Recent advances on thermal analysis of stretchable electronics

2016-12-09YuhngLiYuynGoJizhouSong

Yuhng Li,Yuyn Go,Jizhou Song,c,∗

aInstitute of Solid Mechanics,Beihang University(BUAA),Beijing 100191,China

bDepartment of Engineering Mechanics,Zhejiang University,Hangzhou 310027,China

cSoft Matter Research Center,Key Laboratory of Soft Machines and Smart Devices of Zhejiang Province,Zhejiang University,Hangzhou 310027,China

Review

Recent advances on thermal analysis of stretchable electronics

Yuhang Lia,Yuyan Gaob,Jizhou Songb,c,∗

aInstitute of Solid Mechanics,Beihang University(BUAA),Beijing 100191,China

bDepartment of Engineering Mechanics,Zhejiang University,Hangzhou 310027,China

cSoft Matter Research Center,Key Laboratory of Soft Machines and Smart Devices of Zhejiang Province,Zhejiang University,Hangzhou 310027,China

H I G H L I G H T S

•Recent advances on thermal analysis of stretchable electronics are overviewed.

•Scaling laws for the temperature increase in a constant and pulsed mode are established.

•Design guidelines for thermal management of stretchable electronics are provided.

A R T I C L EI N F O

Article history:

Accepted 16 December 2015

Available online 24 December 2015

Stretchable electronics

Thermal analysis

Scaling law

Stretchable electronics,which offers the performance of conventional wafer-based devices and mechanical properties of a rubber band,enables many novel applications that are not possible through conventional electronics due to its brittle nature.One effective strategy to realize stretchable electronics is to designtheinorganicsemiconductormaterialinastretchableformatonacompliantelastomericsubstrate. Engineering thermal management is essential for the development of stretchable electronics to avoid adverse thermal effects on its performance as well as in applications involving human body and biological tissues where even 1–2°C temperature increase is not allowed.This article reviews the recent advances inthermalmanagementofstretchableinorganicelectronicswithfocusesonthethermalmodelsandtheir comparisons to experiments and finite element simulations.

©2015 The Authors.Published by Elsevier Ltd on behalf of The Chinese Society of Theoretical and Applied Mechanics.This is an open access article under the CC BY-NC-ND license(http:// creativecommons.org/licenses/by-nc-nd/4.0/).

Contents

1.Introduction........................................................................................................................................................................................................................32

2.Thermal analysis ofµ-ILEDs under a constant power.....................................................................................................................................................33

3.Thermal analysis ofµ-ILEDs in a pulsed operation.........................................................................................................................................................33

4.Thermal analysis ofµ-ILEDs in optogenetics...................................................................................................................................................................36

5.Summary............................................................................................................................................................................................................................37

Acknowledgments.............................................................................................................................................................................................................37

References...........................................................................................................................................................................................................................37

1.Introduction

Fast developments and substantial achievements have been made on various aspects of stretchable electronics[1–7],which hassuperiormechanicalpropertiesthatareinaccessibletoconventional wafer-based electronics such as stretched like a rubber band and twisted like a rope without any significant reduction in electronic performance.Two complementary approaches have been demonstratedtodevelopstretchableelectronics.Oneapproachinvolves the use of the intrinsically compliant semiconductor materials to replace the intrinsically brittle inorganic semiconductor materials[8–11]that are widely used in conventional electronics. The other approach designs conventional high-performance inorganic semiconductor materials(e.g.,Silicon)in a novel stretchable structure on a compliant substrate[12–15].One such design is the bridge-island design with functional components residing on the islandinterconnectedbythebridgestokeeptheislandsalmostun-deformed under stretching as shown in Fig.1(a)of inorganic lightemitting diodes stretched onto the sharp tip of a pencil.

