Experimental Study of Integrated Ebullated-bed and Fixed-bed for Hydrotreating Mid-Low Temperature Coal Tar to Clean Fuel

2016-03-22

(SINOPEC Fushun Research Institute of Petroleum and Petrochemicals, Fushun 113001)

Experimental Study of Integrated Ebullated-bed and Fixed-bed for Hydrotreating Mid-Low Temperature Coal Tar to Clean Fuel

Meng Zhaohui; Yang Tao; Fang Xiangchen

(SINOPEC Fushun Research Institute of Petroleum and Petrochemicals, Fushun 113001)

A new hydrotreating technology integrating the ebullated-bed (EB) and the fxed-bed (FB) hydrogenation was proposed to investigate the effciency for hydrotreating mid- low-temperature coal tar to clean fuel, and multiple tests at the bench scale were carried out. The results showed that the distillates obtained from EB reactors were greatly upgraded and could meet the requirements of FB unit without discarding any tail oil. The naphtha produced from FB reactors could be fed to the catalytic reforming unit, while a high quality diesel was also obtained. The unconverted oil (UCO) could be further hydrocracked to clean fuel. It is found that the removal of impurities from the coal tar oil is related with the molecular aggregation structure and composition of the coal tar. Application of the integrated hydrotreating technology to the hightemperature coal tar processing demonstrated that more than half of heavy components could be effectively upgraded.

coal tar; ebullated bed; fxed bed; integrated hydrotreating

1 Introduction

As the consumption of light fuel rises, more and more attention is paid to the alternative oil resources. Every year, over 10 million tons of coal tar are produced in China as a byproduct of coal pyrolysis, but coal tar cannot be converted to high value-added products cleanly and efficiently using the existing hydrotreating processes[1-4]. Traditionally, coal tar is treated to produce chemicals and the surplus heavy distillate is made into bitumen. Because of lack of advanced technology, the conversion of coal tar is unsatisfactory; meanwhile, the traditional processes can cause environmental pollution. So the development of new technologies for coal tar hydrogenation is extremely necessary.

The traditional fixed-bed hydrotreating technology cannot treat coal tar effciently, which contains high concentration of asphaltenes, poly-aromatics, metals, oxygencontaining compounds, and other impurities[5]. The polyaromatics and olefns in coal tar are prone to condensation and coking in the reactors, causing a rising pressure drop and an ultimately shortened on-stream period of units[6]. The ebullated-bed (EB) technology can adapt well to inferior feedstocks due to the fact that catalysts can be replaced online during the operation[7]. The EB technology developed by FRIPP has treated a variety of residues and coal tars. The test results showed that the EB technology can pre-treat coal tar and upgrade the quality of coal tar effectively. An integrated hydrotreating technology combining the ebullated bed and the fxed bed (FB) hydrogenation is a clean and effcient method for hydroprocessing coal tar to produce light fuel oil. The integrated technology has treated different kinds of coal tar, such as the midlow temperature coal tar and the high-temperature coal tar successfully. A large number of experimental data have been obtained[8-10].

