The mechanics and deformation of high temperature steel frame rapidly cooled by spray water in fire fightingYunchun Xia

2016-09-21SchoolofCivilEngineeringAnhuiJianzhuUniversityHefei230022China

School of Civil Engineering,Anhui Jianzhu University,Hefei 230022,China

Letter

The mechanics and deformation of high temperature steel frame rapidly cooled by spray water in fire fighting

Yunchun Xia

School of Civil Engineering,Anhui Jianzhu University,Hefei 230022,China

H I G H L I G H T S

·A steel frame at high temperature is introduced by integrating a new nonstationary mechanics and deformation based on the cooling location and cooling rate.

·The mechanics is mainly affected by the cooling location and cooling rate.

·The results are very useful for providing a new evaluation method for the structure’s damage and failure in a practical fire fighting.

A R T I C L EI N F O

Article history:

in revised form

25 April 2016

Accepted 27 May 2016

Available online 18 July 2016

Steel frame

High temperature

Rapid cooling

Spray water

A finite element is established for analyzing the dynamical mechanics and deformation of steel frame at high temperature when it is rapidly cooled down by spray water in fire fighting.The simulation result shows that remarkable mechanical coupling effects are produced in the process,and the sectional stress in rapid cooling down is found considerably larger than that in heating-up.Meanwhile,the stress and deformation of a beam mainly related to cooling rate and location are much larger than those of a column in rapid cooling.In fire fighting,the structure on the first or second floor was more dangerous than those on other floors in rapid cooling.These results could provide a theoretical reference for the design of steel structure and fire fighting.

©2016 The Author(s).Published by Elsevier Ltd on behalf of The Chinese Society of Theoretical and

Applied Mechanics.This is an open access article under the CC BY-NC-ND license(http://creativecommons.org/licenses/by-nc-nd/4.0/).

In recent years,steel frame is widely used for high-rise buildings.Because of its defects in fire resistance,those steel structures are mainly cooled down by spray water to protect them from damage in fire.However,some structures at high temperature often suddenly are destroyed in fire fighting,and the failure is no foreboding[1-12].

In fire,steel structure is at high temperature when fire fighting system starts[10-15].In rapid cooling by spray water,the deformation cannot recover in a very short period,but large stress is producedinsidethestructurebecausethetemperatureisdifferent, and the stress is even much larger than its yield stress,so the large stress can cause the structure destroyed instantly[4-11].The simulation results can provide a reference for steel structure and fire fighting designs along with a new method of the damage evaluation for steel structure in fire fighting.

Infire,firejusthappensatpartsofbuilding,theeffectofheating on steel structure is very different.According to the effect of local fire on steel structure,the simulation modeling can be simplified as a three-floor and three-span steel structure(see Fig.1),its finite element calculation modeling is shown in Fig.2.

In Fig.1,all of the steel frames are made of H-type structural steel(steelQ235),thesectionaldimensionofbeamisH250×250× 9×14mm,andthesectionaldimensionofallthesecondarybeams is H150×150×7×10 mm,the sectional dimension of column is H300×300×10×15 mm.All the joints of beam-to-column are welded.The loading acting on all beams is just the slab weight. Each column is acted by a vertical load at 300 kN on its top end. Water nozzle is fixed at the ceiling center,its outlet is 10 cm far from the ceiling and the spray angle is 90°.

In cooling,the temperature drop rate of structural steel can be calculated according to the following equation[1]:

where t was time(minute),Thwas the max temperature(◦C),thwas the time at Th(minute).

For the structure,the floor slab is made of concrete C25,thickness 14 cm,its density and Poisson’s rate change little in heatingandcooling,soitsdensityistakenastheconstant2600kg/m3,and its coefficient of thermal expansion is 1.8×10-3mm/(m·◦C),its Poisson’s rate is about 0.24.The thermal conductivity of concrete at temperature T can be calculated as follows[6,7]:

Fig.1.Sketch of the simulation modeling for a steel frame structure(in mm).

Fig.2.Finite element modeling.

Fig.3.The deformation distribution(m)at Z direction.

