Carbon-based photothermal materials for the simultaneous generation of water vapor and electricity

2023-12-20QIUZihanZHAOGuanyuSUNYangWANGXuzhenZHAOZongbinQIUJieshan

QIU Zi-han,ZHAO Guan-yu,SUN Yang,WANG Xu-zhen,ZHAO Zong-bin,QIU Jie-shan

(1.School of Chemistry, Liaoning Key Lab for Energy Materials and Chemical Engineering,Dalian University of Technology, Dalian 116024, China;2.School of Chemical Engineering, Liaoning Key Lab for Energy Materials and Chemical Engineering,Dalian University of Technology, Dalian 116024, China;3.College of Chemical Engineering, State Key Laboratory of Chemical Resource Engineering,Beijing University of Chemical Technology, Beijing 100029, China)

Abstract: Solar-driven interfacial vapor generation (SIVG) is increasingly used for fresh water production,having the advantages of low energy consumption,eco-friendliness,and high efficiency.Carbon-based photothermal materials (CPTMs) can introduce temperature and salinity gradients in the SIVG process because of their outstanding photothermal conversion properties,which have given SIVG great potential for both steam and power generation.Various kinds of CPTMs for clean water and electricity generation are discussed in this review.The basic principles and key performance indices of SIVG are first described and the photothermal and SIVG performance of various CPTMs including graphene oxides,carbon nanotubes,carbon dots and carbonized biomass are then summarized.Finally,current research concerning water/electricity cogeneration and ways to deal with the problems encountered are presented,to provide some guidelines for the use of multifunctional CPTMs for simultaneous steam and electricity generation.

Key words: Photothermal material;Carbon-based material;Solar-driven interfacial vapor generation;Water/electricity cogeneration

1 Introduction

Freshwater resources and electric energy are two intertwined indispensable cornerstones for human civilization and sustainable development.However,the increasing mismatch between growing global population and region-unbalanced freshwater/electric supply poses a great challenge to today’s society.Remarkably,up to now,the technological development of producing freshwater[1–2]and green electricity[3–4]has been taking separate and independent pathways.In the field of water treatment,compared with enormous energy-requiring water production technology(e.g.,membrane distillation[5],reverse osmosis[6]),desalination of seawater using natural solar energy takes advantage of two abundant resources,and offers a sustainable and eco-friendly path to fulfill the requirement of low-energy water production.

Solar thermal technology is a method of directly harvesting solar energy for heating and energy storage.As an implementation of solar thermal technology,solar-driven seawater evaporation is a straightforward water production process,that is,the brine is directly evaporated by solar energy and then condensed into distilled water[7].In conventional solardriven evaporator,heat is concentrated at the bottom of the container or in the bulk of water,and steam appears elsewhere of the system.The separation of heat and steam causes unnecessary temperature drop on the evaporation surface,resulting in a large amount of heat loss,and ultimately leading to relatively low evaporation efficiency (30%-45%) of the systems[7–10].

A recently emerging new strategy of solar-driven interfacial vapor generation (SIVG)[11–14]relies on thermal localization,and its ultimate driving force is solar energy.It has been demonstrated possessing the potential for portable,passive,and high-efficiency solar desalination.Compared with the traditional systems,SIVG localizes the solar-thermal conversion section at the air-liquid interface.The localized energy selectively heats water molecules in the region of evaporation,not the entire body of water,thereby greatly improving the heat utilization rate and water evaporation rate.This approach minimizes the use of photothermal materials while avoiding volume heating,and provides a method for dynamically adjusting evaporation performance,such as evaporation steam flux and steam temperature[7,15–16].Because of these advantages,the SIVG system expands the application of solar thermal technology in assembled,stand-alone and portable solar desalination technologies,making it one of the most promising sustainable solutions to the freshwater crisis.

As the core component of the SIVG system,the photothermal material is mainly responsible for harvesting solar energy and subsequently converting it into heat,thus promoting water evaporation in the liquid-gas interface.Therefore,expanding the light absorption range of photothermal materials and enhancing their photothermal conversion capability are key indicators for upgrading SIVG technology.Over the past decades,various materials have been employed as efficient photothermal conversion materials,including plasmonic metals[17–19],semiconductors[20–22],small organic molecules[23],metal-organic frameworks(MOFs)[24],carbon-based photothermal materials(CPTMs) and their composites.

Among various photothermal conversion materials,CPTMs are regarded as the most promising candidate for practical SIVG device because of not only perfect broad-spectrum solar light absorption ability,excellent antifouling properties,and corrosion resistance,but also tunable surface wetting properties as well as stable physical and chemical properties[25–27].In addition,owing to the thermal localization function in SIVG system,temperature/salinity gradients are normally formed between solar absorber and bulk brine,which is particularly advantageous for electric generation[28].Therefore,enormous multi-functional solar-powered vapor/electric generators with thermoelectric,thermo-electrochemical,and salinity gradient effects have recently caught some interest.

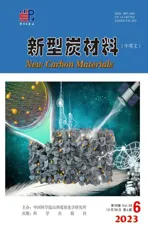

Hence,this review focuses on CPTMs in the field of solar-driven interfacial evaporation for both water and electricity production,as shown in Fig.1.First,the basic principles and key evaluation indices of SIVG system from the aspects of evaporation rate,solar absorption,photothermal conversion and heat loss are introduced.Then,the photothermal and SIVG performance of various CPTMs are summarized,including graphene oxide,carbon nanotubes,carbon dots and carbonized biomass materials.Finally,the current researches concerning water/electricity cogeneration and the strategy to challenges have also been discussed,aiming to provide some guidelines of multifunctional carbon-based photothermal materials for simultaneous steam and electricity generation.

Fig.1 Carbon-based photothermal material for solar-driven interfacial vapor generation and electricity generation simultaneously

2 Solar-driven interfacial vapor generation

2.1 Basic principle of SIVG

Solar energy can be converted into various forms of energy through photovoltaic,photochemical and photothermal processes.Among them,the photothermal conversion process provides the best conversion efficiency.The basic principle of solar photothermal conversion is shown in Fig.2a[29].The lightinduced electric field drives the moving carriers inside the material crystal,and the energy obtained by the carriers is converted into heat,which diffuses out of the material,resulting in an increase in the temperature of the surrounding medium.

Fig.2 (a) Schematic diagram of the solar photothermal conversion process[29] (Reprinted with permission by Springer Nature,Copyright 2012);(b) The basic structure diagram of solar-driven interfacial water evaporation device[33] (Reprinted with permission by Elsevier,Copyright 2016)

The photothermal effect is a surface-dependent process.And solar energy is converted into thermal energy by photoexcitation at the air-water interface.In general,high-efficiency SIVG system should meet the demands of the following 3 aspects: (1) high solar absorption capacity of photothermal materials over the full solar spectral range (250-2500 nm)[30],(2) heat loss minimization of water evaporation interface[31],and (3) sufficient water supply for continuous steam generation on the surface of the photothermal conversion materials[32].Therefore,the SIVG system is generally divided into 3 parts,and its basic structure is as follows (Fig.2b)[33]:

(1) The photothermal absorption layer is composed of photothermal conversion materials for collecting solar energy and then converting it into heat energy to boost water evaporation at the liquid-air interface.

(2) The thermal insulation layer is composed of materials with low thermal conductivity,which contributes to thermal localization at evaporation zone.

(3) The water transport layer sucks water to thermal interface for ensuring the continuous generation of steam.

Obviously,carbon materials can achieve the synergy of the above 3 parts by regulating the pore structure,surface hydrophilicity and hydrophobicity,as well as gradient structure,which is difficult for any other photothermal materials.

