Inherent relationship between process parameters,crystallization and mechanical properties of continuous carbon fiber reinforced PEEK composites

2023-07-04XiolongLihuWenShiyuWngJinyouXioWenhoLiXioHou

Xio-long M , Li-hu Wen , Shi-yu Wng ,*, Jin-you Xio , Wen-ho Li , Xio Hou

a School of Astronautics, Northwestern Polytechnical University, Xi'an, 710072, China

b China Aerospace Science and Technology Corporation, Beijing,100048, China

Keywords:Polymer matrix composites Thermoplastic Processing parameters Mechanical properties Crystallization

ABSTRACT

1. Introduction

In recent years, high-performance thermoplastic composites have been successfully applied in the aircraft industries because they exhibit numerous advantages, such as excellent specific stiffness, high toughness and ductility, outstanding thermal stability(PEEK is exceeding 300◦C), and shorter manufacturing cycles, etc[1—10]. In particular, thermoplastic composites have excellent impact resistance, corrosion resistance, and high service temperature, which have attracted the attention of military applications before commercial use and have been widely used in military aircraft [11—13]. However, due to the long molecular chain structure of thermoplastic resins such as PEEK and PPS, the high viscosity of the molten resin made it difficult to fully infiltrate the fibers [14—18]. And thermoplastic resin contains amorphous domains and crystallites, which can convert to each other upon temperature change or shear flow [19]. Therefore, the molding process conditions can significantly affect the performance of the thermoplastic composites. In addition, thermoplastic resins have high melting temperatures and a narrow processing window.These harsh conditions have brought considerable challenges to the molding process of high-performance thermoplastic composites.Therefore, it is necessary to optimize the molding processing of thermoplastic composites.

Different molding processing parameters significantly affect the mechanical properties of thermoplastic composites. A number of researchers have studied the influence of molding processing parameters on mechanical properties [20—26]. Fujihara K et al. [20]optimized the molding temperature and holding time of continuous CF/PEEK composite laminates with bending performance as an indicator,and it was pointed out that excessively high molding temperature and too long holding time would lead to degradation of PEEK and reduce mechanical properties. Similarly,Xu Z et al. [22] found that when CF/PEEK composites via the wrapped yarn method were held at higher molding temperatures(above 420◦C) for an excessive time (above 60 min), would have decreased mechanical properties due to matrix degradation.Zheng B et al.[23]investigated the influence of molding temperature and molding pressure on the properties of woven CF/PEEK composites,and pointed out that the optimal process conditions for bending performance were 400◦C and 5 MPa, while the molding pressure had little effect on interlaminar shear strength (ILSS). Dai G et al.[24]took the ILSS as the optimization objective,studied the effects of molding temperature,molding pressure,and holding time on the mechanical properties of CF/PEEK cross-ply laminates,and pointed out that the optimal molding conditions were holding time of at least 20 min and molding temperature should be between 400 and 420◦C. The current research mostly phenomenologically established the relationship between the molding process parameters such as molding temperature, pressure, and holding time and the macro-mechanical properties. However, these conclusions did not deeply clarify the regulation mechanism of the processing parameters on the macro-mechanical properties of thermoplastic composites.In addition,the viscosity of the molten thermoplastic resin is affected by factors such as the molding temperature and holding time [27]. Therefore, the thermoforming curing processing parameters of thermoplastic composites are not independent of each other but affect each other. However, to the author’s knowledge,there is little information available in the literature about comprehensively and systematically considering the coupling effect of processing parameters on the mechanical properties of thermoplastic composites.

The mechanical properties of semi-crystalline thermoplastic composites, especially the fracture toughness, were mainly dominated by crystallinity, which was affected by the processing parameters [28—30]. The researchers discussed the effect of processing parameters on the crystallization behavior of thermoplastic resin [31—35]. Yang X and Sun H et al. [33—34] studied the effect of different cooling rates on the non-isothermal crystallization kinetics and discussed the effects of cooling rates on crystal growth and morphology. Gao S L et al. [36] further analyzed the effect of cooling rate on the fracture toughness of thermoplastic composites and revealed the mechanism of cooling rate regulating the fracture toughness of composites by affecting the crystallization process. Processing parameters such as molding temperature,pressure, and holding time also affect crystallization behavior.However, little attention has been devoted to regulating these processing parameters on the crystallization process of thermoplastic composites and their impact on mechanical properties.Therefore,it is of great significance to study the effects of molding temperature, pressure, and holding time on the crystallization of composites and quantitatively discuss the relationship between crystallization and mechanical properties.

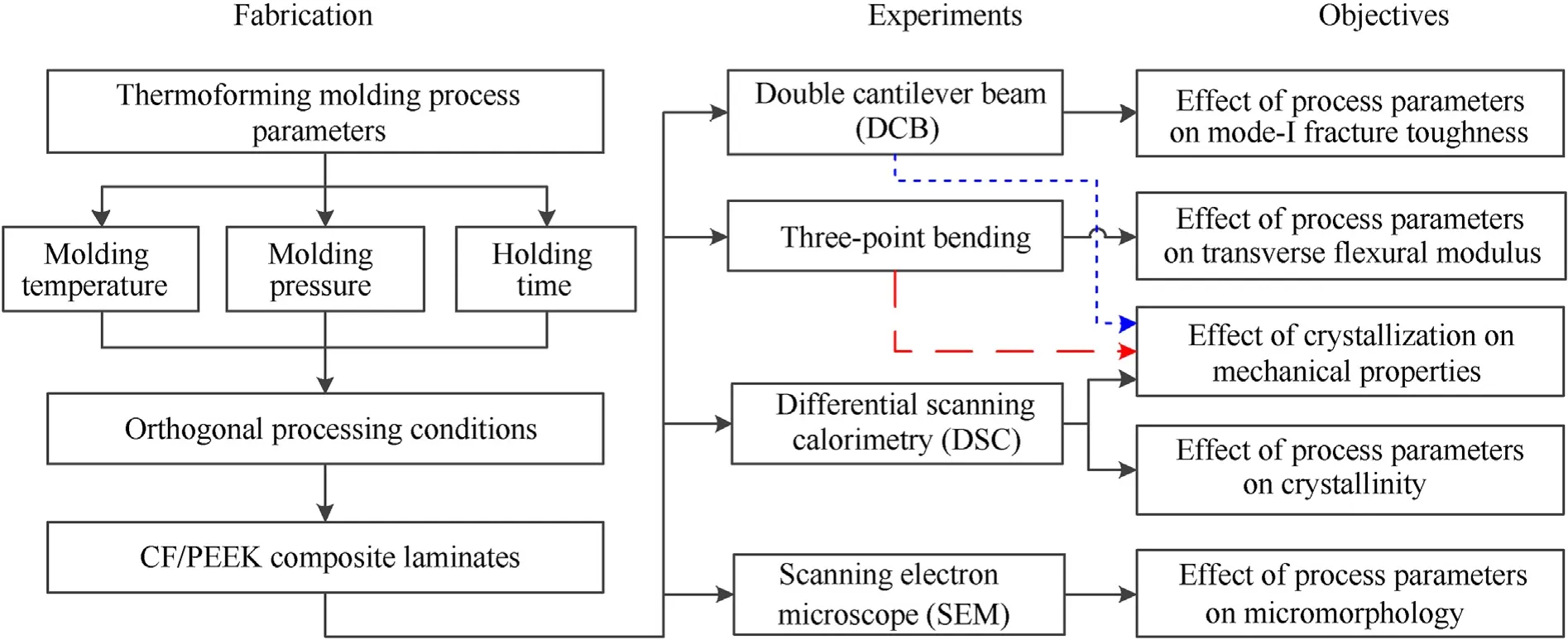

This study aimed to investigate the effects of molding process parameters on molding quality, mechanical properties, and crystallization behavior of continuous CF/PEEK composites. Thus, the CF/PEEK composite laminates were fabricated by three-parameter four-level orthogonal thermoforming process parameters. Threepoint bending test, double cantilever beam (DCB) test, and differential scanning calorimetry (DSC) test were carried out to analyze the effects of the molding process parameters (molding temperature, molding pressure, and holding time) on the mechanical properties and crystallization behavior of the CF/PEEK composites.The molding quality and failure mechanism were investigated by microscopic morphologies of the CF/PEEK specimen.The effects of processing conditions on fiber/resin interaction and crystallization of CF/PEEK composites were systematically discussed, and the mechanism of the effect of matrix crystallization on the mechanical properties of the composites was studied.

