Precipitates Generation Mechanism and Surface Quality Improvement for Aluminum Alloy 6061 in Diamond Cutting

2024-04-10WANGHailongDENGWenpingWANGSujuan

WANG Hailong, DENG Wenping, WANG Sujuan, *

(1.State Key Laboratory of Precision Electronic Manufacturing Technology and Equipment, Guangdong University of Technology, Guangzhou 510006, China; 2.Guangdong Provincial Key Laboratory of Micro-Nano Manufacturing Technology and Equipment, School of Electromechanical Engineering, Guangdong University of Technology, Guangzhou 510006, China)

Abstract: To improve the surface quality for aluminum alloy 6061(Al6061) in ultra-precision machining, we investigated the factors affecting the surface finish in single point diamond turning (SPDT)by studying influence of the precipitates generation of Al6061 on surface integrity and surface roughness.Based on the Johnson-Mehl-Avrami solid phase transformation kinetics equation, theoretical and experimental studies were conducted to build the relationship between the aging condition and the type, size and number of the precipitates for Al6061.Diamond cutting experiments were conducted to machine Al6061 samples under different aging conditions.The experimental results show that, the protruding on the chip surface is mainly Mg2Si and the scratches on the machined surface mostly come from the iron-containing phase (α-, β-AlFeSi).Moreover, the generated Mg2Si and α-, β-AlFeSi affect the surface integrity and the diamond turned surface roughness.Especially, the achieved surface roughness in SPDT is consistent with the variation of the number of AlFeSi and Mg2Si with the medium size (more than 1 μm and less than 2 μm) in Al6061.

Key words: Al6061; precipitates; aging treatment; diamond cutting; surface roughness

1 Introduction

Diamond cutting technology is one of the popular and feasible manufacture technologies for the fabrication of different functional components with sophisticated geometrical features and high-quality requirement.The achieved surface roughness makes great effects on its functionalities, such as adhesion[1]and fatigue resistance[2]etc.The depth of cut in ultraprecision diamond cutting reaches to submicrometer and therefore the work material effect on surface finishing cannot be ignored in ultraprecision machining.

Lots of researches have been conducted to study the factors affecting surface generation in diamond cutting.Toet al[3]studied the effect of crystallographic anisotropy on the ultraprecision diamond machining of single crystals to investigate the chip formation mechanism, the cutting force and the surface microtopography.Cheung and Lee[4,5]investigated the process factors involving cutting conditions, tool geometry and the relative tool-workpiece vibration and the material factors including material anisotropy,swelling and crystallograntation of workpiece materials on the surface generation in single point diamond turning (SPDT).Toet al[6]investigated the effect of material swelling on the surface roughness in ultraprecision diamond turning and reported that the profiles of the tool marks were distorted by the effect of swelling of the materials.Konget al[7]investigated the combined influences of materials swelling and recovery on surface roughness in SPDT.Junet al[8]developed the chip thickness model considering the elastic-plastic nature in the ploughing process, and investigated the unique mechanisms of chip formation.Malekianet al[9]proposed an analytical model by identifying the stagnant point of the workpiece material during the machining under the consideration of the minimum uncut chip thickness of rounded-edge tools.Zonget al[10]established a comprehensive surface roughness prediction model by considering the effects of plastic side flow and elastic recovery of materials in SPDT.Wanget al[11]studied the effects of cutting depth,cutting speed, tool geometric parameters on the surface roughness of Al6061 basing on a three-dimensional surface topography simulation model.Chonet al[12]studied the effects of tool wear factors on cutting force,cutting efficiency and cutting surface quality in ultraprecision machining.Yoon and Ehmann[13]analyzed the effect of the elastic recovery of the work material on the dynamic stability of micro-cutting processes.Zhouet al[14]reported that elastic recovery of the material was innovatively integrated into the surfaces generation to improve the accuracy of instantaneous uncut chip thickness model and pointed out that the elastic recovery had effect on the generated surfaces.Luet al[15]established a comprehensive floor surface model based on the tool vibration displacement and the material elastic recovery as well as the profile of the tool geometry in micro-milling process.

Meanwhile, due to its nanometric surface roughness in diamond cutting, some non-stationary characteristics such as trends, abrupt changes or drifts, on the actual generated surface profiles make influences on the surface integrity, therefore affect the finally achieved surface roughness.Cheunget al[16]found that the pits and cracks caused by the hard SiC reinforcement affected the diamond machined surface of Al6061/15SiCp.Gómez and Barrena[17]also indicated that the percentage of reinforced particles in the matrix alloy was the principal response of the mechanical properties under the same heat treatment condition.Simoneauet al[18]reported that surface micro-defects, such as dimples occurring at a hardsoft grain boundary, influenced the surface roughness during micro-scale cutting.Rahmanet al[19]studied the effect of the micro particles and machining parameters on the chip and surface formations in the ultra-precision machining of aluminum alloy and titanium alloy.

Aluminum alloy (Al6061), being one of Al-Mg-Si alloys, is widely applied in automobile industry, optics,aerospace and other fields, since it is one of the most promising candidates for fabricating high-strength,thermally stable and light-weight nanostructured materials through large strain deformation.Al6061 belongs to the precipitation treatable aluminum alloy and its extent of precipitation is affected by the chemical composition of the material, the manufacturing technology and the heat treatment.Demir and Gündüz[20]studied the effect of artificial aging on the machinability of Al6061 and revealed that both different aging time and the cutting speed significantly affect the surface roughness.Ozturket al[21]studied the aging effect on the mechanical properties of Al6061, including the yield stress,ultimate tensile strength, ductility and strain hardening rate.Wanget al[22,23]used the time-temperatureprecipitates characterize of Al6061 to predict the temperature for the machined surface in ultra-precision raster milling (UPRM) and found the cutting-induced precipitates generation affected the surface finish.However, they only considered the influences of one type of precipitates (Mg2Si) and the time-temperatureprecipitates characterize was built based on one aging temperature (300 ℃).

Therefore, this paper makes a theoretical investigation on the generation mechanism of different types of precipitates for Al-Mg-Si alloy.Several groups of experiments including heat treatment, single cutting and single point diamond turning (SPDT) are designed to build the relationships among the aging conditions(temperature and time), the precipitations (type, size and number) and the surface roughness in SPDT.

