Prediction of condition changes at abrasive/workpiece interface by measuring electric power input

2011-12-28NodokaYAMAMOTOYasuoKONDOKazutakeUEHARAFumioOBATA

Nodoka YAMAMOTO,Yasuo KONDO,Kazutake UEHARA,Fumio OBATA

(Tottori University,Tottori 680-8552,Japan)

Prediction of condition changes at abrasive/workpiece interface by measuring electric power input

Nodoka YAMAMOTO,Yasuo KONDO,Kazutake UEHARA,Fumio OBATA

(Tottori University,Tottori 680-8552,Japan)

A monitoring system is proposed in order to detect the condition changes at abrasive/workpiece interface in abrasive cutoff operation.The system can detect the condition changes from the electric power change consumed by the driving motor of lapping tool.The electric power is strongly related with the abrasive effectiveness.When the abrasive effectiveness has been kept a normal state,the electric power also has been kept a constant value.The bodily removal of abrasive leads to reduce the electric power monotonously.The piling up of cutting chips leads to a peculiar electric power change;the electric power increased gradually at the beginning and then began to fluctuate periodically.The severe adhesion of cutting chips to the cutting edges leads to the loss of nominal function in the cutting edges and the electric power input was thus descended suddenly at an early stage of lapping.

flat lapping;condition change;abrasive/worlpiece interface electric power;AISI304;A5052;Inconel713

Lapping can be defined as a low-velocity and low-pressure finishing operation in which small amounts of materials are removed from workpiece by means of bonded or loose abrasive grains[1].This process is applied in order to produce workpieces with high shape accuracy,excellent surface finish and so on.However,the material removal behavior shows significant variation between trials for repeated experiments[2],because the condition at the workpiece/abrasive interface has been changing continuously over the lapping process.Thus,the machine operator needs to stop the process continuously to measure the results to guarantee that the workpieces will reach the required tolerances.

The condition change at the workpiece/abrasive interface are often corrected with many signals like frictional coefficient,cutting force,electric power input,AE signal[3].Especially,the cutting force acted on the abrasive is influenced quite sensitively by changing the lapping conditions such as loading on abrasive particles,formation of built-up edge and surface roughness of workpiece[4].The cutting force is also related to the electric power consumed by the driving motor of lapping machine[4].Namely,the electric power change would be related with the conditions at the workpiece/abrasive interface over the lapping process.

In this study,we tried to examine the relationship between the condition at abrasive/workpece interface and the electric power consumed changes through the lapping of AISI304,A5052 and Inconel713 with SiC abracives.If the condition changes at abrasive/workpiece interface are atrongly related with the electric power changes.We can develop a monitoring system to detect the condition changes at abrasive/workpiece interface from the electric power change consumed by the lapping machine.The lapping monitoring system has the advantage of disturbing no machining performance and easier to measure than other systems.

