凸轮摆杆式栽植机构运动分析及性能试验

2016-05-17何亚凯李树君杨学军

何亚凯,李树君,杨学军,颜 华,王 薇

(1.中国农业机械化科学研究院,北京 100083;2.现代农装科技股份公司,北京 100083)

凸轮摆杆式栽植机构运动分析及性能试验

何亚凯1,2,李树君1※,杨学军2,颜 华2,王 薇2

(1.中国农业机械化科学研究院,北京 100083;2.现代农装科技股份公司,北京 100083)

该文针对钵苗栽植机构栽植直立度低的问题,设计一套凸轮摆杆式栽植机构。建立了栽植机构的运动学模型,得到机构栽植器栽植轨迹、栽植速度和栽植加速度方程。基于MATLAB/GUI开发了应用于栽植机构运动分析的图形交互界面,分析了栽植机构曲柄CD长度与初始相位角、摆杆OA长度与初始相位角以及平行杆AG长度对栽植轨迹的影响,并通过正交试验方法对移栽结构参数进行优化。根据优化所得参数加工出试验样机,以钵苗直立度为主要检测指标对该试验样机进行田间试验。试验表明:该栽植机构能够在0.556 m/s的工作速度和栽植频率60.7株/min条件下较好地满足钵苗农艺栽植要求,钵苗栽植直立度优良率为95%且其变异系数为2.03%,倒伏率为1.67%,栽植株距误差率为0.22%,无缺苗和漏栽现象。由此表明所设计栽植机构在高栽植效率的条件下,仍具有良好的栽植性能,所涉及的研究方法和试验结果可为后期样机的设计提供参考依据。

农业机械;运动学;优化;凸轮摆杆;移栽机;栽植机构;运动学分析;试验

何亚凯,李树君,杨学军,颜 华,王 薇.凸轮摆杆式栽植机构运动分析及性能试验[J].农业工程学报,2016,32(6):34-41. doi:10.11975/j.issn.1002-6819.2016.06.005 http://www.tcsae.org

He Yakai,Li Shujun,Yang Xuejun,Yan Hua,Wang Wei.Kinematic analysis and performance experiment of cam-swing link planting mechanism[J].Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE),2016,32(6): 34-41.(in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2016.06.005 http://www.tcsae.org

0 引言

作物移栽作为一种现代栽培技术,能够有效地增加作物产量。随着钵苗育苗技术逐渐成熟,钵苗移栽也被广泛应用于烟草和蔬菜等经济作物种植。机械移栽的应用有效地减轻了劳动强度并提高钵苗栽植频率,但现有移栽机栽植机构栽植的钵苗直立度仍然不高[1-5]。目前研究较为成熟的栽植机构主要有转盘式栽植机构、行星齿轮式栽植机构和多连杆式栽植机构,此类栽植机构移栽机不仅能较好地应用于根系不发达、易破碎的钵苗移栽,而且还能较好地应用在膜上和非膜上的钵苗移栽[5-8]。行星齿轮式栽植机构与转盘式栽植机构的工作原理相似,都可以简化为平行四杆栽植机构,该栽植机构栽植鸭嘴的栽植轨迹为余摆线,即栽植轨迹下部存在较大的扣环,造成鸭嘴在栽苗时撕膜较为严重,钵苗栽植直立度难以保证[5,8-11]。多连杆式栽植机构中较为成熟的机构为七连杆式栽植机构,该机构栽植轨迹下部有重合部分且有一定的长度,能够有效保证作物栽植状态且减少栽植器对地膜的破坏程度,但该栽植机构栽植器在栽植过程中处于摆动状态影响钵苗的栽植效果,且该机构的栽植轨迹上部变化不平稳,对栽植机构栽植器接苗造成很大的影响[12-14]。为较好地满足钵苗移栽性能要求,基于四杆机构和多连杆机构基础上[15-23],设计一套凸轮摆杆式钵苗栽植机构,并对该栽植机构进行运动学分析和结构参数优化,得出一组较优的结构参数,为以后钵苗栽植机构设计与研究提供理论支持和参考。