2. Materials and fabrication

The material used unidirectional PEEK-carbon prepreg commercialized by VICTREX, which has a melting temperature of 343◦C and a fiber mass fraction of 54%. For this study, CF/PEEK composite laminates were fabricated using the thermoforming method. The CF/PEEK composite laminates of 2 mm nominal thickness were hand lay-up of 16 plies of unidirectional prepreg,which were consolidated in a matching steel mold.A pre-crack was created by laying a 16 μm thick polyimide high-temperature resistant film on the middle plane, which was coated with a release agent.

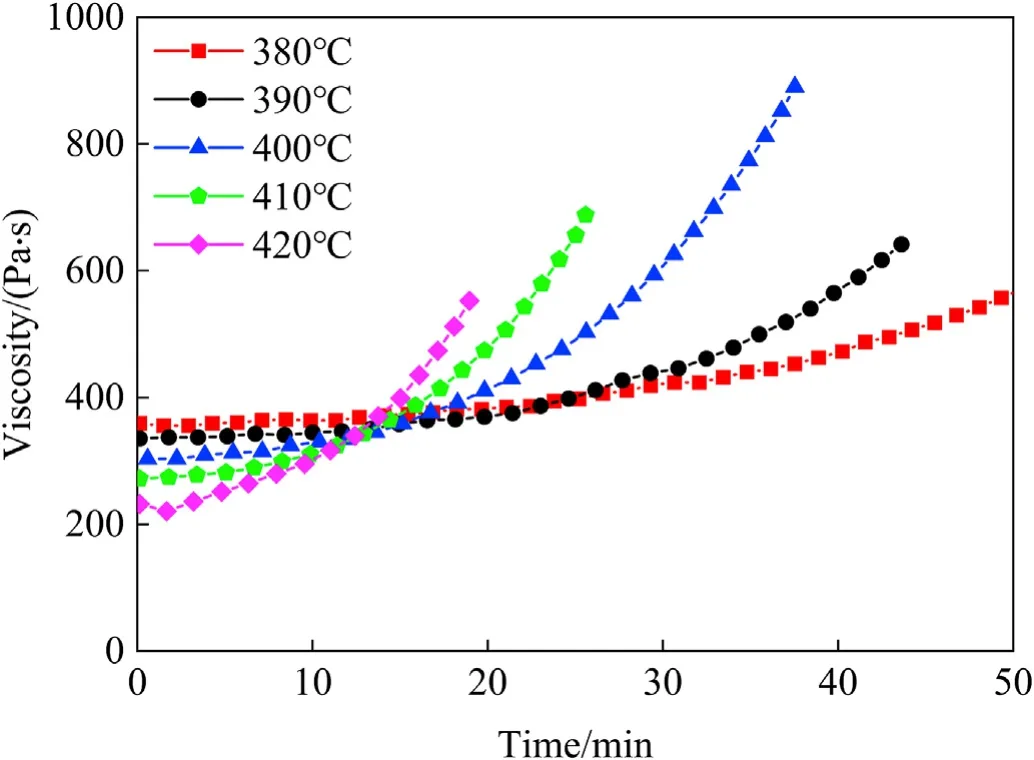

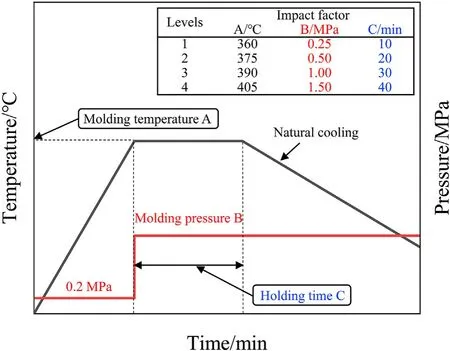

The determination of processing parameters was closely related to the fluidity of the resin. According to the relationship between the viscosity of PEEK and the processing conditions [27], the viscosity of PEEK in the molten state was not only related to molding temperature but also affected by holding time,as shown in Fig.1.In addition,considering the degradation of the PEEK matrix caused by high molding temperature [20,22]. Therefore, this study selected 360—405◦C as the molding temperature,10—40 min as the holding time, and designed the three-parameter four-level orthogonal thermoforming process conditions, as shown in Fig. 2. The experimental design process and objectives of this paper were shown in Fig. 3.

Fig.1. Viscosity of PEEK as a function of time for different temperatures [27].

Fig. 2. Fabrication conditions of continuous CF/PEEK composite laminates by L16 (43)orthogonal experiments.

Fig. 3. Experimental design process and objectives.

Fig. 4. Sketches of specimens and testing fixtures for mechanical characterizations: (a) DCB specimen; (b) Three-point bending specimen.

3. Characterization methods

3.1. Mechanical characterization

In order to characterize the influence of thermoforming process parameters on the mechanical properties of thermoplastic composites, double cantilever beam (DCB) tests and three-point bending tests are carried out through an electromechanical universal testing machine(INSTRON 5569) at room temperature.DCB tests are performed according to the ASTM standard D5528 with a loading speed of 2 mm/min.The nominal size of the DCB specimen with the initial crack length of 50 mm(a0)is 150×25×2 mm3,as shown in Fig.4(a).The digital image correlation(DIC)measurement technique is used for crack extension length measurement,which is recorded using a HIKVISION MV-CA060-11 GM industrial camera(resolution 3072 × 2048, image element size 2.4 μm) with an acquisition framerate of 10 s a piece. Based on the full-field displacement obtained by the DIC measurement system, accurately locate the crack tip position, and obtain the crack extension length in real-time.Regularly track the position of the crack tip and record the applied load and opening displacement at each crack extension. The mode-I interlaminar fracture toughness (GIC) is calculated from Eq. (1) [37].

wherePis the applied load,δ is the load point displacement,bis the width of a specimen,ais the delamination length, and Δ is the corrective factor for crack length.

Three-point bending tests according to the ASTM standard D7264 are conducted.The span-to-depth ratio is 32,and the crosshead speed is 1 mm/min. The specimen dimension is 81 × 12 ×2 mm3,as shown in Fig.4(b).The test specimens are cut out of the laminates thermoformed with different processing parameters using a waterjet cutting machine.Moreover,the fracture surfaces of microstructure are observed using the scanning electron microscope (SEM) to study the influence of molding process conditions on crystallization and mechanical properties of CF/PEEK composites.

