Effect of temperature on the compressive behavior of carbon fiber composite pyramidal truss cores sandwich panels with reinforced frames

2016-11-14XiaodongLiLinzhiWuLiMaXiangqiaoYan

Xiaodong Li,Linzhi Wu∗,Li Ma,Xiangqiao Yan

Center for Composite Materials,Harbin Institute of Technology,Harbin 150001,China

Effect of temperature on the compressive behavior of carbon fiber composite pyramidal truss cores sandwich panels with reinforced frames

Xiaodong Li,Linzhi Wu∗,Li Ma,Xiangqiao Yan

Center for Composite Materials,Harbin Institute of Technology,Harbin 150001,China

H i G H L i G H T s

•Pyramidal panels are fabricated by the water jet cut and interlocking method.

•Good agreement is found between predictions and measurements.

•Results show that the increase of temperature decreases the stiffness and strength.

•The failure modes of sandwich panel under different temperatures are different.

A R T i C L Ei N F O

Article history:

22 January 2016

Accepted 6 February 2016

Available online 4 March 2016

Pyramidal truss structures

Temperature

Novel reinforced frame

Out-of-plane compression

This paper focuses on the effect of temperature on the out-of-plane compressive properties and failure mechanismofcarbonfiber/epoxycompositepyramidaltrusscoressandwichpanels(CF/CPTSP).CF/CPTSP withnovelreinforcedframesaremanufacturedbythewaterjetcuttingandinterlockingassemblymethod in this paper.The theoretical analysis is presented to predict the out-of-plane compressive stiffness and strength of CF/CPTSP at different ambient temperatures.The tests of composite sandwich panels are performedthroughoutthetemperaturerangefrom-90◦Cto180◦C.Goodagreementisfoundbetweentheoretical predictions and experimental measurements.Experimental results indicate that the low temperature increases the compressive stiffness and strength of CF/CPTSP.However,the high temperature causes the degradation of the compressive stiffness and strength.Meanwhile,the effects of temperature on the failure mode of composite sandwich panels are also observed.

©2016 The Authors.Published by Elsevier Ltd on behalf of The Chinese Society of Theoretical and Applied Mechanics.This is an open access article under the CC BY-NC-ND license(http:// creativecommons.org/licenses/by-nc-nd/4.0/).

1.Introduction

Composite truss core sandwich structures have the significant advantage in astronautic and aeronautic applications owing to their high specific stiffness and strength.In recent years,different composite sandwich panels have been designed,tested and analyzed[1-6].Wang et al.[7]fabricated carbon fabric composite pyramidal truss core sandwich panels by using a hot press process.The stiffness and strength of pyramidal truss structures panels were investigated under compression and shear loadings.Xiong et al.[8]manufactured carbon fiber/epoxy composite lattice core sandwich panels by laser cutting.The stiffness and strength of composite lattice core sandwich panels were investigated under out-of-plane compressive.Fan et al.[9]studied the out-of-plane compression,in-plane compression,and threepoint bending properties of carbon fiber/epoxy composite pyramidal truss cores sandwich panels(CF/CPTSP).The delamination and local buckling were revealed by experiments.Experimental results showed that carbon fiber reinforced lattice grids are much stiffer and stronger than foams and honeycombs.George et al.[10]manufactured carbon fiber composite sandwich panels with pyramidal truss core by employing a snap-fitting method.The Euler buckling and delamination of the struts were observed in shear tests.