2 Experimental

2.1 Feedstock and apparatus

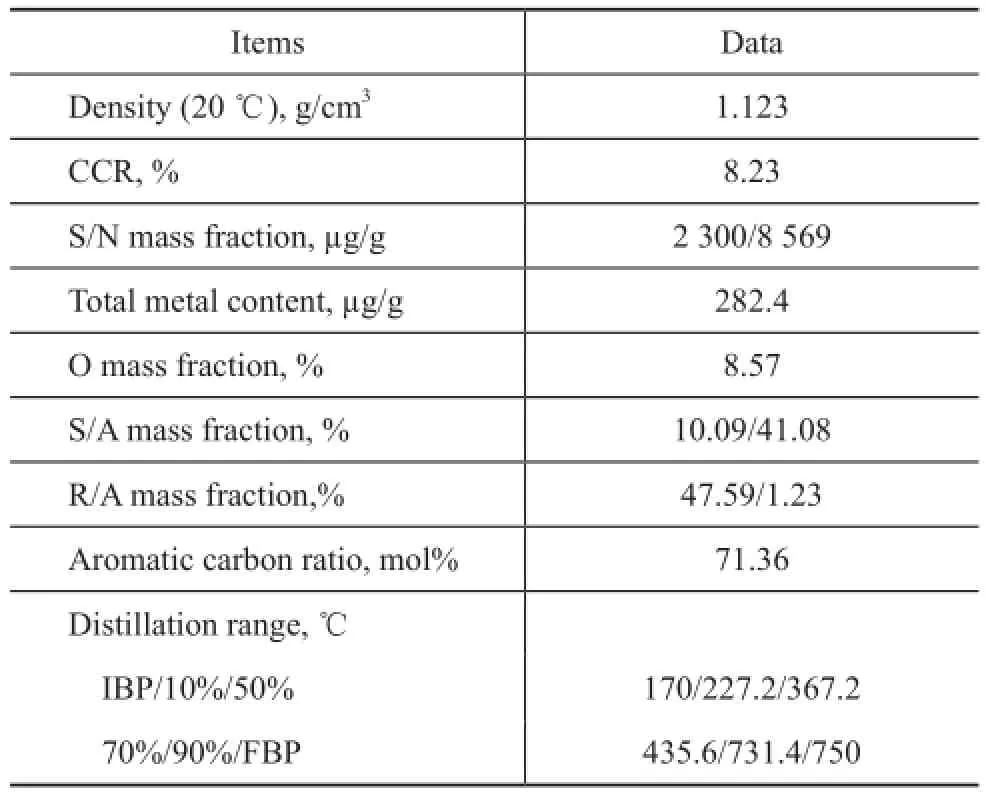

A mid-low temperature coal tar was chosen as the feedstock for the integrated EB and FB hydrogenation technology. The characteristics of coal tar are presented in Table 1, which shows that the density of the coal tar ishigher than that of conventional vacuum residue, and the nitrogen and oxygen content of the coal tar is also high. High oxygen content in coal tar indicates that a lot of water may be generated during hydrotreating, and a new special waterproof catalyst should be used. In addition, the total metal content is high: the content of Fe, Ca and Al is equal to 250.5 µg/g, while the content of Ni and V is about 30 µg/g. The metal content is very different from that of conventional residue, which can be attributed to the process for production of coal tar. The tests were conducted in an EB pilot reactor, which was composed of two connected in series sub-reactors of the same size. The effuent streams produced from the EB reactor were further processed by FB reactors of the same size provided with different catalysts.

Table 1 Characteristics of feed

2.2 Bench tests

About 10%—30% of oxy-compounds in the form of phenols and its ramifcations exist in the coal tar[11], including a large number of alkadienes[12], which are susceptible to aggregation. Oxy-compounds will generate water during de-oxidation reaction, which is harmful to the activity and mechanical strength of cracking catalysts[13], and the pressure drop will rapidly rise if alkadienes are directly processed in FB reactors, which will ultimately result in a shortened on-stream period and frequent catalyst bed skimming. Since most coal tars are composed of cracked fractions under high temperature, it is suggested that relatively moderate conditions are needed to pre-hydrogenate alkadienes and remove a part of impurities so that the coal tar can be hydrocracked under more rigorous conditions. Based on the above considerations, the water-resistant deoxidation catalysts and hydrotreating catalysts are loaded into the EB reactors, and meanwhile the FB reactors are loaded with cracking catalysts, with the characteristics of different catalysts presented in Table 2.

Table 2 Characteristics of different catalysts

Based on the properties of the coal tar, different reaction temperatures were selected to investigate the hydro-conversion performance of coal tar. The operating conditions of EB and FB reactors are shown in Table 3.

Table 3 Operation conditions of EB reactor and FB reactor

2.3 Schematic fl ow diagram

The schematic fow diagram of the integrated hydrotreating technology is presented in Figure 1. Firstly, the material is pre-hydrogenated in the EB reactors under moderate conditions. After most of the olefns and aromatics in the coal tar are hydrogenated, the liquid is separated from gas and is pumped into the FB reactors provided with more active catalysts under more rigorous conditions. At last, the products are fed into the separation and distillation unit to separate different fractions.

