Effciient Direct Decomposition of NO over La0.8A0.2NiO3(A=K, Ba, Y) Catalysts under Microwave Irradiation

2024-04-10WANGHaoZHAOZijianDUANXinghuiZHOUShijia

WANG Hao, ZHAO Zijian, DUAN Xinghui, ZHOU Shijia

(School of Materials Science and Engineering, Wuhan University of Technology, Wuhan 430070, China)

Abstract: La0.8A0.2NiO3 (A=K, Ba, Y) catalysts supported on the microwave-absorbing ceramic heating carrier were prepared by the sol-gel method.The crystalline phase and the catalytic activity of the La0.8A0.2NiO3 catalysts were characterized by XRD and H2 temperature-programmed reduction (TPR).The effects of reaction temperature, oxygen concentration, and gas flow rate on the direct decomposition of nitric oxide over the synthesized catalysts were studied under microwave irradiation (2.45 GHz).The XRD results indicated that the La0.8A0.2NiO3 catalysts formed an ABO3 perovskite structure, and the H2-TPR results revealed that the relative reducibility of the catalysts increased in the order of La0.8K0.2NiO3 > La0.8Ba0.2NiO3 > La0.8Y0.2NiO3.Under microwave irradiation, the highest NO conversion amounted to 98.9%, which was obtained with the La0.8K0.2NiO3 catalyst at 400 ℃.The oxygen concentration did not inhibit the NO decomposition on the La0.8A0.2NiO3 catalysts, thus the N2 selectivity exceeded 99.8% under excess oxygen at 550 ℃.The NO conversion of the La0.8A0.2NiO3 catalysts decreased linearly with the increase in the gas flow rate.

Key words: microwave catalysis; direct decomposition of NO; microwave-absorbing heating ceramics;perovskite catalyst

1 Introduction

Nitrogen oxides are among the atmospheric pollutants that pose serious risk to the ecosystem and human health[1,2].Anthropogenic nitrogen oxides mainly come from the combustion of fossil fuels, and their emission sources include industrial and vehicle exhaust gases[3,4].How to effectively remove nitrogen oxides from waste gas is a non-trivial problem in the air pollution control process.Although selective catalytic reduction (SCR) is currently the most mature NOxtreatment technology, it has the disadvantages of a requirement for a reducing agent and susceptibility to side reactions[5,6].

In contrast, the direct NO decomposition into N2and O2is ideal and economical to remove nitrogen oxides, with no reducing agent involved[7,8].This process can be realized by lowering the reaction activation barrier (364 kJ/mol) on a suitable catalyst, while the decomposition products are the harmless nitrogen and oxygen molecules[9,10].As for the NO catalytic decomposition, the currently studied catalyst systems include noble metals[11,12], metal-ion-exchanged zeolites[13,14],and metal oxides[15-17].Noble metals, such as platinum,have high costs, whereas inexpensive zeolite catalysts,e g, Cu-ZMS-5, have poor high-temperature hydrothermal stability and are severely inhibited by oxygen[7,18,19].On the contrary, perovskite oxides[20,21]are very suitable for direct NO decomposition owing to their low cost,high thermal stability, and reasonable catalytic activity.However, the direct decomposition of NO on perovskite oxides under conventional heating conditions still suffers from the problems of high reaction temperature and severe oxygen inhibition[21-23].Overcoming the above problems is challenging in researching the direct decomposition of NO by perovskite oxide.

In recent years, the positive effect of microwave irradiation on chemical reactions has received much attention from scholars[24-27].Microwave irradiation has also been applied to the catalytic denitration studies,including mainly the catalytic reduction[28,29], catalytic oxidation[30,31], and catalytic decomposition[32-34]of nitric oxide.Tanget al[32]combined microwave technology with the NO decomposition for the first time and reported that the Fe/NaZSM-5 catalyst conversion for the NO decomposition under microwave heating reached 70%.Xuet alreported the direct NO decomposition over BaMnO3-based catalysts[34-36]and MeOx-Cu-ZSM-5 (Me=Mn, Ni) catalysts[37].They reported that at a temperature as low as 250 ℃ under microwave irradiation and excess oxygen, the NO conversion and N2selectivity reached 99.9% over the Ba0.8K0.2MnO3catalyst.