1 栽植机构组成及工作原理

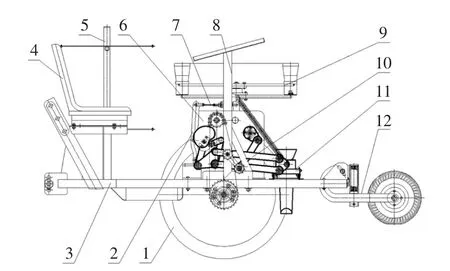

具有凸轮摆杆式钵苗栽植机构的样机结构如图1所示,样机主要由驱动件、转杆、移栽机架、座椅总成、苗盘架、变速箱、拉线、投苗支架、栽植机构、栽植器(鸭嘴)和镇压机构等部件组成。

图1 凸轮摆杆式试验样机结构图Fig.1 Structure diagram of cam-swing rod type prototype

拖拉机拖挂整机行走,同时带动地轮转动。地轮通过链传动将动力传到栽植机构,栽植机构按照机构的约束实现接苗、打穴、栽苗运动。当该栽植机构栽植器(鸭嘴)运动到土壤一定深度时,栽植器将会被凸轮拉线机构控制打开,栽植器内钵苗靠自身重力下落至穴口内。栽植器上升离开钵苗后由覆土镇压轮对钵苗周围土壤进行挤压,使得钵苗栽植稳定,完成移栽过程。

2 凸轮摆杆式栽植机构运动模型

2.1 机构模型建立

凸轮摆杆式钵苗栽植机构运动简图如图2所示,该栽植机构为以一个凸轮和一个曲柄为原动件构成的凸轮摆杆双平行四杆机构,机构中参数及含义见表1所示。凸轮N和曲柄CD均以顺时针方向转动,且角速度大小为定值ω,在凸轮摆杆NQOA和曲柄连杆CDE机构的共同作用下使固结于连杆FG上的栽植杆HJI来完成栽植机构的接苗、栽苗运动。

2.2 凸轮摆杆式栽植机构数学模型

以O点为坐标原点建立如图2所示的笛卡尔平面直角坐标系,设水平方向为x轴且x轴正方向与机组前进方向相反,竖直方向为y轴。机构数学建模过程中所需相关参数及含义详见表1中所示,其中φ2=-ωt,φ1=f(ωt),φ1和φ2之间关系式可根据凸轮摆杆知识得出,且φ1和φ2符号相反。

表1 相关符号及其说明Table 1 Symbol and description of parameters

图2 栽植机构运动模型Fig.2 Motion model of transplanting mechanism

2.2.1 位移方程

通过使用解析法对该机构建立参数方程并求解,最终得出栽植机构栽植点的静轨迹和动轨迹的坐标方程:

式中v是机组前进速度;μ是连杆GH长度与GF长度的比;θ1=180-θ2+θ3。

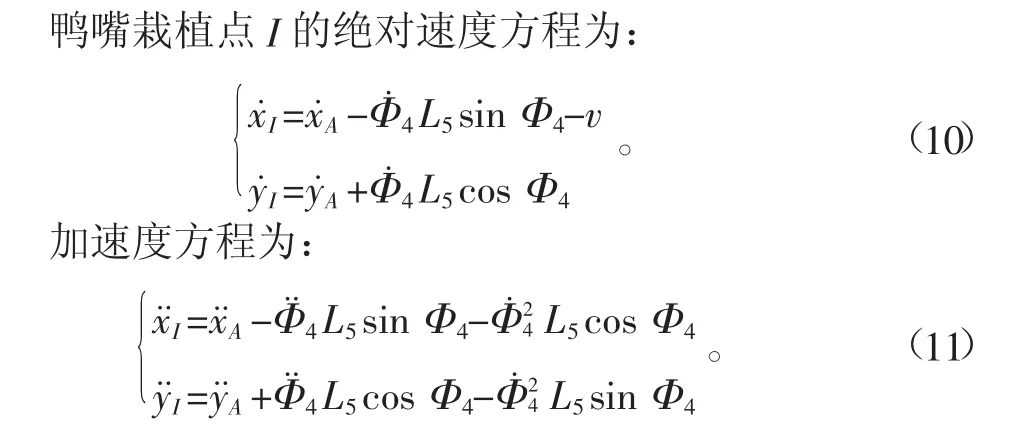

2.2.2 速度和加速度曲线方程

通过对上述位移方程(1)~(9)以时间t为参数变量,分别进行一次和两次导数运算并整理可得到栽植器I点的速度和加速度方程:

3 主要参数对栽植机构运动特性影响分析

根据所建立数学模型,基于MATLAB设计了凸轮摆杆式钵苗栽植机构的GUI图形交互界面[24-25](如图3所示)。该界面主要由参数输入和仿真结果两部分组成。在输入部分对结构参数和运动参数进行调整,可得到栽植器栽植点不同的运动轨迹、速度和加速度轨迹曲线。以栽植机构L1、Φ1、L2、Φ2和L5为变量参数,其他相关参数取值如表2所示,对栽植轨迹进行分析。

图3 凸轮摆杆式栽植机构辅助分析界面Fig.3 Interface of aided analytical program of cam-swing link type transplanting mechanism

表2 参数取值表Table 2 Value of parameters

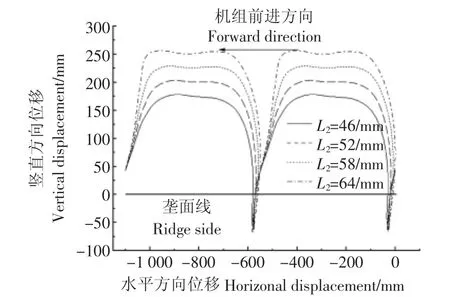

3.1 曲柄CD长度L2对栽植轨迹的影响

取L1=118 mm,L5=310 mm,Φ1=256°,Φ2=316°,研究L2对栽植轨迹曲线的影响,如图4所示。

通过对图4中的栽植轨迹分析得出,曲柄CD长度的变化对栽植轨迹总高度有较大的影响,对栽植株距、栽植深度和栽植穴口尺寸的影响较小;随着曲柄CD尺寸的增大,栽植轨迹的总高度增高,其栽植机构的最佳栽植株距也会相应变大。

图4 曲柄CD长度(L2)对栽植轨迹的影响规律Fig.4 Effects of crack L2on transplanting trajectory

3.2 曲柄CD初始相位角Φ2对栽植轨迹的影响

取L1=118 mm,L2=52 mm,L5=310 mm,Φ1=256°,研究Φ2对栽植轨迹曲线的影响,如图5所示。

图5 初始相位角(Φ2)对栽植轨迹的影响规律Fig.5 Effects of crack Φ2on transplanting trajectory

通过对图5所示的栽植轨迹分析得出,曲柄CD的初始相位角对栽植轨迹高度、栽植深度和轨迹顶部形状有较大的影响;随着CD初始相位角的增大,栽植深度增加,轨迹顶部接苗处会变得光滑平稳,其栽植机构的最佳栽植株距相应变小。

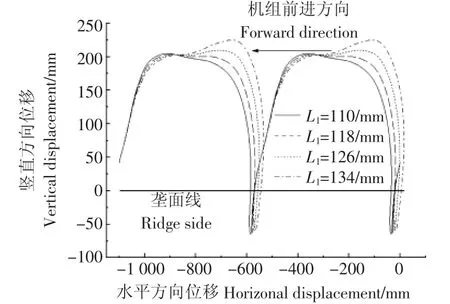

3.3 摆杆OA长度L1对栽植轨迹的影响

取L2=52 mm,L5=310 mm,Φ1=256°,Φ2=316°,研究L1对栽植轨迹曲线的影响,如图6所示。

图6 摆杆OA长度(L1)尺寸对栽植轨迹的影响规律Fig.6 Effects of crack L1on transplanting trajectory

通过对图6中的栽植轨迹曲线比较分析得出,摆杆OA长度变化对接苗处轨迹高度差影响较为明显,对栽植深度影响较小;随着OA长度的增加,接苗处高度差越明显,即接苗状态越不稳定;随着OA长度的增加,栽植机构最佳栽植株距会变大,栽植穴口尺寸会先变小再变大。

3.4 摆杆OA初始相位角Φ1对栽植轨迹的影响

取L1=118 mm,L2=52 mm,L5=310 mm,Φ2=316°,研究Φ1对栽植轨迹曲线的影响,如图7所示。

图7 摆杆OA初始相位角(Φ1)对栽植轨迹的影响规律Fig.7 Effects of crack Φ1on transplanting trajectory

通过对图7中栽植轨迹曲线比较分析得出,OA初始相位角的变化对栽植深度、轨迹高度和栽植穴口有较大的影响;当OA初始相位角增大时,栽植深度增加,栽植轨迹高度下降;随着OA初始相位角的增加,栽植穴口尺寸由大变小再变大,其栽植机构最佳栽植株距由大变小。