It is generally known that polymer matrix of composite sandwich panels are very sensitive to temperature change,lead to potentially dangerous for aeronautical and naval applications where low or high temperature conditions can occur[11-14].However,theresearchonCF/CPTSPmostlyfocusedontheroomtemperature. Currently,the low temperature or high temperature performances of composite laminates have been studied by many researchers. Caoetal.[15]studiedthetensilepropertiesofcompositelaminates subjected to high temperature and they found that temperaturehas the important effect on the strength and failure mode of fiberreinforced polymer composites.Grape et al.[16]study on the effectoftemperatureoncompressivedeformationandfailuremechanisms of two-dimensional braided carbon fiber reinforced polyimide composite laminate.They discovered temperature affects the compressive strength and failure mode of carbon fiber reinforced polyimide composite laminate.Currently,a some work has beendonetoelucidatetheeffectoftemperatureonthemechanical propertiesofCF/CPTSP.Liuetal.[17]investigatedtheeffectoftemperature on compressive strength and stiffness of CF/CPTSP under out-of-plane compression.They adopted the method of hot compression molding to manufacture all-composite pyramidal truss core sandwich structures in one step,in contrast,in this paper,the preparation process is more simple and can be used for mass production.With the introduction of reinforced frames,the bonding area between core and face sheet is increased,the relative slippage isrestrictedandthentheinterfacialfailureisavoided,thusthemechanical properties are increased effectively.

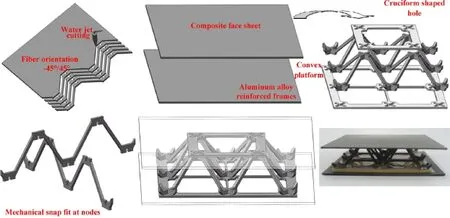

Fig.1.Illustration of the manufacturing route of CF/CPTSP.(a)Patterns of water jet cutting from the-45◦/45◦laminate sheets.The fiber directions are shown in this sketch and indicate that half of the fibers are distributed along the truss axial direction.(b)Interlocking assembly of patterns to form a pyramidal truss core.(c)The assembly process of CF/CPTSP with novel reinforced frames.(d)Pyramidal lattice core with aluminum alloy reinforced frames.(e)Pyramidal truss core sandwich panel.

In the present work,a novel method of water jet cut and interlocking assembly is used to manufacture CF/CPTSP with reinforced frames.The out-of-plane compressive behavior and failure mechanism of CF/CPTSP at the temperature range from -90◦C to 180◦C are investigated,and analytical models are presented to predict the out-of-plane compressive stiffness and strength at different temperatures.

2.Experiment

2.1.Materials and panel fabrication

Continuous carbon fiber reinforced epoxy resin composite is used to fabricate the pyramidal lattice truss core sandwich structure because its high specific stiffness/strength.The sample of carbon fiber reinforced polymer(CFRP)laminate is obtained from 16 layers of unidirectional carbon fiber/epoxy prepreg sheets with the T700/YPH-160 epoxy prepreg,(Shanghai Institute of Liso compositeMaterialsTechnologyCo.Ltd,China).Theepoxyprepreg is heated and cured at the cure cycle for 30 min at 80◦C,followed by heating to 170◦C for 45 min and subjected to a pressure of 0.5 MPa.Epoxy adhesive 603-A and HT-603 which is cured at 180◦C for 2 h(Institute of Petrochemistry,Heilongjiang Academy ofSciences,China)areusedtobondthecoreandthepanel.Boththe pyramid lattice core and the face sheets are made from composite laminates.The glass transition temperature(Tg)of the epoxy is approximately 165◦C.

In the present paper,the water jet cut-interlocking assembly method is used to fabricate the pyramidal truss core sandwich structure.The pyramidal truss core are manufactured from laying direction-45/45°laminate of thickness t=1.5 mm.Firstly,the patterns shown in Fig.1(a)are cut from laminates by water jet cutting.Benefit of the water jet is that it does not produce heat which can damage the matrix material at the cut edge unlike most other machining methods.Secondly,these patterns areinterlockingassemblymethodtoformthecoretruss(Fig.1(b)). Thirdly,aluminum alloy reinforced frames of thickness t= 1.5 mm with cruciform shaped holes are cut by water jet cut from aluminum alloy plates,as shown in Fig.1(c).Finally,the convex platform of the pyramidal truss core covered with the epoxy adhesive is countersunk into the holes of aluminum alloy reinforced frames,and then the composite face sheets are bonded with aluminum alloy reinforced frames and pyramidal truss core with the epoxy adhesive,as shown in Fig.1(c).Completed compositepyramidaltrusscoresandwichpanelsareobtainedafter the curing of the epoxy adhesive,as sketched in Fig.1(d)and the photo of a sample is shown in Fig.1(e).The sandwich structure consists of the composite face sheets,aluminum alloy reinforced frames and pyramidal truss core.