1 Experimental

1.1 Experimental setup

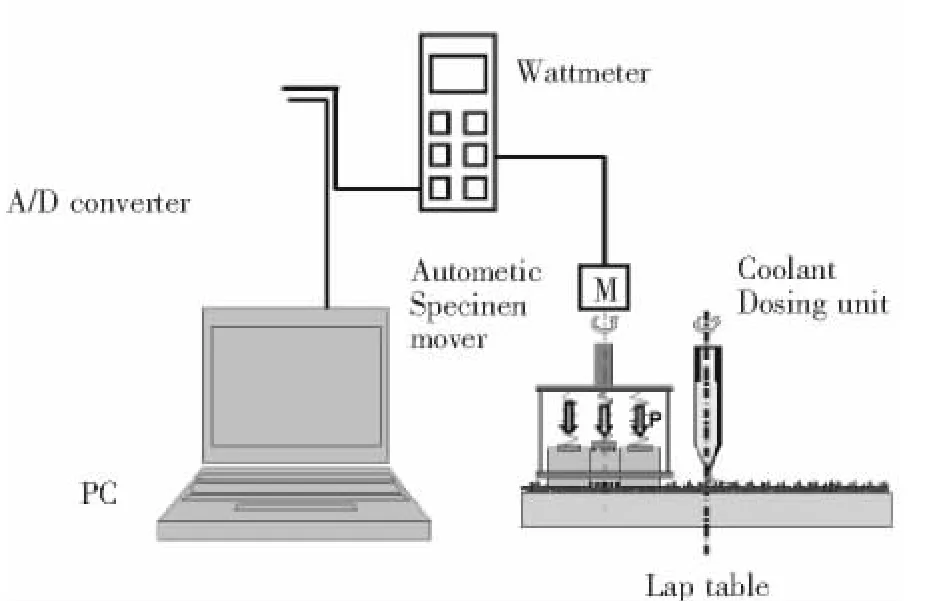

The experimental setup is shown in Fig.1.A commercial machine designed for flat lapping was used.The lapping machine is composed of three units of a lap table with 200 mm diameter,an automatic specimen mover and a coolant dosing unit.The rotational speed of lap table is controlled by an electronic servo system that keeps the selected speed constant between 50~600 r/min,independent of the load.The automatic specimen mover and the coolant dosing unit are connected directly to the lap-ping machine,and all start and stop functions are controlled via the lap table.The specimen mover is running with a speed of 250 r/min and can polish three workpieces with 25 mm diameter at the same time.The load on each workpiece is applied individually,adjustable from 5 to 40 N.The dosing rate of coolant is controlled by a pneumatic cylinder that keeps the dosing rate 20 cm3/min.

The gross power to the specimen mover,i.e.the power actually consumed by the driving motor was measured by use of a wattmeter(Emotron Co.,LTD,EL-FI M-20)in the supply line of the motor.

Fig.1 Schematic drawing of experimental setup

1.2 Experimental procedure

1.2.1 Materials

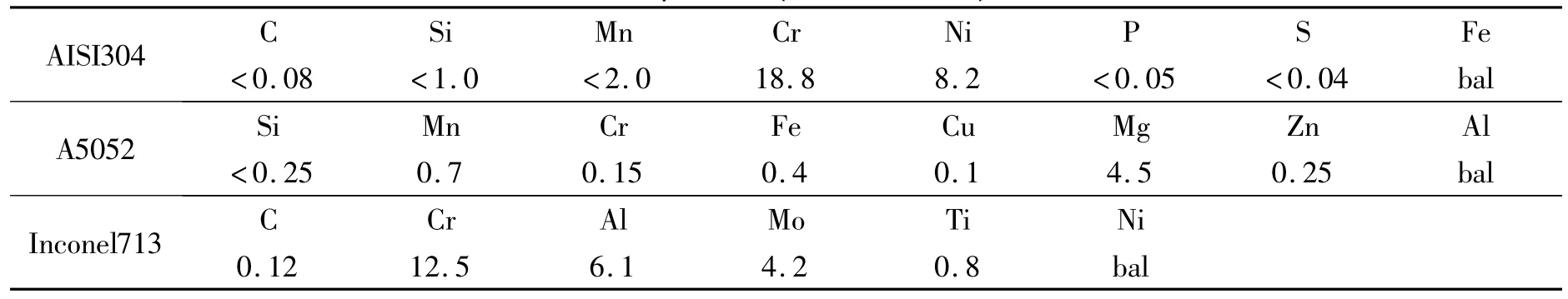

AISI304(HV 177),A5052(HV 63)and Inconel 713(HV 245)are selected as the workpiece.The composition of materials is summarized in Table1.Each material generally shows its own condition change at the workpiece/abrasive interface over the lapping[5].The lapping of AISI304 often fills the space between the abrasives with cutting chips.In the lapping of A5052,the cutting chips are coiled round the abrasives and then the bodily removal of abrasive grains tends to be shown from their retaining resin.The lapping of Inconel 713 often generate the adhesion of cutting chips with abrasives.

1.2.2 Lapping

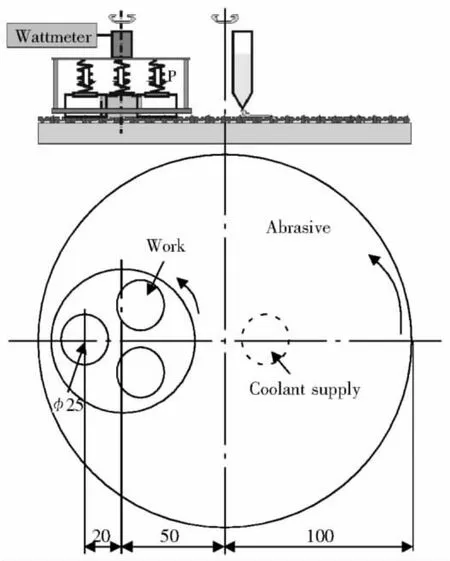

A cylindrical AISI304,A5052 and Inconel 713 with 25 mm of diameter were lapped against a plane lapping paper under a load of 10 N at a relative speed of 2.1 or 4.2 m/s,as shown in Fig.2.Silicon carbide(SiC,Hv2400)of#1 000 of grain size (average diameter of 16 μm)was used as abrasive.A 5%water-soluble coolant or a water-insoluble cutting oil had been pouring onto the lapping paper at the pouring rate of 20 cm3/min.

