Effect of Magnetic Field on Tribological Properties of Lubricating Oils with and without Tricresyl Phosphate

2016-03-22

(Logistical Engineering University, Chongqing 401311)

Effect of Magnetic Field on Tribological Properties of Lubricating Oils with and without Tricresyl Phosphate

Jiang Zeqi; Fang Jianhua; Chen Boshui; Zheng Zhe; Li Hao; Xu Lai

(Logistical Engineering University, Chongqing 401311)

Tribological properties of neat 150 SN mineral base oil and the oils doped with different contents of tricresyl phosphate (TCP) under magnetic feld or non-magnetic feld were evaluated on a four-ball tribotester, on which an external magnetic feld was applied. Furthermore, the morphology and the tribochemical characteristics of the worn surfaces were examined with a scanning electron microscope (SEM) and an X-ray photoelectron spectrograph (XPS). The tribological test results showed that the magnetic feld improved anti-wear properties but impaired the friction-reducing properties of neat base oil and the TCP-doped oils. The worn surfaces tested in magnetic feld were characterized by a slighter wear than those tested in normal condition, especially for the surfaces lubricated with the TCP-doped oils. Furthermore, the results of XPS analysis indicated that tribochemical flms on the surfaces tested with TCP-doped oils were mainly composed of ferriccontaining compounds such as Fe2O3, Fe3O4and FePO4. Under the infuence of a magnetic feld, the atomic concentrations of oxygen and phosphorous in the frictional sub-surfaces were higher than those without magnetic impact. Thus it can be inferred that the improved anti-wear properties and impaired friction-reducing capabilities of lubricating oils with TCP under a magnetic feld were related to the diffusion of phosphorus and oxygen into the substrate induced by magnetism.

magnetic feld; tricresyl phosphate; tribological properties; mechanisms

1 Introduction

In industrial tribological systems, many sliding units work in electric and magnetic surroundings such as the magnetic cutting, the motor brush, the carbon brush of excitation machine, the contact wire of high speed skater, the switch contactor of high power electric transmission[1-4]. It has been known that electromagnetic-induced physico-chemical effect will certainly infuence tribological properties of lubricants[5-7]. On the other hand, the self generated voltage (SGV) induced by friction will produce electric felds which, when varying, will excite magnetic felds[8]. Studies have shown that tribomates under magnetic conditions can produce dynamic magnetization thus affecting the hardness of frictional materials[9-11]. Tang[12]pointed out that the electron clouds inside molecules would deform temporarily under magnetic felds, resulting in changes of intermolecular forces that could influence the physical and chemical properties of a substance such as viscosity. Zhai, et al.[13]demonstrated that the friction coefficients were related to tribochemical reaction on the worn surfaces under electromagnetic condition. Unfortunately, the infuence of electromagnetic effect on the molecular design of traditional lubricant additives is usually not taken into consideration. It is thus of great significance to understand the electromagnetic effect on tribological performance of lubricants to realize the reasonable application and design of lubricants and additives for tribological contacts involved in electromagnetic conditions.

Tricresyl phosphate (TCP), a phosphorus-containing extreme pressure and anti-wear additive, has been widely used in many lubrication applications[14]. In the present paper, the tribological properties of lubricating oils with different contents of TCP were tested and compared with those of neat mineral base oil under magnetic conditions. Furthermore, the possible mechanisms of magnetic feld on infuencing the tribological performance of lubricating oils were also analyzed.

2 Experimental

2.1 Base oil and additive

150 SN base oil: a non-polarized paraffinic base oil obtained from the Shenzhen Lubricating Oil Industry Company, with its kinematic viscosity at 40 ℃ being equating to 31.85 mm2/s.

Additive: Tricresyl phosphate (TCP) was obtained from the Beijing Benzene Ring Fine Chemicals Co., Ltd. The chemical structure and some physicochemical indices of TCP are shown in Figure 1 and Table 1, respectively.