2 Precipitates generation mechanism for Al-Mg-Si alloy

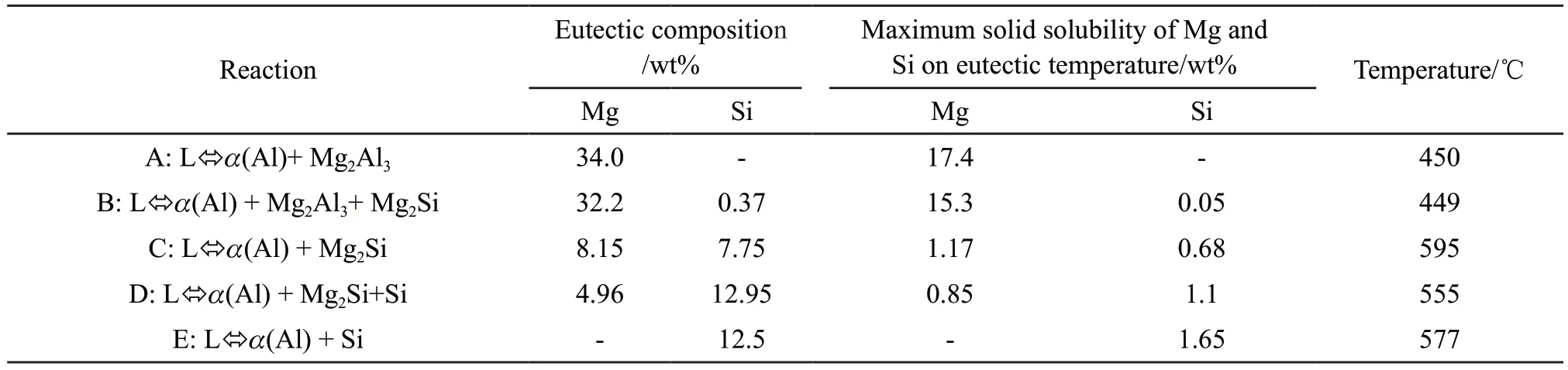

The solid solution reactions of Al-Mg-Si aluminum alloy include binary, ternary[24], quaternion or more eutectic reactions[25].The main phases are α-Al,Mg2Si, α-AlFeSi,β-AlFeSi, Si, and α-Al(FeMn)Si[26,27].Fig.1(a) presents the equilibrium phase diagram of Al-Mg-Si alloy on the solid phase distribution of aluminum angle.It shows that the aluminum corner has two binary eutectic reactions (Points A and E), a pseudo-binary eutectic reaction (Point C) and two ternary eutectic reactions (B, D points)[28].Table 1 lists the temperature and composition of the constant temperature reaction at each point.According to the alloy composition limit, Al6061 belongs to the two-phases region (α(Al)&Mg2Si) (Fig.1(b)).The maximum solubility of Mg2Si at the eutectic temperature of 595 ℃ in Al6061 is 1.85%, which infers that, to study the phase generation of Al6061, the artificial aging temperature must be set lower than 550 ℃.

Table 1 Al-Mg-Si alloy reaction at room temperature on aluminum angle

Fig.1 Equilibrium phase diagram of Al-Mg-Si alloy: (a) the equilibrium phase diagram of Al-Mg-Si alloy on aluminum angle; (b) α(Al)&Mg2Si two phase region of Al6061

On the other hand, after solid solution treatment,the initial phase of Al6061 forms supersatured solid solution in the substrate.The Johnson-Mehl-Avrami solid phase transformation kinetics equation is used to depict the relationship between the solid phase transformation and the aging time (t)[29]:

where,wis the volume fraction of the phase,tis the reaction time,nis determined by the type of phase transition.krefers to the reaction rate and is related to the aging temperature(T).The composition of the original phase and the size of the particles:k=k0exp(-Q/RT), where,k0andQare the diffusion constant and energy constant of the material,respectively.Ris the molar gas constant.

From Eq.(1), it can be seen that the strength phase transition components are represented as the function of the reaction rate (k) related to aging temperature (T),and the aging time (t) and the factor (n) related to the phase transition type, but not a linear function, which infers that the maximum values of number and size of the phase generation do not always occur at the aging treatment with the highest aging temperature and the longest time.