3.2. Thermal characterization

In order to study the crystallization behavior of CF/PEEK laminates under different molding process conditions, differential scanning calorimetry (DSC) is carried out on the Mettler-Toledo DSC machine. The specimen mass is about 10 mg. The DSC tests are heated at a rate of 10◦C/min from 25 to 400◦C in a nitrogen atmosphere[38].The crystallinity degree(XC)is determined using the following equation [39]:

whereHfis the melting enthalpy of 100% crystalline PEEK,Hf=130 J/g[40],ΔHmis value of the melting enthalpy,and α is the fiber mass fraction.

4. Results and discussion

4.1. Mode-I interlaminar fracture toughness

4.1.1. The influence of processing parameters on the fracture toughness of CF/PEEK composites

Fig. 5 illustrates the curves of typical DCB force-displacement andGIC-extended crack length of CF/PEEK specimens fabricated at different molding process conditions. During the load loading process, the interlayer of composites undergoes damage initiation and damage evolution until the load suddenly drops at the peak point and the crack extends. Then the slope of the forcedisplacement curve decreased as the number of crack propagation increased,as shown in Fig.5(a)and Fig.5(b).It is observed that the processing parameters have a significant effect on the crack extension.The load for crack extension increases with the increase of molding temperature and holding time. TheGICof CF/PEEK composites is calculated and plotted in Fig.5(c)and Fig.5(d).It can be clearly found that theGICof CF/PEEK composites increases with increasing molding temperature,pressure and holding time,and a similar trend is proposed in other Ref. [41].

Fig. 5. Mode-I interlaminar fracture toughness of specimens fabricated at different molding process conditions: (a) Force-displacement curves;(b)Force-displacement curves;(c)GIC-extended crack length curves; (d) GIC-extended crack length curves.

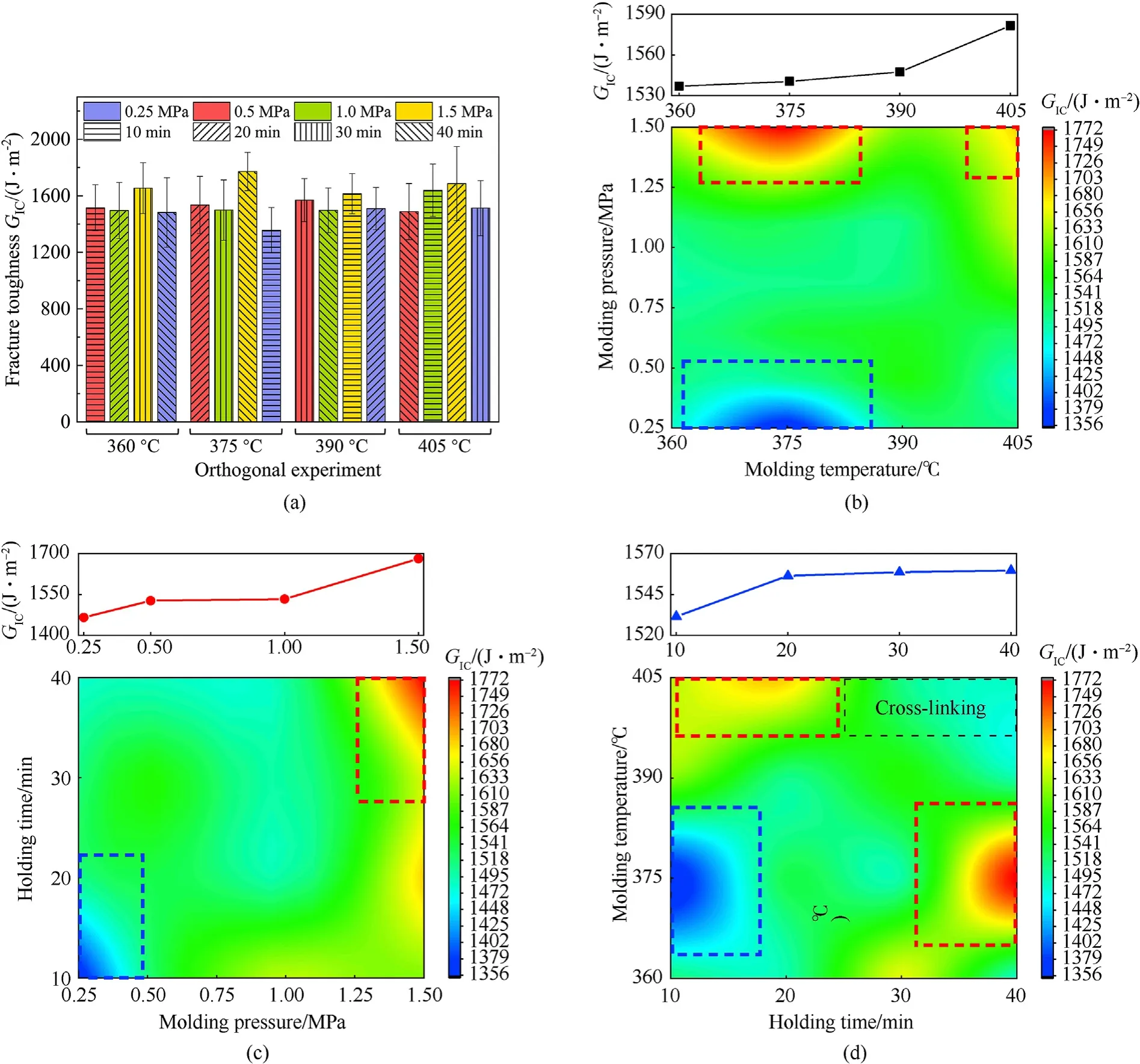

The relationship between theGICof CF/PEEK composites and the processing parameters is summarized in Fig. 6. In order to more intuitively study the influence of the molding process coupling effect onGIC, the orthogonal test results are interpolated to obtain the contour map of each two processing parameters onGIC, as shown in Fig. 6(b), Fig. 6(c) and Fig. 6(d). From the experimental data in Fig. 6(a), it can be found that the influence of processing parameters on theGICof CF/PEEK composites does not change monotonously, which is reflected in the maximum and minimum values occurring at 375◦C,as shown in Fig.6(b).TheGICof CF/PEEK composites results from the coupling effect of various processing parameters. The increase of the molding temperature reduces the viscosity of the resin, and the increase of the molding pressure promotes the permeability of the fiber/matrix, thereby improving the interlayer performance of the composite laminate,as shown in Fig.6(b)and Fig.6(c).Similarly,increasing the molding time allows for better impregnation of the resin with the fibers,improving the fiber/resin bond and thus the mechanical properties, as shown in Fig. 6(d). However, the PEEK matrix evolves over long periods at high temperatures. Chain oxidation and crosslinking are the proposed mechanisms for its thermal degradation, leading to a decrease in the properties and an increase in the viscosity of the PEEK matrix[27], which is detrimental to the impregnation of the fibers with the PEEK matrix.

Fig.6. Relationship between GIC and molding process parameters of CF/PEEK composites:(a)Orthogonal test results of GIC;(b)Contour map of molding temperature and molding pressure; (c) Contour map of molding pressure and holding time; (d) Contour map of holding time and molding temperature.