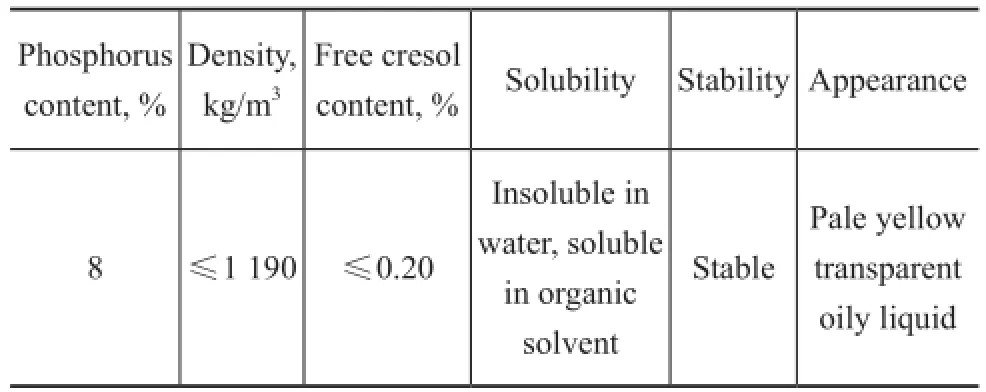

Table 1 The physicochemical properties of TCP

2.2 Friction and wear test

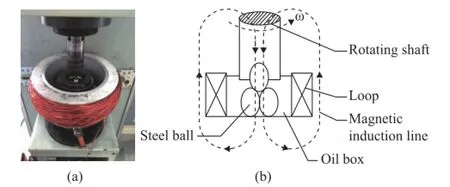

To evaluate the effect of magnetic field on tribological properties of lubricating oils with and without TCP, different mass fraction values of TCP, viz.: 0, 0.5%, 1.0%, 1.5%, 2.0% and 2.5%, respectively, were incorporated into the 150 SN base oil. The tribological tests were performed on a MMW-1 universal four-ball tribotester following the procedures of SH/T 0189—1992, a Chinese standard method for testing friction and wear properties of lubricants. To investigate the effect of magnetic feld on tribological performance of the lubricants, a copper loop of 800 windings was wrapped on an aluminium alloy sleeve and then placed around the friction region as shown in Figure 2(a). During the friction testing, the loop was electrifed to produce a specifc intensity of magnetic field by controlling the current intensity, with magnetic induction lines being mostly perpendicular to the frictional contact surfaces, as shown in Figure 2(b). The friction and wear tests were conducted under a magnetic feld intensity of 0.1 Tesla (0.1 T) and a load of 392 N, at a rotary speed of 1 200 r/min for 30 minutes. After each test run, the wear scar diameters (WSD) and the friction coeffcients were measured to evaluate the anti-wear and friction-reducing ability of the tested lubricants. The balls used in the tests are GCr15 standard steel balls, 12.7 mm in diameter and 59—61 HRC in hardness. The magnetic intensity was measured by a HT201 portable digital Tesla meter.

Figure 2 Assembly of tribotester

2.3 Surface analysis

Prior to the analysis, the steel balls lubricated with 150 SN base oil and oils formulated with 2.0% of TCP, respectively, under magnetic or non-magnetic fields were ultrasonically cleansed with petroleum ether for 10 minutes, respectively. Then the morphology of the worn surfaces was observed by a TESCAN Vega 3 LMH scanning electron microscope (SEM). The chemical characteristics of typical elements on the worn surfaces were analyzed on a Thermo ESCALab250 X-ray photoelectron spectroscope (XPS), with the Al Kα radiation used as the exciting source and a binding energy of contaminated carbon (C1s: 284.80 eV) used as the reference.