Figure 1 Schematic fl ow diagram of integrated hydrotreating technology

3 Results and Discussion

3.1 Results of EB tests on hydrotreating mid-low temperature coal tar

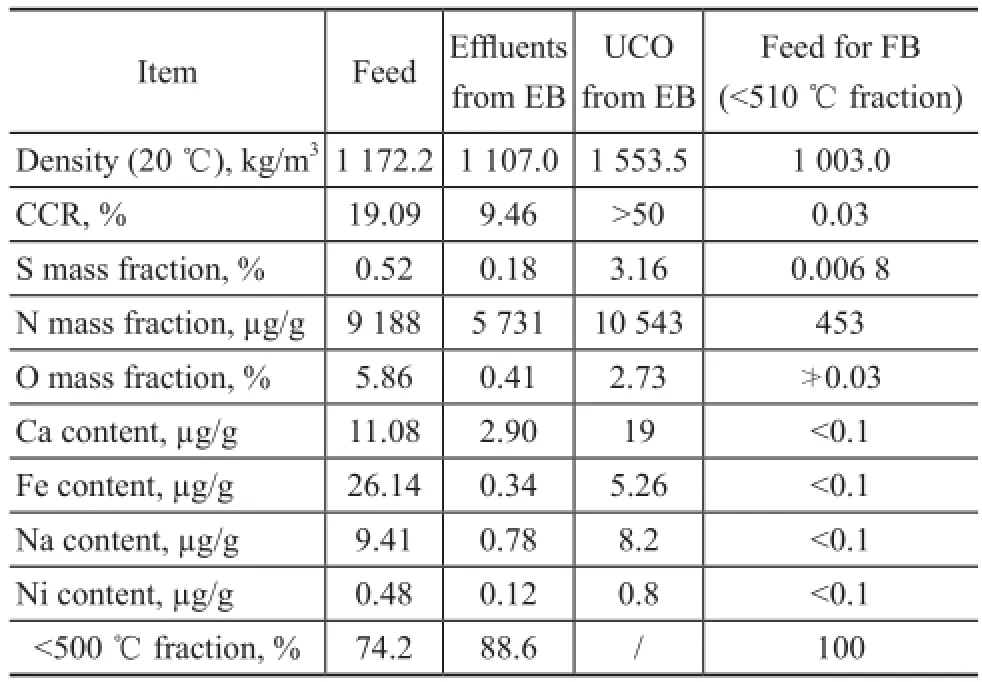

Coal tar was processed by the EB hydrotreating technology according to the conditions presented in Table 3, and the fractions obtained from the bench tests are also shown in Table 4.

It can be seen that after EB hydrotreating, the impurity content of the coal tar was significantly decreased. In terms of distillation range, the content of <350 ℃ fractions in the feed was 46.2%, and the content of <500 ℃fractions accounted for 81.3%. After EB hydrotreating, the quality of the fractions was apparently upgraded, because the content of <350 ℃ fraction in the products increased to 75%, and that of <500 ℃ fraction even rose to 95%, which meant that only a small amount of oil (boiling over 500 ℃) remained unconverted. The whole fraction of the products derived from EB reactors could be fed into the FB reactor without discarding the tail oil. The rate for removal of impurities and the hydro-conversion rate under different conditions are presented in Figure 2.

