Effect of chemical vapor infiltration on the flexural properties of C/C-SiC composites prepared by the precursor infiltration pyrolysis method

2023-12-20JIALintaoWANGMengqianGUOXiaofengZHUJieLIAijunPENGYuqing

JIA Lin-tao,WANG Meng-qian,GUO Xiao-feng,ZHU Jie,LI Ai-jun,PENG Yu-qing

(Institute of Materials, School of Materials Science and Engineering, Shanghai University, Shanghai 200444, China)

Abstract: Carbon/carbon-silicon carbide (C/C-SiC) composites were prepared by impregnation,hot-pressing with curing,carbonization at 800 oC and high-temperature heat treatment (800-1600 oC) using a 2D laminated carbon cloth as the reinforcing filler,and furfurone resin mixed with silicon,carbon from furfurone resin and SiC powders as the matrix.The effects of the addition of the three powders as well as subsequent chemical vapor infiltration (CVI) by methane on the density,microstructure and bend strength of the composites were investigated by scanning electron microscopy,density measurements,X-ray diffraction and mechanical testing.Both the SiC powders formed by the reaction at 1600 oC between the added Si and C particles and the added SiC powder,play a role in the reinforcement of the materials.In three-point bending,the composites had a pseudoplastic fracture mode and showed interlaminar cracking.After 10 h CVI with methane,pyrolytic carbon was formed at the interface between some of the carbon fibers and the resin carbon matrix,which produced maximum increases in the density and flexural strength of the composites of 4.98% and 38.86%,respectively.

Key words: Furfurone resin;C/C-SiC composites;Inorganic powder;CVI;Flexural strength

1 Introduction

At present,solar cells have been getting great attention and rapid development around the world.Silicon nitride is used as an optical anti-reflection film for the anode of silicon wafers[1–2].In the process of preparing silicon nitride film by plasma enhanced chemical vapor deposition (PECVD)[3–4],a carrier frame is required to carry the silicon wafer.The loadbearing frames currently used are graphite frames.Graphite products have low impurity content,high corrosion resistance,high thermal conductivity,moderate electronic conductivity,and stable physical and chemical properties.However,the mechanical properties of graphites are poor in practical applications.It has short service life during coating and cleaning[5–6].

Carbon fiber reinforced carbon matrix (C/C)composites has good high-temperature resistance,corrosion resistance and high strength.It has low density,excellent mechanical properties[7–8].Its service life is longer than graphite products.C/C composites has been widely used in aviation,aerospace and civil fields.It is applicable for the working environment of PECVD.It is understood that the high-strength 2D laminated carbon cloth reinforced C matrix (2D C/C)composite sheets on the market is an ideal material for silicon wafer carrier frame in PECVD process at current stage.2D C/C composite sheet could be used as metal heat treatment rack and single crystal silicon furnace thermal field material (such as cover plate,roof plate and guard plate).There is a huge market space for these applications.However,2D C/C composites is often prepared using the pure chemical vapor infiltration (CVI) process or precursor infiltration pyrolysis (PIP) process.The CVI process has a long fabrication period and high cost.PIP needs multiple cycles of impregnation and carbonization process to obtain high density of C/C composites[9–10].In order to acquire high-density and low-cost 2D C/C composites,Jian et al.and Yan et al.proposed a new method using silicon powder and phenolic resin mixture to prepare C/C-SiC composites through the PIP process.They successfully achieved the high-density C/C-SiC composites.But the preparation time was still long,and the addition of a large amount of silicon powder could cause fiber silicification[11–12].Therefore,it is necessary to combine the CVI process and the PIP process to shorten the production time and improve the mechanical properties of the 2D C/C-SiC composites[13–14].

A simple method to prepare low-cost and highstrength 2D C/C-SiC composites is proposed in this paper.This method only needs a single impregnation carbonization process and a subsequent CVI treatment process to fabricate the desired 2D C/C-SiC composites.Specifically,the mixture of furfurone resin with high carbon yield[15–16]and inorganic powder[17–23](carbon powder,silicon powder,and silicon carbide powder) was applied as the precursor to prepare thermosetting resin matrix composites by impregnation and hot-pressing curing process,followed by carbonization and high temperature heat treatment to obtain 2D C/C-SiC composite.The addition of inorganic powder improves the density,the interface interaction and adhesion strength of the composites.A small amount of silicon powder reacts with carbon powder and resin carbon forming SiC phase at high temperature.This avoids obvious chemical damage to fiber.The SiC particles formed by the mixed SiC powder at the high temperature play a role of particle dispersion reinforcement on resin carbon-based composites to enhance the interlayer adhesion strength of the laminated carbon cloths to avoid interlayer delamination[12,24].In addition,the pyrolytic carbon(PyC) was introduced into the PIP C/C-SiC composites by CVI process to heal the microcracks caused by volume shrinkage in the carbonization process of furfurone resin around the carbon fibers.The PyC thereby improves the interlayer adhesion strength and material integrity resulting in the reinforcing effect of carbon fibers.