2.2 Performance evaluation indices of SIVG system

2.2.1 Evaporation rate

The evaporation rate (υ) of water in SIVG system is normalized by the mass of water lost and the illuminated surface area of photothermal material.In the initial stage of SIVG process,in order to provide sufficient latent enthalpy to ensure the occurrence of water-vapor phase transition on the surface of the evaporator,the surface of the evaporator needs to collect more incident photons and converts them into heat energy,so the initial evaporation rate will be gradually increased[34].According to the research,it generally takes 2 000 s for the SIVG system to reach steady state or equilibrium under a standard simulated light source irradiation (1 kW·m-2).As a result,the evaporation rate is generally obtained by linear fitting the slope of the water mass loss curve under steady state.The calculation formula of evaporation rate is as following[35]:

where,mrepresents the mass of evaporation water,tis the illumination time,Aprojis the projection area of the evaporator,andis the mass flux of the evaporated water,representing the slope of the mass loss curve obtained by linear fitting.

2.2.2 Photothermal conversion efficiency

The photothermal conversion efficiency (η) is defined as the ratio of the energy consumed by water evaporation at the gas-liquid interface (Qevap) to the incident light power (Qs) in SIVG system.The calculation formula is as follows[36]:

where,Coptis the optical intensity of incident light,Iis the standard intensity of direct sunlight (1 kW·m-2).ΔHLVis the total enthalpy of the phase change at the liquid-vapor interface,including the sensible heat caused by temperature rise and the latent heat caused by phase change.The calculation process is as follows[37]:

where,Cpis the specific heat capacity constant of water (4.18 J·g-1·K-1),ΔTis the difference between the water vapor temperature and the ambient temperature,and ΔHvapis the latent heat of steam at the corresponding temperature.After the normalization of Formula(2),the calculation formula of the photothermal conversion rate of the solar interface water evaporation system can be summarized as follows:

It is worth noting that the transient photothermal conversion efficiency can more accurately reflect the working state of the solar interface water evaporation system.Therefore,it can be defined as the total energy used for water evaporation in a certain illumination time interval divided by the input energy of incident solar energy.The calculation formula is as follows:

Or expressed as:

where,Δmrefers to the quality change of evaporated water during the illumination time Δt.

2.2.3 Light absorption rate

The light absorption efficiency of photothermal conversion materials is the basis of SIVG system.Therefore,the light absorption rate (α) is a key metrics of the ability of photothermal conversion materials in the SIVG system.αis determined by the ratio of the absorbed solar radiation to the incident radiation.The total solar absorptivity at a given incident angleθis obtained by weighting the spectral absorptivity of the photothermal conversion materials with the spectral irradiance distribution of the standard solar spectrum (AM 1.5) and integrating the solar radiation within the wavelength range reaching the surface of the solar absorber,and then expressed as the ratio of the total solar irradiance.When the incident angle of the light source isθ,the total solar absorptivityα(θ) of the solar interface water evaporation system can be calculated by the following equation[38]:

where,λminandλmaxare 0.3 and 2.5 μm,respectively,θis the light incident angle measured from the surface normal of the SIVG system,andA(λ) is the solar spectral irradiance related to the wavelength.R(θ,λ) is the total reflectivity at wavelengthλ.

2.2.4 Heat loss

In the SIVG system,the heat energy converted by solar energy mainly acts as the continuous output of steam under the equilibrium condition of the system,while the remaining energy is lost by convection,conduction and radiation,resulting in heat loss (Q).Specifically,the energy consumption in the evaporation process is mainly composed of 3 parts[39]: (1) the heat required to evaporate water,and (2) conduction heat loss with water,and (3) radiation heat loss and convection heat loss with water vapor.The energy balance in the SIVG system can be expressed as the following formula:

First of all,QSIVGis the energy absorbed by the photothermal materials in the system,where the energy loss caused by the reflection and scattering of the incident light at the interface should be subtracted,which can be expressed as:

where,αrepresents the light absorption rate of the photothermal conversion material.

The conduction heat loss between the SIVG system and the water body can be defined as the energy required to heat up the bulk water body after sunlight exposure,which can be calculated by the following equation:

where,m1refers to the quality of the remaining water body after evaporation,ΔT1is the rising temperature of the water body before and after evaporation.

The convective heat loss between SIVG system and water vapor can be defined by Newton’s law of cooling[7]:

where,hrepresents the convective heat transfer coefficient of the system,Aevapis the evaporation area of the evaporator,TevapandTvapare the surface temperature of the evaporation device and the surrounding steam temperature,respectively.

The radiative heat loss between SIVG system and water vapor is calculated by Stefan-Boltzmann equation[40]:

where,σandεrepresent the Stefan-Boltzmann constant (σ=5.670373 × 10-8W·m-2·K-4) and the emissivity of the system in the wavelength range of 2.5-25 μm,respectively.The emissivity depends on the characteristic of the material.The ε of photothermal conversion materials is calculated by the following formula[41]:

where the denominator is the total emissivity power of the blackbody,while the molecule is the total energy emitted by the photothermal conversion material in the wavelength range of 2.5-25 μm.R(λ) andPB(λ) are the reflectivity and the spectral emissivity of the blackbody,respectively,at the measured temperature given by Planck’s law.

It should be pointed out that the researchers found that most of the reported SIVG systems were tested under open conditions.The fluctuations of ambient temperature and humidity,the measurement error of thermocouples on steam and ambient temperature,and the improper selection of thermal conductivity have caused certain errors in energy balance and heat transfer in the current SIVG system.That is,the sum of each part of the energy consumption in the system (energy consumed by water evaporation,conduction heat loss,radiation heat loss and convection heat loss) is greater than or less than 100%.Therefore,it is extremely important to establish a constant experimental environment,where temperature,humidity and pressure remain stable,and to unify the standard measurement methods and evaluation criteria of the SIVG system.It is worth mentioned that,assuming no additional energy input,the evaporation rate is limited by the photothermal conversion efficiency,that is,the maximum evaporation rate of water under 1 kW·m-2light intensity (room temperature 25 °C,humidity 45%) is 1.59 kg·m-2·h-1.By optimizing the structure design,the external environment can be used for additional energy input,so that the total evaporation of the system is higher than the limit evaporation rate under the same solar intensity[42].Therefore,in practical applications,the evaporation rate is more important than the photothermal conversion efficiency when evaluating the performance of the SIVG system.

3 Carbon-based SIVG system

As a solar absorber,the photothermal conversion material (PTM) is a key component of SIVG systems.The performance of a SIVG system is mainly decided by the photothermal conversion performance of the PTM.The design principle of PTMs is focused on the high photothermal conversion efficiency and high light absorption rate in the full solar spectral range of 0.3–2.5 μm[30].Over the past decade,PTMs with excellent light absorption capabilities have been extensively studied over a wide range of solar spectra.They can absorb incident lightvialight excitation and turn it partially or completely into thermal energy,in which moving carriers obtain energy under the driving of light-induced electric field and convert it into heat energy.

