Difficulties and measures of driving super long piles in Bohai Gulf

2015-11-21ShuwngYnJiLiLiqingSunGuominSun

Shuwng Yn,Ji Li,Liqing Sun,Guomin Sun

aSchool of Civil Engineering,Tianjin University,Tianjin 300072,China

bChina Offshore Oil Engineering Co.,Tianjin 300461,China

Difficulties and measures of driving super long piles in Bohai Gulf

Shuwang Yana,∗,Jia Lia,Liqiang Suna,Guomin Sunb

aSchool of Civil Engineering,Tianjin University,Tianjin 300072,China

bChina Offshore Oil Engineering Co.,Tianjin 300461,China

A R T I C L E I N F O

Article history:

Received 23 October 2014

Accepted 28 December 2014

Available online 26 February 2015

Super long pile driving

Refusal

Excessive pore pressure

Hydraulic fracture

Finite element analysis

Prevent measures

Long piles ofthe ocean oilplatform are usually manufactured as the integration ofseveralsegments,which have to be assembled one by one during installation.During pile driving,excessive pore pressure willbuild up in such a high level that hydraulic fracturing in the soil round the pile may take place,which will cause the soilto consolidate much fasterduring pile extension period.Consequently,afterpile extension,the soil strength will recover to some extent and the driving resistance will increase considerably,which makes restarting driving the pile very difficult and even causes refusal.A finite element(FE)analysis procedure is presented for judging the risk of refusal by estimating the blow counts after pile extension,in which the regain of soil strength is considered.A case analysis in Bohai Gulf is performed using the proposed procedure to explain the pile refusal phenomenon.

©2015 The Authors.Published by Elsevier Ltd on behalf of The Chinese Society of Theoretical and Applied Mechanics.This is an open access article under the CC BY-NC-ND license(http:// creativecommons.org/licenses/by-nc-nd/4.0/).

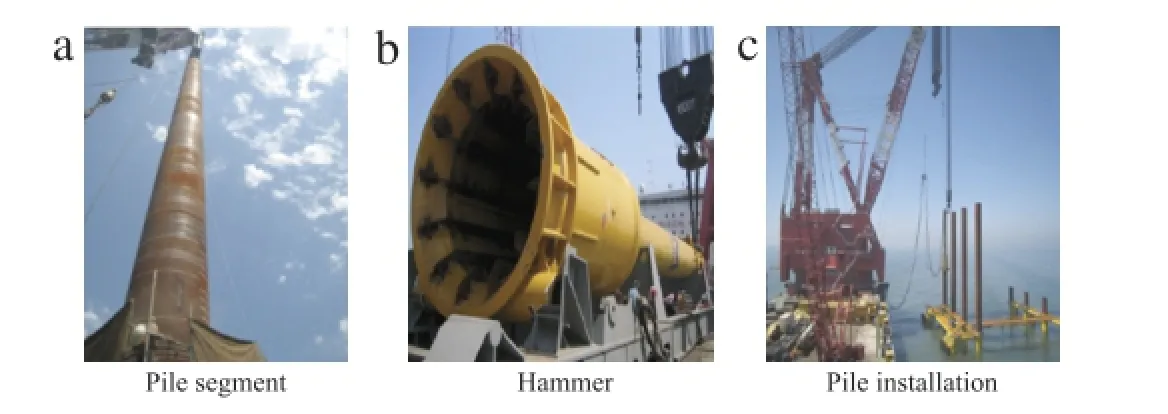

Oil platforms with six or eight legs have been normally adopted in BohaiGulf,China[1].The leg piles with diameters of2 mormore need to be driven to about 100 m below the seabed[2].Such long piles have to be manufactured by segments before installation,because of transportation and hoisting difficulties.The segments of the pile willbe assembled during installation,in which a successive segment will be attached to a formerly penetrated one by welding(Fig.1).Each pile extension work often takes one day or even a longer time.