3 Experimental

3.1 Aging treatment

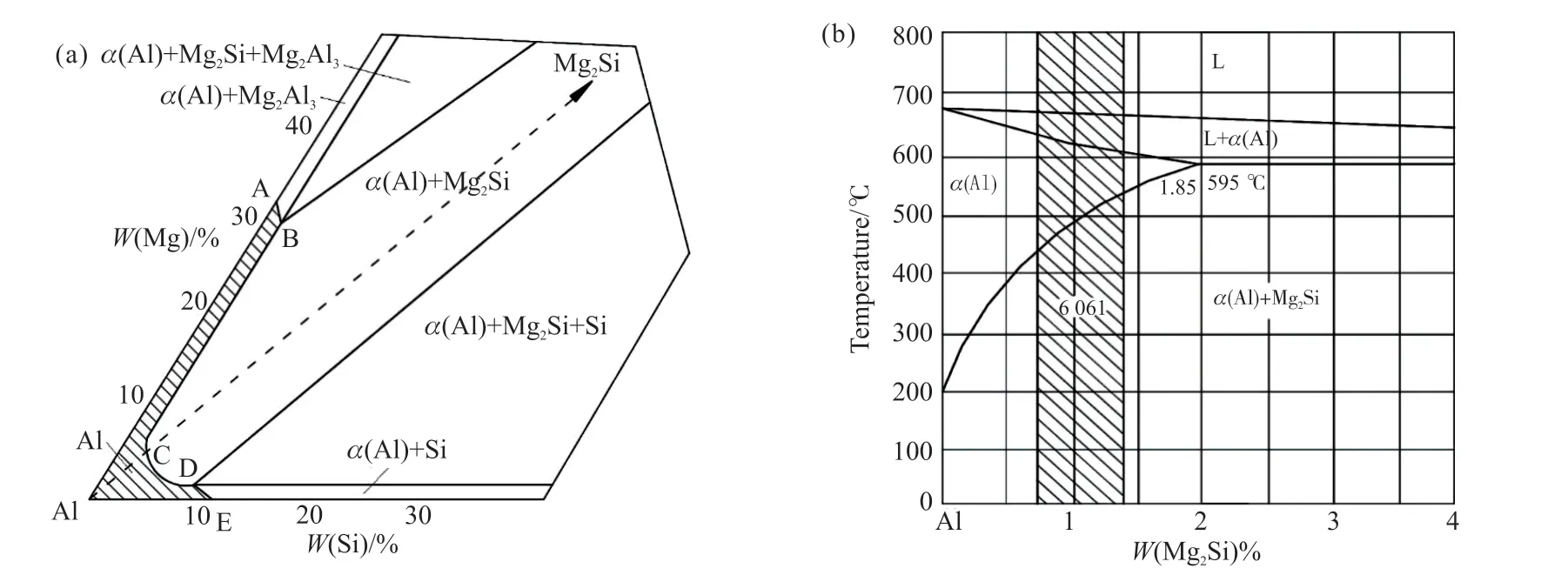

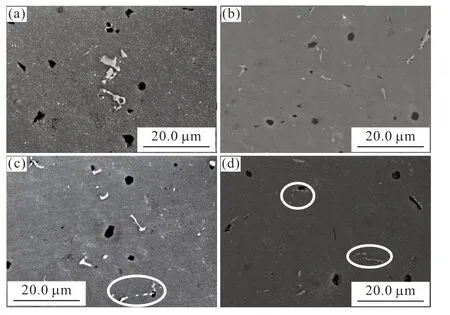

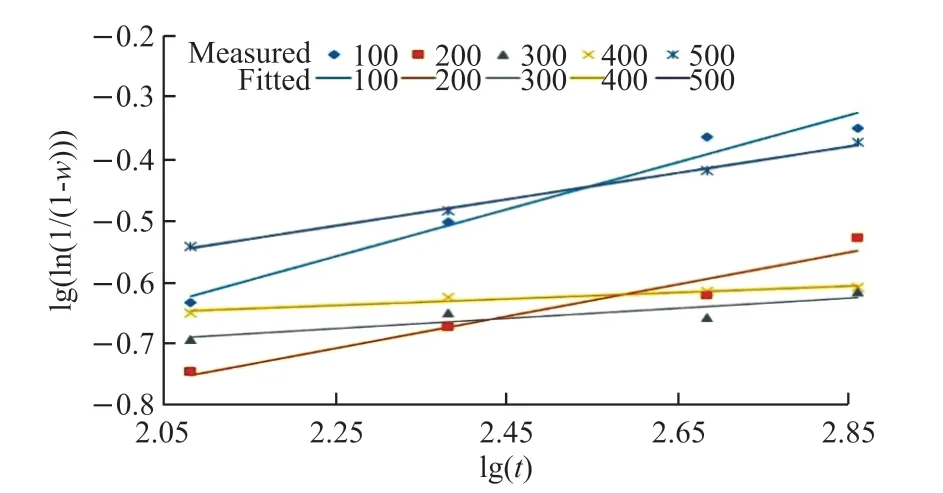

To study the effects of heating temperature and heating time on the precipitate generation for Al6061,groups of two-step aging treatments are conducted.The two-step aging treatment involved the pre-aging at 520 ℃ for 1 hour, followed by final-aging at 100, 200,300, 400, 500 ℃ for 2, 4, 8, 12 h, and then quenched in water.Before aging, Al6061 samples are examined by energy dispersive X-ray spectroscopy analysis and the chemical composition of Al6061 by wt.% is: Mg 0.92,Si 0.76, Fe 0.28, Cu 0.22, Ti 0.10, Cr 0.07, Zn 0.06,Mn 0.04 and Al Balance.After aging treatment, the samples are measured by scanning electron microscope(SEM) and the SEM images of each sample are listed in Figs.2-6, where the needle-shape white particles are broken (see the areas in circles).

3.1.1 Aging effect on particle types

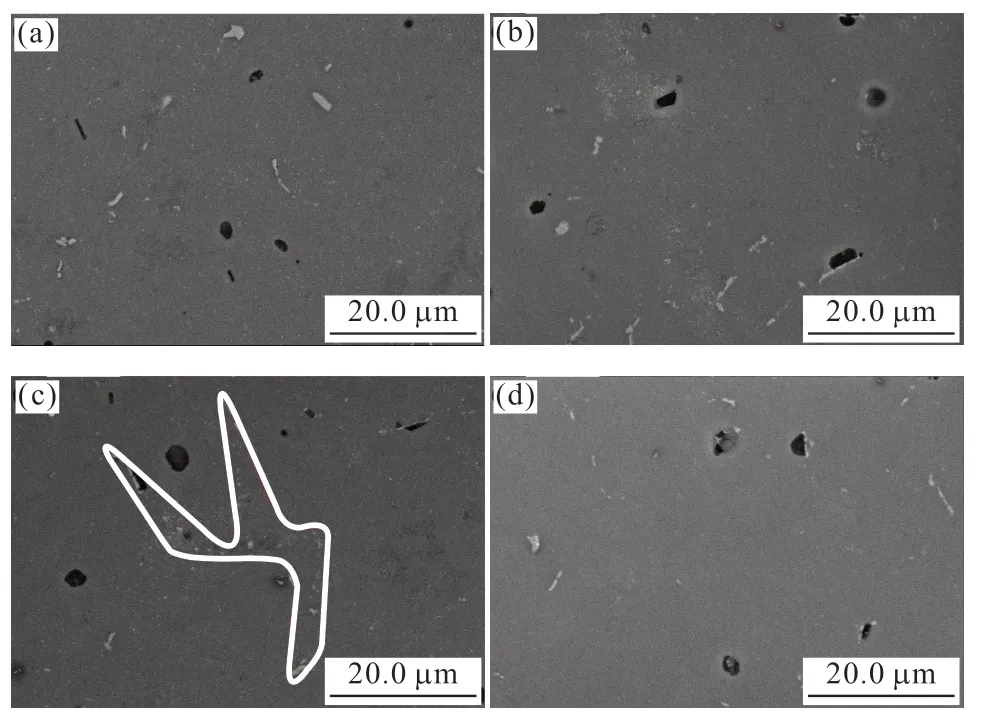

From the SEM images in Figs.2-6, the generated precipitates present two different colors: the white and the black ones.The white precipitates contain two types of shapes: needle-shape and block-shape, while most of the black precipitates present in block-shape.Fig.7 and Table 2 present the EDX analysis results of the Al6061 sample (pre-heating at 520 ℃ for 1 h and final-heating at 200 ℃ for 8 h).From Fig.7(a) and (c), the white precipitate is rich in Al, Fe and Si and the black one is rich in Al, Mg and Si.The white needle-shape particles(Area I in Fig.7(a)) areβ-AlFeSi, as shown in Fig.7(d).The white block-shape precipitates (Area II in Fig.7(a))are α-AlFeSi (Fig.7(e)), while the black ones (Areas Ⅲ& IV in Fig.7(a)) are Mg2Si, as presented in Figs.7(f-g).

Fig.2 Scanning electron microscope (SEM) images of Al6061 samples heated at 100 ℃ for different time: (a) 2 h; (b) 4 h; (c)8 h; (d) 12 h

Fig.3 Scanning electron microscope (SEM) images of Al6061 samples heated at 200 ℃ for different time: (a) 2 h; (b) 4 h; (c)8 h; (d) 12 h

Fig.6 Scanning electron microscope (SEM) images of Al6061 samples heated at 500 ℃ for different time: (a) 2 h; (b) 4 h; (c)8 h; (d) 12 h

Fig.7 EDX analyses for Al6061 with pre-heating at 520 ℃ for 1 h and final-heating at 200 ℃ for 8 h: (a) SEM image; (b) EDX analysis for the base surface; (c) the main element distribution; (d) EDX analyses of Area I; (e) EDX analyses of Area II; (f) EDX analyses of AreaⅢ; (g) EDX analyses of Area IV