2 Experimental

2.1 Experimental materials

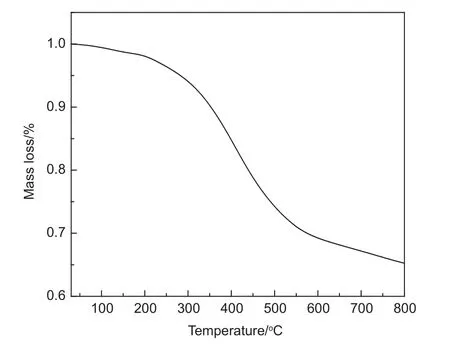

The plain carbon cloth laminated at T700-12K 400 g/m2was obtained from Toray Corporation of Japan.The furfurone resin was purchased from Changshu Duwei Chemical Co.,Ltd.The TGA curve of the furfurone resin in Fig.1 shows that the carbon yield at 800 °C is 65.25%.The 3 μm Si powder with a purity of >99% was from Shandong Huahao Silicon Industry Technology Co.,Ltd.,while the 29 nm particle diameter carbon powder with purity of ≥99%was from Shanghai Carbon Black Factory.α-SiC powder with purity of ≥98.5% and particle size of 0.65 μm was obtained from Shandong Changle Xinyuan Silicon Carbide Micropowder Co.,Ltd..

Fig.1 TGA curve of furfurone resin

The 0.25 MN curing molding machine used for hot-pressing curing was obtained from Wuxi Zhongkai Rubber and Plastic Machinery Co.,Ltd.The Shanghai Jujing CVI-1700 horizontal tube furnace was used for carbonization and high-temperature heat treatment.Nitrogen (N2) with purity of 99.99%provided by Shanghai Youjiali Liquid Helium Co.,Ltd.was used as the protective gas.CVI treatment was carried out in the CVI-1200 vertical tube furnace produced by Shanghai Jujing.The precursor of CVI PyC is propylene supplied by Shanghai Youjiali Liquid Helium Co.,Ltd.,with a purity of 99.9%.

2.2 Sample preparation

The mixture of inorganic powders and furfurone resin was the impregnation precursor.The mixture was uniformly coated on a T700-12K plain carbon cloth with a size of 100 mm2by prepreg process.Then a new layer of carbon cloth with coated mixture was put on the upper layer of the last one.12 layers carbon cloth and a certain quality of resin was used in every sample to make the sample thickness and resin content consistent.

In order to study the effect of the inorganic powders on the properties of the composites,five groups of powder mixture with certain quality of furfurone resin were designed,as shown in Table 1.