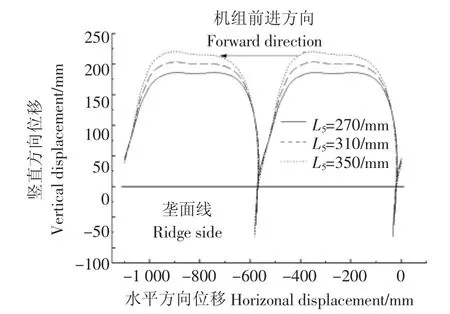

3.5 平行连杆AG长度L5对栽植轨迹的影响

取L5=118 mm,L2=52 mm,Φ1=256°,Φ2=316°,研究L5对栽植轨迹曲线的影响,如图8所示。

通过对图8所示栽植曲线比较分析得知,平行连杆AG长度尺寸L5的变化主要影响栽植深度和栽植轨迹高度,对接苗轨迹和栽植穴口尺寸变化的影响很小;随着AG杆尺寸的变长,栽植深度和栽植轨迹高度都增加。

图8 平行连杆AG长度(L5)尺寸对栽植轨迹的影响规律Fig.8 Effects of crack L5on transplanting trajectory

4 栽植机构结构优化

基于仿生学原理,模拟人工移栽动作。以提高钵苗的栽植直立度为目标,则栽植机构轨迹(图9所示)需满足:

1)栽植轨迹下端有一段尖嘴形,且尖嘴形具有一定长度,确保钵苗栽植深度要求;

2)轨迹尖嘴形有一定的后倾角,以改善钵苗垂直移栽后镇压轮挤土镇压造成的钵苗前倾问题;

3)轨迹入土ab段和出土bc段应有较高的重合度,减小穴口的尺寸;

4)轨迹应有一定的高度,避免钵苗栽植后被栽植器挂带;

5)轨迹接苗de段曲线沿前进方向应变化平稳,利于栽植器接苗稳定。

图9 正交试验结果分析图Fig.9 Analysis graph of orthogonal test result

采用正交试验法,选取对栽植轨迹影响比较显著的参数L1、L2、Φ1、Φ2作为研究因素,并根据栽植轨迹要求进行优化,优选出一组参数组合。其正交试验因素水平编码表如表3所示。在栽植深度同为60 mm的条件下进行仿真分析,试验结果分析图如图9所示,入土角λ为栽植入土点K处的倾斜角,并规定其与水平位移正方向夹角为正。该试验方案及结果见表4所示。

表3 因素水平编码表Table 3 Levels of coded design factors

表4 正交试验方案和结果表Table 4 Timing table of orthogonal experiment and result

由栽植轨迹要求可知,轨迹对栽深abc段的曲线重合度要求较高。以平均残差为主要研究重点,其值越小越好,其次为后倾入土角,其值在轨迹要求范围内越大越好。最大残差为辅助分析,数值越小越好。平均残差极差分析如表5所示。

表5 平均残差极差分析表Table 5 Analysis of range on average residual

对表5进行分析可知,因素较优组合为A1B2C3D2,然而在试验方案表中没有此组合,又由于因素影响主次为B>A>C>D,故首选A1和B2,符合要求的试验号为第2号试验,即在试验中最优组合为A1B2C2D2,此因素组合栽植段曲线重合度为最高,入土角优于其他各组,轨迹高度满足要求。

基于正交试验方法对摆杆OA、曲柄CD的长度和摆杆OA与曲柄CD的初始相位角进行研究分析,得到优化的参数组合:L1=118 mm,L2=52 mm,L3=150 mm,L4=125 mm,L5= 310 mm,L6=58 mm,L7=35 mm,L8=240 mm,L9=82 mm,L10= 104 mm,L11=48 mm,Lx0=21.85 mm,R=32 mm;Φ1=256°,Φ2= 316°,Φ3=237.5°,Φ4=354.3°,Φx=345°,ξ=56°,θ1=90.07°,θ2= 94.4°,θ3=4.47°。在栽植频率为60株/min,栽植株距为550 mm时,该参数组合下栽植机构运动栽植轨迹如图10所示。该栽植轨迹顶部de段变化比较平稳,有利于栽植器接苗。轨迹总高度约256 mm,超出栽植垄高约190 mm,高出钵苗约120 mm,能够有效地避免栽植器栽苗后对钵苗的挂带现象。栽苗abc段曲线最大残差为0.465 mm,平均残差为0.253 mm,说明在满足栽植深度60 mm条件下栽苗穴口尺寸和栽植器尺寸接近,对已铺地膜造成破坏很小。入土点处倾斜角为81.05°,能够较好地改善挤土镇压轮的扶正效果。