Table 1 Chemical composition(mass fraction)of work materials %

After 17 s,40 s,80 s or 120 s lapping,we examined the surface roughness Ra(mean arithmetic deviation)and Rz(maximum roughness)by using a portable surface roughness measurement.The damage at the abrasive/workpiece interface was checked from the observation of abrasive paper by a Scanning Electron Microscope(SEM)or a light microscope.

The electric power consumed by the driving motor of automatic specimen mover is measured from time to time.The measured electric power is closely related with the tangential force acted on the abrasive as indicated in Eq.(1).

Where Ftis the tangential force(N)acted on the abrasive and V is the peripheral speed(m/s)of abrasive[4].The relation of Eq.(1)shows that the less electric power,the less the tangential force acted on the abrasive.

Fig.2 Make-up of lapping system

2 Results and discussion

2.1 Degradation of abrasive paper over lapping

Figure 3 shows the SEM micrographs of abrasive paper before and after lapping of AISI304.Before lapping,the cutting edges are lying in a uniform array at a certain intervals on the abrasive paper.The cutting edges are also lying in a uniform array even after lapping,while a small amount of cutting chips are piled up in a space between the abrasives.

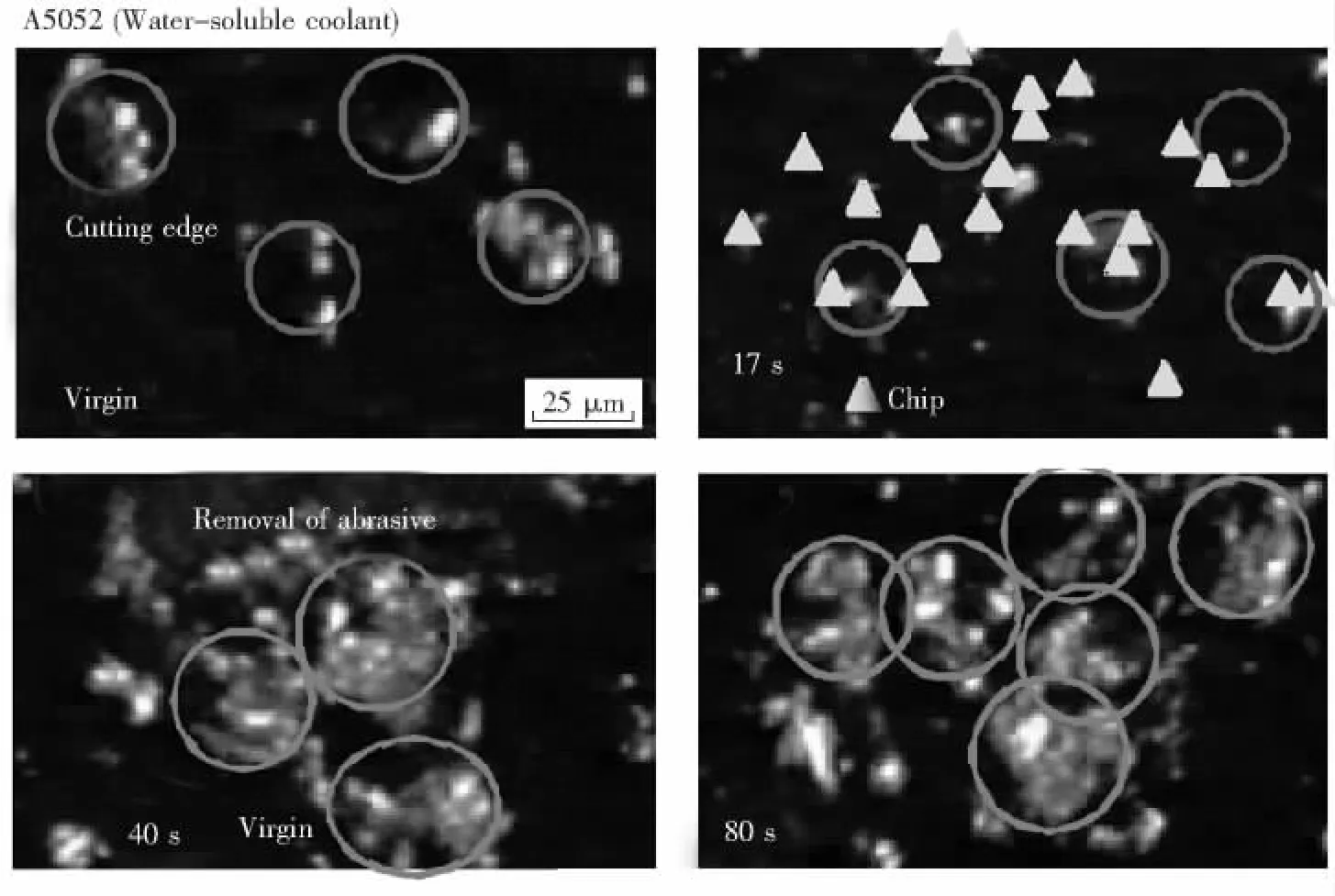

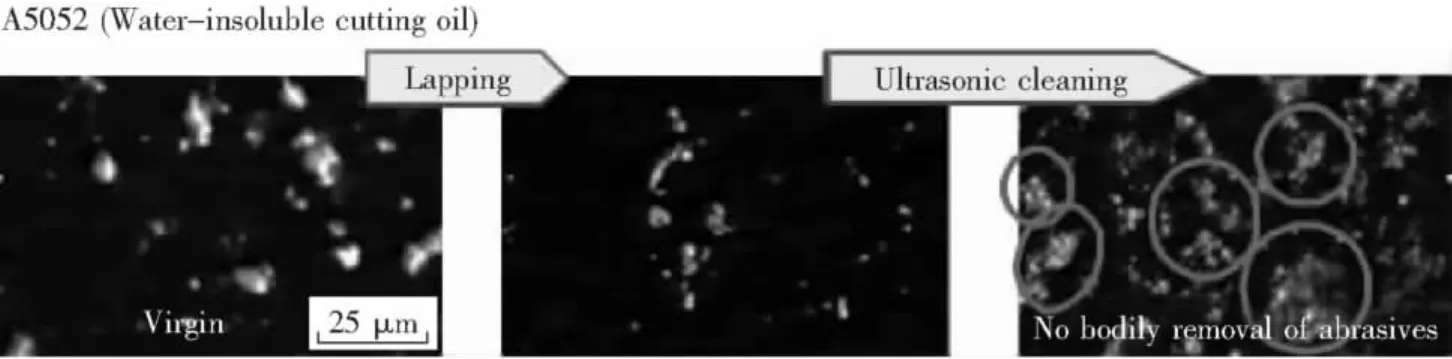

Figure 4 shows the light microscope photographs of abrasive paper after lapping of A5052 for periods of 90,17,40 and 80 s.In this case,5% water-soluble coolant was used as the cutting fluid. At the beginning,the cutting edges are lying in a uniform array as well as