Fig.1.(a)Stretchable inorganic light-emitting diodes with serpentine bridges,tightly stretched onto the sharp tip of a pencil.Reproduced with permission from Ref.[15]. Copyright 2010 Nature Publishing Group.(b)Scanning electron microscope(SEM)image of an injectable array ofµ-ILEDs and the process of injection and release of the µ-ILEDs into the mouse brain for in vivo optogenetics.Reproduced with permission from Ref.[16].Copyright 2013 AAAS.

Thermal management of stretchable electronics is critically important because excessive heating may induce adverse responses such as the reduction of device performance and tissue lesioning(even 1–2°C temperature increase)in applications(e.g.,optogenetics,see Fig.1(b))involving biological tissues.The low conductivity(~0.1 W·m−1·K−1)of elastomeric substrate for stretchable electronics,which is about 3 orders lower than that of typical substrate for conventional electronics,imposes more challenges on the thermal management.This review paper will focus on the latter approach based on inorganic semiconductor materials and take microscale,inorganic light-emitting diodes (µ-ILEDs),which serve as heat sources and the active device islands in the bridge-island design for stretchable electronics,as an example to overview the recent advances in heat management of stretchable electronics through discussions of analytic,finite element simulations and experimental results.

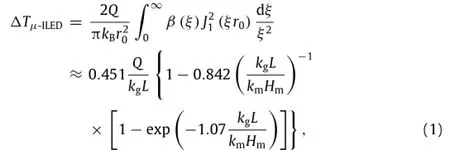

2.Thermal analysis ofµ-ILEDs under a constant power

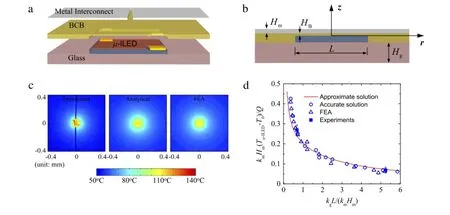

The temperature increase in Eq.(1)is for the singleµ-ILED on a glass substrate and it can be easily extended to study otherµ-ILED system with similar layouts and materials.Figure 3(a)shows the µ-ILED temperature as a function ofµ-ILED size on a polyethylene terephthalate(PET)substrate at 160 mW ·mm2.The analytical prediction agrees very well with experiments.The temperature decreases with decreasing theµ-ILED size,which clearly indicates an effective route for thermal management:to divide a large LED to an array ofµ-ILEDs.To find the temperature increase forµ-ILED array,the method of superposition can be used,i.e.,∑whereΔTi(r,z)is the temperature increase due to ithµ-ILED.The temperature increases for a conventional, macro-size LED(i.e.,0.5×0.5 mm2),an array of 25µ-ILEDs(i.e., 100×100µm2)at different spacings are shown in Fig.3(b).The temperature ofµ-ILED array decreases with increasing spacing and becomes independent of spacing for the spacing larger than~200µm,which suggests a critical spacing to maximally reduce the temperature.