Microwave irradiation provides a new approach to solving the problem of NO decomposition on perovskite oxides.Unlike conventional heating conditions,the catalytic reaction temperature under microwave irradiation is supplied by the thermal effect of microwave-absorbing heating materials in the microwave field.Therefore, the microwave-absorbing heating efficiency of materials will directly affect the catalytic efficiency under microwave irradiation.In the previous study of microwave catalytic decomposition of NO, microwave catalysts were mainly used as microwave-absorbing heating materials.Specifically, we used a tailor-made ceramic oxide with excellent microwave absorption as the microwave-absorbing heating material in the microwave field.In addition, the ceramic material at hand has the characteristics of rapid temperature rise and stable performance under microwave irradiation.

In this study, La0.8A0.2NiO3(A=K, Ba, Y) catalysts supported on the microwave-absorbing heating ceramic material were prepared by the sol-gel method.The microwave-absorbing heating ceramic material is not only the carrier of the catalysts but also the heater that provides a temperature field through a thermal effect under microwave irradiation.Here, we report the effects of reaction conditions such as temperature, oxygen concentration, and gas flow rate on the catalytic decomposition of nitric oxide over the La0.8A0.2NiO3catalysts.

2 Experimental

2.1 Catalysts preparation

The La0.8A0.2NiO3(A=K, Ba, Y) catalysts were prepared through a sol-gel method using citric acid and glycol as complexing agents.First, the metal nitrate was dissolved in distilled water according to the stoichiometric ratio.Then, citric acid and glycol were added according to the molar number of the complex,which was 1.25 times that of metal ions, and the precursor solution was prepared after stirring evenly.

The precursor solution was stirred at 80 ℃ to form gel gradually.The gel was dehydrated at 120 ℃for 12 h, then calcined at 450 ℃ for 4 h, and finally at 800 ℃ for 5 h to obtain the catalyst powder.

Microwave-absorbing ceramic heating carrier particles were added into the precursor solution prepared by the same method and immersed at room temperature for 10 h after ultrasonic oscillation.The above mixture was dried at 120 ℃ for 12 h, then calcined at 450 ℃for 4 h, and at 800 ℃ for 5 h to obtain the catalyst supported on the carrier.

2.2 Catalysts characterization

The X-ray powder diffraction (XRD) experiments were implemented on an Empyrean X-ray diffractometer (Malvern Panalytical) using CuKα radiation.

The H2temperature-programmed reduction (H2-TPR) tests were carried out in an AutoChem II 2920 instrument (Micromeritics).0.05 g of the catalyst samples were placed in a quartz tube, pretreated with 30 ml/min argon atmosphere at 300 ℃ for 0.5 h, and cooled to 50℃ in the same flow rate argon atmosphere.The H2reduction curve was recorded by passing a 10% H2/Ar at a 30 mL/min rate and heating from 50 to 800 ℃ at 10℃/min.

2.3 Catalytic activity test

2.3.1 Micro wave reactor system

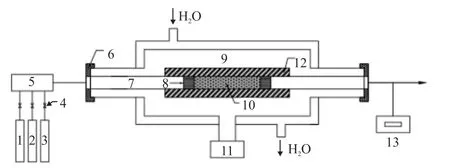

The experimental microwave apparatus is shown in Fig.1.It comprised a gas distribution system for NO,O2and N2, a microwave reaction system, and a flue gas analyzer.Microwave reaction system includes gas-solid catalytic reaction system, microwave generation system, and water cooling system.The microwave generator with a frequency of 2.45 GHz provided microwave energy, in which the power could be varied continuously in the range of 10-1 450 W.The microwave-absorbing ceramic heating carrier particles loaded with the catalyst were filled in the middle of a quartz tube.The reaction temperature was supplied by the thermal effect of the microwave-absorbing heating ceramic support,and the built-in thermocouple accurately measured the real-time temperature of the reaction.The water cooling system prevented the magnetron from being damaged by overheating.