3 Results and Discussion

3.1 Anti-wear capacity

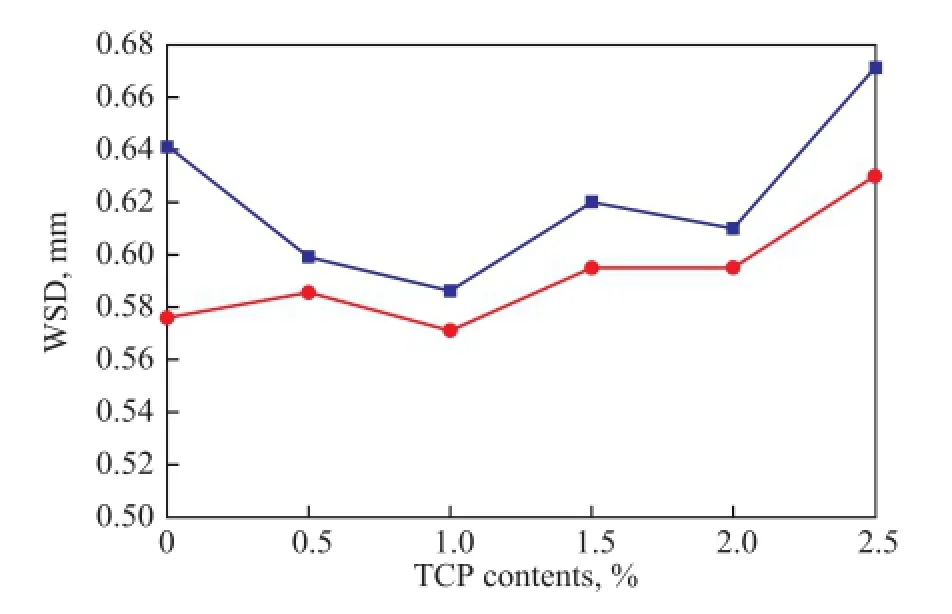

Figure 3 shows the variation of wear scar diameters with the change in mass fraction of TCP under different magnetic fields. It can clearly be observed from Figure 3 that WSDs of the worn surfaces under magnetic felds were much smaller than those under non-magnetic feld, demonstrating that magnetic field could contribute to the improvement of the anti-wear property of lubricating oils.

Figure 3 Variation of WSD with TCP contents under magnetic or non-magnetic fi eld

3.2 Friction-reducing ability

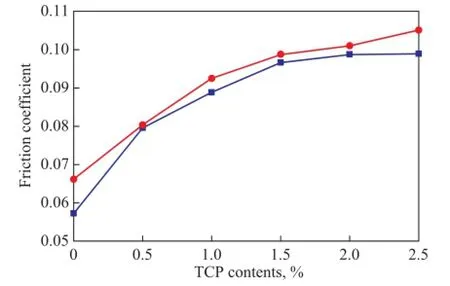

Figure 4 Friction coef fi cient against mass fraction of TCP under magnetic or non-magnetic fi eld