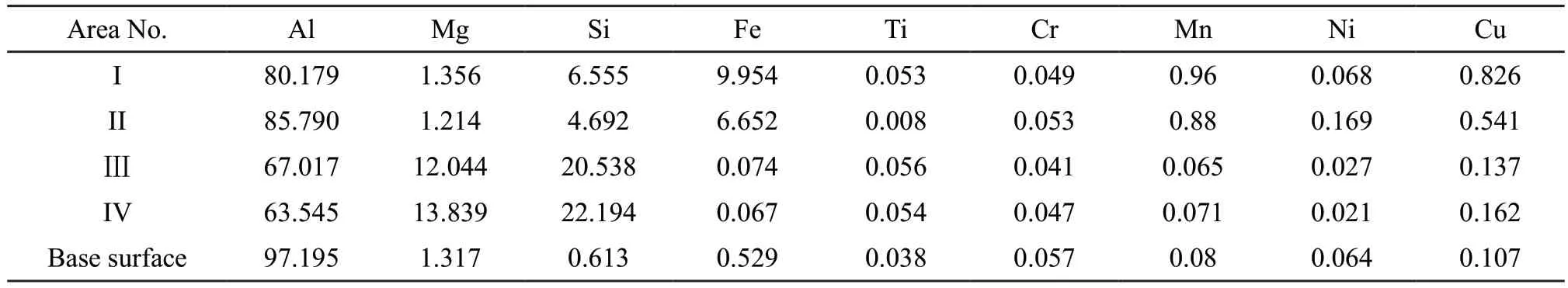

Table 2 EDX analysis results of the Al6061 sample in Fig.7/at%

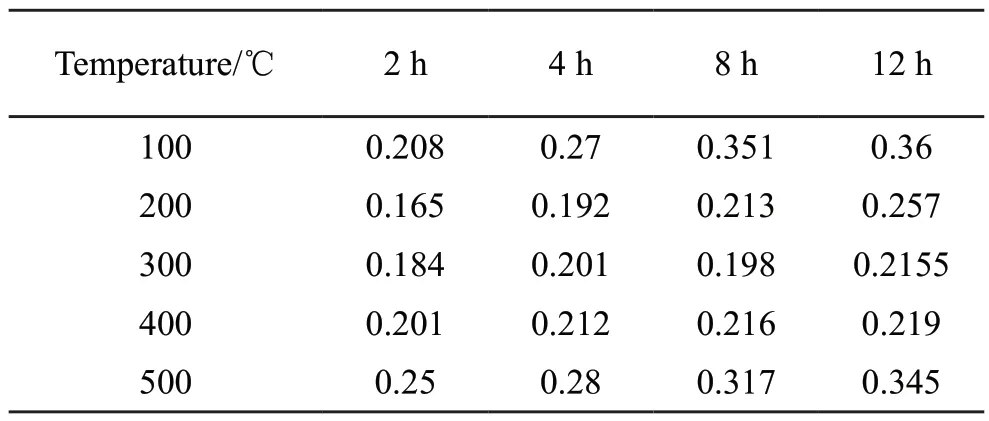

3.1.2 Aging effect on particle size

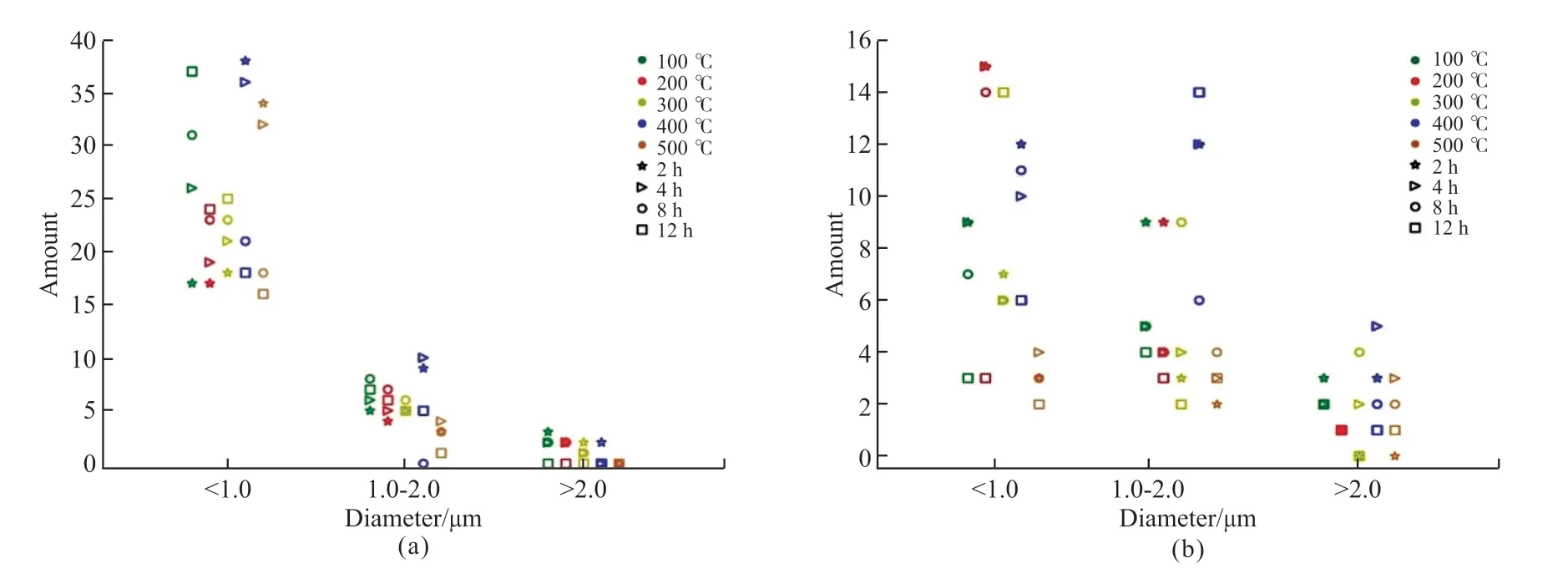

From the SEM images in Figs.2-6, different aging condition generates different size and amount ofα-AlFeSi,β-AlFeSi and Mg2Si in Al6061.In this study, the SEM images are used to evaluate aging effect on the particle size by converting the area of each precipitate into a circle so as to calculate the equivalent diameter of the generated precipitate, as shown in Fig.8.Fig.9(a,b) present the equivalent diameter of the white-AlFeSi and the black-Mg2Si particles under different aging conditions.Note that,each equivalent diameter in Fig.9 is the average value from five different SEM images of each sample.In Fig.9, the equivalent diameters of the generated AlFeSi and Mg2Si are divided into three groups: the small size(smaller than 1.0 μm), the medium size (larger than 1.0 μm and smaller than 2.0 μm) and the large size (larger than 2.0 μm).Figs.10(a) to (c) present the amount summations of AlFeSi and Mg2Si with small, medium and large size.

Fig.8 Calculation of the equivalent diameter of precipitates: (a) SEM images; (b) Mg2Si; (c) α-, β-AlFeSi

Fig.9 Aging effect on the equivalent diameter of different particles: (a) α-, β-AlFeSi; (b) Mg2Si

3.1.3 Analysis and discussion

By comparing the size and the amount of AlFeSi and Mg2Si in Fig.9, those particles with a larger size show a smaller amount.From the number and size ofα-,β-AlFeSi in Fig.9(a), under the same temperature,the number of the particles with medium size firstly increases then decreases as heating time increases from 2 to 12 h, while the particle number with large size keeps decreasing.However, it is different for those Al6061 heated at 400 ℃.On the other hand, when the heating temperature is 100 and 200 ℃, the number of particles (Mg2Si) with the medium and large size decreases with the increasing of aging time (Fig.9(b)).However, when the heating temperature is 300 and 500℃, the number of particles with the medium and large size firstly increases then decreases as heating time increases from 2 to 12 h.Similarly, the same variation characteristics of the number and size of Mg2Si and AlFeSi are found for those Al6061 heated at 400 ℃.