the case of AISI304.A progressive accumulation of cutting chips started to occur as the lapping time increased and some abrasive grains are felled from the abrasive paper along with the cutting chips.The number of falling abrasives gradually increased as the lapping time increased.Using the water-insoluble cutting oil showed the different degradation of abrasive paper from the case of water-soluble coolant,as shown in Fig.5.In this condition,no bodily removal of abrasives was found while infinite number of cutting chips was piled up between abrasives.

Fig.3 SEM micrographs of abrasive paper before and after lapping of AISI304

Fig.4 Micrographs of abrasive paper over lapping of A5052 with water-soluble coolant

Figure 6 shows the SEM micrographs of abrasive paper after lapping of Inconel 713.After a short period lapping,about 17 s,all of the cutting edges were covered with the metallic chips and no abrasives are confirmed visually.In this case,the cutting chips adhered so strongly to the abrasives that it was impossible to remove the chips from the abrasives by an ultrasonic vibration;adhesion of cutting chips with abrasives occurred.

Figure 7 shows representative examples of surface profile for AISI303,A5052 and Inconel713 after lapping time of 90 s.The finishing surface of AI-SI304 shows the typical surface roughness profile with Ra of around 0.03 μm and Rz of around 0.1 μm.The lapping of A5052 produced a roughened surface with larger value of surface roughness; Ra of around 0.09 μm and Rz of around 0.3 μm,independent of the type of coolant.The finishing surface of Inconel 713 shows a jagged surface with some deep valley.