During this period,the excessive pore pressure in the soil around the pile,which was built up during pile driving,will be dissipating[3,4].Consequently,the soil strength will regain to some extent,which makes restarting the successive penetration very difficult and even causes refusal[5].It is usually very costly and timeconsuming to dealwith pile refusalproblems.This matter has been encountered quite often in BohaiGulfand puzzled the designers for years.

In order to avoid pile refusal after pile extension,it is essential to conduct accurate and rigorous pile drivability analysis,based on which comprehensive construction schemes,procedures,and correlative management system should be established.Accurate prediction of the driving response is also important to estimate the capacity of a pile and to select a suitable hammer system.

In this paper,the buildup and dissipation characteristics of excessive pore pressure in the soil is discussed.According to the engineering experience and theoretical analysis,it is proved that the accumulated high pore pressure will cause fracturing of soils around the pile.The developed fissures will greatly increase the consolidation ratio during pile extension time and make the soil strength to recover,which will make restarting driving difficult. The finite element(FE)procedure is established to estimate the risk ofpile refusalafter pile extension,in which a suitable fatigue factor,which is related to the degree of consolidation of the soil,is chosen to consider the regain of soil strength.A case is analyzed by using the proposed procedure to explain the pile refusal phenomenon.

Figure 2 shows a typical pile driving records of the platform WHPE in Bohai Gulf,which is one of the refusal cases in this area.

From the record charts it can be seen that,when the pile is driven continuously,for example,from 22 m to 47 m,the blow counts for every 30 cm penetration are increasing smoothly,indicating that the pile is penetrated without difficulty.This may be due to several factors.(1)The structure of the soil around the pile has been disturbed so that the soil resistance decreases.(2)Excessive pore pressure in the soilhas accumulated to a high levelso that the effective confining stress on the soil-pile interface reduces.(3)The soil-pile interface has been polished by the repeated relative movement.

The first and second factors will cause both tip bearing resistance and the normal stress acting on the soil-pile interface to decrease.The third factor will diminish the interface frictional coefficient.Since the shaft frictional force is the product of the effective normal stress and the frictional coefficient,it will decrease with pile driving sharply.The total penetration resistance is the sum of the tip bearing resistance and the shaft frictional force on the soil-pile interface.Therefore,penetration resistance is greatly decreased from the initial state.It is obvious that without the resistance reduction induced by these influencing factors,driving a pile would become very difficult or even impossible.

In the commonly used FE programs for drivability analysis,such as TNO and GRLWEAP[6,7],a so called fatigue factor,β(β≤1),is consistently introduced to cover all these three influencing factors. In the analysis,the soil resistance is multiplied byβto calculate the blow counts versus penetration.There are several assumed distribution types forβ.The most commonly used is the following one:

Fig.1.Pile installation of oil platform in Bohai Gulf,China.

Fig.2.Pile driving records of the platform WHPE.

whereβis the fatigue factor,Y is the designed penetration,and X is the specified pile tip penetration.Theβvalue is increased from zero to 1 along with the pile tip penetration 5 mabove the designed pile tip penetration.For the last 5 m penetration,the fatigue effect can be neglected.Engineering experiences have shown that this type ofβdistribution is good for predicting the blow counts for driving a pile continuously,otherwise it will give fault results.The reason will be discussed hereinafter.

Research results have shown that when the excess pore pressure is increased to a high level,the hydraulic fracturing phenomenon will occur[9].By applying high water pressure to the drilling hole,fracturing of the soil or rock wall of the drilling hole will take place.During this process,many fissures will be developing in the soil or rock near the wall,which will greatly increase the permeability of the soil or rock.Vaughan[10]put forward a formula to predict the hydraulic fracturing of clayey soils based on specially designed in situ experiment

Fig.3.Variation of normalized maximum excess pore pressure ratio with distance to pile driving.