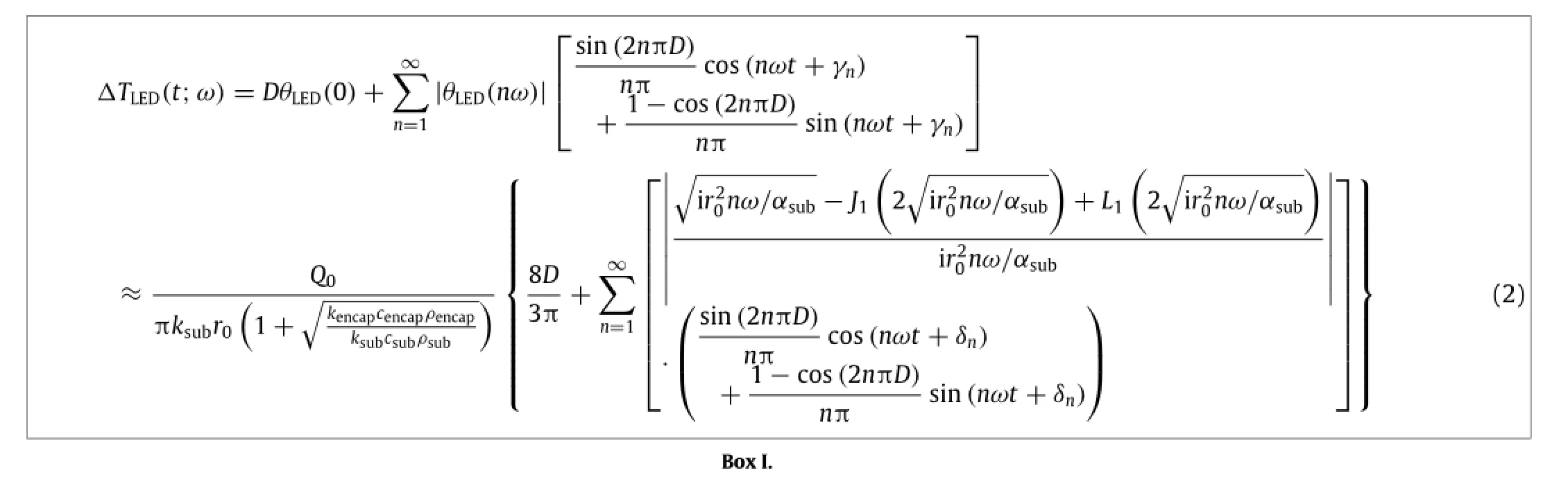

3.Thermal analysis ofµ-ILEDs in a pulsed operation

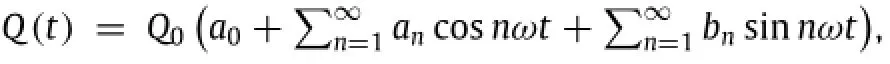

Fig.2.Thermal management ofµ-ILEDs on a glass substrate.(a)Three-dimensional illustrations of theµ-ILED structure.(b)A schematic illustration of the analytical model.(c)Surface temperature distribution given by experiments,analytical model and FEA for the input power Q=37.6 mW with L=100µm.(d)The normalized µ-ILED temperature increase as the function of the normalizedµ-ILED size for the approximate solution(solid line),accurate solution(circles),FEA(triangles)and experiments(squares).Reproduced with permission from Ref.[17].Copyright 2012 The Royal Society.

Fig.3.Thermal management by controlling size and spatial distributions ofµ-ILEDs on a PET substrate.(a)Measured(black symbols)and analytical predicted(black line) temperature as a function ofµ-ILED size at 160 mW/mm2.(b)Measured and(black symbols)and analytical predicted(black line)temperature of(5×5)µ-ILED array (100×100µm2)as a function of spacing.Reproduced with permission from Ref.[18].Copyright 2012 Wiley-VCH Verlag GmbH&Co.KGaA,Weinheim.