In Fig.10, as heating temperature increases from 100 to 300 ℃ and from 400 to 500 ℃, the particle amounts of small, medium and large size decrease,while from 300 to 400 ℃, all the particle amounts increase.However, some sample shows different trend for the aging effect on the precipitation generation,like the generation of small particles at 2 and 12 h,the medium at 8 h and the large at 8 and 12 h.This infers that, sensitivities to the aging time for Mg2Si and AlFeSi are different under different aging temperature.

Fig.10 The amount summation of AlFeSi and Mg2Si for different particle sizes: (a) the small; (b) the medium; (c) the large

After T6-solid solution treatment, Al6061 is in a state of supersaturation and the supersaturation increases from the center to the edge of the dendrite arms due to microsegregation.In the experiment, aging treatment can be divided into three processes: (1)heating process: temperature increases to the designed heating temperature; (2) holding process: temperature keeps constant for a specific time; (3) cooling process.During the heating process, the nucleation of Feintermetallic phases and Mg2Si gradually grows with the temperature increasing.As the temperature increases, the small Mg2Si gradually forms and grows up, therefore the number of small particles increases.At certain temperature, the dissolution rate of particles increases and the number of particles decreases.Meanwhile, since the dissolution rate of AlFeSi is lower than that of Mg2Si, there is a difference in the number of particles for the two phases.

During the holding process, the dissolved concentration gradient of strengthen phases is gradually homogenized within the range of the dendrite arm, which reduces supersaturation degree of the dendrite arm edge.As a result, part of the phases that precipitates at the edge of the dendrite arm in the heating process is dissolved and the transformation fromβ-AlFeSi toα-AlFeSi occurs.Shown as the red circle areas in Figs.2-6, the needle-shape white particlesβ-AlFeSi are broken and coarsen to the blockshape α-AlFeSi, which reduces the number of AlFeSi with large size and increases the number of small particles.Simultaneously, as aging time gets longer,those particles (Mg2Si) forming at a lower temperature begin to dissolve or multiple small particles combine to form large particles, therefore the particle number decreases.During the cooling process, parts of phases dissolved in the holding process get re-precipitation therefore increases the sizes of Mg2Si and AlFeSi.Note that, the final sizes of Mg2Si and AlFeSi are significant for recrystallization[30].

On the other hand, since both AlFeSi and Mg2Si contain the Si-element, in this study, the atomic percentage of Si-element is evaluated for each sample after different aging conditions to describe precipitation generation of Al6061 in a different way, as listed in Table 3.Referring to Eq.(1), the Johnson-Mehl-Avrami Equation can be rewritten to represent the volume fraction and the aging time for Si-element:

Table 3 Atomic percentage of Si under different aging conditions/at%

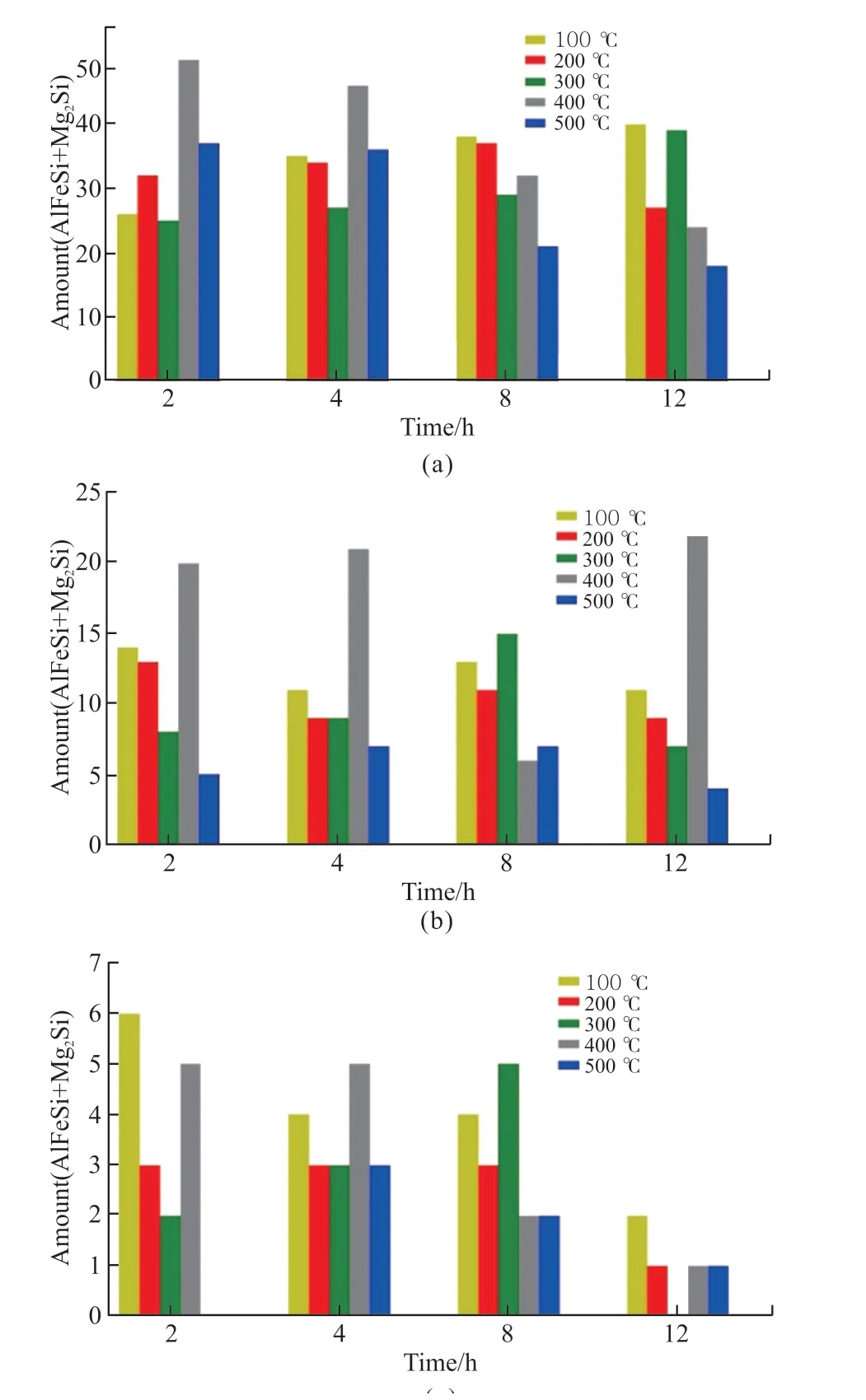

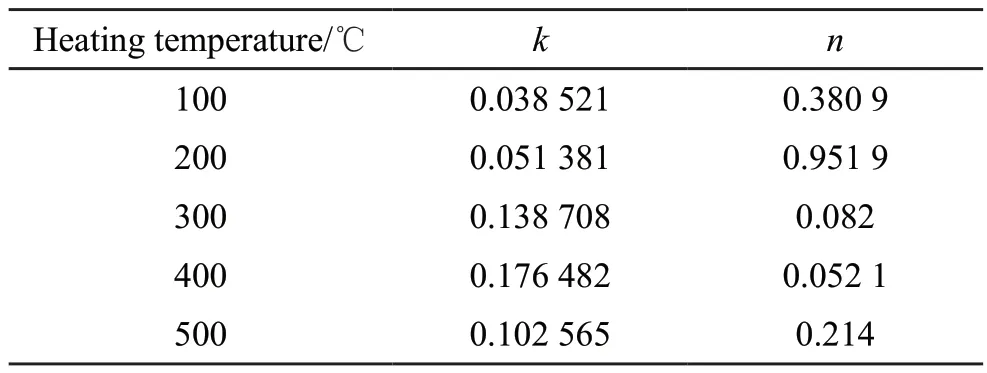

Based on the data in Table 3, the values ofkandnin Eq.(2) can be confirmed, as shown in Fig.11 and Table 4.From Table 4, the value of factorkreaches the maximum at 400 ℃; especially the value of factorkat 300 ℃ is larger than that at 500 ℃.This infers that, for Al6061, the transformation at 300 and 400℃ are relatively faster and the quenching sensitivity is relatively higher as compared with other heating temperature.Therefore, the variation magnitudes of particle size and number at 300 and 400 ℃ are totally different from those under other heating temperatures,as shown in Fig.9 and Fig.10.This agrees well with the DSC analyses results reported in Ref.[31].Meanwhile,at 200 ℃,n=0.951 9.The value ofnis close to 1,which infers that the phase (β-AlFeSi) transformation mostly presents needle-shape thickening (Fig.3), while thenvalue smaller than 0.5 indicates the mainly blockshape (α-AlFeSi) thickening phase transformation[29].

Table 4 The values of k and n under different aging conditions

Fig.11 The relationship between the volume fraction of Si-element and the aging time under different aging temperature

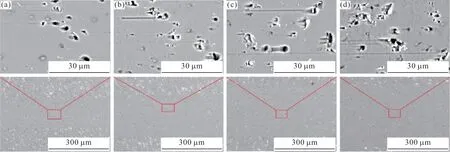

3.2 Aging effect on surface integrity in single diamond cutting

To study the influences of the generated precipitates on the surface generation in ultra-precision machining of Al6061, single cutting experiment with different depths of cut are conducted on ultra-precision machine tools (Moore Nanotech 350FG, from USA).The Al6061 sample under aging temperature of 400 ℃and aging time of 12 h is selected since it contains the largest number of those particles (AlFeSi and Mg2Si)with medium size, as presented in Fig.10(b).The nose radius, rake angle and clearance angle of the diamond cutting tool are 1.679 mm, 0°, 40°, respectively.The depths of cut are changed as: 2, 4, 6, and 8 μm and the cutting speed is 500 mm/min.

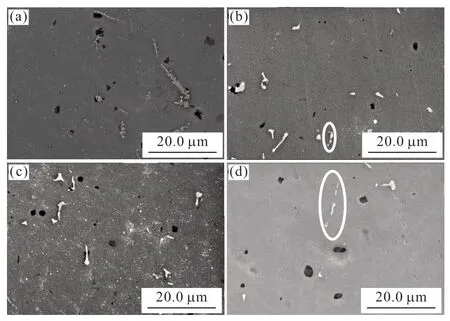

Fig.12 shows the SEM images of the machined Al6061 under different depths of cut.From Fig.12,after diamond cutting, the fresh generated surfaces contain white and black particles as well as scratch marks.Moreover, as the depth of cut increases from 2 to 8 μm, the number of white and black particles increases, especially the scratch marks on the machined surface become more and longer.

Fig.12 The SEM images of the cutting surface on the diamond machined Al6061 under different depths of cut: (a) 2 μm; (b) 4 μm; (c) 6 μm; (d)8 μm