During pile driving,the pore pressure will both generate and dissipate,and the accumulated pore pressure is the offset result of the two adverse processes.The pore pressure generating rate is always greater than the dissipating one.From Fig.3 it can be seen that the accumulated pore pressure is much smaller in sandy soils than that in clayey soils,because of the difference in dissipation rates between clayey soilsand sandy soils.Once pile driving ceases,the accumulating process will stop while the dissipating process continues and the soil around the pile will undergo consolidation,which will decrease the excessive pore pressure and increase in effective stress in the soils.

For sandy soils,the consolidation process will accomplish quickly because of their high permeability.For clayey soils,the pore water will be drained out through the developed fissures much faster than through the soil voids.Therefore the consolidation coefficient,cv,will be much higher than that of the soil in the initial state.Hwang[4]compared the data observed in situ with that calculated with Terzaghi’s 1D consolidation theory at the same location.The initial coefficient of consolidation of the soil is 6×10-3cm2/s according to the laboratory test results.The predicted dissipation time based on the 1D model is 120 times greater than that observed from in situ tests,which means that the cvis increased by 120 times from the initial value after pile driving.

During pile driving,soil plug may be formed which makes the driven pile behavior as a close-ended one and greatly increase the difficulty to drive.It has been proved that for large diameter piles,the plug is rarely formed during penetrating[11].

As mentioned above,pile extension usually takes one day or more.Some bad weather conditions may even stop the driving work for a longer time.During this period,the excessive pore pressure willbe dissipating fast,the soilstrength willregain rapidly and the pile will probably be fully plugged.This will thereafter cause restarting driving the pile difficult.As the given example shows(refer to Fig.2),before the first pile extension was carried out,when the penetration is about 47 m,the blow count is about 50 in 30 cm. When pile driving restarted after pile extension about 24 h later,the blow count for further penetration increased to about 250 in 30 cm.Before the second pile extension was carried out,when the penetration isabout71 m,the blow countis about100 in 30 cm.After pile extension,it was very hard to penetrate the pile any further.

For long and large dimension piles,it is essential to conduct accurate and rigorous pile drivability analyses,based on which,comprehensive construction schemes,procedures,and correlative management system can be established.Some commercial softwares,such as TNO and GRLWEAP[6,7],are available for pile driving analysis.These programs are based on the one dimensional wave equation and coordinate with useful engineering experiences.

With proper input parameters,the software can predict the stresses development in the pile during pile driving,the blow count per feet penetration and even the bearing capacity ofthe pile.With the predicted blow count along with depth and the hammer used,the drivability of the pile can be predicted in the design stage.

When the softwares are used to analyze the drivability of a pile after pile extension,the input parameters need to be determined according to the specified soil conditions,among whichβis the most important one.

Considering the high speed ofpore pressure dissipation,the soil around the pile will regain a large portion of its strength.Calculating results have shown that the excessive pore pressure induced by the cavity expansion is much greater than that induced by the dynamic effect[9].When restarting driving a pile,since less penetration is taking place,the excessive pore pressure is more likely to be induced by the dynamic effect,which may not be able to disturb the soil in such an extent that the hammer driving energy can overcome the soil resistance and penetrate the pile further.That is why it is so difficult to restart driving a pile.The extent of difficulty depends on the degree of pore pressure dissipation,and thus relates to the interval time between ceasing and restarting driving.

To predict the drivability of the pile which restarts after pile extension,and for the purpose ofobtaining a conservative estimation with the FE programs,it is reasonable to treat the pile to behavior as close ended,and setβto be a constant value according to the degree of consolidation of the soil at all depth for the first 30 cm penetration.Ifthe calculated blow countfordriving the pile to penetrate 30 cm is too large,the risk of refusal may arise.In this way,the strength recovery due to the dissipation of the accumulated pore pressure can be considered in the analysis.

Fig.4.Piles position of WHPE platform in Bohai Gulf,China.

Several measures can be taken to reduce the refusal risk for restarting a segmented pile.Firstly,the strength recovery ratio of the soil depends on the time for pore pressure dissipation,which will greatly increase the driving resistance.Therefore,cutting down the pile extension time is the most effective measure to minimize the refusal risk.