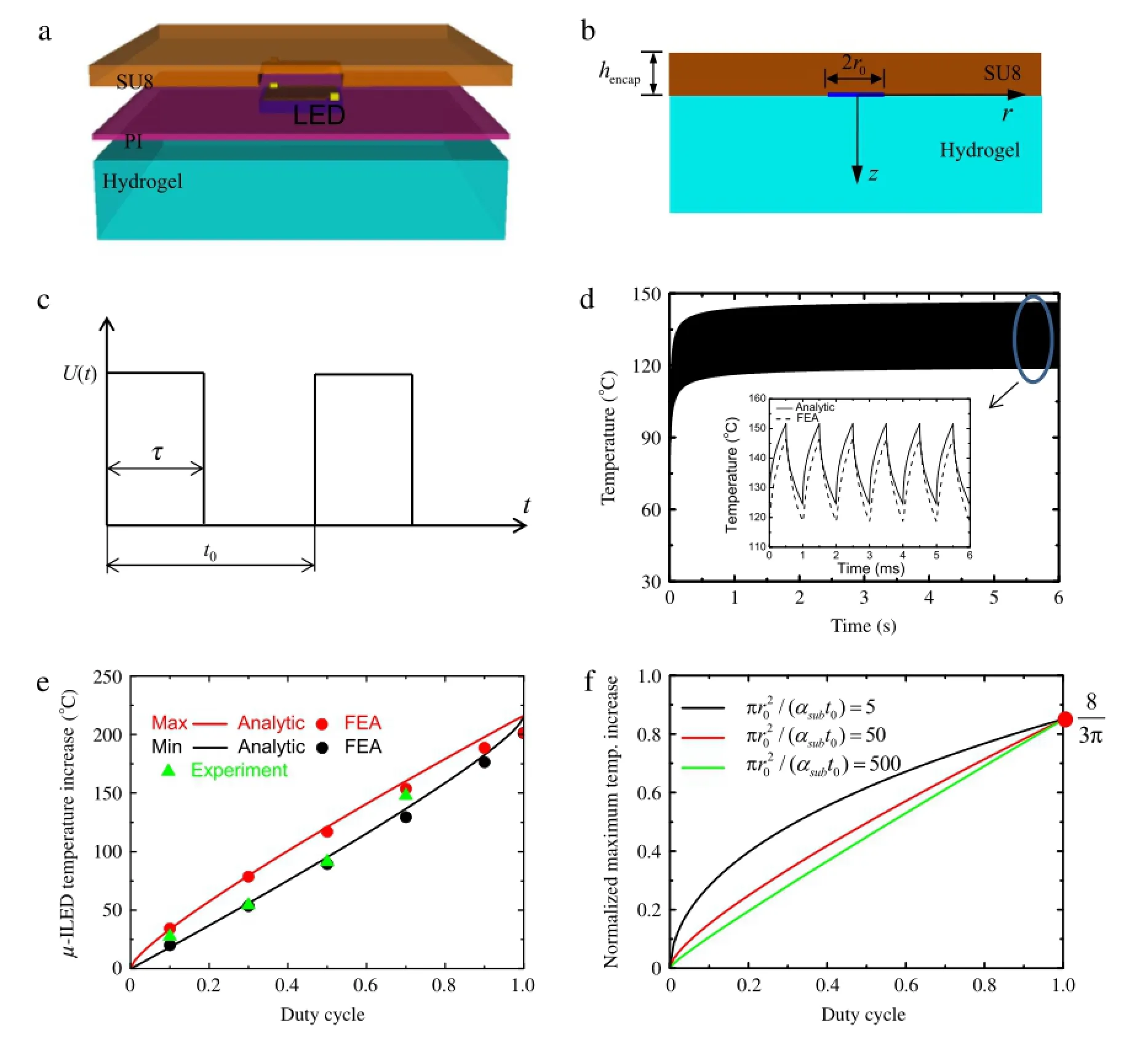

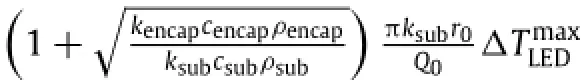

Fig.4.(a)Three-dimensional illustration of theµ-ILED on a hydrogel substrate.(b)A schematic illustration of the analytical model.(c)A unit pulsed power with duration timeτand period t0.(d)Temperature for the pulsed peak power 20 mW with D=50%and t0=1 ms with the inset as the temperature after saturation.(e)The maximum and minimumµ-ILED temperature increase as the function of the duty cycle for the peak power 30 mW with t0=1 ms.(f)The normalized maximumµ-ILED temperature increase at a pulsed power as the function of the duty cycle.Reproduced with permission from Ref.[19].Copyright 2013 American Institute of Physics.