The curves above the contour maps in Fig.6(b)—Fig.6(d)are the trend graphs of the three process parameters onGICaccording to range analysis. It can be seen that the recommended molding process parameters are 405◦C, 1.5 MPa, and 40 min with the objective ofGIC. The range analysis results indicate that the influence degree of process parameters onGICis molding pressure,temperature, and holding time in descending order. The detailed analysis is carried out in Section 4.4.

4.1.2. The influence of processing parameters on the fracture morphology of DCB specimens

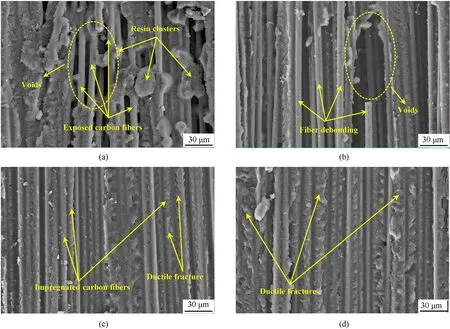

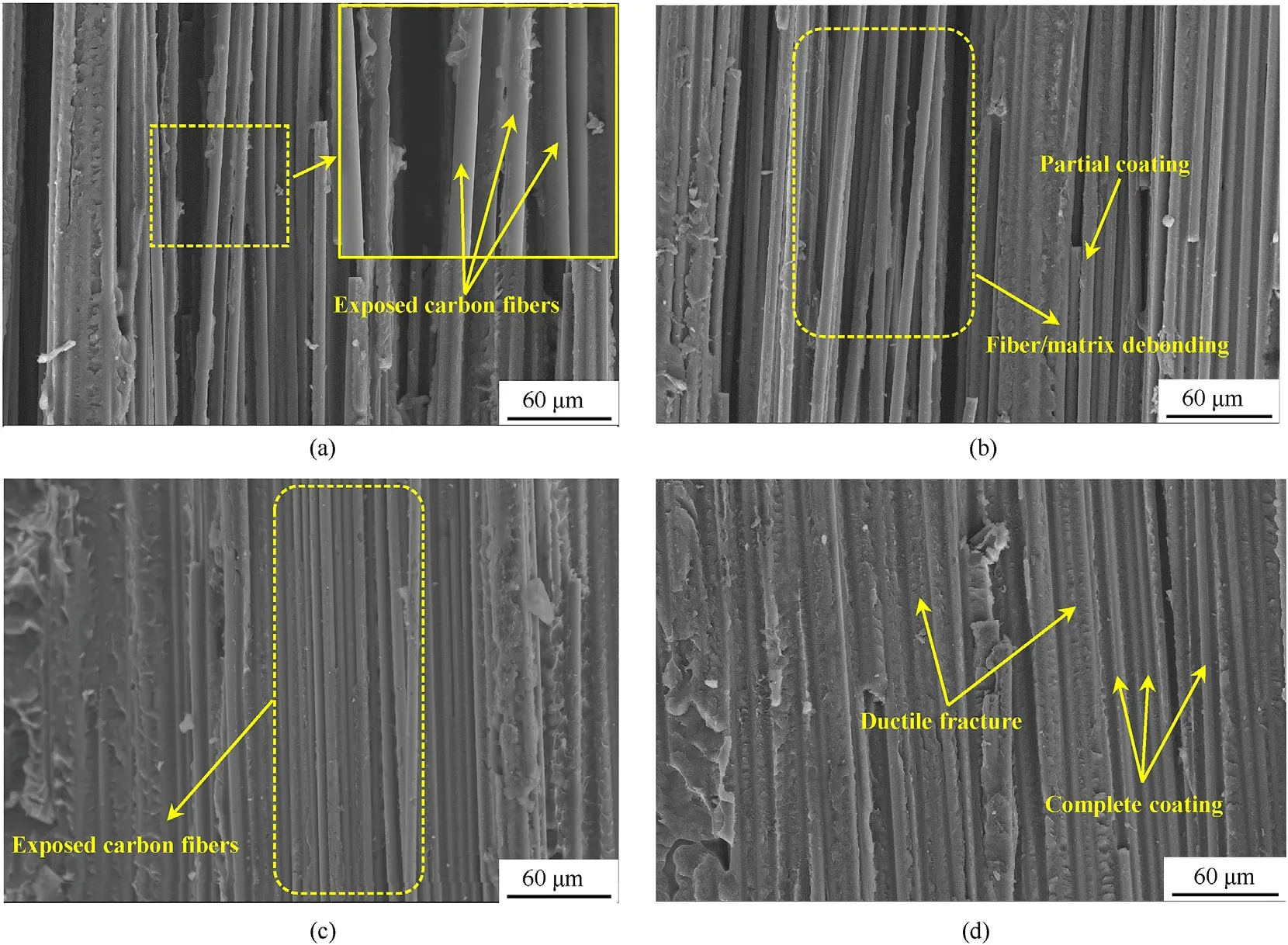

The fracture morphologies of the DCB specimens fabricated at different temperatures and pressures are observed to identify the influence of the processing parameters on the failure mechanism in Fig.7.As shown in Fig.7(a)and Fig.7(b),the exposed fibers and the voids can be clearly seen at the fracture of the specimens. This is mainly due to the poor fluidity of the resin when the molding temperature is low,and the lower molding pressure is not enough to promote penetration of the resin between the fibers,which leads to a weaker bonding interface of the CF/PEEK composites. As the molding temperature and pressure increase, as shown in Fig. 7(c)and Fig.7(d),a large amount of resin residue on the surface of the fiber and a well-bonded fiber/matrix interface can be observed at the fracture of the specimens. These clarify that the fiber/resin forms a strong interfacial bond under high temperature and pressure. More energy is needed for interlaminar crack propagation,and the composite material exhibits higher interlaminar fracture toughness.

Fig.7. SEM micrographs of the DCB fracture surfaces of specimens fabricated at different molding process conditions:(a)360 ◦C,0.25 MPa(40 min);(b)375 ◦C,0.5 MPa(20 min);(c) 390 ◦C,1 MPa (40 min); (d) 405 ◦C,1.5 MPa (20 min).

The fracture morphologies of the DCB specimens fabricated at different holding times are observed in Fig. 8. As seen in Fig. 8(a)and Fig.8(b),exposed carbon fibers and separate resin clusters are clearly visible on the fracture surface of specimens.This is because the short holding time leads to insufficient infiltration of the resin and fiber. The molten resin is unable to infiltrate the fiber bundles between the different layers, resulting in poor fiber/matrix interface bonding. As the holding time increases, as shown in Fig. 8(c)and Fig. 8(d), the exposed fibers are significantly reduced, and the improved fiber/resin bonding interface can be observed at the fracture of the specimens.These indicate that a longer holding time ensures adequate fiber and resin infiltration and interface strength,thus improving theGICof CF/PEEK composites.

Fig.8. SEM micrographs of the DCB fracture surfaces of specimens fabricated at different process conditions:(a)10 min(360 ◦C,0.5 MPa);(b)20 min(390 ◦C,0.25 MPa);(c)30 min(375 ◦C,1 MPa); (d) 40 min (405 ◦C, 0.5 MPa).

Fig. 9. Three-point bending typical stress-displacement curves of specimens fabricated at different molding process conditions.