In recent years,carbon-based PTMs (CPTMs)have attracted widespread attention owing to their high abundance,favorable chemical stability,and efficient light absorption abilities.The photothermal conversion effect of CPTMs is mainly caused by 2 aspects.From the microscopic point of view,carbon materials typically contain a great quantity of 6-membered ring-based lattices,where delocalized π bonds are spontaneously formed by unbound free electrons.These rich electrons with weak interactions are excited from their highest occupied molecular orbitals to the lowest unoccupied molecular orbitals through energy-matched incident photons.In addition,heat will be released during the stages of relaxation[43].From the meso-and macroscopic points of view,CPTMs have complex inner hole/slit/channel structures and relatively rough surfaces.These characteristics promote the multiple scattering of light,thereby improving the light utilization rate and reducing the transmittance loss[44–46].So far,a variety of CPTMs have been explored,such as graphene oxide (GO)[47],reduced graphene oxide (rGO)[48],graphite[49],carbon nanotubes (CNTs)[50],carbon dots (CDs)[51]and carbonized biomass materials[52].These materials have their own advantages in the application of solarpowered interfacial vapor generation process.

3.1 Graphene-based SIVG system

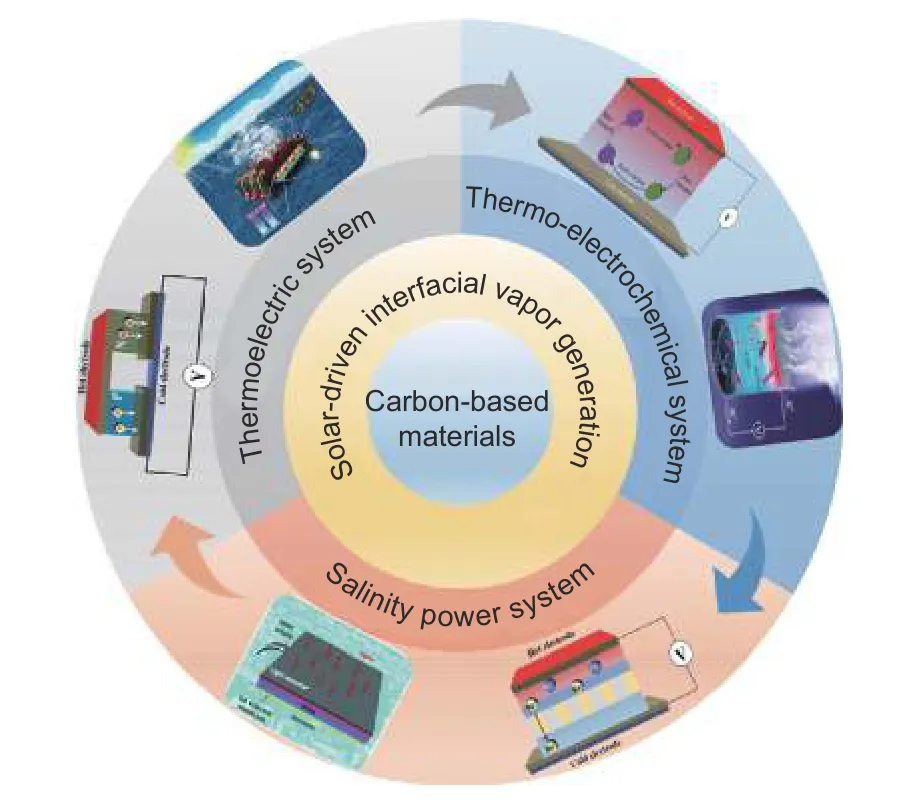

Graphene-based materials are ideal materials for solar-driven evaporation,purification,and desalination as a result of their excellent solar energy absorption properties,large specific surface area,and controllable thermal conductivity.Various graphenebased PTMs including graphene metamaterials[53],vertically aligned graphene films[54],GO films[55],redox graphene composite aerogels[56]and layered graphene foams[57]have been investigated.These materials exhibit excellent photothermal conversion efficiency owing to their controllable structure properties.For example,Qu’s group[58]prepared defect-abundant graphene aerogel (DAGA) by a freeze-drying process.They used the laser reduction method to replace the traditional thermal annealing treatment of GO,so that GO can be partially reduced while maintaining the oxygen-containing groups and defects on its surface,improving the hydrophilicity,thermal insulation and solar absorption ability of the system.The DAGA aerogel obtained a water evaporation rate (υ) of 1.78 kg·m-2·h-1and a photothermal conversion efficiency(η) of 91% (Fig.3a).Subsequently,Qu’s group[54]prepared vertically aligned graphene sheet membrane(VA-GSM).Ethanol was added as antifreeze to affect the growth direction of ice crystals and accurately control the freezing direction (Fig.3b).The vertical channels can effectively serve as a light trap for solar harvesting and a water path for facilitating water transport,enabling 86.5% photothermal conversion efficiency under one standard solar intensity.

Fig.3 Preparation process diagrams and cross section SEM images of (a) DAGA[58] (Reprinted with permission by Elsevier Ltd.,Copyright 2018)and (b) VA-GSM[54] (Reprinted with permission by American Chemical Society,Copyright 2017).Schematic diagram of(c) BHMG synthesis process and optical properties[59] (Reprinted with permission by Royal Society of Chemistry,Copyright 2013)and (d) SIVG device and evaporation efficiency with rGO/AgNPs-MS[60] (Reprinted with permission by Elsevier,Copyright 2019)

Using graphene and its derivatives to modify the surface of porous materials is another strategy to prepare efficient PTMs for SIVG.Yang’s group[59]conducted a comprehensive analysis and discussion on this issue.As shown in Fig.3c,a bridge-arched hollow melamine foam/rGO composite (BHMG) was reported,where melamine foam (MF) was used to transport water molecules and rGO served as solar absorber.BHMG exhibited a high photothermal conversion efficiency (η≈ 92.9%) and water evaporation rate(υ≈ 1.476 kg·m-2·h-1) under a standard solar irradiation.Liu’s group[60]constructed a composite SIVG system by fixing rGO and Ag nanoparticles on melamine sponge skeleton (rGO/AgNPs-MS) through a coating method (Fig.3d).The modified sponge not only retained high water absorption of the original matrix,but also showed excellent photothermal conversion performance and hydrophobicity,achieving a highηof 86.8%.And the rGO/AgNPs-MS also showed outstanding sorption capacity for organic solvents and low viscosity oil.