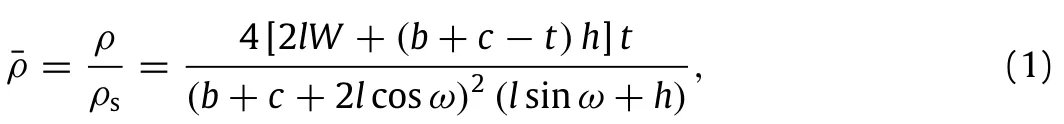

The critical parameters which describe the geometry of the patterns are sketched in Fig.2,including strut length l,thickness t,widthw,angleωbetween the horizontal plane and strut,node outside width b and node internal width c,respectively.Thus,the relative density of the core is given by

whereρis the density of the pyramidal lattice truss core barring reinforced frames andρsis the density of the parent materials. The present pyramidal truss structure has the following geometric parameters:l=19.66 mm,t=1.5 mm,W=1.5 mm,b=8 mm,c=7.96 mm,h=2.1 mm andω=45°.Substituting these parameters into Eq.(1),we have

2.2.Mechanical tests

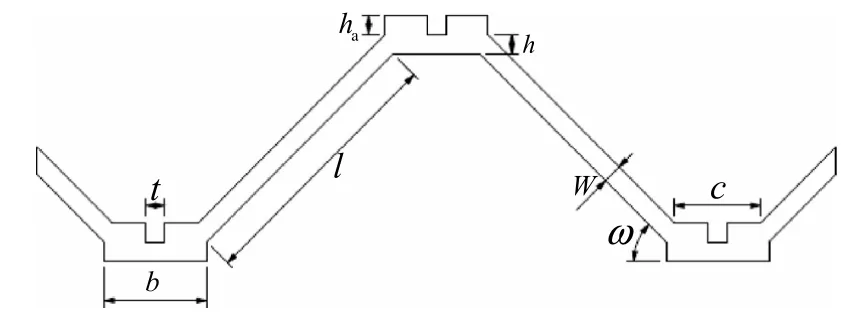

The compression tests are conducted using INSTRON 5569 test machine with corresponding environmental chamber.The lowtemperatureenvironmentisachievedbyusingliquidnitrogen,and the high temperature environment is supported by heater.The compression tests for pyramidal truss core composite struts are performed according to ASTM D-695-96[18].In order to obtain thecompressivemodulusoftheparentmaterialsforthepyramidal core,the composite struts are tested under axial compression along the fiber direction.The schematic of compression tests is shown in Fig.3(a),and the molds in Fig.3(b)are used to guarantee the vertical state of test specimens under compression.The outof-plane compression tests for pyramidal truss core sandwich panels are performed according to ASTM standard C365 with a displacement loading rate of 0.5 mm/min[19].Compression tests are conducted at the temperatures-90◦C,-70◦C,-50◦C,-30◦C,-25◦C,-80◦C,-120◦C,-160◦C,180◦C,respectively.Five repeated tests are conducted at the same temperature in order to gauge the level of the experimental scatter.

Fig.2.Pyramid truss core interlocking strip.

Fig.3.(a)Compression test schematic of strut;(b)Molds of composite strut for compression test.