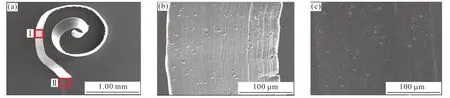

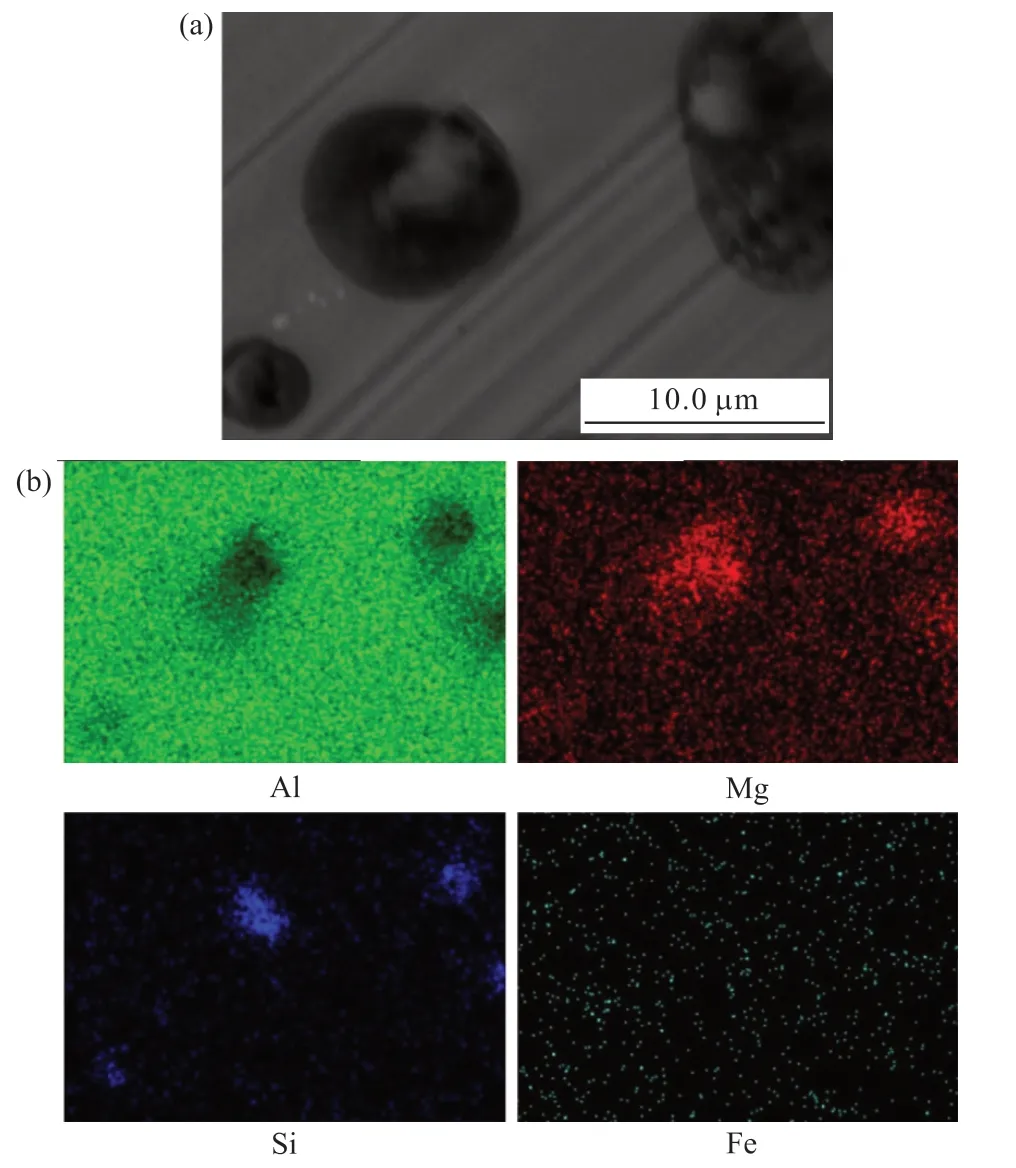

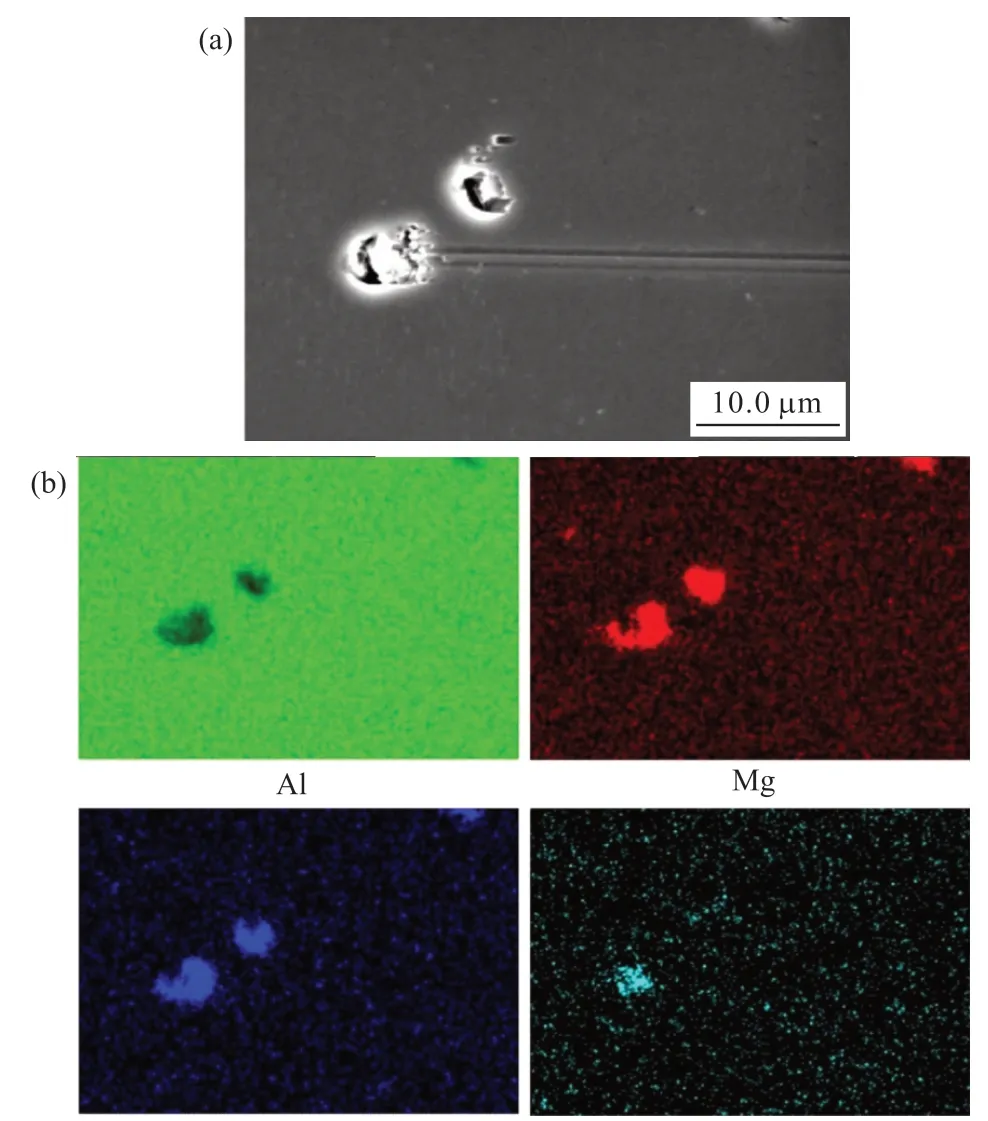

To investigate the reason for the generated scratch marks and particles on the machined Al6061, both the generated chip and the machined cutting surface are examined by SEM, as shown in Fig.13.From Fig.13,the single cutting generates one single groove on the machine surface and continuous chip.There are scratch marks and protrusions on the chip surface while on the generated cutting surface, there are some cavities and scratch markers.The EDX analysis result for the chip surface in Fig.14 indicates the generated protrusions are mostly Mg2Si.The EDX results for the machined surface in Fig.15 show that the scratch marks on the diamond machined Al6061 mostly come from the Fephases.

Fig.13 (a) SEM images of the chip generation in single cutting and the enlarged images of (b) chip surface of Area I and (c) diamond machined-surface of Area II

Fig.14 EDX analysis of chip surface protrusion: (a) SEM image; (b)the main element distribution

Fig.15 EDX analysis of scratch residues: (a) SEM image; (b) the main element distribution

Consequently, the number and size ofα-,β-AlFeSi and Mg2Si are important factors affecting the surface integrity in diamond cutting of Al6061.Moreover,the increase of depth of cut increases the number and size ofα-,β-AlFeSi and Mg2Si on the diamond machined Al6061, since a larger depth of cut induces more material removal in single cutting and therefore a higher cutting force.In ultra-precision diamond cutting,the increase of cutting force generates more heat on both the machined surface and the removed chips.