Fig.5 Micrographs of abrasive paper over lapping of A5052 with water-insoluble cutting oil

Fig.6 SEM micrographs of abrasive paper before and after lapping of Inconel713

2.2 Electric power change

Figures 8,9 and 10 show representative examples of electric power change for AISI304,A5052 and Inconel 713 over lapping time of 90 s,respectively.AISI304,A5052 and Inconel 713 show their own electric power change.

In the case of AISI304(Fig.8),the electric power increased to a maximum value at the early stage of lapping.Thereafter the electric power subsequently decreased to a constant value.After lapping time of around 45 s,the electric power input kept an almost constant value.

The lapping of A 5052(Fig.9)showed different electric power change between the water-soluble coolant and the water-insoluble cutting oil.In the case of water-soluble coolant,after the electric power increased to a maximum value at the early stage,it tended to decrease monotonously and had never converged to a constant value.Contrastively,the lapping with water-insoluble cutting oil showed a peculiar electric power change.The electric power increased gradually as the lapping proceeded and then that began to fluctuate periodically after showing a maximum value.

Fig.7 Typical surface profile of work materials after lapping time of 90 s

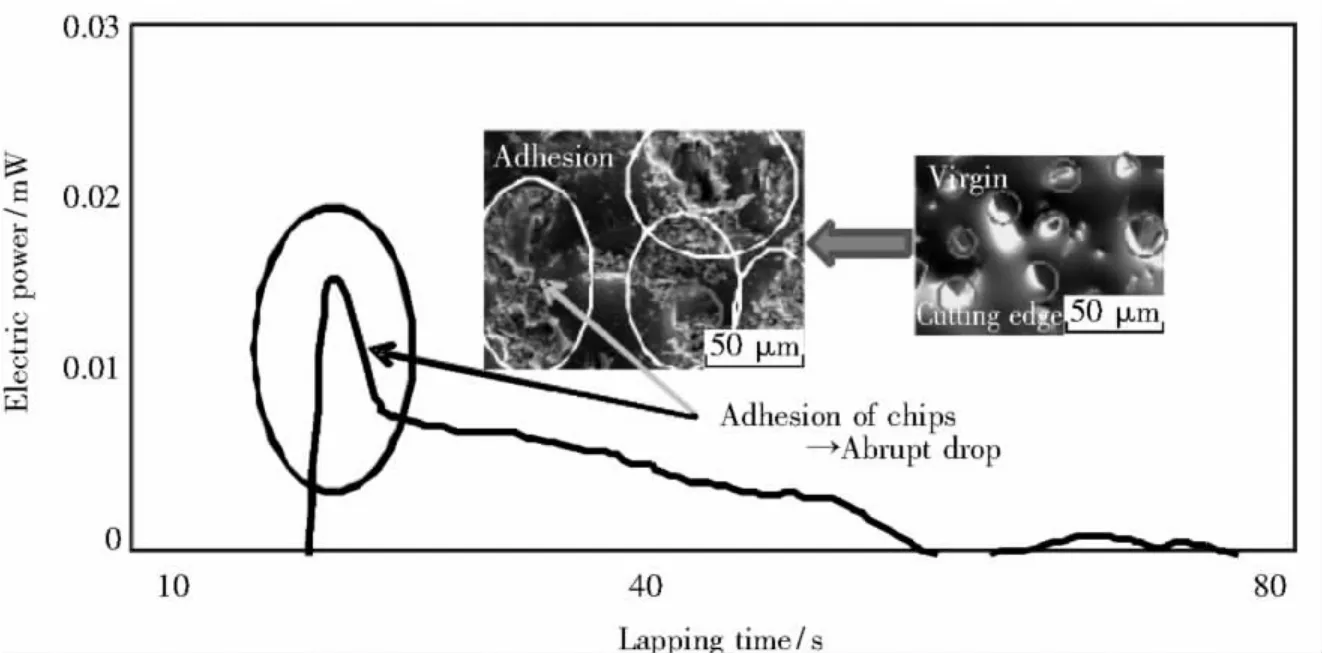

A marked difference was observed in Inconel 713 from AISI304 and A5052(Fig.10).The electric power was descended suddenly after showing a maximum value and decreased subsequently after-wards.

2.3 Prediction of condition changes at abrasive/workpiece interface

The condition changes at the abrasive/workpiece interface,such as abrasive wear,adhesion, formation of built-up edge and removal of abrasives,have direct effect on the effectiveness of abrasive paper[6~8].Table 2 shows the summary of relations between interface condition and electric power changes obtained from this study.