4.2. Transverse bending performance

4.2.1. The influence of processing parameters on theflexural modulus of CF/PEEK composites

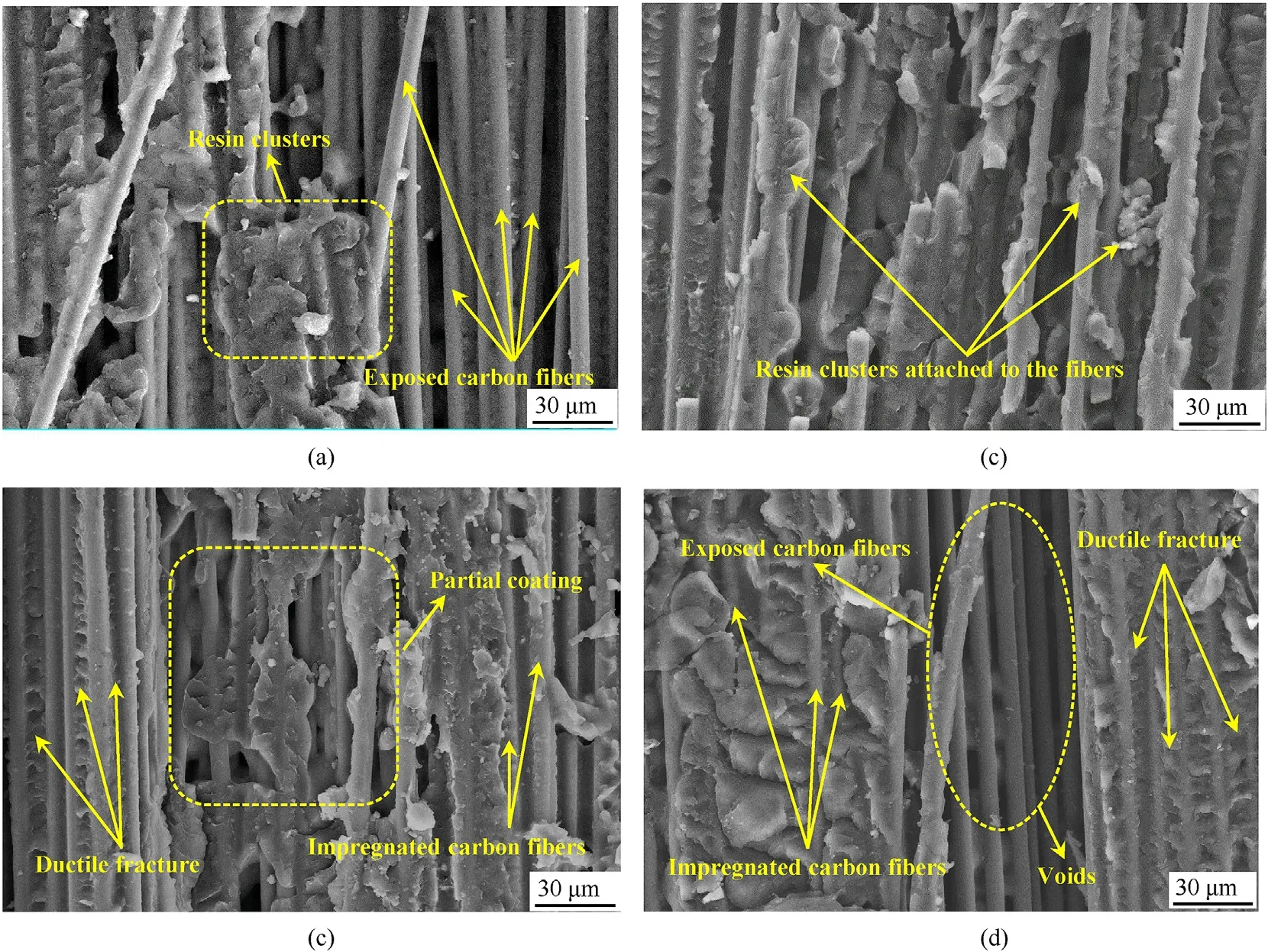

Fig.9 presents the typical bending force-displacement curves of CF/PEEK composites specimens fabricated at different processing conditions. The CF/PEEK specimens show linear elastic characteristics until brittle failure. The different slopes of the curves reveal the variation of transverse flexural modulus (Eyy) of CF/PEEK composites with the processing parameters. With the increase of molding temperature and molding pressure,theEyyof the CF/PEEK composites increases, which is consistent with the experimental results of Zheng B et al. [23].

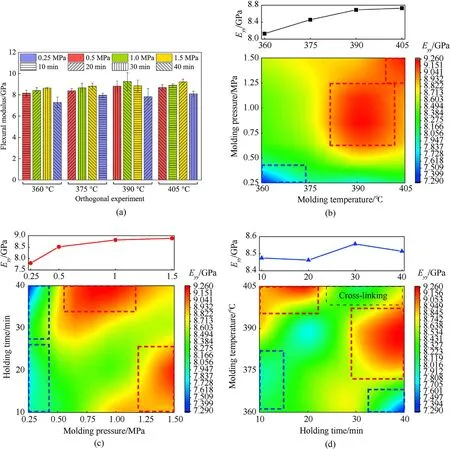

The relationship between theEyyof CF/PEEK composites and the processing parameters is summarized in Fig.10. In order to more intuitively investigate the coupling effect of processing parameters on mechanical properties of CF/PEEK composites,the contour map of theEyyunder different processing parameters is obtained by interpolating the results of the orthogonal experiments,as seen in Fig.10(b)—Fig.10(d)From the experimental data in Fig.10(a),it can be found that the effect of processing parameters onEyyis not linear.According to Fig.10(b)and Fig.10(c),the increase of molding temperature reduces the viscosity of the resin, and the increase of molding pressure and holding time promotes the infiltration of fibers with resin,thus improving theEyy,and a similar trend is found in other literature [22]. Meanwhile, increasing the molding pressure can increase the density of the crystallization domain,reduce the crystal gap, and further increase the contact boundary area of crystals.Due to the high stiffness of the crystal boundary structure,which improves the modulus of the CF/PEEK composites.Similar to the results of theGICanalysis, the longer holding time at higher temperatures results in PEEK degradation and crosslinking [27],which reduces theEyy,as shown in Fig.10(d).The detailed analysis of the influence of molding process parameters on crystallization and the effect of crystallization on mechanical properties is carried out in Sections 4.3 and 4.4.

Fig.10. Relationship between Eyy and molding process parameters of CF/PEEK composites:(a)Orthogonal test results of Eyy;(b)Contour map of molding temperature and molding pressure; (c) Contour map of molding pressure and holding time; (d) Contour map of holding time and molding temperature.

The curves above the contour maps in Fig.10(b)—Fig.10(d) are the trend graphs of the three process parameters onEyyaccording to range analysis. The results show that the influence order of process parameters onEyyis the same asGIC,and the recommended molding process parameters are 405◦C,1.5 MPa and 30 min with the objective ofEyy.