Secondly,refusal usually takes place when the last segment of the pile is assembled.It is the common knowledge that driving resistance in sand is much higher than that in clay.Therefore,it is recommended to keep the pile tip in a clay layer instead ofthe sand layer when extending the pile segment.

Thirdly,pile driving resistance at upper positions is less than that in deeper position.Therefore,to cease the pile tip at a smaller penetration can make restarting the pile easier.This means that it is better to design the length of the last segment of the pile as long as possible,provided the other requirements,such as the stick-up stability,are satisfied.

The WHPE platform is one of the drilling platforms constructed in Bohai Gulf,China.The pile foundation of this platform consists of eight piles,as shown in Fig.4.

The water depth is 27.6 m.The soil profile is described in Table 1.The data needed for FE analysis are also given in the same table,which are determined with the API code[12]based on the soil properties.Each of the piles is 141 m long with outer diameter of 1.676 m and consists of 4 segments,i.e.,61 m,30 m,25 m,and 25 m,respectively.The designed penetration for the piles is 96 m. Details of the pile are given in Table 2.The MENCK MHU 800S hammer was used for driving the piles.The parameters for the hammer are listed in Table 3.

Driving records for pile A2,A3,A4,and B3 are shown in Fig.5. The first segment of the pile sank into the ground for about 10 m under the selfweight plus the hammer weight and then was penetrated to about 22 m by hammering.Afterwards the second segment was assembled.It can be seen from Fig.6 that,a few more blows were needed to restart driving the pile at this depth,and after overcoming the resistance caused by soil strength recovery,the driving process became normal.The third segment was assembled at depth 47 m in the silt sand layer.The driving records show that many more blows were needed to restart driving the pile after 24 h extension time.The last segment was assembled at depth 71 m.Driving work restarted 7 days after pile extension because of the bad weather.At this time,it was found impossible to penetrate these piles further;even the more powerful MHU1200S hammer was used.

The software GRLWEAP was used to simulate the driving process.The input data for soil,pile,and hammer are shown in Tables 1-3,respectively.The analysis consists of the following parts.

Continuous driving.The purpose of this analysis is to select a suitable hammer for the specified pile and soil conditions.In the analysis,the pile is treated as an integrated structure and driven to the designed depth without stopping.The value ofβis calculated with Eq.(1).The FE analysis results are shown in Fig.6,which indicates that the pile can be driven to the design penetration with the MHU800S hammer.

Table 1Soil properties.

Table 2The pile data.

Fig.5.Pile driving process(recorded and simulated).

Checking of blow counts at all the restart penetrations.In order to predict if refusal may occur at any restart penetration after pile extension,blow counts needed to penetrate the pile forfurther 30 cm are estimated by FE analysis.In this analysis,the value ofβ is assumed to be a constant along with the pile penetration.The magnitude ofβcan be taken as the average degree of consolidation of the soil,which is achieved during the pile extension time. This is because the regained strength is roughly in proportion to the degree of consolidation.If the estimated blow counts less than an acceptable value(800 blows in 30 cm is usually taken as the criterion in this area),refusal is considered not to take place at this penetration.For sandy soils,the excessive pore pressure dissipates very fast and only the consolidation of clayey soils needs to be concerned.Referring to Hwang’s achievement[4],introducing the consolidation coefficient Cv=0.72 cm2/s and time t=24 h into Terzaghi’s consolidation theory,the average degree of consolidation ofthe clayey soils can be calculated to be 65%.Settingβ=0.65 in the FE software,the blow count at 47 m depth was calculated(see Fig.5),which indicates that 285 blows are needed to penetrate the pile for 30 cm after pile extension at this depth.Since theblow count is acceptable,it can be judged that refusal may not take place atthis depth.From Fig.5 itcan also be seen thatthe predicted blow count is very close to the maximum number among the driving records of the four piles at this depth,indicating the analysis procedure is reasonable.