Table 1 Powder formula of 5 groups of samples

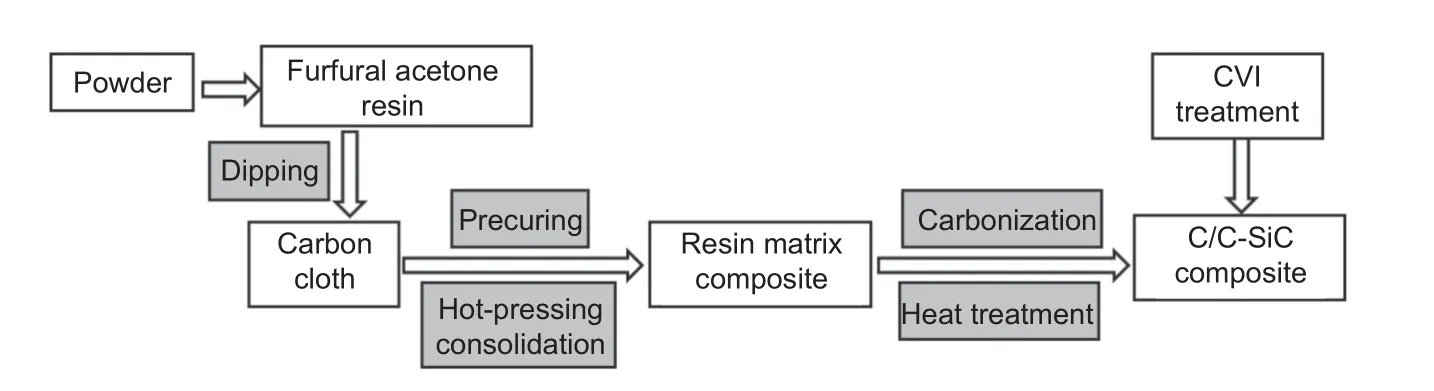

Fig.2 shows the preparation process of the 2DC/C-SiC composites.The 2D laminated carbon cloth impregnated with resin mixture was pre-cured in an oven at 120 °C for hours to avoid the spilling of the furfurone resin during hot-pressing curing process.Then the samples were further cured and molded on a hot-pressing curing machine with 4 metal blocks of 5.7 mm height limit around the samples to ensure the constant thickness and resin content of the 2D laminated carbon cloth reinforced resin matrix composites(2D CFRP).The curing temperature is 200 °C with a pressure of 6 MPa.The cured 2D CFRP were placed in the CVI-1700 furnace for carbonization under the N2protection of micro-positive pressure.The temperature was slowly raised to 800 °C for hours.The samples were heated from 800 to 1 600 °C with a heating rate of 5 °C/min for high temperature ceramic treatment,and naturally cooled down.After keeping 1 600 °C for 2 h,the natural cooling process was performed.Finally,they were put into CVI-1200 vertical tube furnace to deposit PyC (950 °C,3 kPa) for 10 h.The samples before CVI and after CVI were tested and analyzed.

Fig.2 Preparation flow chart of C/C-SiC composites

2.3 Test method

The density and open porosity of the samples were determined by the DE-150VP multifunctional density tester based on the Archimedes theory.The fracture morphology was observed by Hitachi SU-1500 tungsten filament scanning electron microscope(SEM).An 18 kW D/MAX200 V+/PC X-ray diffractometer was used to analyze the phase composition.ZEISS Axio Scope A1 polarizing microscope was used to observe the microstructure of the CVI PyC.The pore distribution before and after CVI was tested by the AutoPore Iv 9510 high-performance automatic mercury porosimeter.The three-point bending strength was measured by the BZ2.5/TS1S mechanical testing machine.The bending strength testing samples of 2D C/C-SiC composites were prepared by referencing to China national standard GB/T 1449-2005.The sample size is 65 mm×8 mm×5.5 mm with the span length of 60 mm and the loading speed 1 mm/min.The average value of the 3 tested samples of each group samples was taken as the bending strength of the group.

3 Results and discussion

3.1 The influence of powder content on the density and microstructure of C/C-SiC

The results of various powder contents on the density and open porosity of PIP 2D C/C-SiC composites are shown in Fig.3.It is showed that the density of 2D C/C-SiC composites increases and the open porosity decreases with the increase of powder content.The density of the resin carbon is lower than that of the powders.Therefore,the density of the pure furfurone resin sample S1 after carbonization is just 1.343 g/cm3.The density of S2 sample with 5% silicon powder increased slightly.The results prove that the addition of powder could increase the densification of the 2D C/C-SiC composites by fill the holes in resin carbon.

Fig.3 (a) Bulk density and (b) open porosity of C/C-SiC composites with different powder content