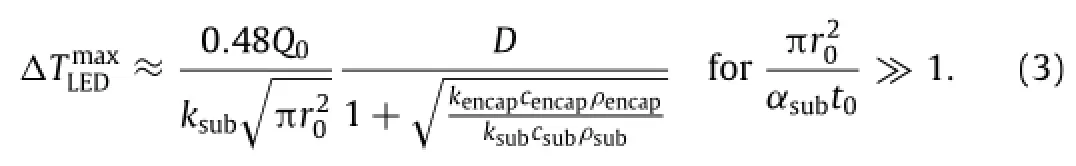

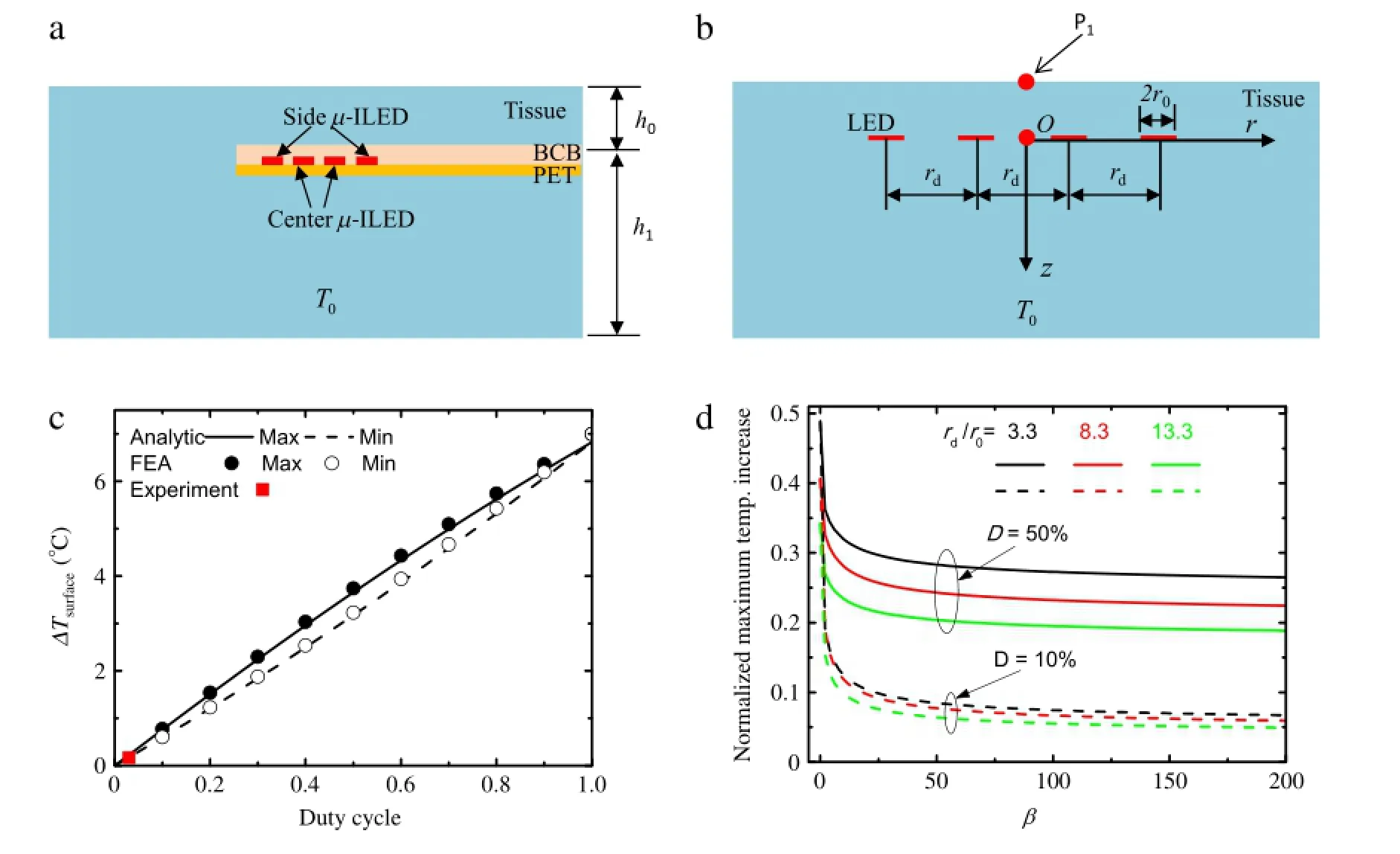

Fig.5.(a)Cross-sectional illustration of fourµ-ILEDs in biological tissue.(b)A schematic illustration of the analytical model.(c)Surface temperature increase determined by analytical model,FEA,and experiments as the function of duty cycle with the frequency 3 Hz,peak power Q0=2.5 mW,r0=60µm,rd=200µm,h0=0.3 mm,and h1=3.7 mm.(d)Maximum normalized temperature increase of centerµ-ILED as the function of the normalized parameter.Reproduced with permission from Ref.[20]. Copyright 2013 The Royal Society.

4.Thermal analysis ofµ-ILEDs in optogenetics

Li et al.[21]further extended the above model to perform thermal management ofµ-ILEDs in optogenetics.Kim et al.[21] developed injectable,wireless optoelectronic devices withµ-ILED arrays delivered into the mouse brain using a releasable microneedle for in vivo optogenetics.Figure 5(a)schematically shows the cross-section of fourµ-ILEDs coated with a thin(6µm) layer of benzocyclobutene(BCB)on a 2.5µm thick polyethylene terephthalate(PET)substrate in an explanted piece of tissue from the mouse brain with the dimension of 9×4×4 mm3held at T0= 37°C by a thermal stage.h0and h1denote the tissue thicknesses above and below theµ-ILEDs,respectively.The thermal properties of BCB and PET are similar to those of tissue,and therefore their effects on the temperature are neglected.Li et al.[21] developed an analytical model forµ-ILED arrays in a pulsed operation in biological tissues and established a simple scaling law for the maximum temperature increase in terms of material, geometric and loading parameters.An array of 4µ-ILEDs used in experiments[16]is taken as an example to illustrate the approach.