Fig.1 Schematic diagram of the microwave reaction system: (1)N2; (2) NO; (3) O2; (4) Valve; (5) Multichannel intelligent air supply box; (6) Sealing sleeve; (7) Quartz tube; (8) Plug;(9) Resonant cavity; (10) Catalyst/Carrier; (11) Microwave generator; (12) Refractory insulation brick; (13) Flue gas analyzer

2.3.2 Catalytic activity evaluation

In the test, 100 g of microwave-absorbing ceramic heating carrier loaded with the catalyst (loading amount is 2%) was placed in a quartz glass tube.The inlet gas was composed of 0.1% NO, O2with a 0-10%concentration range, and N2as equilibrium gas.The gas flow rate range was 100-300 mL/min, and the reaction temperature range was 400-700 ℃.The temperature of the reaction was controlled by adjusting the output power of the microwave.The catalytic activity at each temperature was measured about 30 min after the reaction started.The concentration of NO and NO2in tail gas was detected by an Optima7 portable flue gas analyzer produced by the German MRU Company.In the experiment of NO decomposition reaction, N2was the main product, and NO2was the byproduct.The NO conversion (X(NO)) and N2selectivity (S(N2)) can be expressed by the following formula:

where,c1(NO)represents the inlet concentration of NO,c2(NO)andc2(NO2)represent the outlet concentration of NO and NO2, respectively.

3 Results and discussion

3.1 Catalyst characterization

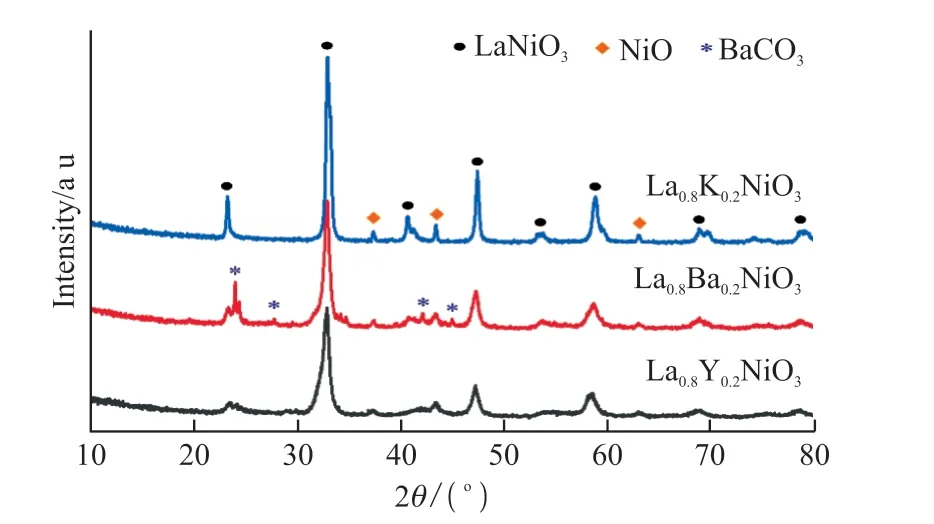

The XRD patterns of the La0.8A0.2NiO3catalysts are shown in Fig.2.The prominent diffraction peaks for all three catalysts could be assigned to the LaNiO3phase, which indicates that all catalysts possessed the ABO3perovskite structure.A small amount of NiO phase segregated due to A-site substitution[38].In addition, the diffraction peaks belonging to the BaCO3phase were also found in the La0.8Ba0.2NiO3catalyst.In this experiment, the highest calcination temperature of the catalyst was 800 ℃, which did not exceed the decomposition temperature of BaCO3[39].Therefore, the BaCO3phase was retrieved from the XRD data of the La0.8Ba0.2NiO3catalyst.

Soon afterwards he came to a city,28 where a king29 ruled who had a daughter who was so serious that no one could make her laugh. So he had put forth10 a decree that whosoever should be able to make her laugh should marry her.30 When Dummling heard this, he went with his goose and all her train before the King s daughter, and as soon as she saw the seven people running on and on, one behind the other, she began to laugh quite loudly,31 and as if she would never leave off. Thereupon Dummling asked to have her for his wife, and the wedding was celebrated11. After the King s death, Dummling inherited the kingdom32 and lived a long time contentedly13 with his wife.