3.3 Aging effect on surface roughness of Al6061 in SPDT

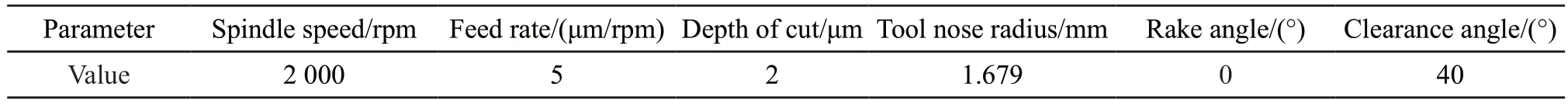

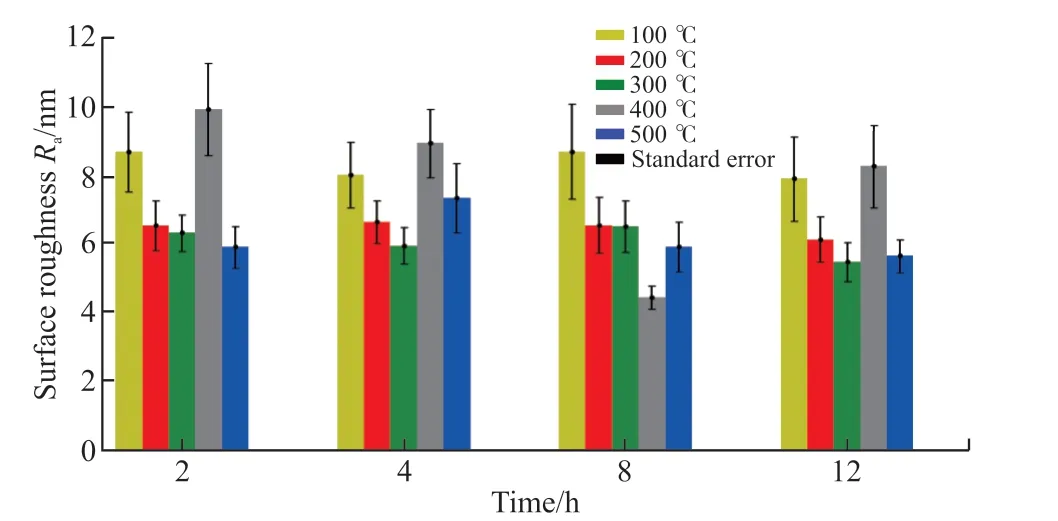

To make a further study for the precipitation generation effect on surface roughness of diamond machined Al6061, all the Al6061 samples are machined by single point diamond turning (SPDT) on the ultraprecision machine (Moore 350FG, from USA).Table 5 lists the turning parameters and the geometrical information of the diamond cutting tool for the experiment.After machining, all samples are examined by an optical profiler (BRUKER Contour GT-X, from Germany) to evaluate the surface roughness.Fig.16 presents the surface roughness of the machined Al6061 under different aging.

Table 5 Machining parameters and tool geometries

Fig.16 The measured surface roughness (Ra) of Al6061 in SPDT under different aging

Firstly, the lowest surface roughness is achieved under 400 ℃ for 8 h while the highest surface roughness is generated under 400 ℃ for 12 h.Referring to Fig.10(b), the maximum amount of the medium particle is generated under 400 ℃ for 12 h and the minimum amount of the medium particle is generated under 400 ℃ for 8 h.This indicates that, the surface quality of diamond turned Al6061 depends on the number of the generated particles with medium size(more than 1 μm and less than 2 μm).

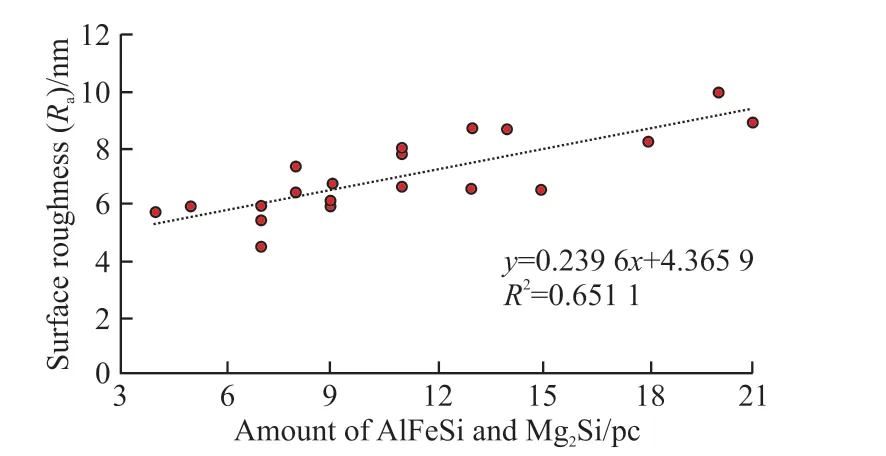

Secondly, under the same heating time, the surface roughness (Ra) of diamond turned Al6061 decreases when heat temperature increases from 100 to 300 ℃, then increases as temperature increases from 300 to 400 ℃, and decreases lastly as temperature increases from 400 to 500 ℃.This also meets with the number variation of the medium particle size in Fig.10(b).Fig.17 presents the correlation analysis between the amount of the medium particles (AlFeSi and Mg2Si) and the surface roughness, which indicates that the variation trend of the surface roughness is similar.Therefore, the aging temperature and aging time can help to control the generation of precipitates for Al6061, to improve the surface integrity, and so as to decrease the surface roughness in ultra-precision machining.

Fig.17 Correlation analysis between the amount of the medium particles (AlFeSi and Mg2Si) and the surface roughness of Al6061

4 Conclusions

a) Aging conditions affect the types, sizes and amounts of the generated precipitates.The main precipitates generated in Al6061 include the black blockshape Mg2Si, white block-shape α-AlFeSi and white needle-shapeβ-AlFeSi;

b) The equivalent diameter of the generated precipitates in the experiment can be divided into three

groups: the small size (smaller than 1.0 μm), the medium size (larger than 1.0 μm and smaller than 2.0 μm) and the large size (larger than 2.0 μm);

c) The generated precipitates affect the surface integrity of Al6061 in diamond cutting by generating cavities, scratch markers or leaving residues/protrusions on the machined surface.In diamond cutting of Al6061,the scratch marks on the machined surface mostly come from the Fe-phases while the protrusions generated on the chips are mostly Mg2Si;

d) The increases of depth of cut in single cutting process generates more heat and therefore induces an increasing of the particle number and size on the diamond machined Al6061;

e) The surface roughness of Al6061 in SPDT is related to the amount of the generated particles with the medium size: the more the medium size particles, the higher the surface roughness.

f) This study not only provides an important means for better understanding the mechanism of surface generation in diamond cutting but also contributes to provide a novel solution to improve the surface integrity and surface quality for Al-Mg-Si alloys.

Conflict of interest

All authors declare that there are no competing interests.

杂志排行

Journal of Wuhan University of Technology(Materials Science Edition)的其它文章

- One-pot Synthesis of Hierarchical Flower-like WS2 Microspheres as Anode Materials for Lithium-ion Batteries

- Controllable Synthesis of Au NRs and Its Flexible SERS Optical Fiber Probe with High Sensitivity

- Effciient Direct Decomposition of NO over La0.8A0.2NiO3(A=K, Ba, Y) Catalysts under Microwave Irradiation

- Appreciable Enhancement of Photocatalytic Performance for N-doped SrMoO4via the Vapor-thermal Method

- Infulence of Current Density on the Photocatalytic Activity of Nd:TiO2Coatings

- The Negative Thermal Expansion Property of NdMnO3 Based on Pores Effect and Phase Transition