3.Results and discussion

3.1.Compressive response of composite struts

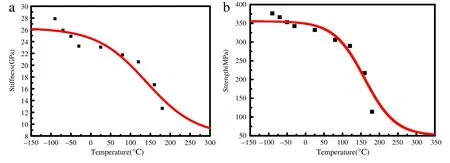

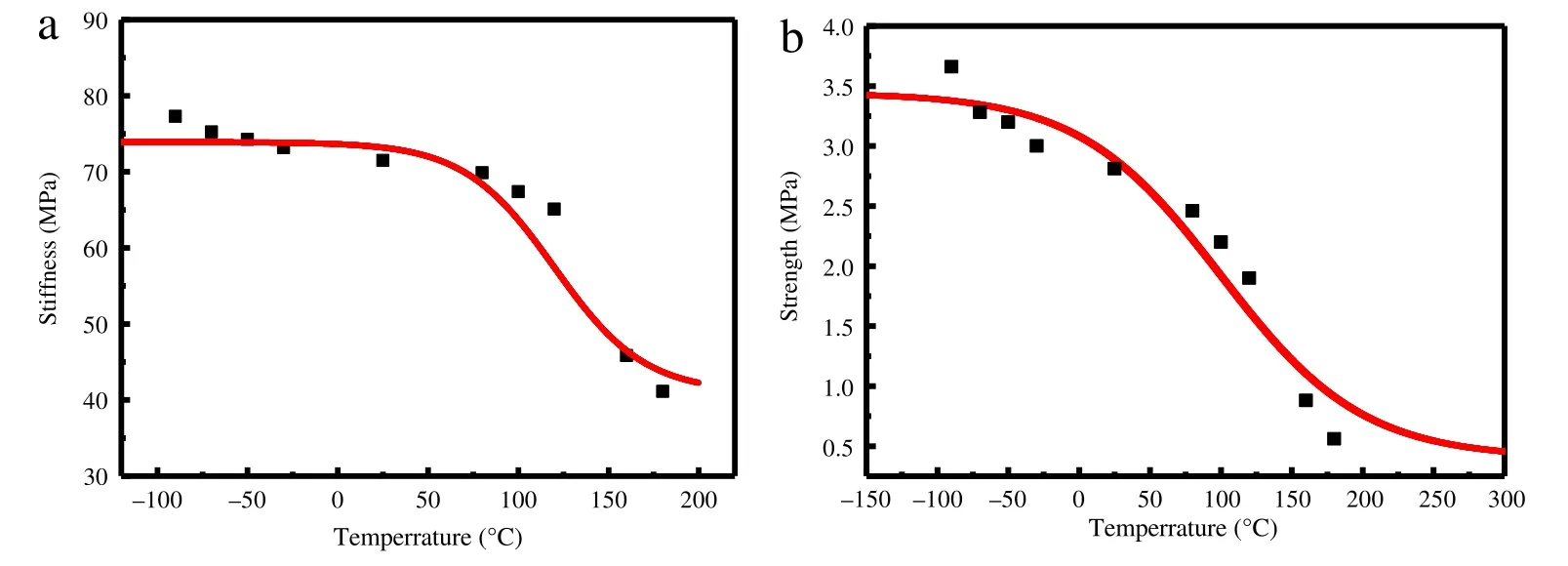

To predict the compressive performance of CF/CPTSP under different environment temperatures,we investigate the compressive modulusandstrengthofcompositestrutsatdifferentenvironment temperatures.ThedetailedexperimentalresultsasshowninFig.4. The compressive modulus and strength of struts are to obtain the average value of five experimental values at each testing temperature points.

From Fig.4,it can be seen that the compressive stiffness and strength of composite struts are strongly dependent on temperature.The compressive stiffness and strength of composite struts at low temperature are higher than ones at room temperature.The compressive stiffness and strength increase by 20.9%and 19.35%,respectively,when test temperature drops from 25◦C to-90◦C. The reason is as follows:the polymer chain segment motion is frozen and the molecules of polymer matrix are more closely compacted,and the epoxy resin matrix remains in the rigid glassy state at cryogenic temperature where the composite has the high elastic modulus and small elastic deformation.At the same time,the residual compressive stresses on the carbon fiber radial surface due to the thermal shrinkage of epoxy resin matrix create good bonding conditions within the interface at cryogenic temperature,which improve the compressive stiffness and strength of composite struts.However,the stiffness and strength of composite struts little by little decrease as the temperature increases.The stiffness and strength decrease by 45.06%and 64.65%as temperature increases from 25◦C to 180◦C,respectively.This is because the epoxy resin matrix represents the soft high elastic state and the composite has the low elastic modulus and bigger elastic deformation when the chain segment becomes the free motion from the thaw at high temperature.