Fig.2 XRD patterns of La0.8A0.2NiO3 (A=K, Ba, Y) catalysts

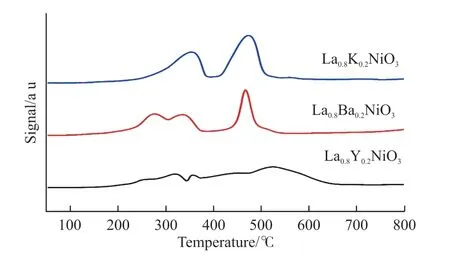

The H2-TPR measurements were performed to investigate the relative reducibility of the La0.8A0.2NiO3catalysts, and the results are presented in Fig.3.The reduction test of the LaNiO3catalyst sample led to two reduction peaks in the H2-TPR profile, where the low-temperature reduction peak was related to the reduction of Ni3+to Ni2+, and the high-temperature peak indicated that Ni2+was reduced to Ni0[40,41].For the La0.8K0.2NiO3catalyst, two reduction peaks were observed at 353 and 472 ℃.For the La0.8Ba0.2NiO3catalyst, three reduction peaks were observed at 276, 334,and 466 ℃.The two intersecting reduction peaks at 276 and 334 ℃ may be related to the reduction of the NiO phase produced by segregation and the process of reducing Ni3+to Ni2+[38,42].For the La0.8Y0.2NiO3catalyst,two small reduction peaks were additionally seen at 318 and 524 ℃, compared to the above two catalysts.In the H2-TPR profile, the peak temperature with the maximum signal (Tmax) reflects the reducibility of the catalyst, and the peak areas represent the total amount of H2consumed[20].Based on these experiments, theTmaxwas 472 ℃ for La0.8K0.2NiO3, 466 ℃ for La0.8Ba0.2NiO3, and 524 ℃ for La0.8Y0.2NiO3.Among them,theTmaxof La0.8K0.2NiO3and La0.8Ba0.2NiO3were relatively close, but the H2consumption of La0.8K0.2NiO3was greater than that of La0.8Ba0.2NiO3.Therefore, the TPR results indicate that the relative reducibility of these three catalysts increases in the order of La0.8K0.2NiO3> La0.8Ba0.2NiO3> La0.8Y0.2NiO3.