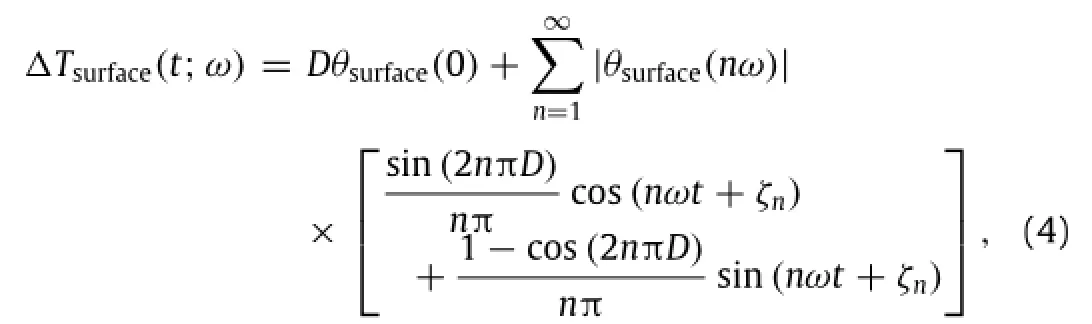

Figure 5(b)shows a schematic illustration of the analytical model for 4µ-ILEDs in the tissue with a pulsed power Q(t)= Q0U(t)applied to a singleµ-ILED.Let rddenote the distance between the centers of two adjacentµ-ILEDs.With the origin at the center of arrays,the coordinates ofµ-ILED centers are (±3rd/2,0)and(±rd/2,0),respectively.Following the similar approach as the one forµ-ILED on a hydrogel substrate[20],the temperature increase for a singleµ-ILED in biological tissue is obtained first and then the method of superposition is used to obtain the temperature increase for theµ-ILED array.Letθ(r,z;ω) denote the temperature increase for a singleµ-ILED due to a sinusoidal power Q0cos(ωt)[or Q0sin(ωt)].The temperature increase at the center point P1of the top surface due to a sinusoidal power is obtained as.The temperature increase at the center point P1of the top surface due to the pulsed power is then obtained as

whereζnis the phase angle ofwith the expression that canfoundinRef.[21].Figure5(c)comparesthemaximumandminimum temperature increase after saturation from Eq.(4),3D FEA andexperimentsforthefrequency3Hz,peakpowerQ0=2.5mW, r0=60µm,rd=200µm,h0=0.3 mm,and h1=3.7 mm.The good agreement indicates that the analytical model could predict the temperature distributions accurately.