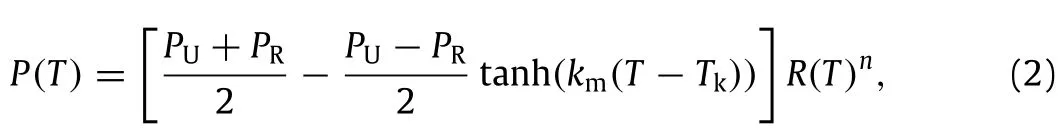

If the compressive stiffness and strength of composite struts with temperature change can be characterized,the compressive stiffness and strength of CPTSP with temperature change can be predicted by the compressive stiffness and strength of composite struts.The compressive strength and stiffness of composite struts are experimentally determined as a function of temperature using compression tests and subsequently modeled by Gibson et al.[20]:

where P(T)is a particular stiffness and strength,and PUand PRare the initial and residual modulus and strength values,respectively. kmisaconstantdescribethebreadthofdistributionsandTkistemperature of mechanical properties decay half.PR,kmand Tkcan be obtainedbyexperimentaldataofthelaminate.Theremainingresin content,R(T)is used in the decomposition of the polymer matrix(0<R(T)<1).Thecompressiveperformanceofcompositestruts are represented as a function of temperature in Fig.4.The curves in Fig.4 are fitted by Eq.(2).

3.2.Out-of-plane compressive response of CF/CPTSP

The effect of temperature on the compressive properties of CF/CPTSPisinvestigatedinthissection.Theexperimentalresultsof the compressive strength and stiffness of CF/CPTSP under different temperatures are shown in Fig.6.It is well observed that the outof-plane compressive stiffness and strength of CF/CPTSP decreaseas the temperature increases from-90◦C to 180◦C.Taking room temperature as a reference temperature,the compressive stiffnessandstrengthofCF/CPTSPdecrease,respectively,by42.47% and 80.07%as temperature increases from 25◦C to 180◦C,but the compressive stiffness and strength of CF/CPTSP increase,respectively,by 8.09%and 30.25%as temperature drops from 25◦C to-90◦C.It can be concluded that the stiffness and strength of CF/CPTSP are significantly dependent on temperature.

Fig.4.(a)Effect of temperature on the stiffness of composite struts;(b)Strength of composite struts as a function of temperature(solid curve:fitted data,data points: experimental data).

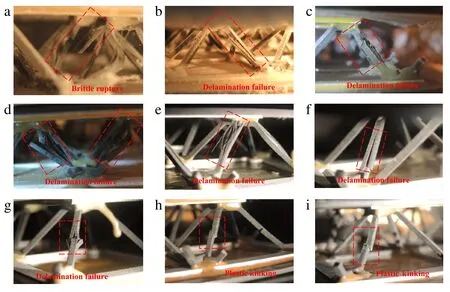

Fig.5.Different failure modes of pyramidal truss core sandwich panels with temperature variation.(a)-90◦C;(b)-70◦C;(c)-50◦C;(d)-30◦C;(e)25◦C;(f)80◦C;(g)120◦C;(i)160◦C;(j)180◦C.

Figure 5 shows the different failure modes of CF/CPTSP with temperature change.It indicates that temperature significantly affects the compressive failure mode.At the temperature-90◦C,the failure under compression load is characterized by the brittle ruptureofcomposite strutsas shown inFig.5(a).The delamination failureofstrutsofCPTSPisobservedinthetemperaturerangefrom -70◦C to 160◦C in Fig.5(b)-(g).The reason that these two failure modes occur is as follows:When the temperature is below-90◦C,the thermal contraction of epoxy resin matrix is serious,which hinders the relative slippage of molecular chains.At the moment,the molecule is in the relative rest state,which is similar to the brittle material.Therefore,the brittle rupture of composite struts is easy to occur under the low temperature.When temperature varies from-70◦C to160◦C,themainmolecularchainsofpolymer are still frozen,but some small molecular chains(e.g.side group of benzene ring whereon main molecular chains)are gradually unfrozen with temperature increases.Therefore,it can be seen that the failure mode changes from the rigid brittle rupture to the flexible plastic kinking failure.When temperature is more than 160◦C,the plastic kinking failure is the main failure mode of CF/CPTSP as shown in Fig.5(i)-(j).That is the reason that when temperature overtops the Glass transition temperature of epoxy resin,the main molecular chains of epoxy resin are thawed,which leads to the occurrence of the thermal softening,and decrease the stiffness at last.