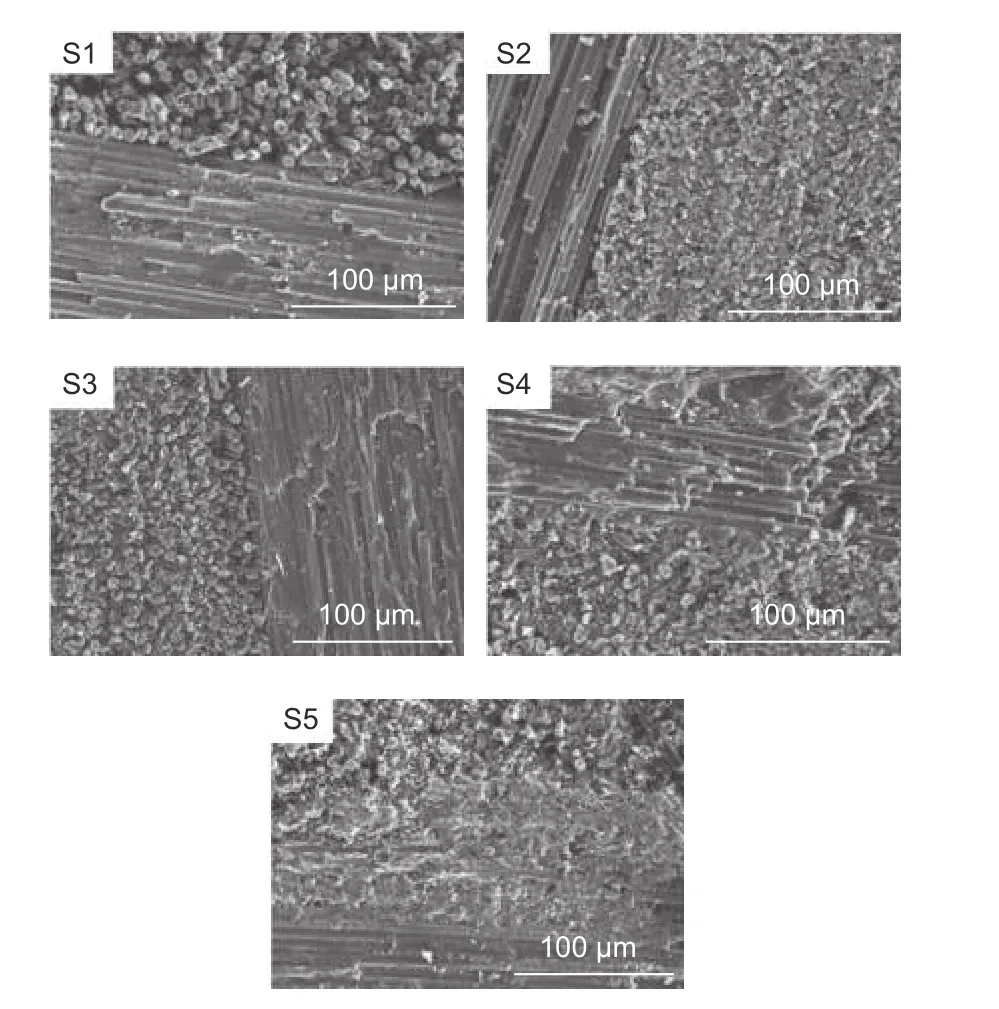

Fig.4 shows the micro-morphology of 2D C/CSiC composites at various powder mixtures.It is not difficult to find that the densification degree of the 2D C/C-SiC composites increases with the increasing powder content[21].There are some obvious defects in the fiber bundles of S1,reflecting the low density of S1.Despite the same total powder content of S4 and S5,Fig.4 shows that the densification degree of S5 is higher than that of S4.Because a part of the carbon powder and the silicon powder of S4 were replaced by 0.65 μm silicon carbide powder with better sintering in the mixture of S5.

Fig.4 SEM images of C/C-SiC with different powder contents

The XRD results are shown in Fig.5.The S1 without powder addition only showed the diffraction peak of carbon.The other samples with powder additives showed the diffraction peaks of silicon carbide and carbon.It suggests that silicon carbide was formed from the reaction of the carbon powder and silicon powder after heat treatment at 1 600 °C.The pinning effect of silicon carbide particles in resin carbon matrix could improve the mechanical property of the composites[12].