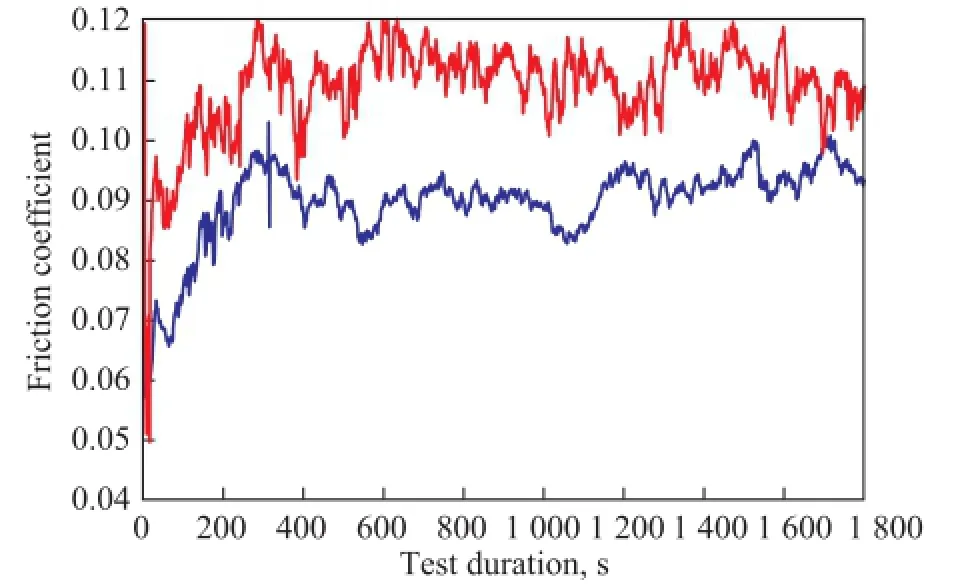

Figure 5 Variation of friction coef fi cient with test duration under magnetic or non-magnetic fi eld conditions

Figure 4 shows the variation of friction coeffcients with the mass fraction of TCP under different magnetic felds. Also shown in Figure 5 is the variation of friction coefficient versus test duration of lubricant oil containing 2.0% of TCP. It can be seen from Figure 4 and Figure 5 that the friction coefficients of the tested oils increased with an increasing content of TCP. In addition, the friction coefficients under magnetic conditions were higher than those under non-magnetic conditions. Furthermore, in the whole test process of 30 minutes, the friction coeffcient of oil containing 2.0% of TCP under the magnetic feld condition fuctuated more obviously than that under non-magnetic feld condition as shown in Figure 5. The results indicated that the magnetic impact could impair the friction-reducing ability of lubricants.