Fig.8 Electric power change over lapping of AISI304

Fig.9 Electric power change over lapping of A5052

In the lapping of AISI304,no appreciable wear took place in the abrasives.The abrasive effectiveness was thus hardly reduced over the lapping and the electric power kept a constant value after lapping time of 40 to 50 s.

The lapping of A5052 with water-soluble coolant induced a progressive removal of abrasives along with the cutting chips as the lapping time increased. In other words,the abrasive effectiveness reduced little by little because the number of cutting edges in contact with the workpiece decreased gradually as increasing the lapping time.The monotonous decreasing of electric power would be strongly related with the reducing of abrasive effectiveness.On the contrary,the lapping of A5052 with water-insoluble cutting oil induced the piling up of numerous cutting chips between the abrasive and workpiece and showed a peculiar electric power change;the electric power increased gradually at the beginning and then began to fluctuate periodically after showing a maximum value.The peculiar electric power change should be related with the piling up of cutting chips between abrasives and workpiece but a detailed study has not be done.

Fig.10 Electric power change over lapping of Inconel 713

The severe adhesion of chips to the cutting edges occurred right after starting the lapping of Inconel713.In this case,almost all of the cutting edges were covered with cutting chips in a moment and the cutting edges lost nominal function.The loss of nominal function in the cutting edges led to a rapid reduction of abrasive effectiveness and the electric power input was thus descended suddenly at an early stage of lapping.

These facts indicate that the condition change at the abrasive/workpiece interface is strongly related with the electric power changes over the lapping process.If you look at it from the opposite side,measuring the electric power can predict the condition changes at abrasive/workpiece interface.

Table 2 Relations between interface conditions and electric power changes

3 Conclusion

A monitoring system is proposed in order to detect the condition change at the abrasive/workpiece interface over the lapping process.The system can predict the condition change from the electric power change consumed by the driving motor of lapping machine;the less electric power,the less abrasive effectiveness.

The electric power consumed by the driving motor of lapping machine is strongly related with the abrasive effectiveness.When the abrasive effectiveness has been kept a normal state,the electric power also has been kept a constant value over the lapping.The bodily removal of abrasive leads to reduce the abrasive effectiveness little by little and then the electric power decrease monotonously.The piling up of cutting chips leads to a peculiar electric power change;the electric power increased gradually at the beginning and then began to fluctuate periodically.The severe adhesion of cutting chips to the cutting edges leads to the loss of nominal function in the cutting edges and the abrasive effectiveness is rapidly dropped.As a consequence,the electric power input was thus descended suddenly at an early stage of lapping.

These facts indicates that the electric power consumed changes sensitively in response to a given interface condition at abrasive/workpiece interface.In other words,we may conculude that we can monitor the condition changes at abrasive/workpiece interface by measuring the electric power consumed.

[1]Moore M A.A review of two-body abrasive wear[J].Wear,1974,27:1-17.

[2]Xiaboin L,Peterson M L.Material removal rate in flat lapping[J].J Manufacturing Process,1999,1:71-78.

[3]Crichigno J M,Teixeira C R,Valentina L V O D.An investigation of acoustic emission to monitoring flat lappimg with non-replenished slurry[J].Int J of Advanced Manufacturing Technology,2007,33:730-737.

[4]Kaever M.NC integrated process monitoring and control for intelligent autonomous manufacturing system[C]//Proc of the 29th CIRP Int.seminar of manufacturing system,1997:69-82.

[5]Yamane Y,Sekiya K.An evaluation of difficulty in machining difficult-to-cut materials by using difficult-to-cut rating[J].The Japan Society for Precision Engineering,2004,70: 407-411.

[6]Mercer A P,Hutchings I M.The deterioration of bonded abrasive papers during the wear of metals[J].Wear,1989,132:77-97.

[7]Avient B W E,Goddard J,Wilman W.An experimentally study of friction and wear during abrasion of metals[J].Proc R Soc London,Ser A,1960,258:159-180.

[8]Date S W,Malkin S.Effects of grit size on abrasion with coated abrasives[J].Wear,1976,40:223-235.

TG 580

A

1671-6620(2011)01-0070-06

2010-05-20.

山本和,女,日本国三重县人,日本鸟取大学大学院生,E-mail:ndk_513@yahoo.co.jp;近藤康雄,男,日本国茨城县人,日本鸟取大学准教授,E-mail:kondo@mech.tottori-u.ac.jp.