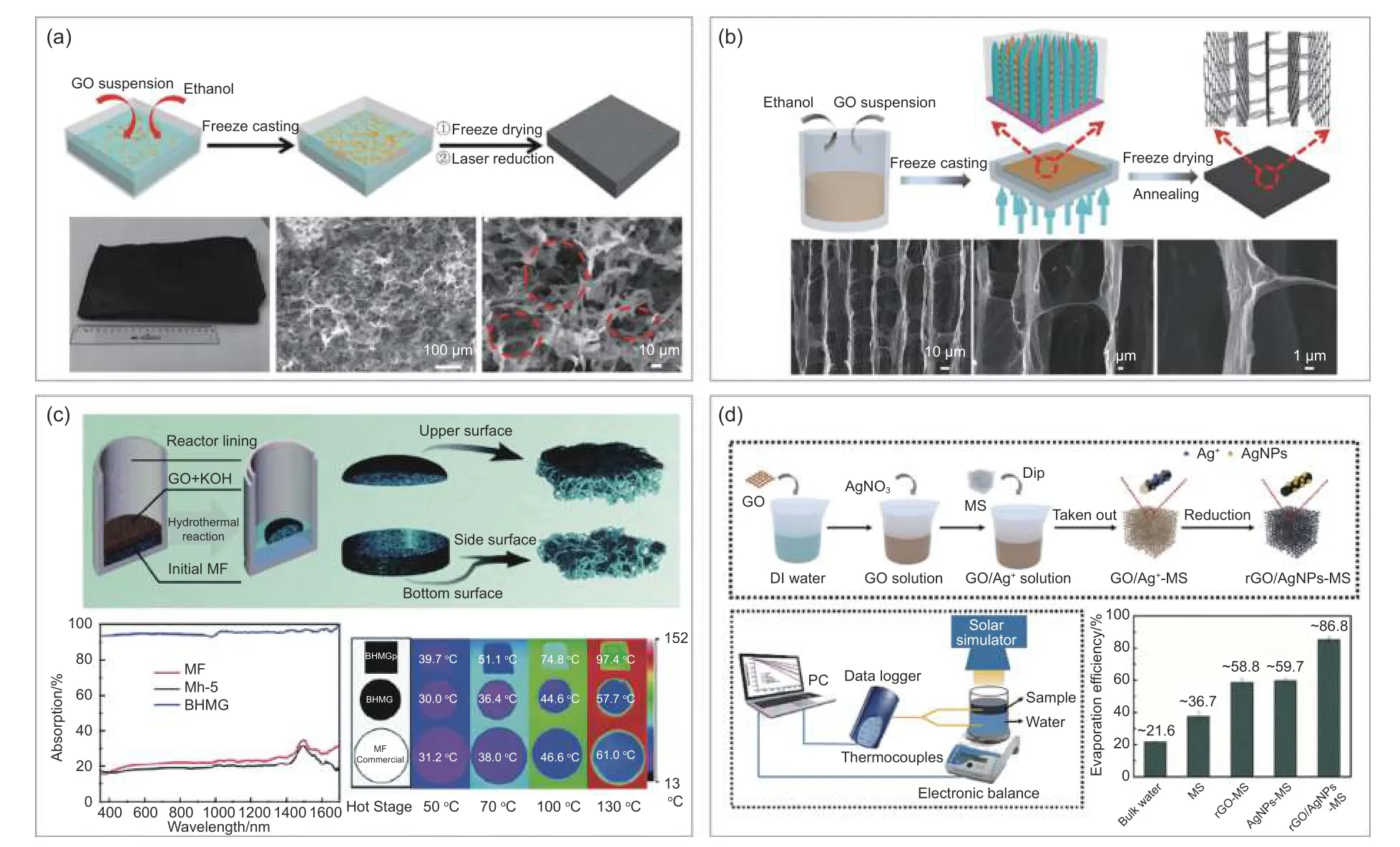

It is also a feasible method to construct a threedimensional (3D) porous graphene-based SIVG device by mixing graphene derivatives with other functional materials.In this case,graphene derivatives are not only used as photothermal absorbing materials,but also as structural supporting materials.As shown in Fig.4a,Peng’s group[61]prepared a hierarchical graphene foam (h-G foam) with continuous pores by adding the secondary micro-nano structure of graphene to the primary structure of the macroscopic graphene 3D skeletonviavapor deposition.The light trap’ phenomenon can reduce reflection and transmission of incident light,thereby achieving an excellentηabout 93.4% and a highυof 1.4 kg·m-2·h-1.At the same time,Yu’s group[62]first designed an rGOpolyvinyl alcohol (PVA) hybrid hydrogel with capillarity-facilitated water transport.Since interaction between the polymer network and the rGO additive,the hydrogel exhibited a synergistic function of customizing water transport,effective energy limitation and reduction of water evaporation enthalpy (Fig.4b).This novel design endowed it with high evaporation rate (~2.5 kg·m-2·h-1) .In addition,various advantages of rGO-PVA hybrid hydrogels including antifouling function,low cost and scalability further ensured their great application potential in practical environment.

Fig.4 (a) Photothermal conversion difference diagram of ordinary graphene foam and h-G foam[61] (Reprinted with permission by WILEY-VCH Verlag GmbH &Co.KGaA,Weinheim,Copyright 2017);Schematic illustrations of (b) hydrogel-based antifouling solar evaporator and solar absorption of rGO-PVA hybrid hydrogel[62] (Reprinted with permission by RSC Publishing,Copyright 2008),(c) surface-modified hydrogel for solar vapor generation[63] (Reprinted with permission by American Chemical Society,Copyright 2019),and (d) preparation and structure of HGPA[64](Reprinted with permission by Royal Society of Chemistry,Copyright 2013).

For the material selection of solar absorbers,the patterning of graphene and its derivatives is also one of the factors affecting the water evaporation rate.Yu’s group[63]studied the evaporation properties of graphene-coated hydrogels with different customized surface morphologies,that is,flat,grooved,and obviously depressed surfaces.The results showed that the surface with obvious depression had the highestυ(≈ 2.6 kg·m-2·h-1) andη(≈ 91%) values (Fig.4c).Qu’s group[64]constructed a highly vertically aligned GO pillar array (HGPA) with a high-precision laser,which was based on freeze-dried GO aerogel coupled with polystyrene foam and wicking cotton.The increased contact area can promote the water/steam escape process,thereby achieving theυof 2.02–2.10 kg·m-2·h-1and theηof 95% (Fig.4d).It can be seen that materials such as GO not only have excellent photothermal properties of carbon-based materials,but also are rich in a large number of oxygen-containing groups.Therefore,they can be combined with other materials to form CPTMs with stable structure.In addition,a reasonable design of geometric structure can reduce the energy loss caused by light reflection,thereby improving the photothermal performance of CPTMs and improving the evaporation efficiency.

3.2 Carbon nanotubes-based SIVG system

Carbon nanotubes (CNTs) possess high light absorption coefficient and low thermal capacity.When strong coupling occurs between incident photons and surface electrons of CNTs,a large amount of heat will be generated in CNTs.Therefore CNTs have been widely used as CPTMs in SIVG systems,in which CNTs are usually compounded with hydrophilic substrates to improve light absorption capability of the entire SIVG system.

Xie’s group[65]fabricated a CNTs-modified flexible wood membrane (F-Wood/CNTs) SIVG system(Fig.5a).By embedding CNTs into the wood with highly ordered porous structure,the ultra-high solar absorption rate of CNTs (~98%) and the natural water transport channel of wood were conducive to the generation of solar vapor,enabling itsυof 0.95 kg·m-2·h-1.Similarly,Ding’s group[66]designed CNTs@SiO2nanofibrous aerogels (CNFAs) (Fig.5b) for efficient solar-driven water evaporation.This double-layer material consisted of the top of hydrophobic CNTs and the bottom of hydrophilic porous silica substrate,obtaining an excellent light absorption rate of about 98%.In addition,owing to the synergistic effect of excellent light absorption performance and tubular structure of CNTs,CNFA aerogels exhibited excellent evaporation performance (υ≈ 1.50 kg·m-2·h-1).Liu’s group[67]designed an arch evaporator based on CNTs modified polytetrafluoroethylene (PTFE) hollow fiber (Fig.5c).CNTs were coated on the film to enhance sunlight absorption.The heteromorphic arch-like evaporator displayed a light absorption rate of 94.5% and an indoor evaporation rate of 2.15 kg·m-2·h-1.

Blending with polymeric hydrogel matrix is also a common method to construct CNTs-based SIVG system.Peng’s group[68]used copper hydroxide nanochain solution (CHN),single-walled carbon nanotubes (SWCNT),and gelatin to fabricate a composite SIVG system based on SWCNT/gelatin membrane(Fig.5d).The light absorption efficiency (α≈ 97.3%)of this SIVG system endowed it with a rapidυof 1.39 kg·m-2·h-1.In another case,Huang’s group[69]embedded CNTs into PVA molecular network to prepare CNTs/PVA hybrid hydrogel (CPG).CNTs showed excellent dispersibility in the PVA polymer network,and some crosslinking points also appeared,which helped improve the flexibility and mechanical properties of the CPG.Furthermore,molecular network of CNTs wrapped by PVA polymer network can limit the converted energy to reduce heat loss.The hybrid gel had theαof more than 90% and theυof 2.06 kg·m-2·h-1.Obviously,the properties of the complex materials are generally coordinated with each component to enhance the water evaporation efficiency of the photothermal interface.By combining the outstanding light absorption performance of CNTs with other materials,the structure and steam generation ability of composite materials can be effectively improved.