3.3 Morphology of worn surfaces

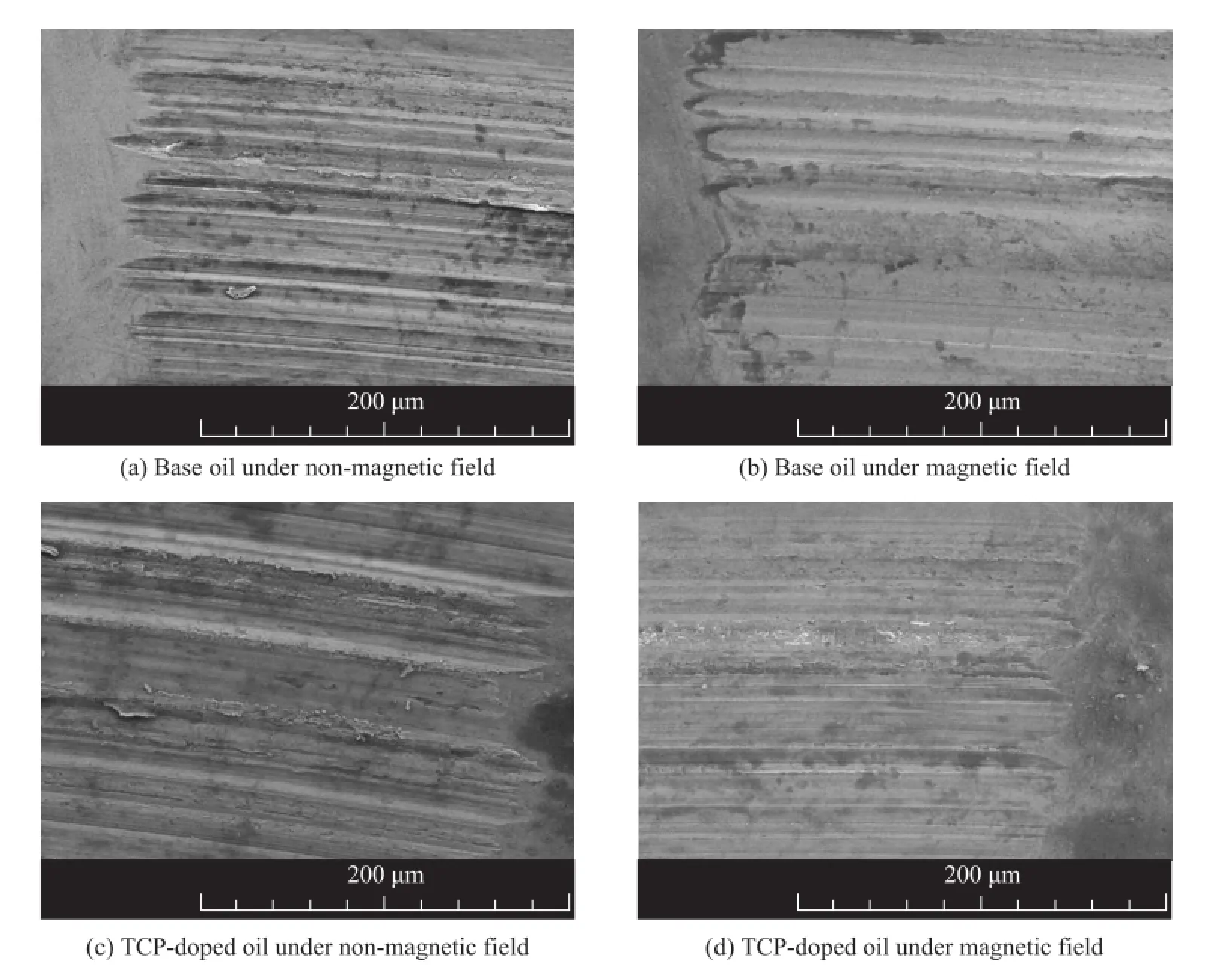

The SEM morphology of worn surfaces lubricated with 150 SN mineral oil and the oils formulated with 2.0% of TCP under a load of 392 N for 30 minutes in the presence of different magnetic felds are shown in Figure 6. It can be seen from Figure 6(a) and Figure 6(b) that smoother wear scar could be observed on surfaces lubricated with base oil under magnetic condition, a similar situation of surfaces lubricated with TCP-doped oils could be observed from Figure 6(c) and Figure 6(d), indicating the positive effect of magnetic feld on anti-wear property of tested oils. The results are well correlated with the antiwear test results shown in Figure 3.