With the same procedure,the average degree of consolidation is estimated to be 92%after 7 days at 71 m depth.Settingβ=0.92 in the FE software,the estimated blow count is about 900 in 30 cm even the MHU1200S hammer was used,indicating that refusal would take place in this depth.The analysis results coincide with the practical event(see Fig.5).

When driving sectioned long piles of the ocean oil platform,refusal may take place after pile extension.This is because the accumulated excessive pore pressure may cause hydraulic fracturing in the soilsaround the pile,which makes the soilconsolidate very fast and regain a large portion of strength during pile extension time. The soil consolidation effect is considered in the proposed analysis procedure by associating the fatigue factor with the degree of consolidation in the FE analysis.The proposed procedure can be used to predictthe refusalrisk ofthe sectioned pile afterextension work. Case study indicates the procedure can also help to understand the pile refusal phenomenon and to verify the validity of the measures to reduce the risk of refusal after pile extension.

This work was supported by the National Natural Science Foundation of China(51322904 and 51279127)and the Program for New Century Excellent Talents in University(HCET-11-0370).

Fig.6.FE analysis results for continuous driving.

Table 3Hammer data.

[1]S.W.Yan,Q.H.Zhou,R.Liu,W.Dong,Pip bearing capacity effect on status of soil plug during pile driving in ocean engineering,China Ocean Eng.25(2011)295-304.

[2]S.W.Yan,et al.,Research on the influencing factors of driving super long piles in Bohai Gulf,in:International Conference on Piling and Deep Foundations,Stockholm,Sweden,2014.

[3]M.F.Randolph,Science and empiricism in pile foundation design,Géotechnique 53(2003)847-875.

[4]J.H.Hwang,N.Liang,C.H.Chen,Ground response during pile driving,J.Geotech.Geoenviron.Eng.127(2001)939-949.

[5]K.Fleming,A.Weltman,M.Randolph,K.Elson,Piling Engineering,Blackie A&P,Glasgow and London,1994.

[6]I.M.Smith,Y.K.Chow,Three-dimensional analysis of pile driveability,in:Proc. of the 2nd Int.Conf.on Numerical Methods in Offshore Piling,1982,pp.1-19.

[7]M.F.Randolph,H.A.Simons,An improved soil model for one dimensional pile driving analysis,in:Proc.of the 3rd Int.Conf.on Numerical Methods in Offshore Piling,1986,pp.1-17.

[8]L.Bjerrum,I.J.Johannessen,Pore pressure resulting from driving piles in soft clay,in:Proc.Conf.on Pore Pressure and Suction in Soils,Butterworths,Sydney,1960,pp.108-111.

[9]J.B.Clark,Hydraulic process for increasing the productivity of wells,RIME 1(1949)186-198.

[10]P.R.Vaughan,The use of hydraulic fracturing tests to detect crack formation in embankment dam cores,Department of Civil Engineering,Imperial College,London,1971.

[11]S.G.Paikowsky,R.V.Whitman,The effects ofplugging on pile performance and design,Can.Geotech.27(1990)429-440.

[12]American Petroleum Institute,Recommended Practice for Planning,Designing and Constructing Fixed Offshore Platforms—Working Stress Design,API RP 2A WSD,21st ed.,Dec.,2000.

∗Corresponding author.

E-mail address:yanshuwang@tju.edu.cn(S.Yan).

*This article belongs to the Solid Mechanics

杂志排行

Theoretical & Applied Mechanics Letters的其它文章

- Failure mechanisms of a spudcan penetrating next to an existing footprint

- Assessment of pipeline stability in the Gulf of Mexico during hurricanes using dynamic analysis

- Long-term dynamic behavior of monopile supported offshore wind turbines in sand

- Coupling model for waves propagating over a porous seabed

- Elasto-plasticity and pore-pressure coupled analysis on the pullout behaviors of a plate anchor

- Experimental study on the stability of plate anchors in clay under cyclic loading