3.3 Carbon dots-based SIVG system

Carbon dots (CDs),an integral member of carbon family,have gained interests from researchers in the field of SIVG owing to their inherent properties,including non-toxic,easy functionalization,low thermal conductivity,abundant surface functional groups and excellent light capture capability[70].As one of the emerging photothermal agents,CDs possess broadband absorption result from tightly packed energy level of looselypelectrons,which excites electrons and relaxes to the ground state,accompanied by local heating of the lattice and the release of phonon transport energy[51].Hence,CDs have been widely considered as potential alternatives in solar absorber of SIVG systems[71–73].

Up to now,combining with their unique properties of water-solubility and excellent biocompatibility,CDs have been widely integrated with hydrophilic matrix for SIVG systems as solar absorbers.Hu’s group[74]designed CDs-grafted cellulose nanofibrils(CNFs@CDs) for SIVG (Fig.6a).The integration of CDs with cellulose nanofibers derived from biomass waste not only achieved a fastυof 2.5 kg·m-2·h-1under one sun irradiation,but also possessed longterm salt-rejection ability under solar desalination.Hu’s group[75]also constructed a carbonized CDsmodified starch aerogel (C-CDSA) for SIVG(Fig.6b).The introduced CDs played a significant role in solar evaporation performance from 2 aspects:(1) CDs were beneficial to the polymerization and carbonization of starch chains,thus regulating the structure and components of C-CDSA.(2) By virtue of the introduced CDs with abundant oxygen-containing functional groups,C-CDSA exhibited super hydrophilicity and water activation ability.C-CDSA achieved theυof 2.29 kg·m-2·h-1withη=93.5%.In addition,Hu’s group[76]designed the wood-supported CD assemblies (CDs@Wood) for solar-vapor generation (Fig.6c).The micropores of CDs@Wood effectively reduced vaporization enthalpy of water.Meanwhile,hydroxyl groups ingrafted on surface of CDs mainly contributed to high solar-vapor efficiency in comparison with the other oxidized functional groups(carboxyl and carbonyl).As a result,CDs@Wood displayed a fastυof 2.27 kg·m-2·h-1,along with theηof 92.5% (solar to vapor).

CDs can not only be used as a single photothermal agent,but also be coupled with semiconductor materials to form heterostructures for efficient photothermal conversion.Wang’s group[77]fabricated a self-desalinating,ultra-flexible SIVG system(MnCDs@PPy),which was established byin-situpolymerization (polypyrrole) of CDs modified MnO2nanowires coated on cotton fabrics (Fig.6d).The defect chemistry of functionalized CDs promoted electron migration between CDs and MnO2,enhancing the superior solar absorption and form of heat.These excellent solar-thermal conversion behaviors ensure the highυ(1.68 kg·m-2·h-1).

Overall,CDs-based SIVG system exhibits excellent solar absorption,tunable surface chemistry and easy-to-assemble ability,favoring the highly SIVG performance.However,large-scale synthesis of CDs material with low thermal conductivity is still a challenge.Heteroatom doping and defect engineering would be the way to further enhance its photothermal properties.

3.4 Biomass-based carbon for SIVG system

Natural plant species possess ingenious and complex structures owing to their evolution through million years.The multi-channel water transport structure in biomass materials provides water transport channels for transpiration.In addition,biomass materials,as a renewable precursor,have the characteristics of low cost and wide sources.Plant biomass mainly consists of cellulose,hemicellulose and lignin.In particular,cellulose-based biomass materials are ideal candidates for SIVG system substrates owing to their good hydrophilicity and low thermal conductivity.

Therefore,researchers have combined cellulose and carbon materials with good performance to prepare a series of evaporators.Wang’s group[78]constructed a composite cellulose hydrogel coupled with CNTs (CNTs-CH) (Fig.7a).Benefiting from the superior water holding capacity of cellulose hydrogels and excellent solar absorption ability of CNTs,the CNTs-CH performed the averageυof 1.52 kg·m-2·h-1and the solar-steam conversion efficiency of 92%.On the basis of cost-effective materials such as cellulose and carbon black,Zhang’s group[79]prepared a tripod porous wood-mimetic cellulose evaporator by 3D printing process (Fig.7b).The evaporator had a wideband solar absorptance as high as 97%,and an extremely low thermal conductivity (0.075 W·m-1·K-1).In addition,theυcan reach 5.79 kg·m-2·h-1under 5 solar irradiations.Pan’s group[80]prepared biomassbased hydrogel evaporator by forming a hydrogel layer between cellulose-lignin composite hydrogel(LCG) and lignin-derived carbon (LC) (Fig.7c).Lignin diminished the vaporization heat of water,thus increasing the evaporation rate.LC also had abundant micropores and ultra-high specific surface area.The double-layer hydrogel evaporator exhibited a highυof 1.84 kg·m-2·h-1and theηof 86.5% under one sun illumination.

