javier Puentes. Hardened properties and microstructures of SCC with mineral additions[J]. Construction and Building Materials, 2015, 94: 728-736.

[4] Bey H B, Hot J, Baumann R, et al. Consequences of competitive adsorption between polymers on the rheological behaviour of cement pastes[J]. Cement and Concrete Composites, 2014, 54: 17-20.

[5] Zhang Y, Kong X, Gao L, et al. In-situ measurement of viscoelastic properties of fresh cement paste by a microrheologyanalyzer[J]. Cement & Concrete Research, 2016.

[6] Melo J P, Aguilar A S, Olivares F H. Rheological properties of aerated cement pastes with fly ash, metakaolin and sepiolite additions[J]. Construction and Building Materials, 2014, 65(13): 566-573.

[7] Kaufmann J, Winnefeld F, Hesselbarth D. Effect of the addition of ultrafine cement and short fiber reinforcement on shrinkage, rheological and mechanical properties of Portland cement pastes[J]. Cement and Concrete Composites, 2004, 26(5): 541-549.

[8] Calmon J L, Tristão F A, Giacometti M, et al. Effects of BOF steel slag and other cementitious materials on the rheological properties of self-compacting cement pastes[J]. Construction and Building Materials, 2013, 40(3): 1046-1053.

[9] Jiménez-Quero V G, León-Martínez F M, Montes-García P, et al. Influence of sugar-cane bagasse ash and fly ash on the rheological behavior of cement pastes and mortars[J]. Construction and Building Materials, 2013, 40(3): 691-701.

[10] Baldino N, Gabriele D, Lupi F R, et al. Rheological behaviour of fresh cement pastes: Influence of synthetic zeolites, limestone and silica fume[J]. Cement and Concrete Research, 2014, 63(9): 38-45.

[11] Collodetti G, Gleize P J P, Monteiro P J M. Exploring the potential of siloxane surface modified nano-SiO2, to improve the Portland cement pastes hydration properties[J]. Construction and Building Materials, 2014, 54(11): 99-105.

[12] Senff L, Labrincha J A, Ferreira V M, et al. Effect of nano-silica on rheology and fresh properties of cement pastes and mortars[J]. Construction and Building Materials, 2009, 23(7): 2487-2491.

[13] QU Jiang-ying, LI Yu-jia, LI Chuan-peng, et al. Synthesis of reduced graphene oxide/Mn3O4nanocomposites for supercapacitors[J]. New Carbon Materials, 2014, 29(3): 186-192.

[14] LI Shao-juan, GAN Sheng, MU Hao-ran, et al. Research progress in graphene use in photonic and optoelectronic devices[J]. New Carbon Materials, 2014, 29(5): 329-356.

[15] Lv S, Ma Y, Qiu C, et al. Effect of graphene oxide nanosheets of microstructures and mechanical properties of cement composites[J]. Construction and Building Materials, 2013, 49(12): 121-127.

[16] Pan Z, He L, Qiu L, et al. Mechanical properties and microstructures of a graphene oxide-cement composite[J]. Cement and Concrete Composites, 2015, 58: 140-147.

[17] Wang Q, Wang J, Lu C X, et al. Influence of graphene oxide additions on the microstructures and mechanical strength of cement[J]. New Carbon Materials, 2015, 30(4): 349-356.

[18] Shang Y, Zhang D, Yang C, et al. Effect of graphene oxide on the rheological properties of cement pastes[J]. Construction and Building Materials, 2015, 96: 20-28.

[19] Zhang Y, Kong X, Hou S, et al. Study on the rheological properties of fresh cement asphalt paste[J]. Construction and Building Materials, 2012, 27(1): 534-544.

[20] Celik F, Canakci H. An investigation of rheological properties of cement-based grout mixed with rice husk ash (RHA)[J]. Construction and Building Materials, 2015, 91(2015): 187-194.

[21] Yahia A, Khayat K H. Analytical models for estimating yield stress of high-performance pseudoplastic grout[J]. Cement and Concrete Research, 2001, 31(5): 731-738.

[22] Khayat K H, Yahia A. Effect of welan gum-high-range water reducer combinations on rheology of cement grout[J]. Aci Materials Journal, 1997, 94(5): 365-372.

[23] Yahia A. Shear-thickening behavior of high-performance cement grouts — Influencing mix-design parameters[J]. Cement and Concrete Research, 2011, 41(3): 230-235.

[24] Yahia A. Effect of solid concentration and shear rate on shear-thickening response of high-performance cement suspensions[J]. Construction and Building Materials, 2014, 53(2): 517-521.

[25] 张力冉, 王栋民, 张伟利, 等. 运用激光扫描共聚焦显微镜观察新拌浆体多级絮凝结构[J]. 电子显微学报, 2013, 32(3): 231-236. (Zhang L R, Wang D M, Zhang W L, et al. Observation of the multi-level flocculation structures of fresh cement pastes by confocal laser scanning microscope[J]. Journal of Chinese Electron Microscopy Society, 2013, 32(3): 231-236.)