图10 较优参数下的栽植机构栽植轨迹Fig.10 Planting trajectory of transplanting mechanism under optional parameters

5 试验结果与分析

为了检验参数优化后的栽植机构移栽性能,根据以上优化参数加工出具有凸轮摆杆式栽植机构的试验样机,并以钵苗直立度为主要检测指标对该试验样机进行田间试验。该试验于2015年3月在河南省宜阳县工业园区进行,试验前对土地进行耕整并起垄覆膜,试验动力为东方红300拖拉机,试验对象为自制钵苗,钵苗的基质高度在40~60 mm之间,基质上端直径平均为30 mm,基质下端直径平均为20 mm,钵苗总高度在140~150 mm之间。试验按照相关检测方法和标准[26-27]对样机移栽性能进行测定,并根据农艺要求[26]规定知钵苗栽植直立状态为:钵苗茎秆与地面夹角大于70°为优良,夹角小于45度为不合格,其余为合格。试验过程中拖拉机拖带机组前进速度为0.556 m/s,移栽机栽植频率为60.7株/min,试验样机田间试验如图11所示,钵苗栽植直立度和株距测试数据统计结果如表6和表7所示,由表中数据可知,钵苗栽植直立度优良率为95%且其变异系数为2.03%,倒伏率为1.67%,株距误差率[21]为0.22%,无缺苗和漏栽现象,能够很好地满足钵苗农艺栽植要求。

图11 试验样机及田间试验Fig.11 Prototype and field test

表6 直立度测量结果表Table 6 Measured results table of upright degree

表7 株距测量结果表Table 7 Measured results table of plant spacing

6 结论

1)设计了一套凸轮摆杆式栽植机构,建立了该机构的运动数学模型,并基于MATLAB/GUI建立了该模型的一种辅助分析工具,得到栽植机构主要参数变化对栽植轨迹的影响规律。

2)在移栽株距为550 mm时,基于正交试验方法优选出一组最优参数组合:L1=118 mm、L2=52 mm、L3=150 mm、L4=125 mm、L5=310 mm、L6=58 mm、L7=35 mm、L8=240 mm、L9=82 mm、L10=104mm、L11=48 mm、Lx0=21.85 mm、R=16 mm;Φ1=256°、Φ2=316°、Φ3=237.5°、Φ4=354.3°、Φx=345°、ξ= 56°、θ1=90.07°、θ2=94.4°、θ3=4.47°。

3)加工出该栽植机构部件并组装成试验样机,以钵苗直立度为主要检测指标对该样机进行田间试验,结果表明:该移栽机能够在拖拉机0.556m/s,栽植频率为60.7株/min的工作条件下满足钵苗农艺栽植要求,且在该条件下,钵苗栽植直立度优良率为95%且其变异系数为2.03%,倒伏率为1.67%,株距误差率为0.22%,无缺苗和漏栽现象。

[1]张冕,姬江涛,杜新武.国内外移栽机研究现状与展望[J].农业工程,2012,2(2):21-23.Zhang Mian,Ji Jiangtao,Du Xinwu.Status and prospect of transplanter at home and abroad[J].Agricultural Engineering, 2012,2(2):21-23.(in Chinese with English abstract)

[2]于向涛,胡良龙,胡志超,等.我国旱地移栽机械概况与发展趋势[J].安徽农业科学,2012,40(1):614-616.Yu Xiangtao,Hu Lianglong,Hu Zhichao,et al.Development trend and general situation of nonirrigated farmland transplanting mechanizationinChina[J].JournalofAnhuiAgriculturalSciences, 2012,40(1):614-616.(in Chinese with English abstract)

[3] 贺智涛,郑治华,刘剑君,等.膜上移栽机的发展现状及存在的问题[J].农机化研究,2014,(9):252-255.He Zhitao,Zheng Zhihua,Liu Jianjun,et al.Development status of up-film transplanting mechanism and the problems[J].Journal of Agricultural Mechanization Research,2014,(9):252-255. (in Chinese with English abstract)