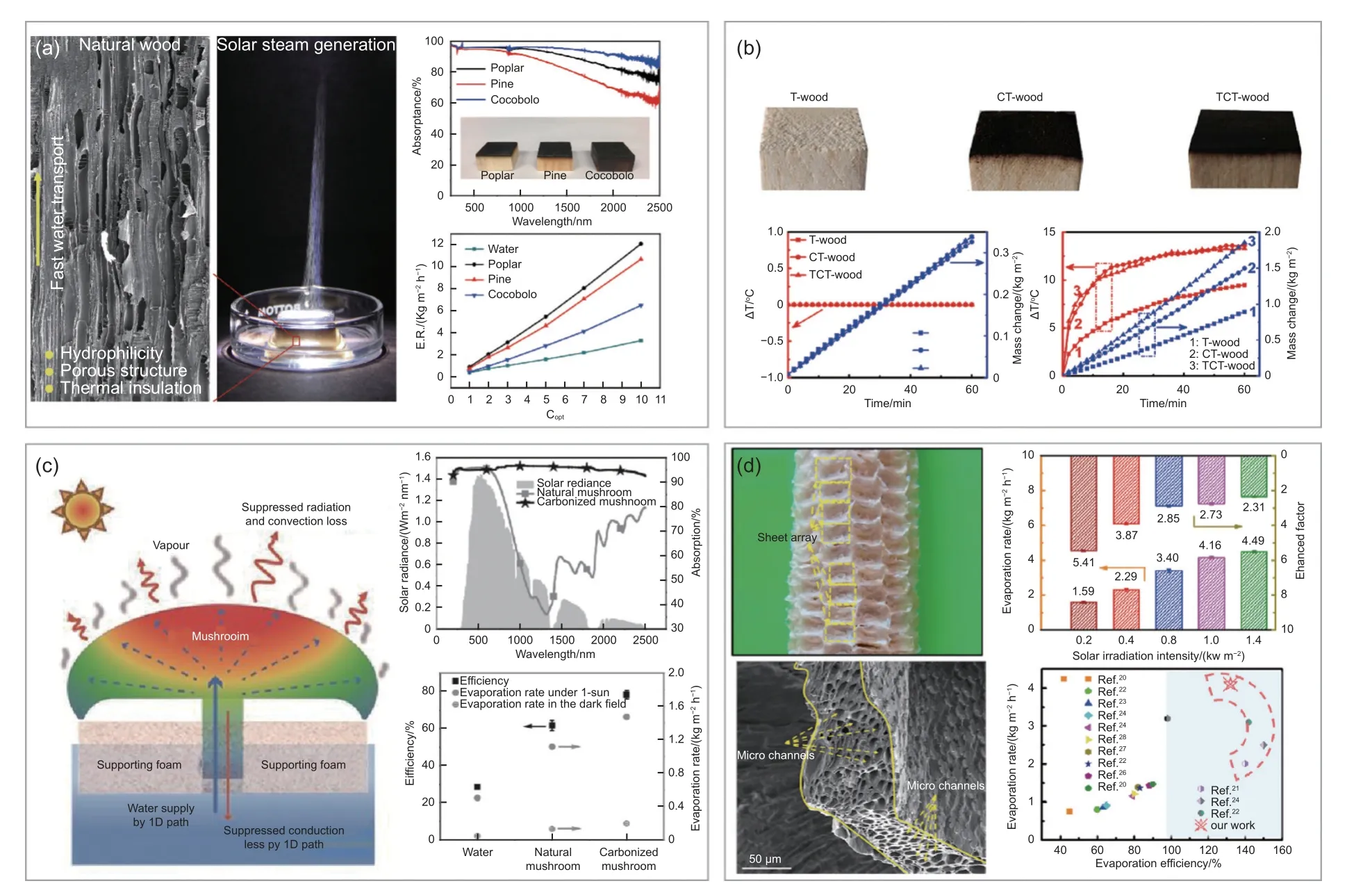

In addition to using the extracted cellulose from biomass,biomass can also be directly carbonized.Biomass carbonization can not only retain the advantages of pore structure,but also increase the light absorption performance.Carbonized wood with modified surface is the most common biomass-based PTMs in SIVG systems,owing to its rich channel structure,good processing performance and cost-effectiveness.In 2017,Hu’s group[81]first proved that the suitable carbonization process of wood can retain the natural porosity of wood,thus promoting water delivery.At the same time,the influence of pore structure between different types of wood (softwood and hardwood) on the performance of SIVG was discussed in detail.As shown in Fig.8a,the wood structure with high porosity is more efficient owing to the fast water transport channel retained by carbonization and low thermal conductivity.Subsequently,Hu’s group[82]developed an efficient solar steam generator in 2018,which was composed of graphite sprayed on a natural,vertically cut medium-hole basswood block.The anisotropy of the thermal conductivity of mesoporous wood increased the temperature of the evaporation zone,which meant that the conduction heat loss to the bulk water was reduced.Xue’s group[83]designed a SIVG system consisting of chemically-treated carbonized wood (TCT-wood) (Fig.8b).The system not only had a highυabout 1.85 kg·m-2·h-1,but also showed high adsorption capacity for metal ions and excellent reuse ability.It was proved that the concentration gradient of metal ions and the local temperature field in the small channel,caused by the evaporation of water,can improve the adsorption capacity of the system towards heavy metal ions.It was also verified that SIVG technology was an effective strategy to enhance the removal efficiency of heavy metals.Hu’s group[84]designed a new type of Janus wood evaporator.The evaporator had asymmetric wettability,which ensured good salt resistance,thermal insulation,and evaporation efficiency when treating high-concentration brine.

Fig.8 (a) Digital photos and SEM images of wood solar evaporator[81] (Reprinted with permission by Elsevier Inc.,Copyright 2017).Schematic of biomass derived carbon-based SIVG systems: (b) TCT-wood[83] (Reprinted with permission by Elsevier B.V.,Copyright 2020),(c) mushroom[85] (Reprinted with permission by WILEY-VCH Verlag GmbH &Co.KGaA,Weinheim,Copyright 2017),and (d) c-corncob[88] (Reprinted with permission by Elsevier Ltd.,Copyright 2021).

Apart from wood,other biomasses are also employed as SIVG systems.Zhu’s group[85]confirmed the practicability of carbonized mushroom as solar water evaporator.The umbrella structure separated evaporator from the water channel,enhancing its thermal localization.Theυof 1.48 kg·m-2·h-1was obtained under a standard solar irradiation (Fig.8c).Similarly,carbonized rice stalk[86]had theυof 1.2 kg·m-2·h-1.Chen’s group[87]also demonstrated the possibility of using bamboo-derived carbon as interfacial solar water evaporator,which provided theυof 1.522 kg·m-2·h-1.Recently,Zhao’s group[88]designed a 3D corncob-derived monolithic carbon (C-corncob)with well interconnected hierarchical micro/nano pore structures.The unique pore structure on the side around the monolith carbon allowed the occurrence of side evaporation and the input of environmental energy,thus enhancing a highυof 4.16 kg·m-2·h-1at one sun illumination (Fig.8d).

The above natural structures have their own advantages and disadvantages.After proper modification of the material,its photothermal conversion performance can be greatly improved.In particular,the preparation of porous carbon materials by carbonization of biomass can improve surface chemical properties,microstructure,wettability and light absorption,so as to achieve more efficient evaporation of upper water.It can be seen that SIVG technology provides a sustainable solution for clean water production through seawater desalination and wastewater purification.Excellent photothermal conversion efficiency can be achieved by using the porous structure of carbon materials and the interface evaporation device.Build an interface system for solar-driven water evaporation,and improve thermal insulation effect of the interface system to achieve high evaporation efficiency.For another thing,this method also provides tremendous potential for steam or power generation.Water collection devices based on solar photothermal conversion systems usually involve sundry physical phenomena during operation,namely local high temperature,local high salt concentration,vapor generation,and condensate flow.These phenomena are conducive to the SIVG system using solar energy to achieve multi-functional uses,namely power generation,thermal insulation,thermal dissipation,and vapor condensation,thereby promoting the synergistic enhancement of SIVG system for vapor and electricity generation.

4 Solar-driven vapor/electric co-generation systems

Water and electricity are 2 valuable resources closely related to social development.Some advanced technologies using solar energy as energy source have been explored for power generation by photovoltaic,photochemical,and photothermal processes[89–90].With the rapid development of SIVG technologies,an innovative integrated solar hybrid system[28,91–93],which combines electric generation with water-vapor phase transition for the co-production of electric and water,is considered as a potential route to resolve the freshwater and energy scarcity.The existence of solar evaporation-induced temperature/salinity gradients between the evaporation region and water body is used to produce electricityviathermoelectric,thermoelectrochemical,or salinity gradient effects[94].Thanks to the concurrent production of energy and freshwater,the overall efficiency of energy conversion could be elevated in solar-driven vapor/electric co-generation systems,shown as the following.

4.1 Thermoelectric system

The working principle of thermoelectric power generation relies on the Seebeck effect[95].That is,when there is a temperature difference between the two sides of different thermoelectric materials (n-and p-type),the concentration of holes and electrons at the hot-side will be higher than that at the cold-side.Driven by the concentration difference,holes and electrons spontaneously diffuse to the cold-side.In the thermal equilibrium state,the temperature difference between the hot-side and the cold-side determines the generation of electric energy,and thermoelectric devices utilize spatial temperature gradients to generate electrical energy.The operating temperatureTand thermoelectric figure of meritZTdetermine the device efficiency (ηte)[96–97].The calculation formula is as follows:

where,σrepresents the conductivity,αrepresents the Seebeck coefficient,TCandThare the temperature of the cold-side and the hot-side,respectively,andκis the thermal conductivity[98].