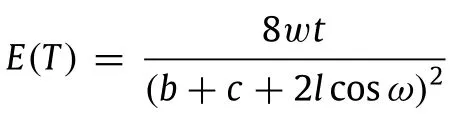

The effective out-of-plane compressive modulus and strength of CF/CPTSP can be obtained according to the expression of Finnegan[21].

TheeffectivecompressivemodulusE(T)ofpyramidaltrusscore is expressed as:

where ES(T)is the Young’s modulus of composite strut.The value of ES(T)is dependent on temperature,and the relationship between ES(T)and T is given by Eq.(2).

The effective compressive strengthσpk(T)of pyramidal truss core is written as

whereσpf(T)is the compressive strength of the composite strut.The value ofσpf(T)is dependent on temperature,and the relationship betweenσpf(T)and T is obtained by Eq.(2).

The compressive modulus and strength of CF/CPTSP are expressed as a function of temperature in Fig.6.The data points are the experimental values while the solid-line curves show the predicted compressive modulus and strength calculated using Eqs.(3)and(4),respectively.As can be seen in Fig.6,the predicted values and experimental data is good agreement between.

4.Conclusions

The water cutting and interlocking assembly method are developed to manufacture the CPTSP with reinforced joints. The effects of temperature on the out-of-plane compressive properties and failure mechanism of CF/CPTSP are investigated experimentally and theoretically.Good agreement is found between the theoretical predictions and experimental results. Experimental results indicate compressive stiffness and strength of CF/CPTSP are dependent on temperature.The cryogenic temperature results in the increasing of the compressive stiffness and strength of CPTSP.However,the high temperature causes the degradation of the compressive stiffness and strength of CPTSP.There is transformation of the failure mode of CPTSP at the critical temperature.At the temperature below-90◦C,the failure is characterized by the brittle rupture of composite struts. The delamination failure of composite struts is observed in the temperature range from-70◦C to 160◦C.At the temperature above 160◦C,the failure is characterized by the plastic kinking of composite struts.

Fig.6.(a)Comparison of the predicted and measured stiffness of CF/CPTSP with temperature change;(b)Comparison of the predicted and measured strength of pyramidal truss core sandwich panels with temperature change(solid curve:prediction,data points:experiment).

Acknowledgments

The present work was supported by the Major State Basic Research Development Program of China(973 Program)under Grant No.2011CB610303,and the National Natural Science Foundation of China under Grant No.11432004.

[1]B.Wang,L.Wu,L.Ma,et al.,Fabrication and testing of carbon fiber reinforced truss core sandwich panels,J.Mater.Sci.Technol.25(2009)547.

[2]H.L.Fan,F.H.Meng,W.Yang,Sandwich panels with Kagome lattice cores reinforced by carbon fibers,Compos.Struct.81(2007)533-539.

[3]B.Wang,L.Z.Wu,L.Ma,et al.,Low-velocity impact characteristics and residual tensile strength of carbon fiber composite lattice core sandwich structures,Composites B 42(2011)891-897.

[4]H.Fan,F.Jin,D.Fang,Characterization of edge effects of composite lattice structures,Compos.Sci.Technol.69(2009)1896-1903.

[5]H.L.Fan,F.N.Jin,D.N.Fang,Mechanical properties of hierarchical cellular materials.Part I:Analysis,Compos.Sci.Technol.68(2008)3380-3387.

[6]A.G.Xu,G.C.Zhang,H.Li,et al.,Temperature pattern dynamics in shocked porous materials,Science China Physics,Mech.Astron.53(2010)1466-1474.