4.2.2. The influence of molding parameters on the fracture morphology of three-point bending specimens

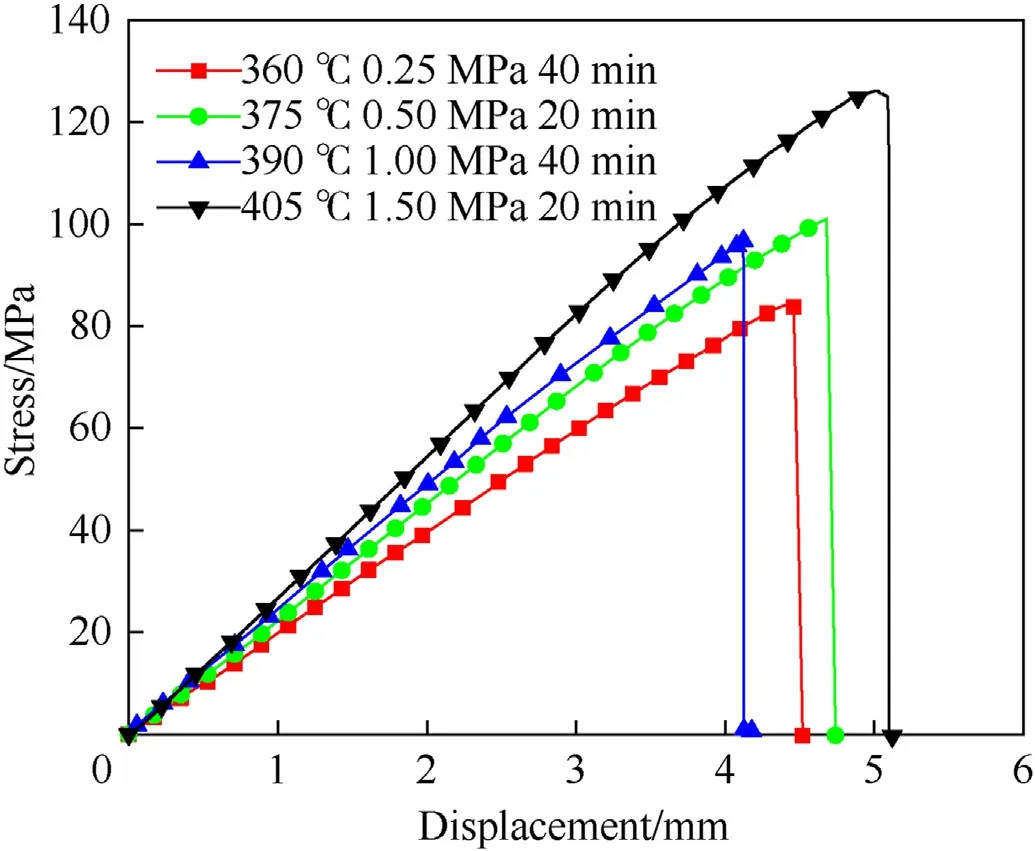

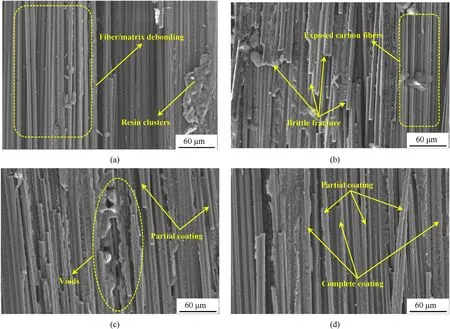

To analyze the effects of the processing parameters on the failure mechanism of CF/PEEK composites, the fracture morphologies of the three-point bending specimens fabricated at different temperatures and pressures are observed using SEM. As shown in Fig. 11(a) and Fig. 11(b), exposed carbon fibers and the fibers debonding can be observed in the fracture of the specimens. This reflects that the movement of PEEK resin molecular chain segments of PEEK resin under lower molding temperature and pressure is impeded. Higher energy is required to overcome the movement between the chain segments, which is manifested by high resin viscosity and poor fluidity, resulting in incomplete penetration of the matrix, high porosity of the composites, and poor fiber/matrix interface strength. As the molding temperature and pressure increase,Fig.11(c)and Fig.11(d)show that the exposed carbon fibers and the voids are significantly reduced. These indicate that increasing the molding temperature and pressure can ensure the fiber/resin interface strength and improve resin and fiber infiltration while making the composite laminate denser and reducing porosity, thus enhancing the bending performance of the CF/PEEK composites.

Fig.11. SEM micrographs of the three-point bending fracture surfaces of specimens fabricated at different molding process conditions: (a) 360 ◦C, 0.25 MPa (40 min); (b) 375 ◦C,0.5 MPa (20 min); (c) 390 ◦C,1 MPa (40 min); (d) 405 ◦C,1.5 MPa (20 min).

The fracture morphologies of the three-point bending specimens fabricated at different holding times are observed in Fig.12.As shown in Fig. 12(a) and Fig. 12(b), the fiber/matrix debonding can be observed at the fracture of specimens.This is mainly due to the inability of the fibers and the matrix to fully infiltrate in a short time, which leads to a weaker bonding interface of the CF/PEEK composites. As the holding time increases, as shown in Fig.12(c)and Fig.12(d), it can be observed that the resin attached to the fibers has increased. These clarify that increasing the holding time can increase the fiber/matrix interface strength,thereby improving the transverse bending performance of the CF/PEEK composites.

Fig.12. SEM micrographs of the three-point bending fracture surfaces of specimens fabricated at different molding process conditions: (a) 10 min (360 ◦C, 0.5 MPa); (b) 20 min(390 ◦C, 0.25 MPa); (c) 30 min (375 ◦C,1 MPa); (d) 40 min (405 ◦C, 0.5 MPa).

Fig. 13. DSC results of CF/PEEK composites fabricated under different heating histories: (a) Heat flow-temperature curves; (b) Relationship between crystallinity, melting temperature, and molding temperature.