The maximum temperature increase in the array of four µ-ILEDs occurs at the centerµ-ILED.For large ratios of h0/r0and h1/r0as in experiments[21],the analytical model gives the normalized temperature increase of the centerµ-ILED as in Box II, where E is the complete elliptic integral of the second kind,β= A/(αt0)withas the total surface area ofµ-ILED,J0is 0th-order Bessel function of the first kind,andηnis the phase angle ofdξ. Eq.(5)shows a simple scaling law for the normalized maximum temperature increaseas shown in Fig.5(d),which only depends on three non-dimensional parameters:βand D.The normalized maximum temperature increase of the centerµ-ILED drops significantly for 0<β<40 and then remains almost unchanged forβ>40.The results show that largesmallβand D help to reduce the maximum temperature increase.The above results forµ-ILEDs in a constant or pulsed operation are applied to optimize the injectable optoelectronics tomaintain the temperature low enough to avoid tissue lesioning for in vivo optoelectronics[16].

5.Summary

In summary,with fast developments and substantial achievements made on various aspects of stretchable electronics,thermal management of stretchable electronics becomes more and more important due to its adverse effects on its performance as well as in applications involving human body,where even a small temperature increase(1–2°C)is not allowed.This paper overviews the recent advances on thermal analysis of stretchable inorganic electronics and provides design guidelines for thermal management(e.g.,to use small functional components in a pulsed mode). Whileseveraleffortshavebeendevotedtodevelopanalyticalmodels with certain assumptions,there are still many open challenges and opportunities for future research.For example,a biophysically realistic model,which accounts for the effects of blood perfusion and metabolic heat generation,is needed and remain an attracting area of research.Such a model will help researchers to optimally design experiment and offer the possibility of direct integration of stretchable electronics and optoelectronics with biological tissues for emerging applications.

Acknowledgments

This work was supported by the Zhejiang Provincial Natural Science Foundation of China(Grant No.LR15A020001),the National Natural Science Foundation of China(Grant Nos.11502009, 11372272 and 11321202),and the National Basic Research Program of China(Grant No.2015CB351900).

References

[1]D.H.Kim,J.H.Ahn,W.M.Choi,et al.,Stretchable and foldable silicon integrated circuits,Science 320(2008)507–511.

[2]J.Viventi,D.H.Kim,L.Vigeland,et al.,Flexible,foldable,actively multiplexed, high-density electrode array for mapping brain activity in vivo,Nature Neurosci.14(2011)1599–1605.

[3]D.H.Kim,R.Ghaffari,N.Lu,et al.,Flexible and stretchable electronics for biointegrated devices,Annu.Rev.Biomed.Eng.14(2012)113–128.

[4]H.C.Ko,M.P.Stoykovich,J.Song,et al.,A hemispherical electronic eye camera based on compressible silicon optoelectronics,Nature 454(2008)748–753.

[5]R.C.Webb,A.P.Bonifas,A.Behnaz,et al.,Ultrathin conformal devices for preciseandcontinuousthermalcharacterizationofhumanskin,NatureMater. 12(2013)938–944.

[6]S.Xu,Y.Zhang,L.Jia,et al.,Soft microfluidic assemblies of sensors,circuits, and radios for the skin,Science 344(2014)70–74.

[7]C.Dagdeviren,B.D.Yang,Y.Su,et al.,Conformal piezoelectric energy harvesting and storage from motions of the heart,lung,and diaphragm,Proc. Natl.Acad.Sci.USA 111(2014)1927–1932.