[26] 王栋民, 张力冉, 张伟利, 等. 超塑化剂对新拌水泥浆体多级絮凝结构的影响[J]. 建筑材料学报, 2012, 15(6): 755-759. (Wang D M, Zhang L R, Zhang W L, et al. Effects of superplasticizer on multi-level flocculation structures of fresh cement paste[J]. Journal of Building Materials. 2012, 15(6): 755-759.)

[27] 张力冉, 王栋民, 潘 佳, 等. 新拌水泥浆体絮凝结构与流变行为及有效体积分数的关系[J]. 硅酸盐学报, 2014, 42(9): 1209-1218. (Zhang L R, Wang D M, Pan J, et al. Relationship between flocculent structures and rheological behavior/effective volume fraction of fresh cement paste[J].Journal of the Chinese Ceramic Society, 2014, 42(9): 1209-1218.)

[28] Khayat K H, Yahia A, Sayed M. Effect of Supplementary Cementitious Materials on Rheological Properties, Bleeding, and Strength of Structural Grout[J].Aci Materials Journal, 2008, 105(6): 585-593.

[29] 谢友均, 陈小波, 马昆林, 等. 粉煤灰对水泥浆体的剪切变稀和剪切增稠作用[J]. 硅酸盐学报, 2015, 43(8): 1040-1046. (Xie Y J, Chen X B, Ma K L, et al. Effects of fly ash on shearing thinning and thickening of cement paste[J]. Journal of the Chinese Ceramic Society, 2015, 43(8): 1040-1046.)

[30] 谢友均, 陈小波, 马昆林, 等. 石灰石粉对水泥-粉煤灰浆体剪切变稀和剪切增稠的影响[J]. 建筑材料学报, 2015, 18(5): 824-829. (Xie Y J, Chen X B, Ma K L, et al. Effects of limestone powder on shear thinning and shear thickening of cement-fly ash paste[J]. Journal of Building Materials, 2015, 18(5): 824-829.)

[31] Zhang Y, Kong X. Correlations of the dispersing capability of NSF and PCE types of superplasticizer and their impacts on cement hydration with the adsorption in fresh cement pastes[J]. Cement & Concrete Research, 2015, 69(69): 1-9.

[32] Hoffman R L. Explanations for the cause of shear thickening in concentrated colloidal suspensions[J]. Journal of Rheology, 1998, 42(42): 111-123.

1007-8827(2016)06-0574-11

氧化石墨烯水泥浆体流变性能的定量化研究

王 琴1, 王 健1, 吕春祥2, 崔鑫有1, 李时雨1, 王 皙1

(1.北京建筑大学 土木与交通工程学院 工程结构与新材料北京市高校工程研究中心 绿色建筑与节能技术北京市重点实验室,北京100044;2.中国科学院山西煤炭化学研究所 碳纤维制备技术国家工程实验室,山西 太原030001)

采用流变仪和激光共聚焦显微镜对不同氧化石墨烯(GO)掺量的新拌水泥浆体的流变参数以及浆体微观形态进行了定量化研究,并采用Modified-Bingham (M-B)模型和Herschel-Bulkley (H-B)模型对所测数据进行了拟合处理,提出了GO影响新拌水泥浆体的作用机理。结果表明,GO的掺入可以使新拌浆体中在减水剂作用下分散的水泥颗粒发生再次凝聚,形成重组絮凝结构,且随着GO掺量的增加,重组絮凝结构的数量越多,从而使得浆体流变性发生显著变化。一方面,新拌浆体的塑性粘度、屈服应力以及触变性随GO掺量的提高而显著增加。另一方面,GO的掺入提高了新拌浆体的临界剪切速率,使其在较大剪切速率下的流变行为仍然表现为剪切变稀;降低了浆体的剪切增稠程度,提高了浆体的稳定性。

氧化石墨烯; 水泥浆体; 流变性能; 絮凝结构

TB321

A

国家自然科学基金(51508020); 北京市教育委员会基金资助项目(KM201510016003); 北京高校创新团队建设与教师职业发展计划项目(IDHT2013).

王 琴,讲师. E-mail: wangqin@bucea.edu.cn

Foundationitem: National Natural Sciences Foundation of China (51508020); Beijing Educational Commission (KM201510016003); Beijing College Innovation Team-building and Teacher Career Development Project (IDHT2013).

WANG Qin, Lecturer. E-mail: wangqin@bucea.edu.cn

10.1016/S1872-5805(16)60033-1

Receiveddate: 2016-08-15:Reviseddate: 2016-12-10

English edition available online ScienceDirect (http:www.sciencedirect.comsciencejournal18725805).

猜你喜欢

杂志排行

新型炭材料的其它文章

- Al-Si-C改性C/C复合材料的微结构特征与烧蚀行为

- Microstructure and molten salt impregnation characteristics of a micro-fine grain graphite for use in molten salt reactors

- 含空位缺陷单壁碳纳米管断裂行为的有限元模拟

- 氧化石墨烯对L-色氨酸荧光猝灭及机理研究

- Microstructures of carbon nanoscrolls characterized by polarized micro-Raman spectroscopy

- 纳米MnO2/膨胀石墨复合材料的制备及其电化学性能