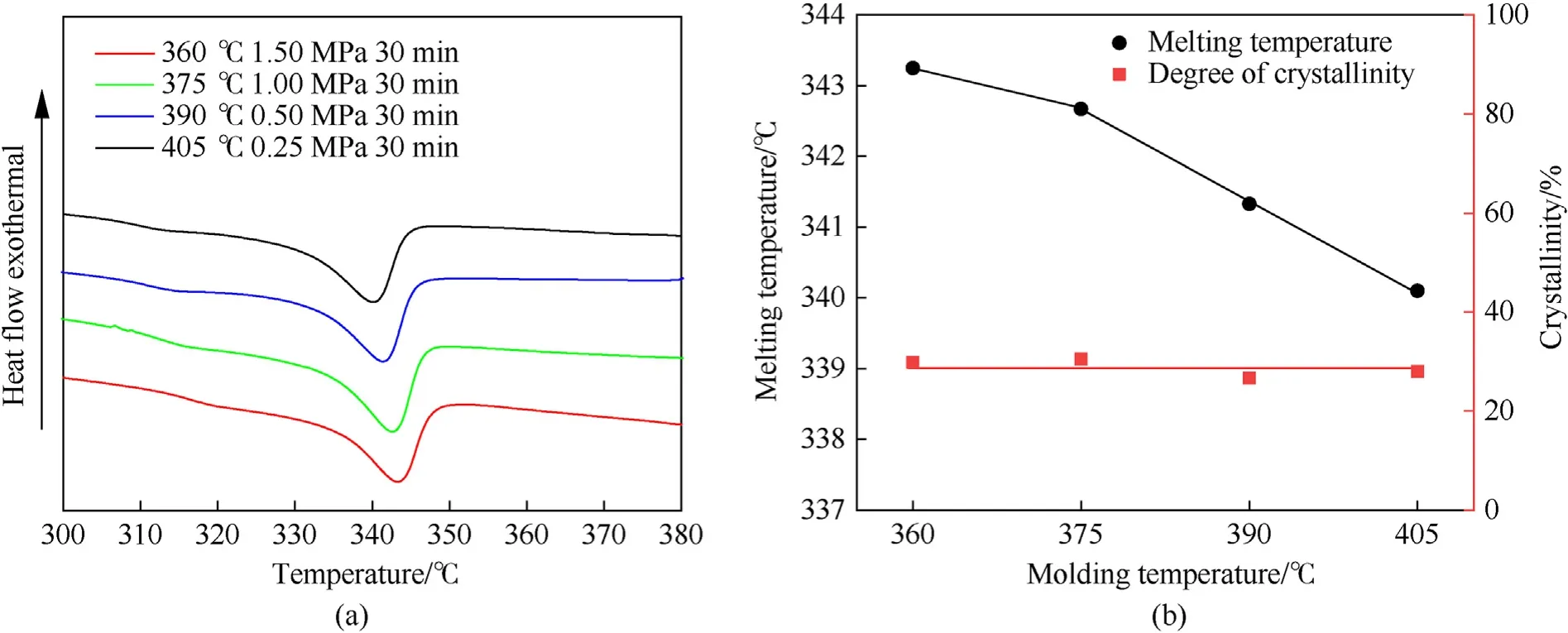

4.3. The influence of processing parameters on the crystallization of CF/PEEK composites

Generally, the decrease in crystallinity leads to a reduction in stiffness and strength of semi-crystalline polymers but an increase in ductility due to fewer secondary intermolecular bonds and an increase in disorder. Therefore, it is essential to investigate the effect of molding process parameters on the crystallization behavior of semi-crystalline polymer composites.To reveal the effects of the processing parameters on CF/PEEK composites, DSC tests are applied on the CF/PEEK specimens after thermoforming. The DSC curves are shown in Fig.13(a). The crystallinity of CF/PEEK specimens is calculated according to Eq. (2), as shown in Fig.16(a).

As shown in Fig.13,the melting temperature decreases with the increase of molding temperature and increases with the increase of molding pressure. This is because, on the one hand, the melting temperature decreases as the molding temperature increases from 360 to 405◦C, and a similar trend has been found in other studies[42]. The decrease in melting temperature may be related to the reduction of the number of remaining crystalline entities and the change in the molecular structure of the PEEK matrix.On the other hand, molten resin mobility increases with molding pressure,accompanied by increased melt shear effects leading to enhance molecular chain orientation, thereby increasing the melting temperature of the PEEK matrix. In addition, as shown in Fig.13(b), it can be seen that the crystallinity remains relatively constant as the molding temperature increase. This is also consistent with the conclusions of other studies that the molding temperature mainly affects the number and size of crystalline entities but does not change the ultimate crystallinity level of the composite material[42].