[4]周德义,孙裕晶,马成林.移栽机凸轮摆杆式扶苗机构设计与分析[J].农业机械学报,2003,34(5):57-60.Zhou Deyi,Sun Yujing,Ma Chenglin.Design and analysis of a supporting-seedling mechanism with cam and combined rocker [J].Transactionsofthe Chinese Society ofAgricultural Machinery,2003,34(5):57-60.(inChinesewithEnglishabstract)

[5]王英.面向高立苗率要求的栽植机构参数优化与试验研究[D].杭州:浙江理工大学,2014.Wang Ying.Parameter Optimization and Experimental Study on High Seedling Erectness Rate Oriented Planting Mechanism[D]. Hang Zhou:Zhejiang Sci-Tech University,2014.(in Chinese with English abstract)

[6]张为政,王君玲,张祖立.悬杯式蔬菜移栽机的设计[J].农机化研究,2011,33(8):104-106.ZhangWeizhang,WangJunling,ZhangZuli.Design of cantilever cup vegetable transplanter[J].Journal of Agricultural Mechanization Research,2011,33(8):104-106.(in Chinese with English abstract)

[7]胡建平,张建兵,何俊艺,等.移栽机行星轮转臂式栽植器运动分析与试验[J].农业机械学报,2013,44(10):57-61.Hu Jianping,Zhang Jianbing,He Junyi,et al.Motion analysis and experiment for planting mechanism with planetary gears of transplanting machine[J].Transactions of the Chinese Society of Agricultural Machinery,2013,44(10):57-61.(in Chinese with English abstract)

[8]Ji Jiangtao,He Yakai,Du Xinwu,et al.Design of the up-film transplanter and kinematic analysis of its planting devices[C].// ICAMechS,2013 International Conference on.IEEE,2013: 312-316.

[9]崔巍,赵亮,宋建农,等.吊杯式移栽机栽植器运动学分析与试验[J].农业机械学报,2012,43(Z1):35-38,34.Cui Wei,Zhao Liang,Song Jiannong,et al.Kinematic analysis and experiment of dibble-type planting devices[J].Transactions of the Chinese Society for Agricultural Machinery,2012,43(S1): 35-38,34.(in Chinese with English abstract)

[10]封俊,秦贵,宋卫堂,等.移栽机的吊杯运动分析与设计准则[J].农业机械学报,2002,33(5):48-50.Feng Jun,Qin Gui,Song Weitang,et al.The kinematic analysis anddesigncriteriaofthedibble-typetransplanters[J].Transactions of the Chinese Society for Agricultural Machinery,2002,33(5): 48-50.(in Chinese with English abstract)

[11]陈建能,赵匀.高速插秧机椭圆齿轮行星系分插机构的参数优化[J].农业机械学报,2003,34(5):46-49.Chen Jianneng,Zhao Yun.Parameters optimization of transplanting mechanism with planetary elliptic gears for highspeed transplanter[J].Transactions of the Chinese Society of Agricultural Machinery,2003,34(5):46-49.(in Chinese with English abstract)

[12]郑治华.膜上高速移栽机构试验研究[D].洛阳:河南科技大学,2014.Zheng Zhihua.Experimental Research of Up-film Transplanting Mechanism[D].Luoyang:Henan University of Science and Technology,2014.(in Chinese with English abstract)

[13]陈建能,王伯鸿,张翔,等.多杆式零速度钵苗移栽机植苗机构运动学模型与参数分析[J].农业工程学报,2011,27(9):7-12.Chen Jianneng,Wang Bohong,Zhang Xiang,et al.Kinematics modeling and characteristic analysis of multi-linkage transplanting mechanism of pot seeding transplanter with zero speed[J].Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE),2011,27(9):7-12.(in Chinese with English abstract)

[14]Ji Jiangtao,Jin Xin,Du Xinwu,et al.Motion trajectory analysis and performance test of up-film punch transplanting mechanism [J].International Agricultural Engineering Journal,2015,24(2): 30-38.

[15]Cui Wei,Liu Shuangxi,Gao Lijuan,et al.Development of 2ZFS-1A multifunctional tobacco transplanting machine[J].Transactions of the Chinese Society of Agricultural Engineering,2012,28 (S2):36-41.