Fig.5 XRD patterns of C/C-SiC composites with different powder contents

3.2 The influence of powder content on the bending strength of C/C-SiC

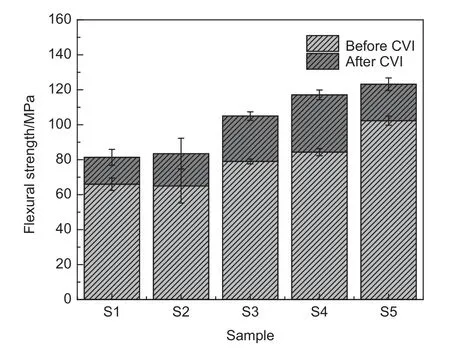

Fig.6 shows the results of various powder contents on the bending strength of 2D C/C-SiC composites before CVI.The addition of silicon powder has no positive effect on the bending strength of S2.On the contrary,the bending strength of S2 sample is slightly decreased compared with that of S1.The attenuation of bending strength is ascribed to the reaction between silicon powder and the resin carbon in carbonization and heat treatment processes.On the whole,the addition of mixed powder is valuable for improving the bending strength of composites.The higher powder content results in the higher bending strength of composites.It is obvious that the addition of carbon powder has a great contribution to the bending strength of S2 and S3.Carbon powder could provide carbon element to react with silicon powder in hightemperature heat treatment process.The formation of silicon carbide particles from carbon powder and silicon powder enhances the stiffness of the composites without consuming the original resin carbon.The remaining carbon powder effectively enhances the carbon yield to reduce the porosity of the composites.The SiC powder with a good sintering property greatly improves the bending strength of the composites as a particle reinforced phase.Therefore,the bending strength of S5 is higher than that of S4.

Fig.6 Flexural strength of C/C-SiC composites with different powder contents

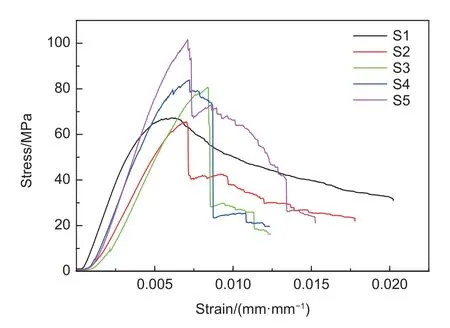

Fig.7 shows the typical flexural stress-strain curve of each group samples.It shows that the samples are mainly pseudoplastic fracture[25].The stress droped rapidly after reaching the ultimate strength.Then the stress volatility gradually decreased with increasing strain.This indicates that the samples mainly cracked between layers under load.After the interlayer crack,the load and crack propagate along the interlayer,the next interlayer crack occurs until it is completely broken[26].The fibers strength are not fully utilized.

Fig.7 Flexural stress-strain curves of C/C-SiC composites with different powder contents