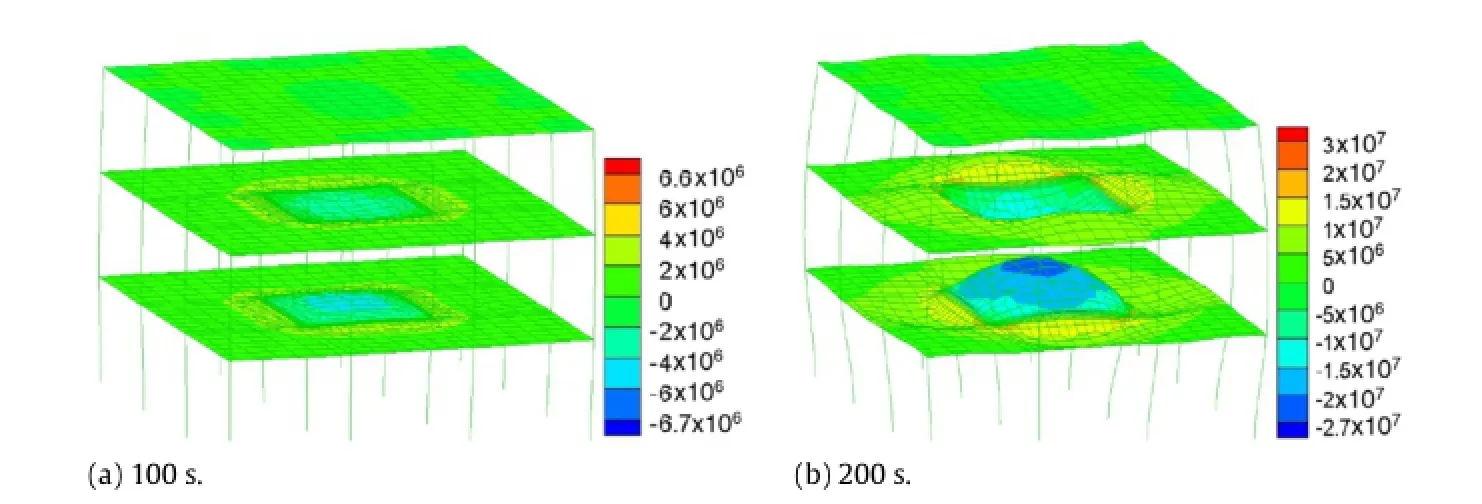

Fig.4.Tensile stress distribution(Pa)of floor slab after cooled.

For concrete C25,its specific heat capacity can be calculated as follows[6,7]:

Fig.5.Surface stress distribution(Pa)of floor slab after cooling.

Fig.6.Mechanics of beams and columns when the fire happened in the middle span.

Fig.7.Deformations of beam and column at different cooling rate.

Table 1Physical parameters.

For structural steel,its density changes little to 7800 kg/m3. The Poisson’s ratio is 0.3,coefficient of thermal expansion is 1.4×10-3mm/(m·◦C).Yield stressσYTand elastic modulus ETat temperature T can be calculated according to the following equations[8]:

whereσY0and E0are the yield stress and elastic modulus at 20◦C.

The expansion or shrinkageΔl of structural steel can be expressed as the following equations[9]:

where l is the length of test specimen at 20◦C.

For the structural steel,its physical parameters are shown in Table 1.

For structural steel,the relation between stress and strain fits for Ramberg-Osgood model.At temperature T,the relation between stress and strain can be calculated according to Eq.(9)[11]:

where ETis the elastic modulus at temperature T,fyis the yield strength at temperature T,σis the stress at its cross section,n is the slope of stress-strain curve at temperature T.

When fire happens at center of the 1st floor,the steel frame in fire room is heated up to 600◦C and the cooling rate is 2◦C/s,the deformationandmechanicsofthestructureareshownfromFigs.3 to 5.

In the early cooling,the beam is at the elastic recovery stage,it shrinks at axial direction,but the deformation recovery at fire span is small and only about 20%of the expansion in heating.Stresses on both beams and columns are large,and they both increased sharplyinrapidcoolingbecausetheirelasticmodulusandstiffness cannot recover.With further cooling,the stress does not reduce, but increases.

When the columns and beams in fire room are rapidly cooled from 600◦C and temperature drop rate is at 2◦C/s,the mechanics of the beams and columns near fire are shown in Fig.6.

In rapidly cooling,the axial force on beam sharply drops to zero at first,and then it increases and changes from pressure to tensile force.However,the shearing force increases in cooling except fire happened on the 3rd floor.For the columns near fire,their axial forces change little.When fire happens on the 1st or the 2nd floor, the axial force just increases less than 15%.However,it reduces about 22%when fire happens on the 3rd floor.

Whenfirehappensatthemiddlespan,allthebendingmoments quickly increase from low negative to zero,and then they increase toveryhighpositivelevel,thedifferenceisfromabout120%toover 200%in only about 4 minutes.When fire happens on the top floor, the bending moments at top and bottom ends of columns change from negative to positive,but the change is relatively small,the difference just is about 41%-66%.So it was more dangerous when fire happened on the 1st and the 2nd floor.

When fire happens at the middle span and the cooling rate is at 2,3,and 5◦C/s respectively,the deformations and mechanics are shown in Fig.7.

In rapid cooling,the lateral deflection of column reduced,the axial force of beam rapidly changed from negative to positive,but theaxialforceofcolumnincreasesrapidly.Whenthecoolingrateis at 2◦C/s,for the beam1 near fire,its deflection increases about 11% after it is cooled down for near 52 s,and then it reduces quickly. The axial force reduces until zero in cooling,then it increases, and it changes from pressure to tensile force,but their peaks are close.The shearing force increases in cooling,its peak increases about 11%,31%,and 53%when the cooling rate is at 2,3,and 5◦C/s respectively.The bending moment at the right end of the cooling beam is much larger in rapid cooling,it changes from near -12 kN·m at 600◦C to 127 kN·m at ambient temperature.The bending moment at the left end of beam also changes from-65.6 to 84.2 kN·m.