3.4 Tribochemical characteristics

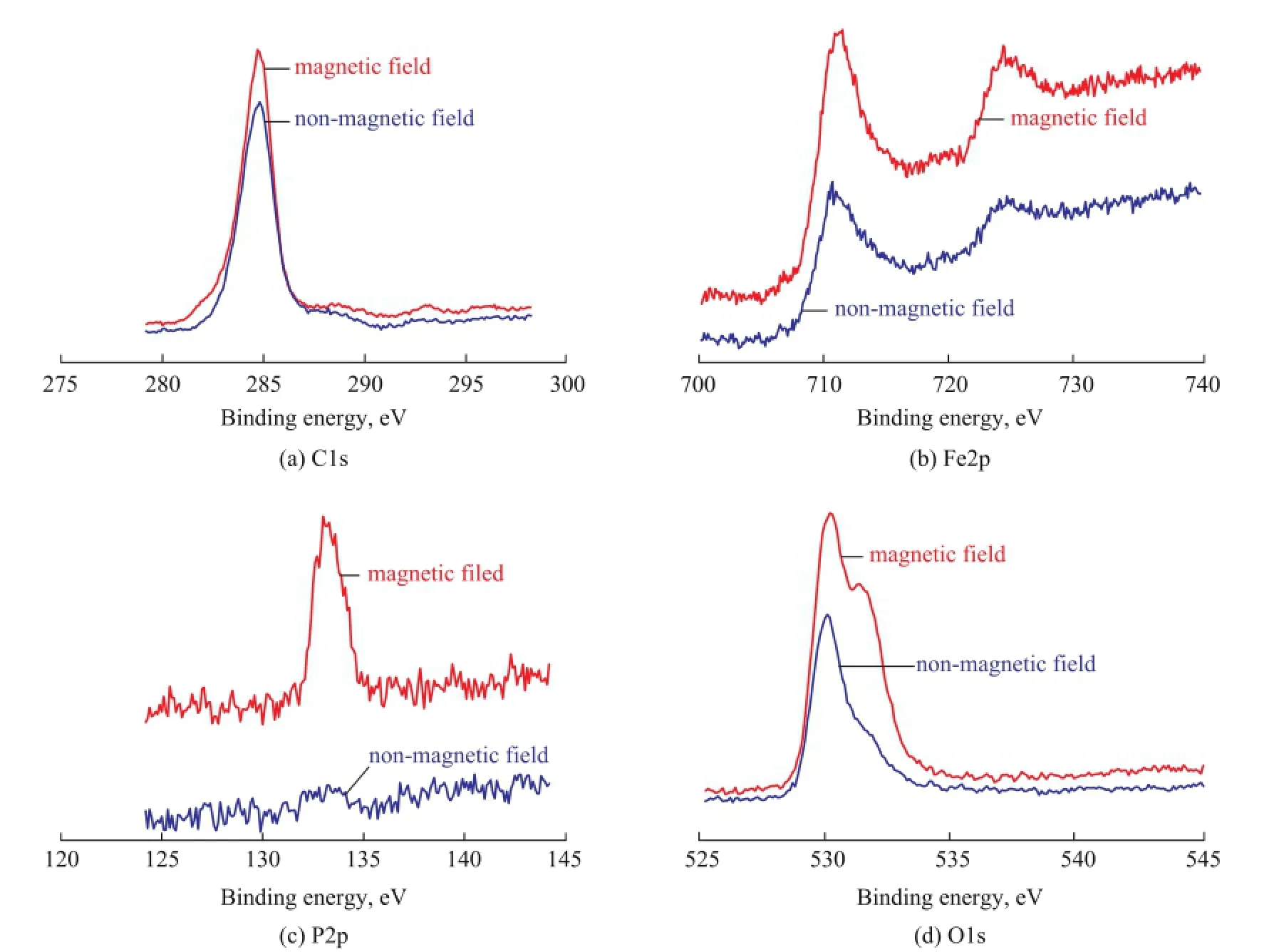

Figure 7 shows the XPS spectra of worn surface lubricated with oil samples containing 2.0% of TCP under the influence of magnetic or non-magnetic field. The XPS spectrum of C1s (Figure 7a) showed a peak in the binding energy range of 284.7—288.4 eV, which was assigned to organic species of C—C bonds, indicating that the lubricant molecules were adsorbed on the metal surfaces. In Figure 7b, the peak of Fe2p at a binding energy of 710.5 eV indicated that iron was oxidized to Fe3O4or Fe2O3. In the spectrum of P2p (Figure 7c), the peak at a binding energy of 133.4 eV might be attributed to the chemical species of FePO4. The peak of O1s (Figure 7d) around a binding energy of 531.4 eV might be attributed to P=O or iron oxide, in combination with the peak of Fe2p and P2p. It can be inferred from the results of XPS that a composite boundary lubrication film was mainly composed of FePO4, Fe2O3, and Fe3O4.

Figure 6 SEM images of worn surfaces lubricated with base oil and TCP-doped oil.

Figure 7 XPS spectra of worn surfaces lubricated by oil containing 2% of TCP under magnetic or non-magnetic fi eld