[16]武科,毕新胜,陈永成.吊篮式移栽机栽植器的研究[J].农机化研究,2010,32(6):73-75,79.Wu Ke,Bi Xinsheng,Chen Yongcheng.The research of the dibble-type transplanter[J].Journal of Agricultural Mechanization Research,2010,32(6):73-75,79.(in Chinese with English abstract)

[17]王文明,窦卫国,王春光,等.2ZT-2型甜菜移栽机移植系统的参数分析[J].农业机械学报,2009,40(1):69-73.Wang Wenming,Dou Weiguo,Wang Chunguang,et al.Parameter analysis of the planting process of 2ZT-2 beet transplanter[J]. Transactions of the Chinese Society of Agricultural Machinery, 2009,40(1):69-73.(in Chinese with English abstract).

[18]陈建能,黄前泽,王英,等.钵苗移栽机椭圆齿轮行星系植苗机构运动学建模与分析[J].农业工程学报,2012,28(5):6-12.Chen Jianneng,Huang Qianze,Wang Ying,et al.Kinematics modeling and analysis of transplanting mechanism with planetary elliptic gears for pot seedling transplanter[J].Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE),2012,28(5):6-12.(in Chinese with English abstract)

[19]肖名涛,孙松林,罗海峰,等.双平行多杆栽植机构运动学分析与试验[J].农业工程学报,2014,30(17):25-33.Xiao Mingtao,Sun Songlin,Luo Haifeng,et al.Kinematic analysis and experiment of dual parallelogram multi-pole planting mechanism[J].Transactions of the Chinese Society of Agricultural Engineering(Transactions of the CSAE),2014,30 (17):25-33.(in Chinese with English abstract)

[20]金鑫,李树君,杨学军,等.膜上移栽钵苗栽植机构运动分析与参数优化[J].农业机械学报,2012,43(Z1):29-34.Jin Xin,Li Shujun,Yang Xuejun,et al.Motion analysis and parameter optimization for pot seedling planting mechanism based on up-film transplanting[J].Transactions of the Chinese Society for Agricultural Machinery,2012,43(S1):29-34.(in Chinese with English abstract)

[21]付鹏洋,胡建平,刘发,等.齿轮连杆凸轮组合式栽植机构仿真与试验[J].农业机械学报,2014,45(S1):52-56.Fu Pengyang,Hu Jianping,Liu Fa,et al.Simulation analysisand experiment for gear-linkage-cam combination planting mechanism[J].Transactions of the Chinese Society of Agricultural Machinery,2014,45(S1):52-56.(in Chinese with English abstract)

[22]陈建能,王伯鸿,任根勇,等.蔬菜移栽机放苗机构运动学模型建立与参数分析[J].农业机械学报,2010,41(12):48-53.Chen Jianneng,Wang Bohong,Ren Genyong,et al.Kinematics modeling and parameters analysis of seven-linkage vegetable seedling transplanting mechanism[J].Transactions of the Chinese Society of Agricultural Machinery,2010,41(12):48-53.(in Chinese with English abstract).

[23]张祖立,王君玲,张为政,等.悬杯式蔬菜移栽机的运动分析与性能试验[J].农业工程学报,2011,27(11):21-25.Zhang Zuli,Wang Junling,Zhang Weizheng,et al.Kinematic analysis and performance experiment of cantilever cup vegetable transplanter[J].TransactionsoftheChineseSocietyofAgricultural Engineering(Transactions of the CSAE),2011,27(11):21-25. (in Chinese with English abstract)

[24]刘浩,韩晶.MATLAB R2012a完全自学一本通[M].北京:电子工业出版社,2013.

[25]陈杰.MATLAB宝典[M].北京:电子工业出版社,2013.

[26]封俊,顾世康,曾爱军,等.导苗管式栽植机的试验研究(Ⅱ)栽植机的性能评价指标与检测方法[J].农业工程学报,1998,14(2):73-77.Feng Jun,Gu Shikang,Zeng Aijun,et al.Study on transplanter with chute and seedling aid springs(PartⅡ)Judging-targets system fortransplanters[J].TransactionsoftheChineseSocietyofAgricultural Engineering(Transactions of the CSAE),1998,14(2):73-77.(in Chinese with English abstract)

[27]JB/T 10291-2013,旱地栽植机械[S].