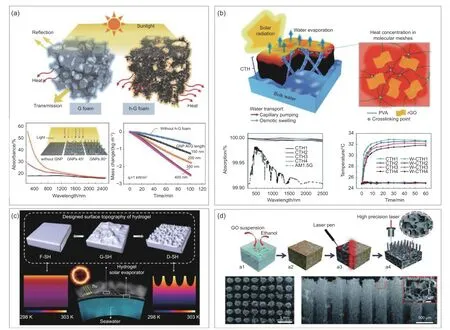

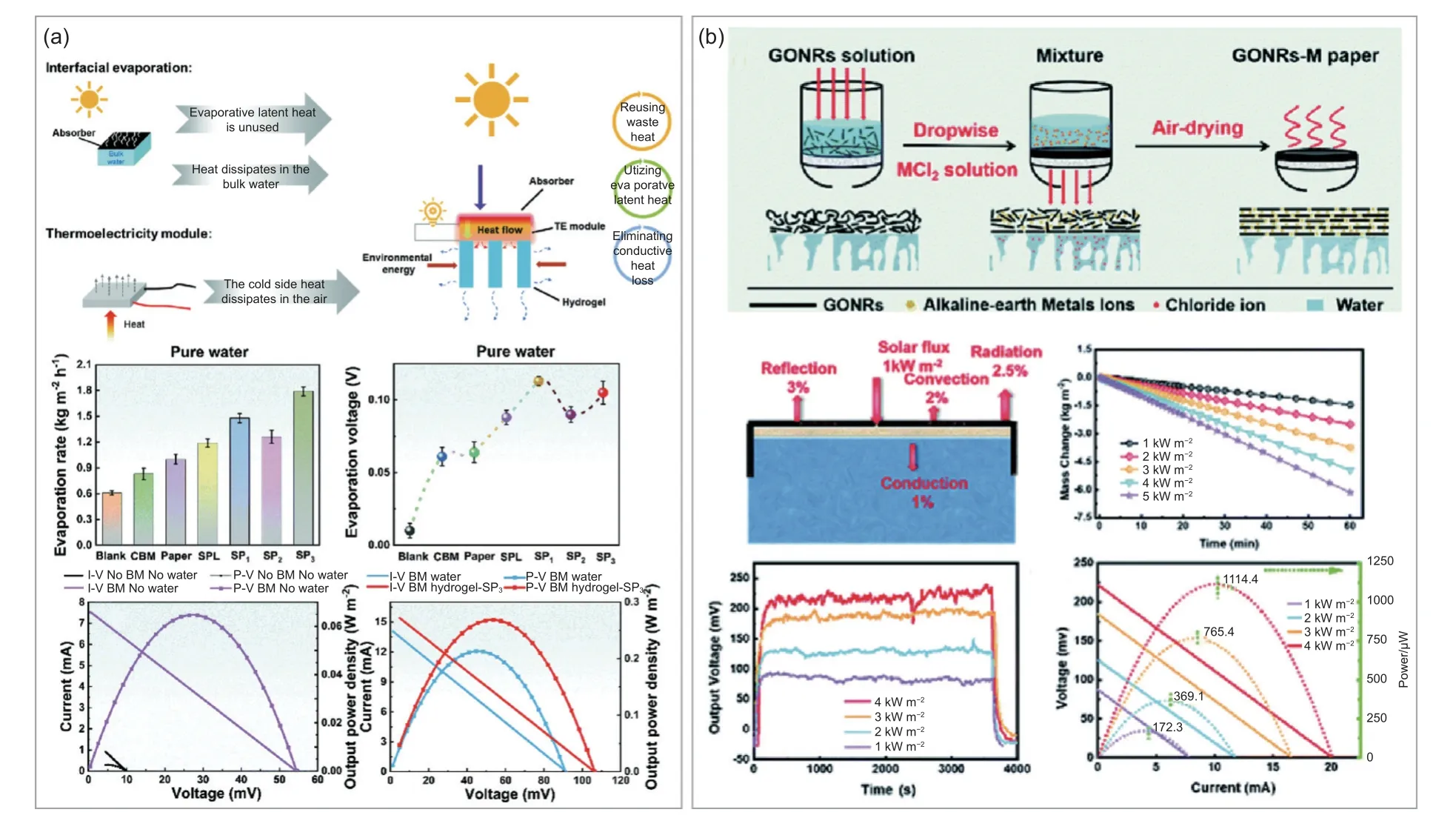

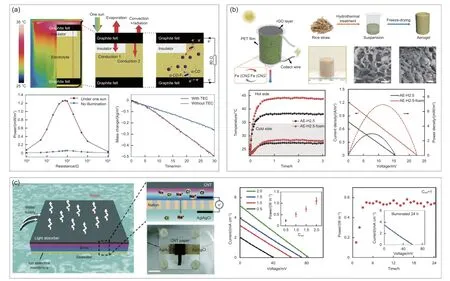

The thermoelectric module can collect the lowgrade heat loss during the evaporation of interfacial water through the Seebeck effect to realize the conversion of heat energy to electric energy.At the same time,it can also be used as a thermal insulator of the evaporation device for promoting the evaporation process.The feasibility of synergistic SIVG and thermoelectric power generation is further demonstrated.Miao’s group[99]designed a thermoelectric-freshwater cogeneration device composed of thermoelectric generator (TEG) and starch-polyacrylamide (S-PAM) hydrogel (Fig.9a).Owing to the use of scavenging energy,the TEG-based hybrid co-generator yielded a maximum output power density of 11.39 W·m-2under single solar illumination.Zhao’s group[100]created a 2D GONR-M paper,through the ring-opening and crosslinking reaction of graphene oxide nanoribbon paper (GONR) mediated by alkaline earth metal ions(M=Mg2+,Ca2+,Sr2+or Ba2+).The integration of GONR with M produced a unique structure,showing excellent full-spectrum solar absorption,mechanical stability,and high hydrophilicity,resulting in the GONR-M paper continuously produce clean water from seawater with aηof~ 91.5% under one standard solar intensity.Theυof seawater was as high as 1.36 kg·m-2·h-1,revealing the feasibility of the material in actual seawater desalination.The simultaneous evaporation power generation device was composed of independent flexible GONR-M and thermoelectric modules (Fig.9b).The output power density of the system was about 0.11 W·m-2under 1 kW·m-2solar illumination,reflecting the synergistic effect of solar evaporation and sustainable power generation.

Fig.9 (a) Schematic diagrams of the cogenerator based on TEG for electricity and water[99] (Reprinted with permission by The Royal Society of Chemistry,Copyright 2022).(b) Performance of simultaneous desalination power generation device based on GONRs-M paper[100](Reprinted with permission by Royal Society of Chemistry,Copyright 2013)

4.2 Thermo-electrochemical system

The solar photothermal-electrochemical system is a new type device that combines photothermal conversion with electrochemical energy conversion and storage.The device converts thermal energy into electrical energy though temperature-dependent redox couple electrolyte and electrodes[101–103].Redox reactions occur on both the anode and cathode,and a temperature gradient is generated on the electrodes.The reaction substances between the electrodes produce convection and migration transmission through the electrolyte,generating continuous current in the thermal battery,thereby establishing a closed cycle reaction.In the redox A+ne-↔B,the Seebeck coefficient (S) is calculated as follows:

where,Vrepresents the voltage,nrepresents the number of electrons involved in the reaction,Fdenotes the Faraday constant,∆SB.Ais the reaction entropy of electrolyte.

The cell performance can be expressed as:

where,Rrepresents the gas constant,zrepresents the ionic charge,κis the thermal conductivity,Dlimdenotes the diffusion coefficient,andcis the electrolyte concentration[101].