[7]B.Wang,L.Wu,L.Ma,et al.,Mechanical behavior of the sandwich structures with carbon fiber-reinforced pyramidal lattice truss core,Mater.Des.31(2010)2659-2663.

[8]J.Xiong,L.Ma,A.Vaziri,et al.,Mechanical behavior of carbon fiber composite lattice core sandwich panels fabricated by laser cutting,Acta Mater.60(2012)5322-5334.

[9]H.L.Fan,L.Yang,F.Sun,et al.,Compression and bending performances of carbon fiber reinforced lattice-core sandwich composites,Composites A 52(2013)118-125.

[10]T.George,V.S.Deshpande,H.N.G.Wadley,Mechanical response of carbon fiber composite sandwich panels with pyramidal truss cores,Composites A 47(2013)31-40.

[11]K.G.Schmitt-Thomas,Z.G.Yang,R.Malke,Failure behavior and performance analysis of hybrid-fiber reinforced PAEK composites at high temperature,Composites science and technology 58(1998)1509-1518.

[12]X.P.Han,S.L.Han,L.Y,A study on dynamic fracture toughness of composite laminates at different temperatures,Composites science and technology 63(2003)155-159.

[13]A.A.M.Badawy,Impactbehaviorofglassfibersreinforcedcompositelaminates at different temperatures,Ain Shams Eng.J.3(2012)105-111.

[14]S.K.Foster,L.A.Bisby,High temperature residual properties of externallybonded FRP systems,ACI Spec.Publ.230(2005)1235-1252.

[15]S.Cao,W.U.Zhis,X.Wang,Tensile properties of CFRP and hybrid FRP composites at elevated temperatures,J.Compos.Mater.43(2009)315-330.

[16]J.A.Grape,V.Gupta,The effect of temperature on the strength and failure mechanisms of a woven carbon/polyimide laminate under compression,Mech.Mater.30(1998)165-180.

[17]J.Y.Liu,Z.G.Zhou,L.Z.Wu,et al.,A study on mechanical behavior of the carbonfibercompositesandwichpanelwithpyramidaltrusscoresatdifferent temperatures,Sci.China Phys.,Mech.Astron.55(2012)2135-2142.

[18]ASTM:D695-96.Standard test method for compressive properties of rigid plastics.West Conshohocken(PA):ASTM Int.,1996.

[19]ASTM:C365.Standard test method for flat wise compressive prop-erties of sandwich cores.West Conshohocken(PA):ASTM Int.,2006.

[20]K.Finnegan,G.Kooistra,H.N.G.Wadley,et al.,The compressive response of carbon fiber composite pyramidal truss sandwich cores,Int.J.Mater.Res.98(2007)1264-1272.

[21]A.G.Gibson,Y.S.Wu,J.T.Evans,et al.,Laminate theory analysis of composites under load in fire,J.Compos.Mater.40(2006)639-658.

8 October 2015

.Tel.:+86 451 86412549.

E-mail address:wlz@hit.edu.cn(L.Wu).

http://dx.doi.org/10.1016/j.taml.2016.02.002

2095-0349/©2016 The Authors.Published by Elsevier Ltd on behalf of The Chinese Society of Theoretical and Applied Mechanics.This is an open access article under the CC BY-NC-ND license(http://creativecommons.org/licenses/by-nc-nd/4.0/).

in revised form

*This article belongs to the Solid Mechanics

杂志排行

Theoretical & Applied Mechanics Letters的其它文章

- The optimum layer number of multi-layer pyramidal core sandwich columns under in-plane compression

- Analytical design of effective thermal conductivity for fluid-saturated prismatic cellular metal honeycombs

- Elastic properties of chiral,anti-chiral,and hierarchical honeycombs: A simple energy-based approach

- The effect of Görtler instability on hypersonic boundary layer transition

- Stability analysis of liquid filled spacecraft system with flexible attachment by using the energy-Casimir method

- Cicada(Tibicen linnei)steers by force vectoring