Kinematic analysis and performance experiment of cam-swing link planting mechanism

He Yakai1,2,Li Shujun1※,Yang Xuejun2,Yan Hua2,Wang Wei2

(1.Chinese Academy of Agricultural Mechanization Sciences,Beijing 100083,China;2.Modern Agricultural Equipment Co.,Ltd.,Beijing 100083,China)

The application of mechanical transplanting on crops can effectively increase the product of crops and reduce the labor intense as modern cultivation techniques.But the popularization and application are limited by the problem of lower upright degree to some certain extent.A new type cam-swing link type transplanting machinewas designed to solve the problem of lower upright degree in current pot seedling planting machine.In addition,the receiving seedling stability of planting apparatus can be guaranteed well,owing to double parallel four-bar mechanism of this planting machine.In this paper,the kinematic model of the transplanting machine was established,including the equations of planting trajectory,planting velocity and planting acceleration for the planting device.For the purpose of high efficiency,interactive GUI design tool had been explored based on the MATLAB/GUI according to these mathematic equations.The influences on the transplanting trajectory of main parameters were analyzed based on MATLAB tool,including the length L1and original phase angle Φ1of crank CD,the length L2and original phase angle Φ2of swing AB,and the length L5of link AG.The system parameters which had great effects on the planting trajectory were L1,L2,Φ1and Φ2.These parameters were analyzed and optimized through the method of orthogonal experiment.The experimental scheme was designed according to orthogonal table off our factors and three levels.By analyzing the range table of residual,the parameter couldbe ranged as L2,L1,Φ1and Φ2from big to small,considering the degree of significant on upright degree of seedlings.The optimal combination could be selected that L1is 118 mm,L2is 52 mm,Φ1is 256°,and Φ2is 316°.Under the condition of this optimal combination,the motion model of transplanting machine was reestablished to generate a new optimized planting trajectory. The top of this trajectory was smooth to benefit the receiving seedling stability of planting device.As the total height of this trajectory was about 256 mm with 190 mm higher the ridge side,the planting device couldavoid touching down seedlings planted effectively.When the planting depth reached 60 mm,the maximum residual of curve at planting seedlings parts was 0.465 mm,the mean residual was 0.253 mm,and penetration angel was 81.05°.The simulation results indicated that this optimized planting trajectory can improved the anteversion problem of seedlings that caused by compaction wheel and ensured the seedling planted higher upright degree.In order to verify the reasonability and accuracy of the theoretical model,the prototype was processed with the optimized parameters.Based on the prototype,field tests were carried out according to relevant standards in Yiyang county industrial park of China in March 2015.No crops were planted and the ridge film was mulched in the test plot before the testing,for simply obtaining test results without effects of the other crops. During the course of experiment,30 horse-power tractor was selected as the only power.The total height of seedlings used was no more than 150 mm,and the height of seedlings substrate less than 60 mm.The plant vertical degree was considered as the main optimization indicator which influenced by the main parameter smentioned above.The data results showed that the mechanism proposed meet the requirements of pot seedling agricultural plant at the speed of 0.556 meter per second, and planting frequency was 60.7 plant percent minute.The qualified rate of upright degree with the variationco efficient of 2.03%was 95%,lodging rate was no more than 1.67%,and plant spacing error rate was only 0.22%with no lacking of seedlings.The results indicated that this machine had the good planting performances of high upright degree and low spacing error rate under the condition of high efficiency of planting.What this paper studied will provide theoretical reference for the subsequent transplanter research and development.

agricultural machinery;kinematics;optimization;cam-swing link;transplanter;transplanting mechanism; kinematic analysis;test

10.11975/j.issn.1002-6819.2016.06.005

S223.94

A

1002-6819(2016)-06-0034-08

2015-12-02

2016-01-29

国家高技术研究发展计划(863计划)资助项目(2012AA10A 501);国家科技基础性工作专项(创新方法工作)项目(2013IM030700);“十二五”国家科技支撑计划资助项目(2013BAD08B03)

何亚凯(1989-),博士生,主要从事智能化农业装备技术研究。北京 中国农业机械化科学研究院,100083。

※通信作者:李树君(1962-),研究员,博士生导师,主要从事高新技术装备在农副产品和食品加工中的应用研究。北京 中国农业机械化科学研究院,100083。Email:lisj@caams.org.cn