Fig.3 H2-TPR profiles of La0.8A0.2NiO3 (A=K, Ba, Y) catalysts

3.2 Catalytic activity

3.2.1 Effects of reaction temperature

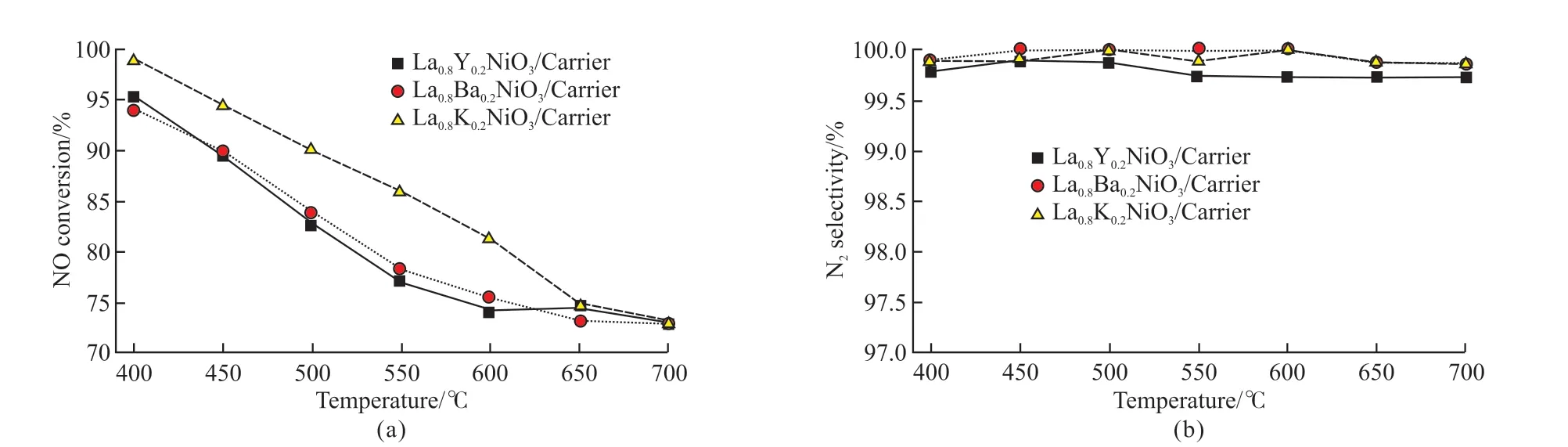

Fig.4 displays the effect of reaction temperature on the NO decomposition over the La0.8A0.2NiO3catalysts under microwave irradiation.With the increase in the reaction temperature (400-700 ℃), the NO conversion of the catalysts shows a downward trend(Fig.4(a)).When the reaction temperature was 400℃, the NO conversion was maximized to 98.9% for La0.8K0.2NiO3, 94.2% for La0.8Ba0.2NiO3, and 95.3% for La0.8Y0.2NiO3.As shown in Fig.4(b), the N2selectivity of the La0.8A0.2NiO3catalysts was more than 99.7%.It can be seen from Fig.4 that all the three catalysts displayed good catalytic performance for NO decomposition under microwave irradiation, while La0.8K0.2NiO3performed better than La0.8Ba0.2NiO3and La0.8Y0.2NiO3.The catalytic performance of the three catalysts under microwave irradiation increased in the order of La0.8K0.2NiO3> La0.8Ba0.2NiO3> La0.8Y0.2NiO3, which is consistent with the results of the H2-TPR characterization.

Fig.4 NO conversion (a) and N2 selectivity (b) versus the reaction temperature for La0.8A0.2NiO3 (A=K, Ba, Y) catalysts under microwave irradiation (Reaction conditions: molar fraction of NO = 0.1%, molar fraction of O2 = 4%, N2 as the balance, and the gas flow rate is 250 mL/min)

Under conventional heating conditions, the decomposition temperature of NO on the LaMO3-based perovskite catalyst is usually above 600 ℃[10].Yokoiet al[43]studied the catalytic performance of the LaNiO3catalyst for the NO decomposition under conventional heating and found that the NO conversion was only 22.9% and 38.9% at 600 and 700 ℃, respectively.In contrast, the NO conversion of the La0.8A0.2NiO3(A=K,Ba, Y) catalysts investigated in this research exceeded 74% at 600 ℃ and 72% at 700 ℃ under microwave irradiation.Comparing the results under the two different heating modes, it proves that microwave irradiation significantly improves the NO catalytic transformation performance of the La0.8A0.2NiO3(A=K, Ba, Y) catalysts, thus realizing the NO decomposition at relatively low temperatures using perovskite oxide catalysts.Indeed, microwave irradiation can provide the temperature required for NO decomposition through the thermal effect of the microwave-absorbing ceramic heating carrier and significantly reduce the activation energy of the NO decomposition reaction.

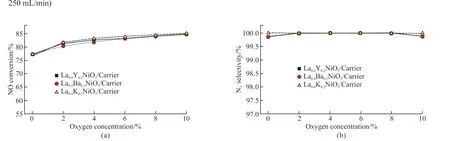

3.2.2 Effects of oxygen concentration

Fig.5 shows the effects of oxygen concentration on the NO decomposition over the La0.8A0.2NiO3(A=K,Ba, Y) catalysts under microwave irradiation.With the increase of oxygen concentration (0-10%), the NO conversion of the catalysts showed a slight upward trend(Fig.5(a)).When the oxygen concentration was 10%,the optimum NO conversion was reached, equal to 85%for La0.8K0.2NiO3, 84.7% for La0.8Ba0.2NiO3, and 84.7%for La0.8Y0.2NiO3.As shown in Fig.5(b), the N2selectivity of the La0.8A0.2NiO3catalysts was more than 99.8%.The high N2selectivity with the investigated catalysts indicates that almost all NO molecules are decomposed into N2and O2under microwave irradiation.