Table 4 Characteristics of different products

Figure 2 Hydro-conversion performance under different operating conditions

It can be seen from Figure 2 that the rate for removal of impurities initially increased rapidly with an increasing rate of hydro-conversion of feedstock, especially in terms of the denitrifcation rate. With respect to the test 2, the rate for removal of all impurities was very high, among which the rates for removal of metals and CCR were above 99%. As the hydro-conversion degree further increased, the rate for removal of impurities remained almost unchanged. Generally speaking, the impurities contained in coal tar were nearly completely removed under the conditions shown above, which was better than the situation for processing the vacuum residue. This phenomenon has something related with the aggregation structures and properties of the coal tar. Firstly, the coal tar is composed of readily crackable fractions formed at high temperature, the size of which is small. These fractions of small size are connected by the hydrogen bond and the Van der Waals’ force, which is very weak. Hence these fractions can be easily cracked. Secondly, the inter-actions among molecules are so weak that the viscosity of the coal tar is low. It is well-known that the diffusion resistance is a control step during hydrogenation; the lower the viscosity is, the less the resistance would be, so it is relatively easy to remove impurities from the coal tar. This phenomenon can also be derived from the SARA analysis, denoting that the content of aromatics and resins in the coal tar makes up nearly 90%, while the content of asphaltenes in the coal tar is the least. Asphaltenes accumulate most sulfur compounds, nitrogen compounds and other impurities, and their strong polarity and complex molecular structure hinder the removal of impurities. Since less asphaltenes exist in coal tars, the hetero-atoms are evenly dispersed in saturates, resins and aromatics, the structure of which is much simpler than that of asphaltene. Therefore, the removal of impurities, as compared to the case with vacuum residue, is much easier and more complete. It is also noted that because of the hydrogenation reaction and the alkyl side chains cracking reaction, the content of aromatics and resins reduces, leading to an increasing content of saturates, which is also verifed by the changes in the aromatic carbon ratio, which is reduced from 71.36 mol% to 27.46 mol%. The increasing saturability or decreasing unsaturated components in the effuents can reduce the risk of coking in the downstream units.

In Table 4, the properties of products obtained from the conditions 2 and 3 are better than those obtained from the condition 1, and they are the superior feeds for FB reactors. However, when the reaction temperature rises in condition 3 by 10 ℃ higher than in condition 2, the properties of the effuents do not change much. Upon considering the economic cost, the condition 2 is a priority choice for pretreating the coal tar.

3.2 Results of fi xed-bed tests

The whole fraction of EB hydrotreated effuents was used as the feed for the FB unit, in which two reactors connected in serial were operated at a hydrogen partial pressure of 15 MPa and a H2/oil ratio of 600, while the temperature regime and the LHSV value were the same in the reactor 1 and the reactor 2. The effuents obtained from FB reactors were distilled into three fractions, with the yields and properties of fractions presented in Table 5.

Table 5 Properties and yields of different fractions

After FB hydrotreating of effuents from the EB reactors,

the diesel yield increased to 74.8%, while the light naphtha yield accounted for 9.3%. Moreover, the yield of>370 ℃ fraction which was dominantly composed of VGO only accounted for 13.4%, and the overall liquid yield after hydrotreating reached 97.5%. The results demonstrate that the FB hydrotreating greatly reduced the boiling range of the whole fraction of the coal tar to achieve a high liquid yield. Moreover, the unconverted oil (UCO) can be fed into a hydrocracking unit.

It is found that the density of naphtha is 0.76 g/cm3, while the content of nitrogen and sulfur is 1.0 μg/g and 1.0 μg/g, respectively. The potential aromatic content of the naphtha is 56%, making itself a promising feed for catalytic reforming unit. The diesel yield reaches up to 74.8%, with a density of 0.86 g/cm3and a nitrogen content of 3.0 μg/g. Furthermore, the cetane number of diesel fraction is as high as 53, indicating to its potential feed to be processed to a high quality product or a good additive. The UCO is of high quality with its sulfur content and nitrogen content equating to 30 μg/g and 21 μg/g, respectively. Moreover, the CCR is as low as 0.15%. Superior gasoline and diesel have been obtained through hydro-cracking process along with a good quality of UCO[15].

3.3 Advantages and disadvantages of different technologies

Advantages and disadvantages of different integrated hy-drotreating technologies for processing coal tar that are currently available are compared in Table 6.