3.3 The influence of CVI treatment on the bending properties of C/C-SiC

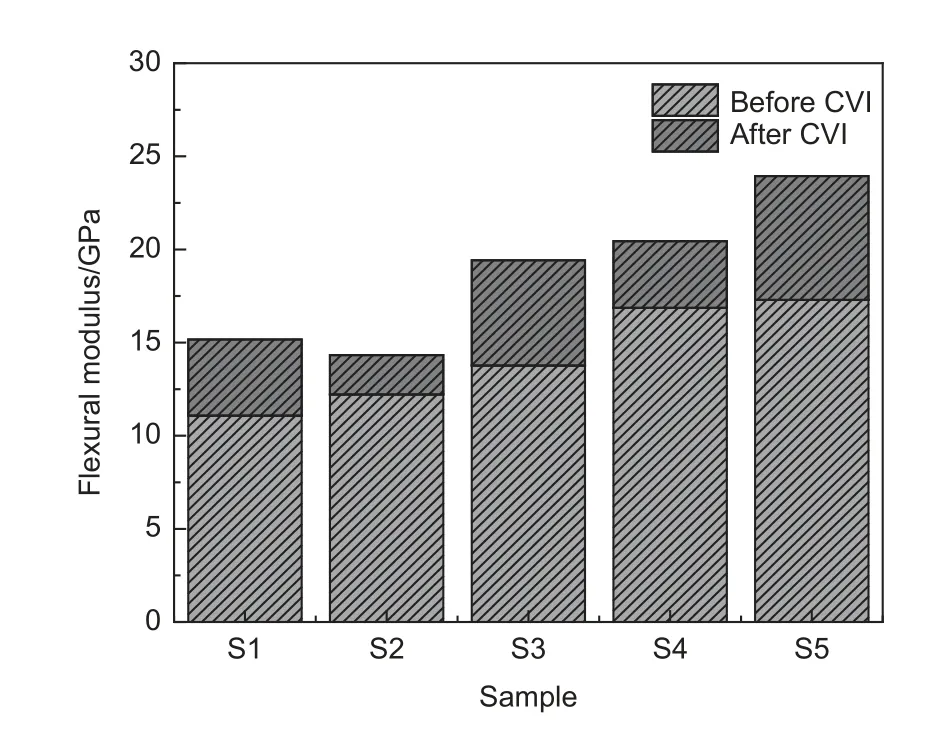

The density of S1-S5 samples after 10 h CVI treatment is shown in Fig.8.The density of 2D C/CSiC composites increased by 4.24%-4.98%.The open porosity decreased by about 5%.Fig.9 shows the bending strength of 2D C/C-SiC composites after 10 h CVI.The bending strength of 2D C/C-SiC composites increased by 20.36%-38.86%.The results in Fig.10 indicates that the 2D C/C-SiC samples after CVI treatment is still pseudoplastic fracture.Fig.11 shows the flexural modulus of 2D C/C-SiC composites before and after CVI processes.It is found that the flexural modulus after CVI is significantly higher than that before CVI.This indicates that the stiffness of the C/C-SiC greatly increased after CVI.The PyC significantly enhances the interlayer adhesion strength of the 2D C/C-SiC composite after CVI process.

Fig.8 (a) Bulk density and (b) open porosity of C/C-SiC composites after CVI enhancement process

Fig.9 Flexural strength of C/C-SiC composites after CVI enhancement process

Fig.10 Flexural stress-strain curves of C/C-SiC composites after CVI enhancement process

Fig.11 Flexural modulus of C/C-SiC composites before and after CVI

The amorphous,loose and porous resin carbon matrix formed by the carbonization of furfurone resin before CVI can not bind closely to the fiber.The defects appeared between resin carbon and fiber after the volume shrinkage of the resin during the carbonization process.Therefore,the samples are delamination cracked with low strength and pseudoplastic fracture under the action of three-point bending load.However,the precursor gas could diffuse into the micropores of the C/C-SiC samples to deposit PyC during CVI process,as shown in Fig.12.The results show that the PyC plays a role of the interface between resin carbon and fiber.The interface layer helps to transfer the load to the fiber.Moreover,PyC could heal the defects in resin carbon and increase the adhesion strength between fiber cloth layers,thereby improving the bending strength of the 2D C/C-SiC composites.

Fig.12 PLM image of PyC deposition between resin carbon and fiber of S5 sample

Fig.13 shows the pore size distribution of the S5 before and after CVI.It shows that the pore size after CVI are significantly decreased compared to that before CVI,especially the pores with sizes below 10 μm.The introduction of CVI PyC could enhance the interconnection and load transfer capacity of the fiber filaments.It indicates that the CVI PyC improved the bending strength of the 2D C/C-SiC by healing the small pores in the resin carbon matrix.

Fig.13 Porosity distribution of S5 sample before and after CVI

4 Conclusion

Low-cost,high-strength 2D C/C-SiC composites were prepared by combining single PIP and subsequent CVI treatment using the furfurone resin mixed with silicon powder,carbon powder and silicon carbide powder as the precursors,and 2D laminated carbon cloth as the reinforcement.

The density of 2D C/C-SiC composites increases with increasing powder content.Silicon powder,carbon powder and silicon carbide powder form a silicon carbide reinforcing phase after the high temperature ceramization process.Silicon carbide as the second phase of matrix is beneficial to improve the bending strength of 2D C/C-SiC composites.But it is not enough to give full play to the high strength of the fibers.

After 10 h CVI treatment,the density of the C/CSiC composites increased by 4.24%-4.98%,and the bending strength increased by 20.36%-38.86%.PyC was deposited into the micropores between the porous resin carbon matrix and fibers.PyC is used as interface layer to transfer load from matrix to fiber during the loading process.The CVI PyC is helpful to give full play to the reinforcing effect of fiber.

Acknowledgements

National Natural Science Foundation of China(21676163,51602189),Aeronautical Science Foundation of China (2016ZFS6001,2017ZFS6001) and The Shanghai Natural Science Fund (No.18ZR1417700).

杂志排行

新型炭材料的其它文章

- Carbon-based photothermal materials for the simultaneous generation of water vapor and electricity

- 生物质炭材料作为金属空气电池阴极的研究进展

- 3D porous NiCo2(CO3)3/reduced graphene oxide aerogel with heterogeneous interfaces for high-efficiency microwave absorption

- 煤基富氧多孔炭纳米片的制备及其超级电容器性能

- Mott-Schottky heterojunction formation between Co and MoSe2 on carbon nanotubes for superior hydrogen evolution

- A 2D montmorillonite-carbon nanotube interconnected porous network that prevents polysulfide shuttling