[8]B.Crone,A.Dodabalapur,Y.Y.Lin,etal.,Large-scalecomplementaryintegrated circuits based on organic transistors,Nature 403(2000)521–523.

[9]Y.L.Loo,T.Someya,K.W.Baldwin,et al.,Soft,conformable electrical contacts for organic semiconductors:high-resolution plastic circuits by lamination, Proc.Natl.Acad.Sci.USA 99(2002)10252–10256.

[10]T.Sekitani,T.Yokota,U.Zschieschang,et al.,Organic nonvolatile memory transistors for flexible sensor arrays,Science 326(2009)1516–1519.

[11]M.Kaltenbrunner,T.Sekitani,J.Reeder,et al.,An ultra-lightweight design for imperceptible plastic electronics,Nature 499(2013)458–463.

[12]H.Jiang,D.Y.Khang,J.Song,et al.,Finite deformation mechanics in buckled thin films on compliant supports,Proc.Natl.Acad.Sci.USA 104(2007) 15607–15612.

[13]D.H.Kim,J.Song,W.M.Choi,et al.,Materials and noncoplanar mesh designs for integrated circuits with linear elastic responses to extreme mechanical deformations,Proc.Natl.Acad.Sci.USA 105(2008)18675–18680.

[14]S.Xu,Y.Zhang,J.Cho,et al.,Stretchable batteries with self-similar serpentine interconnects and integrated wireless recharging systems,Nature Commun.4 (2013)1543.

[15]R.H.Kim,D.H.Kim,J.Xiao,et al.,Waterproof AlInGaP optoelectronics on stretchable substrates with applications in biomedicine and robotics,Nature Mater.9(2010)929–937.

[16]T.Kim,J.G.McCall,Y.H.Jung,et al.,Injectable,cellular-scale optoelectronics with applications for wireless optogenetics,Science 340(2013)211–216.

[17]H.S.Kim,E.Brueckner,J.Song,et al.,Unusual strategies for using indium gallium nitride grown on silicon(111)for solid-state lighting,Proc.Natl.Acad. Sci.USA 108(2011)10072–10077.

[18]C.Lu,Y.Li,J.Song,et al.,A thermal analysis of the operation of microscale, inorganic light-emitting diodes,Proc.R.Soc.Lond.Ser.A Math.Phys.Eng.Sci. 468(2012)3215–3223.

[19]T.Kim,Y.H.Jung,J.Song,et al.,High-efficiency,microscale GaN light-emitting diodes and their thermal properties on unusual substrates,Small 8(2012) 1643–1649.

[20]Y.Li,Y.Shi,J.Song,et al.,Thermal properties of microscale inorganic lightemitting diodes in a pulsed operation,J.Appl.Phys.113(2013)144505.

[21]Y.Li,X.Shi,J.Song,et al.,Thermal analysis of injectable,cellular-scale optoelectronics with pulsed power,Proc.R.Soc.Lond.Ser.A Math.Phys.Eng. Sci.469(2013)20130142.

16 October 2015

in revised form 2 December 2015

http://dx.doi.org/10.1016/j.taml.2015.12.001

2095-0349/©2015 The Authors.Published by Elsevier Ltd on behalf of The Chinese Society of Theoretical and Applied Mechanics.This is an open access article under the CC BY-NC-ND license(http://creativecommons.org/licenses/by-nc-nd/4.0/).

∗at:Department of Engineering Mechanics,Zhejiang University,Hangzhou 310027,China.

E-mail address:jzsong@zju.edu.cn(J.Song).

杂志排行

Theoretical & Applied Mechanics Letters的其它文章

- Editorial:Recent advances in mechanics of unconventional electronics

- The finite deformation of the balloon catheter

- Adhesion-governed buckling of thin-film electronics on soft tissues

- Mechanics of bioinspired imaging systems

- Recent development of transient electronics

- Acoustomechanics of semicrystalline polymers