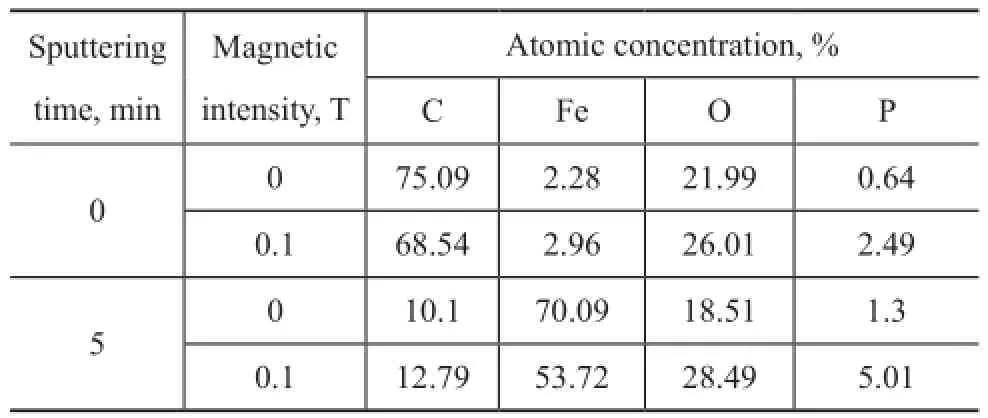

Table 2 Atomic percentage of typical elements on the worn surfaces

To further explore the magnetic effect on tribological property of lubricating oils formulated with TCP, the elemental compositions of worn surfaces obtained during testing in different magnetic felds were also determined by XPS analysis. The atomic concentrations of typical elements in the worn surfaces are listed in Table 2. As it can be seen from Table 2, the atomic contents of oxygen and phosphorus contained in the surface film under a magnetic feld of 0.1 T were higher than those under nonmagnetic feld. After sputtering for 5 minutes, higher concentrations of oxygen and phosphorus were detected in the sub-surface, indicating that tribo-diffusion of oxygen and phosphorus was promoted by magnetic affection. The higher content of oxygen obtained under magnetism quite well complied with the phenomenon that oxygen tends to gather around the magnetic feld because of its paramagnetic property[15]. Tribo-diffusion of oxygen and phosphorus into the sub-surface under magnetic condition can be an attribute of TCP to fortify anti-wear performance and impair friction-reducing ability of lubricating oils. Zhou[16]reported that the π bond structure of graphite exhibited good magnetization performance under the infuence of magnetic felds. Higher concentrations of oxygen and phosphorus on the surface and in the sub-surface of metal under magnetic condition can also be explained on the basis of the structural characteristics of TCP. The molecule of TCP contains a conjugated π bond structure because of three benzene rings (as can be seen from Figure 1), which can be a positive factor for TCP to exhibit good magnetization performance in the perpendicular direction of molecular plane with magnetic affection to improve the adsorption of TCP on the metal surfaces.

4 Conclusions

Based on the results given above, the following conclusions can be drawn.

(1) The wear scar diameters of steel balls lubricated with 150 SN mineral oil or oils formulated with TCP under magnetic fields were smaller than those obtained under non-magnetic condition, while the friction coefficients of the tested oils under magnetic field were higher than those under non-magnetic field condition. Magnetic field to some extent improved the anti-wear properties but impaired the friction-reducing properties of 150 SN mineral oil and TCP-doped oils.

(2) Composite boundary flms mainly were composed of FePO4, Fe2O3, and Fe3O4generated on the worn surfaces, and tribo-diffusion of phosphorus and oxygen into the sub-surfaces of metal under magnetic field might be an attribute for the improved anti-wear performance and impaired friction-reducing ability of TCP-doped oils with magnetic affection.

Acknowledgements: The authors gratefully acknowledge the financial support provided by the National Natural Science Foundation of China (Project No. 51375491), the Natural Science Foundation of Chongqing (Project No. CSTC, 2014JCYJAA50021) and the Innovation Fund of Logistical Engineering University of PLA (Project No. YZ13-43703).