Fig.5 NO conversion (a) and N2 selectivity (b) versus oxygen concentration for La0.8A0.2NiO3 (A=K, Ba, Y) catalysts under microwave irradiation (Reaction conditions: reaction temperature = 550 ℃, molar fraction of NO = 0.1%, N2 as the balance, and the gas flow rate is 250 mL/min)

Fig.5(a) shows that an increase in the oxygen concentration does not inhibit the NO decomposition on the perovskite catalysts under microwave irradiation.This observation is similar to the findings of Xuet alon the decomposition of NO molecules under excess oxygen by microwave catalysis on BaMnO3-based catalysts[34-36].Microwave irradiation eliminates the oxygen inhibition issue during the NO decomposition on perovskite catalysts, which can be ascribed to the microwave selective effect.According to the microwave heating principle, polar molecules can be activated in a microwave electromagnetic field[36,44,45].NO is a polar molecule in this experiment, and O2is a nonpolar molecule.Therefore, it can be speculated that NO is more readily activated than O2under microwave irradiation.As reported previously, the NO molecule adsorbed on the catalytically active sites can be effectively activated when exposed to a microwave electromagnetic field than O2[34-36,46].For perovskite catalysts, the oxygen vacancy in the structure is the active site for NO decomposition.Therefore, when the NO molecule adsorbed on the active site of the La0.8A0.2NiO3catalyst is activated in the microwave field, it is conducive to the occurrence of a redox reaction.On the other hand, the O2molecules are difficult to be activated under such conditions and will not inhibit the NO decomposition by occupying the active sites.

The increase in the oxygen concentration promotes the NO conversion, which may be related to the formation of NO2species.It is generally accepted that the NO molecule adsorbed on the active site of perovskite catalysts will produce N2(g)and O(ads)after dissociation, and the desorption of O(ads)requires high-temperature conditions[47,48].The O(ads)desorption from the catalytic sites will affect the NO decomposition on the La0.8A0.2NiO3catalysts.Zhuet al[49]proposed that the presence of NO2(g)can realize the desorption of O(ads)from active sites.When the temperature is below 600 ℃, NO2(g)and O(ads)can generate NO3(ads)species,which can be further decomposed into NO(g)and O2(g).It can be shown that the NO2species can promote the desorption of O(ads)and realize the regeneration of the active sites.With the increase of oxygen concentration in the atmosphere, the probability of the NO molecules reacting with O2to produce NO2will increase.The NO2species thus generated lead to the regeneration of active sites by promoting the desorption of O(ads), which is conducive to the NO decomposition, resulting in improved NO conversion in this reaction system.