For all columns,their lateral and axial deflections reduce about 11%,but the axial force gradually increases,the bending moment rapidlychangesfromnegativetopositive,andtheirpeaksareclose, too.So the column is relatively safer in rapid cooling.

For a steel frame exposed to fire,the rapid cooling down by spray water exerts a strong impact on it in fire fighting.In rapid cooling,its deformation cannot recover in a short period.The rapid coolingcanproduceaforceandbendingmomentmuchlargerthan those produced in heating.Therefore,the corresponding damage might be much more serious than that in heating-up.When the steel structure is cooled down by spray water from 600◦C,the deflection of columns recovers less than 20%of the expansion. When cooled from 600◦C,the deflection of the beam near fire increases at first,and then it is reduced.When fire happens on the 1st and the 2nd floor,the whole deflection increases about 50%-70%incoolingdown byspray water.Inrapidcooling,the high temperature beam fails at first,but the column is relatively safer.

Acknowledgment

This work was supported by the National Natural Science Foundation of China(51478002).

[1]L.Wang,Numerical Analysis on the Fire Resistance of Steel Frame Structure[Ph.D.Thesis],Tianjin University,2006.

[2]P.Song,Numerical Analysis on the Whole Structure of Steel Frame under Fire[Master Thesis],Tianjin Polytech University,2006.

[3]T.Sun,Response Analysis of Steel Frame During Overall Local Room Fire Process of Heating and Cooling[Master Thesis],Chang’an University,2012.

[4]J.W.B.Stark,F.S.K.Bijlaard,Structural Properties Connections in Steel Frame, Connections in Steel Structures Behavior,Strength and Design,Elsevier Applied Science Publishers,London,1987.

[5]A.N.Sherbourne,M.R.Bahaari,3D simulation of end-plate bolted connections, J.Struct.Eng.120(1994)1-3.

[6]M.U.Rahaman,R.E.Rowlands,Finite element analysis multiple-bolted joints in orthotropic plate,Comput.Struct.46(1993)2-5.

[7]ASCE Manuals and Reports on Engineering Practice No.78,Structural Fire Protection,Published by ASCE,New York,2001.

[8]European Committee for Standardization,ENV 1991-2-2,Euro-code 1-Basis of design and actions on structure-Part 2-2,Actions on structures-Actions on structures exposed to fire,English Version(1995).

[9]S.E.Magnusson,Temperature-time curve for the complete process of fire development:A theoretical study on wood fuel fires in enclosed space,Acta Polytech.Scand.,Civil Eng.Build.Construct.65(1970).

[10]International Standard ISO834,Fire-Resistance Tests-Elements of Building Construction,Amendment 1 and Amendment 2(1980).

[11]J.A.Purkiss,Developments in the fire safety design of structural steelwork,J. Construct.Steel Res.11(1988)149-173.

[12]A.Rubert,P.Schaumann,Structural steel and plane frame assemblies under fire action,Fire Saf.J.10(1986)173-184.

[13]A.Yngue,Modeling steel behavior,Fire Saf.J.13(1988)17-26.

[14]EuropeanRecommendationsfortheFireSafetyofSteelStructures,Calculation of the Fire Resistance of Load-bearing Elements and Structural Assemblies ExposedtotheStandardFire,ECCS-TechnicalCommittee3,EuropeanConvention for Constructional Steelwork,Amsterdam,Oxford,New York,1983.

[15]D.A.Crozier,M.B.Wong,Elasto-plastic analysis of steel frames at elevated temperatures,in:13th Australian Conference on the Mechanics of Structures and Materials,University of Wollongong,1993,pp.71-96.

Letter

1 March 2016

E-mail address:wxiayc@126.com.

http://dx.doi.org/10.1016/j.taml.2016.05.007

2095-0349/©2016 The Author(s).Published by Elsevier Ltd on behalf of The Chinese Society of Theoretical and Applied Mechanics.This is an open access article under the CC BY-NC-ND license(http://creativecommons.org/licenses/by-nc-nd/4.0/).

*This article belongs to the Solid Mechanics

杂志排行

Theoretical & Applied Mechanics Letters的其它文章

- Editorial:Advances in Optical Techniques for Mechanical Measurements

- Residual stress measurement for injection molded componentsAchyut Adhikari∗,Thomas Bourgade,Anand Asundi

- Fabrication of nanoscale speckle using broad ion beam milling on polymers for deformation analysisQinghua Wanga,∗,Satoshi Kishimotob,Yoshihisa Tanakab,Kimiyoshi Naitob

- Instantaneous phase-stepping interferometry based on a pixelated micro-polarizer arraySatoru Yoneyama∗,Shuichi Arikawa

- Visualizing surface strain distribution of facial skin using stereovisionNagisa Miura,Tsubasa Sakamoto,Yuichi Aoyagi,Satoru Yoneyama∗

- Fabrication of micro-scale gratings for moiré method with a femtosecond laserGaosheng Yana,Jianguo Zhua,∗,Yanlong Huanga,Wenfen Haoa,Yanjie Lib