[1] Zhang M, Feng Y. Effect of electric current on the friction and wear behavior of carbon nanotubes-silver-graphite composite[J]. Tribology, 2005, 25(4): 328-332

[2] Hu B, Meng Y G, Wen S Z. A preliminary experimental study on voltage-controlled friction clutch[J]. Tribology, 2004, 24(1): 46-49

[3] Senouci A, Zaidi H, Frene J, et al. Damage of surfaces in sliding electrical contact copper/steel[J]. Applied Surface Science, 1999, 144: 287-291

[4] Jiang Z Q, Zheng Z, Fang J H, et al. Effect of magnetic field on frictional and wearing properties[J]. Synthetic Lubricants, 2016, 43(1): 23-25 (in Chinese)

[5] Muju M K, Radhakrishna A. Wear of non-magnetic materials in the presence of a magnetic feld[J]. Wear, 1980, 58(1): 49-58

[6] Dong X L, Chen J R, Jian X G. Research situation and prospects for effect of a magnetic feld on friction and wear of metals[J]. Materials Science and Engineering, 2000, 18(1): 116-120 (in Chinese)

[7] Wei Y H, Zhang Z Y, Chen Y. Dry sliding friction and wearof high-speed steel/45 steel tribo-pair under direct current steady magnetic feld[J]. Tribology, 2010, 30(4): 399-403 (in Chinese)

[8] Zhou Q, Li J P, Long H S. The friction and wear of sleevering pair lubricated by active lubricants in the presence of magnetic field[J]. Journal of Wuhan University of Technology, 2004(11): 69-71 (in Chinese)

[9] Han H B, Gao Y K, Zhang Y Z, et al. The magnetic flux density and magnetic attraction force on the contact surface of pin-disk friction pair under DC magnetic feld[J]. Chinese Mechanical Engineering, 2015, 26(4): 503-507 (in Chinese)

[10] Han H B, Liu H, Zhang Y Z, et al. The electromagnetic induction phenomena in friction contact area of pin and disk under DC magnetic feld[J]. Tribology, 2015, 35(5): 557-562 (in Chinese)

[11] Zhou Z Z, Xiao J J, Zheng W. Recent research of the triboelectrifcation mechanism between the friction surfaces[J]. Journal of Wenzhou Vocational and Technical College, 2005, 5(1): 28-30 (in Chinese)

[12] Tang H B, Zhang M Q. Effect of magnetic felds on viscosity of alkane and alcohol[J]. Journal of Shenyang University of Technology, 2000, 22(5): 448-449 (in Chinese)

[13] Zhai W J, Hao G P. Influence of externally applied electrical factors on friction coefficient of steel/steel pair with boundary oil lubrication[J]. Journal of Harbin Institute of Technology, 2003, 35(8): 946-949 (in Chinese)

[14] Fang C M, Li M S, Liu X Q, et al. Research progress in synthesis and application situation of P-containing antiwear and extreme pressure additives[J]. Lubricating Oil, 2007, 22(1): 35-38 (in Chinese)

[15] Hu H, Gao H, Jia S Y. Effect of magnetic feld on physical and chemical properties of matter[J]. J Magn Mater Devices, 2000, 6: 36-38 (in Chinese)

[16] Zhou Q, Zheng Y J. Magnetizing friction and its boosting action on lubrication[J]. Tribology, 2002, 22(4): 479-482 (in Chinese)

Received date: 2016-04-20; Accepted date: 2016-06-17.

Prof. Fang Jianhua, Telephone: +86-23-86731410; E-mail: fangjianhua71225@sina.com.

杂志排行

中国炼油与石油化工的其它文章

- Removal of Nitrogen Compounds from Shale Diesel Fraction Using Ionic Liquid [C4mim]HSO4

- Improved Ti-containing Mesoporous Silica Catalyst Synthesized by Using Anionic Surfactant as Co-template

- Synthesis of Hierarchically Porous FAU/γ-Al2O3Composites with Different Morphologies via Directing Agent Induced Method

- Study on CO2Absorption by Aqueous Benzylamine and Its Formulations with Monoethanolamine as a Component for Post-Combustion Capture Process

- Preparation and Lubricating Properties of A New Antibacterial Emulsion Containing Nano-TiO2for Cold Rolling Strips

- The Effect of Surfactant on Synthesis of ZSM-5 in a Super-Concentrated System