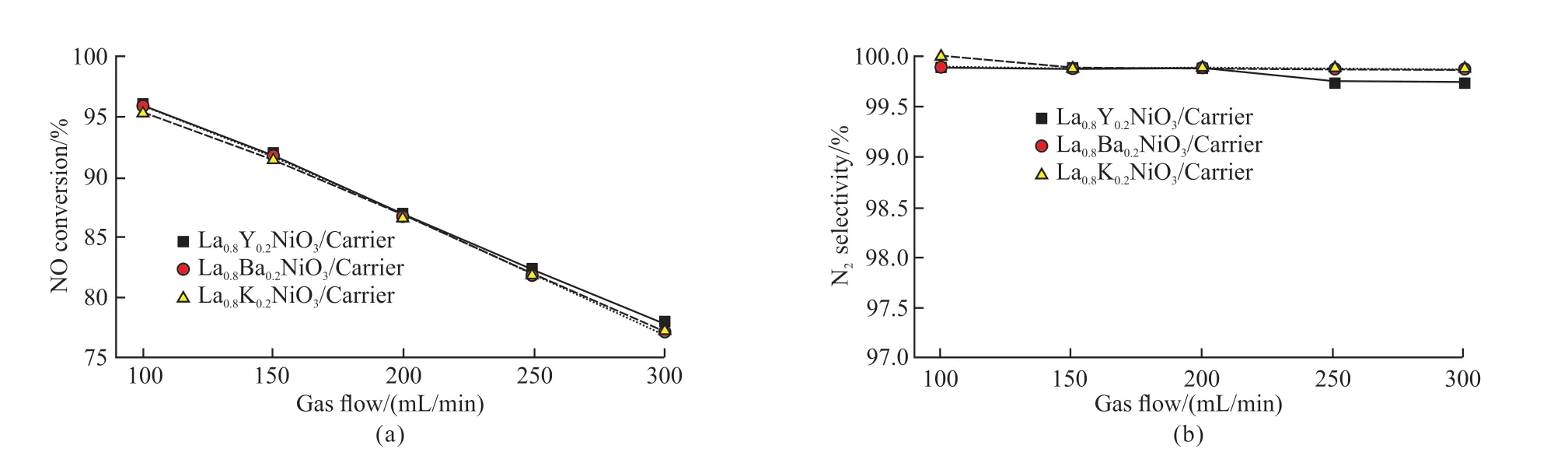

3.2.3 Effects of gas flow rate

Fig.6 shows the effects of gas flow rate on NO decomposition over the La0.8A0.2NiO3catalysts under microwave irradiation.With the increase in the gas flow rate (100–300 mL/min), the NO conversion of the catalysts decreased monotonically (Fig.6(a)).When the gas flow rate was at the minimum level of 100 mL/min, the optimal NO conversion was reached, equal to 95.4% for La0.8K0.2NiO3, 95.8% for La0.8Ba0.2NiO3, and 95.9% for La0.8Y0.2NiO3.As shown in Fig.6(b), the N2selectivity of the La0.8A0.2NiO3catalysts remained higher than 99.7%.

Fig.6 NO conversion (a) and N2 selectivity (b) versus gas flow rate for La0.8A0.2NiO3 (A=K, Ba, Y) catalysts under microwave irradiation(Reaction conditions: reaction temperature = 550℃, molar fraction of NO = 0.1%, molar fraction of O2 = 4%, and N2 as the balance)

As shown in Fig.6(a), the NO conversion decreases linearly with the increase in the gas flow rate.Tanget al[32]found a similar behavior when studying the relationship between the NO conversion and the space velocity on the Fe/NaZSM-5 catalyst under microwave irradiation.Wanget al[50]also found that the NO conversion decreased gradually with the increase of space velocity in the catalytic NO decomposition over the Cu/Si-TiNbO5catalyst.It can be inferred that the contact time between the gas and the catalyst is directly related to the NO conversion.A higher gas flow rate makes the contact time between the gas and the catalyst shorter,which is not conducive to the NO decomposition reaction and leads to a lower NO conversion.On the contrary, a lower gas flow rate increases the contact time between the NO molecules in the gas and the catalyst surface, which is conducive to the NO decomposition and gives rise to higher NO conversion.

4 Conclusions

The direct NO decomposition over the La0.8A0.2NiO3(A=K, Ba, Y) catalysts supported on a microwave-absorbing ceramic heating carrier was investigated under microwave irradiation.The results showed that microwave irradiation significantly improved the catalytic performance of the La0.8A0.2NiO3catalysts,such that the highest NO conversion of 98.9% was obtained with the La0.8K0.2NiO3catalyst at 400 ℃.Furthermore, thanks to the microwave selective effect, the synthesized La0.8A0.2NiO3catalysts exhibited promising anti-oxygen inhibition under microwave irradiation such that the N2selectivity exceeded 99.8% under excess oxygen at 550 ℃.In addition, the lower gas flow rates were conducive to the NO decomposition over the La0.8A0.2NiO3catalysts.

Acknowledgements

The authors would like to express their gratitude to EditSprings (https://www.editsprings.cn/) for the expert linguistic services provided.

Conflict of interest

All authors declare that there are no competing interests.

杂志排行

Journal of Wuhan University of Technology(Materials Science Edition)的其它文章

- Effect of VEGF/GREDVY Modified Surface on Vascular Cells Behavior

- Evolution of Biofilm and Its Effect on Microstructure of Mortar Surfaces in Simulated Seawater

- Synthesis of Organic-Inorganic Hybrid Aluminum Hypophosphite Microspheres Flame Retardant and Its Flame Retardant Research on Thermoplastic Polyurethane

- Surface Metallization of Glass Fiber (GF) /Polyetheretherketone (PEEK) Composite with Cu Coatings Deposited by Magnetron Sputtering and Electroplating

- Effect of Size Change on Mechanical Properties ofMonolayer Arsenene

- Effects of Sinusoidal Vibration of Crystallization Roller on Composite Microstructure of Ti/Al Laminated Composites by Twin-Roll Casting