It can be seen from Table 6 that the new integrated EB and FB hydrotreating technology is capable of achieving much better performance than the other two technologies. In comparison with the traditional integrated technology, such as the pre-distillation and FB hydrotreating technology, and the delayed coking and FB hydrotreating technology, in both of which the overall liquid yields are 75%—80%, the new integrated EB and FB hydrotreating technology can achieve an overall liquid yield of 94%—96%, while no low-value coke and heavy fuel oil are produced from this new technology. Additionally, no secondary or potential contamination is generated by the new technology. In short, the new technology can transform inferior coal tar into clean and high-value gasoline and diesel as much as possible. Besides, the new technology generates no coke and heavy fuel oil and is an environmentally-friendly technology for coal tar utilization.

Table 6 Comparison of different integrated technologies

3.4 Results of integrated technology on hydrotreating high-temperature coal tar

The integrated technology mentioned above can process the mid-low temperature coal tar effciently with less tail oil generated. High-temperature coal tar is inferior as compared to the mid-low temperature coal tar[15-18], and it is more diffcult to be treated by the conventional technology. Only one commercial unit for processing high-temperature coal tar is reported in the literature[19], in which a<360 ℃ fraction was distilled from high-temperature coal tar and pumped into FB unit for further processing, while the >360 ℃ fraction was fed into a delayed coke unit or was used as heavy fuel oil. Generally, the proportion of>360 ℃ fraction in high-temperature coal tar is higher than 50%, and the conventional processes for treating the hightemperature coal tar can only generate a lot of low-value coke or heavy fuel oil with low liquid yield.

Similar tests were carried out with high-temperature coal tar using the new integrated technology. The results shown in Table 7 indicate that more than half of the >500 ℃fraction is upgraded with only 11.4% of tail oil discarded, which is much less than that obtained from the conventional commercial unit. Meanwhile, the new integrated technology can obtain higher liquid yield to achieve higher economic benefts. It is also observed that the UCO is of inferior quality. Some tests carried out with the UCO on indexes of road asphalt in the paper showed that UCO derived from coal tar is fragile with high hardness, which can hardly be melted even at high temperature. UCO derived from the high-temperature coal tar is not suited for manufacture of road asphalt; besides, some other analyses made in the paper indicate that UCO from coal tar has high viscosity, which cannot meet the requirement for the quality of fuel oil. Upon considering the above factors, UCO was only employed as the feed for delayed coking unit or the solvent de-asphalting (SDA) unit, which have strong adaptability to inferior feedstocks. Furthermore, light fractions can be obtained after treating UCO in DC or SDA units.

Table 7 Properties of high-temperature coal tar feed and products

4 Conclusions

1) The quality of coal tar processed by the EB hydrotreating technology was greatly improved with a decreasing content of CCR and metal, and it could satisfy the feed requirements of FB reactors. Furthermore, the saturability of coal tar hydrotreated by the EB hydrotreating technology rose greatly, which would help to avoid coking during hydroconversion reaction.

2) The naphtha produced by the integrated hydrotreating technology could be fed to the catalytic reforming unit, and the diesel could be used as a good additive, while the UCO which was dominantly composed of VGO could be hydrocracked into naphtha and diesel fractions.

3) Compared to the conventional coal tar hydrotreating technologies, the new integrated hydrotreating technology could achieve a much higher effciency.

4) The integrated hydrotreating technology could also handle the high-temperature coal tar to upgrade most of the heavy components.

5) The UCO derived the high-temperature coal tar was not suitable for manufacture of road asphalt and fuel oil, but could be further processed by DC or SDA units, from which more liquid yield could be obtained.

Acknowledgment: The authors thank SINOPEC for its fnancial support (No. 2011AA05A203).

[1] IEA. World Energy Outlook[R]. 2009

[2] Liu Z, Shi S, Li Y. Coal liquefaction technologies development in China and challenges in chemical reaction engineering[J]. Chem Eng Sci, 2010, 65(1): 12-17

[3] Cui H, Yang J, Liu Z, et al. Effects of remained catalysts and enriched coal minerals on devolatilization of residual chars from coal liquefaction[J]. Fuel, 2002, 81(11/12): 1525-1531

[4] Dai Fei, Gong Maoming, Li Chunshan, et al. New kinetic model of coal tar hydrogenation process via carbon number component approach[J]. Applied Energy, 2015, 137: 265-272