Solar photothermal-electrochemical devices provide a series of new ideas for low-cost realization of solar cogeneration.Deng’s group[104]reported a thermo-electrochemical cell (TEC) that improved electrochemical performance by photothermal evaporation (Fig.10a).The cell used graphite felt as an electrode material and solar-absorbing material,and I3-/Ias the redox electron.Under sun light,the potential difference between the 2 pairs of electrodes was generated by the temperature gradient.During the thermal process,the top graphite felt acted as a solar absorber to convert solar energy into heat energy,greatly increasing the evaporation rate of TEC.Under 1.0 solar illumination,the maximum output power density reached 1.3 mW·m-2,and the evaporation rate reached 1.1 kg·m-2·h-1,realizing the good integration of water evaporation and electrochemical power generation.Xu’s group[105]designed a TEC device,which composed of straw fiber aerogel,reduced graphite oxide(rGO) photothermal layer,and Fe(CN)63-/4-redox couple for collecting solar radiation heat and releasing latent heat in SIVG devices (Fig.10b).As an efficient light absorption material,rGO nanosheets adhered to bamboo paper by using agarose.The solar absorption capacity of the prepared photothermal film was >90%.Furthermore,a sustainable temperature difference can be maintained between the electrodes,and the output power density of the designed TEC reached up to 6.94 mW·m-2under the light intensity of 1 kW·m-2.

Fig.10 Schematic diagrams of (a) an open TEC enabled by interfacial evaporation[104] (Reprinted with permission by Royal Society of Chemistry,Copyright 2013),(b) preparation of straw fiber aerogel and power-voltage curve of the TEC[105] (Reprinted with permission by the Hong Kong Polytechnic University and John Wiley &Sons Australia,Ltd.,Copyright 2022),and (c) the hybrid system for solar salinity power extraction[109](Reprinted with permission by Royal Society of Chemistry,Copyright 2008)

4.3 Salinity power system

Salinity gradient power is derived from the difference of the chemical potential between seawater and freshwater or between 2 kinds of seawater with different salinity.Salinity gradient energy is a green energy with the largest energy density in ocean energy.The so-called “blue energy” is obtained during the blending of seawater and fresh water.Theoretically,the Gibbs free energy ΔGmixcan be used to calculate the maximum work released in the mixing process.The energy difference per unit volume of mixing is calculated as follows:

where,χis the volume fraction of seawater,cmis the concentration of mixed solution,csrepresents the concentration of seawater,andcrrepresents the concentration of river water[106–107].In practical processes,the useful work per unit is always less than ΔGmixdue to the inevitable generation of entropy[106,108].Zhou’s group[109]proposed a multifunctional photothermal device by using a CNT modified hydrophilic filter paper as a photothermal device.Meanwhile,a commercial Nafion membrane was selected as an ion selective membrane (Fig.10c).Under one sun irradiation,solar-driven seawater desalination with theηof 75%and salinity gradient-induced power output about 1 W·m2can be simultaneously achieved.Therefore,the difference of ion concentration in the process of solar seawater desalination was used to realize the conversion of light,heat,and electricity.The power generation principle of this device was different from that of traditional photovoltaic (PV) cells,which promoted the utilization of solar energy.

5 Conclusion and outlook

To sum up,this review provides a summary of the current status and progresses of carbon-based materials in the subject of interfacial solar-driven vapor and electricity generation.According to classification of carbon species,some impressive progresses have been summarized in the research of carbon-based PTMs,which may have reference and guiding significance for the design of new high-performance SIVG systems.Meanwhile,according to the electricity generation mechanisms,various emerging carbon-based water/electricity co-generators are discussed,paving avenues for highly efficient solar evaporation applications.

Although some advanced researches have been conducted,more extensive systematic investigation is still needed to provide a reliable experimental and theoretical basis about the design of high-performance practical CPTMs for simultaneous steam and electricity generation.On the basis of the preliminary research in this field,the challenges that need to be solved and the corresponding strategies are proposed.

(1) Theoretical guidance

Although many strategies have been proposed for improving the photothermal conversion performance of carbon-based materials,there is still a lack of indepth understanding of the relationship between material/structural engineering and the energy transfer and flow of SIVG systems.The interactions of SIVG including heat transfer,water transport,and vapor diffusion may be synergistically influenced by specific designs.In particular,it is difficult to quantify and track the system energy in the energy conversion process,when it exists in different forms of multifunctional CPTMs and their interfacial water evaporation performance patterns.Further understanding of the energy flow of the system is beneficial not only to optimizing thermal management and evaporation efficiency,but also to designing practical applications.In addition,water transport and vapor diffusion are mainly dependent on the porous structure of the solar water evaporator.However,it is not yet clear how these behaviors are affected by pore size,curvature,partitioning,and distribution.And more comprehensive theoretical and experimental validation is needed.By introducing computer-aided simulations into SIVG systems,standard theoretical models can be developed to elucidate the constitutive relationships between water/heat transport and the composition and structure of materials in SIVG systems,which can be used to understand and predict the performance of individual components and even entire systems,and to provide theoretical guidance for material preparation and assembly.

(2) Experimental practice

The development of SIVG technology is still in the laboratory stage.In practical applications,there is still a large gap between the photothermal conversion efficiency and water collection efficiency as one side and their theoretical values as the other side.Therefore,in order to ensure the highest possible rate of water evaporation and stability of the system,the development of new carbon matrix composites and new structural design is essential.Different photothermal conversion capabilities depend on not only various types of PTMs,but also the different morphologies and structures of the same material.Mimicking the natural structures of organism can provide a new idea for the structural design of solar evaporators.The construction of efficient steam production structure,salt deposition resistance structure and water condensation structure is expected to realize the continuous practical application of SIVG technology.The coupling of material properties and unique structures can achieve synergistic advantages,while the coordination of material innovation and system-level engineering is also conductive to promoting the practical application of SIVG purification technology.

In terms of the prospects for solar-driven vapor/electric co-generation systems,despite intensive efforts have been made to explore the feasibility of co-generation of vapor and electricity in SIVG system,elevating the clean water flux and power density at the same time is still a great challenge.A few promising initiatives are proposed as follows: (1) developing and employing highly efficient CPTMs for light harvesting,(2) optimizing comprehensive management of thermal and mass transfer for reduction of non-essential energy loss in coupled systems,(3) constructing co-generator of water and electricity network for scaling up the system either in dimensions or in quantity,and series and parallel devices for the improvement of open-circuit voltage and the short-circuit current,respectively,and (4) coupling with photovoltaic technology or solar-concentrator for enhancing the integral energy input.

Acknowledgements

The authors acknowledge the financial support from projects funded by the National Natural Science Foundation of China (22179017 and 52172038),the National Key Research and Development Program of China (2022YFB4101600,2022YFB4101601) and the assistance of DUT Instrumental Analysis Centre.

杂志排行

新型炭材料的其它文章

- 生物质炭材料作为金属空气电池阴极的研究进展

- 3D porous NiCo2(CO3)3/reduced graphene oxide aerogel with heterogeneous interfaces for high-efficiency microwave absorption

- 煤基富氧多孔炭纳米片的制备及其超级电容器性能

- Mott-Schottky heterojunction formation between Co and MoSe2 on carbon nanotubes for superior hydrogen evolution

- A 2D montmorillonite-carbon nanotube interconnected porous network that prevents polysulfide shuttling

- A one-pot method to prepare a multi-metal sulfide/carbon composite with a high lithium-ion storage capability