[5] Ramakanta Sahu, Song B J, Ji S I, et al. A review of recent advances in catalytic hydrocarcking of heavy residues[J]. Journal of Industrial and Engineering Chemistry, 2015, 27: 12-24

[6] Sun Guoquan, Yao Chunlei, Quan Hui, et al. Development and commercialization of clean fuels production technology from medium and low temperature coal tars[J]. Petroleum Processing and Petrochemicals, 2015, 46(8): 12-17 (in Chinese)

[7] Xue Qian, Zhang Yu, Liu Mingrui, et al. Preparation of #180 marine fuel oil by ebullated-bed hydrotreatment of medium temperature coal tar[J]. Petroleum Processing and Petrochemicals, 2015, 46(10): 88-92 (in Chinese)

[8] Xu Jie, Liu Ping, Wang Liyan. Study on anthracene oil to light fuel through hydrogenolysis[J]. Coal Chemical Industry, 2008(5): 21-24 (in Chinese)

[9] Fang Xiangchen, Xu Jie. A technology for coal tar hydrogenating into fuel oil: China, 101294107 [P]. 2007-08-27

[10] Yao Chunlei, Quan Hui, Zhang Zhongqing. Hydrogenating process for mid-low coal tar into clean fuel oil[J]. Chemical Industry and Engineering Progress, 2013, 32(3): 501-507 (in Chinese)

[11] Yang Tao, Fang Xiangchen, Jiang Lijing, et al. Research on STRONG ebullated bed residue hydrotreating technology[J].Acta Petrolei Sinica (Petroleum Processing Section), 2010, 26(S1): 33-36 (in Chinese)

[12] Zhang Xiaojing. Hydrogenating process for coal tar from mid-low-temperature coal carbonization[J]. Journal of China Coal Society, 2011, 36(5): 840-844 (in Chinese)

[13] Chen Tieniu. Hydrogenating process for mid-low-temperature coal tar [J]. Fuel & Chemical Processes, 2013, 44(4): 52-54

[14] Fang Xiangchen, Guan Minghua. Hydrofning[M]. Beijing: China Petrochemical Press, 2006: 446-448 (in Chinese)

[15] Zhu Jiliang, Fan Xing. Molecular characterization of heteroatomic compounds in a high-temperature coal tar using three mass spectrometers[J]. Fuel Processing Technology, 2015, 138: 65-73

[16] Sun Zhihui, Li Dong, Ma Haixia. Characterization of asphaltene isolated from low-temperature coal tar[J]. Fuel Processing Technology, 2015, 138: 413-418.

[17] Jin Lijun, Bai Xiaoyu, Li Yang, et al. In-situ catalytic upgrading of coal pyrolysis tar on carbon-based catalyst in a fxed-bed reactor[J]. Fuel Processing Technology, 2016, 147: 41-46

[18] Zhang W, Anderson J T, Rader H J. Molecular characterization of large polycyclic aromatic hydrocarbons in solid petroleum pitch and coal tar by high resolution MALDITOF MS and insights from ion mobility separation[J]. Carbon, 2015, 95: 672-680

[19] Zhou Jun, Gao Mingyan. Hydrogenating process for high temperature coal tar[J]. Shandong Chemical Industry, 2012, 41(6): 38-40 (in Chinese)

Received date: 2016-05-22; Accepted date: 2016-06-05.

Prof. Fang Xiangchen, E-mail: fangxiangchen.fshy@sinopec.com.

杂志排行

中国炼油与石油化工的其它文章

- Synthesis of Hierarchically Porous FAU/γ-Al2O3Composites with Different Morphologies via Directing Agent Induced Method

- Puri fi cation of Aromatics over a PromisingCatalyst

- The Effect of Surfactant on Synthesis of ZSM-5 in a Super-Concentrated System

- Removal of Nitrogen Compounds from Shale Diesel Fraction Using Ionic Liquid [C4mim]HSO4

- Effect of Magnetic Field on Tribological Properties of Lubricating Oils with and without Tricresyl Phosphate

- Improved Ti-containing Mesoporous Silica Catalyst Synthesized by Using Anionic Surfactant as Co-template