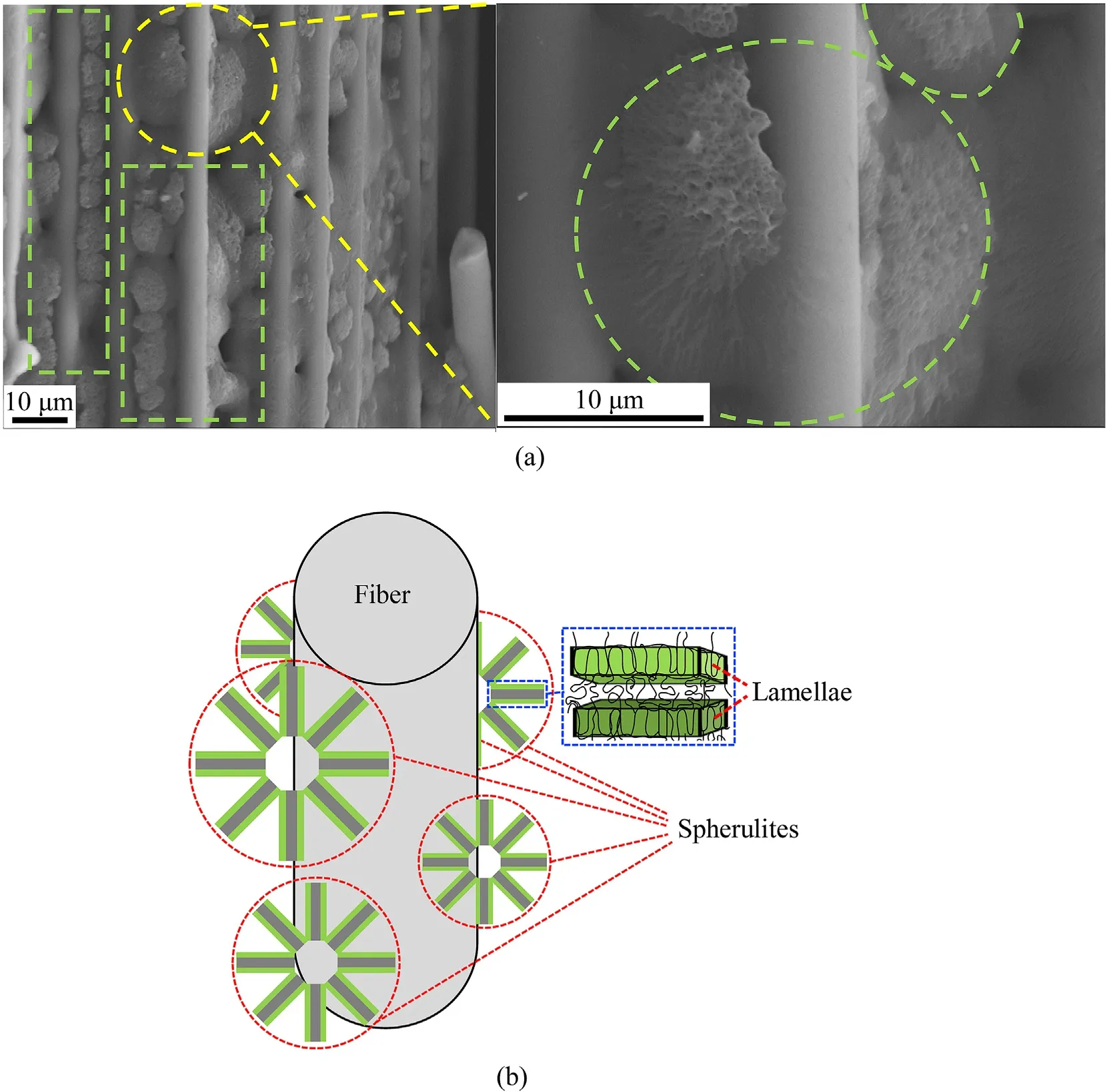

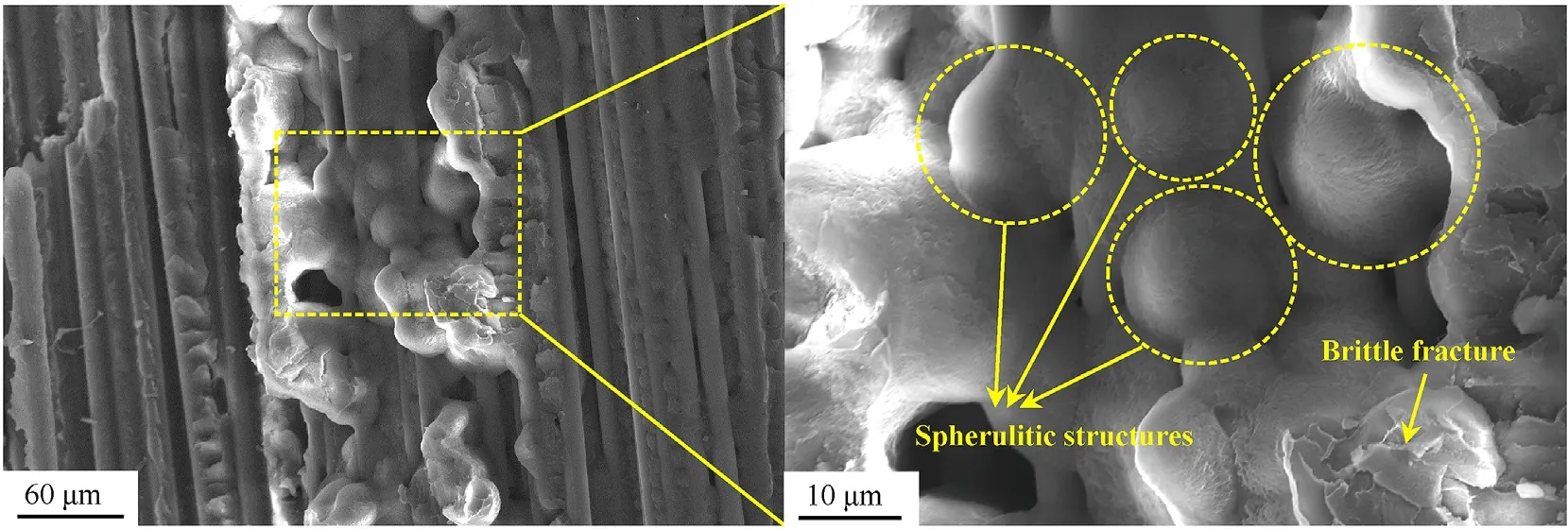

The melting temperature of semi-crystalline polymer composites is determined by factors such as crystal size, folding surface energy and plate thickness [38]. Fig.14(a) shows the microscopic morphology of the CF/PEEK fracture fabricated at 405◦C,1.5 MPa,and 20 min process parameters. It can be observed that highoriented spherulites are distributed on the fiber surface, and these spherulites constitute the columnar crystalline structure of high quality. Schematic diagram of the high-oriented spherulites generated on the fiber surface, as shown in Fig.14(b). This is also consistent with the conclusions of other studies that the lower the matrix melting temperature, the larger the size of the spherical crystal, and the higher the molecular integrity. Conversely, the higher the matrix melting temperature, the smaller the spherical crystal size[43,44].The crystal structures formed at lower molding temperatures are not well defined,mainly due to the low mobility of the polymer chains when the molding temperature is low,which limits the ability of the chains to diffuse to the growing crystal fronts.Moreover,columnar crystal structures can be observed only when the molding temperature is high enough to destroy the preexisting crystalline entities [42]. Therefore, based on the above results, it can be concluded that the higher the molding temperature,the larger size of the well-defined spherical crystals generated in the CF/PEEK composites,and the number of crystals is lower than that of the specimen fabricated at lower molding temperatures.

Fig.14. (a) SEM observation of the columnar crystalline structures and (b) schematic diagram of high-oriented spherulites on the fiber surface.

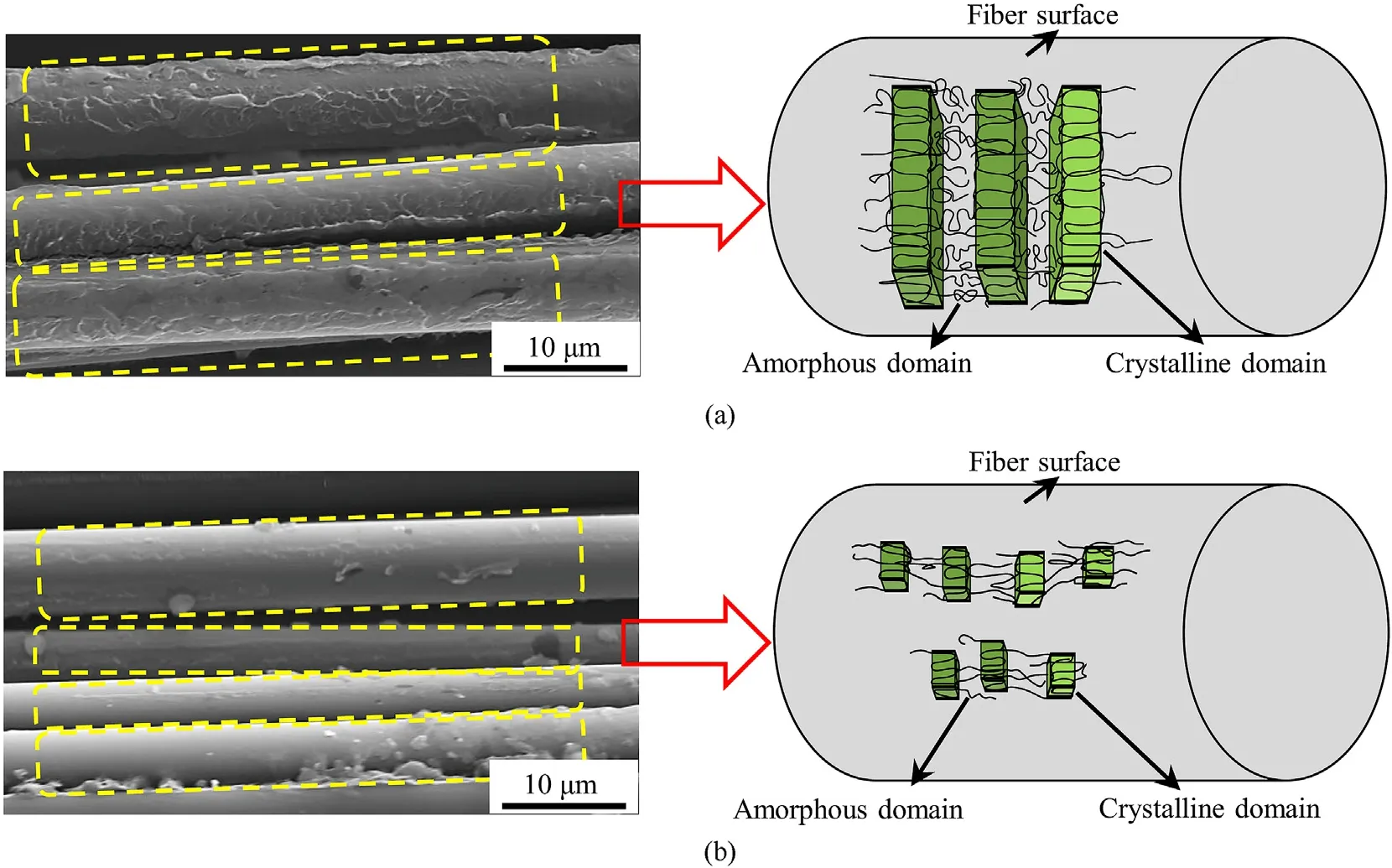

The relationship between molding process parameters,lamella,and fiber-matrix bonding mechanisms on the degree of crystallinity is shown in Fig.15.The micro-morphology of the fiber surface of the specimen fabricated at 405◦C,0.5 MPa,and 40 min is shown in Fig.15(a).The results indicate that higher molding temperatures and longer holding time allow the PEEK matrix tends to diffuse and strongly adsorbs to the fiber surface, which is consistent with the conclusion of Brady R L et al. [45]. The schematic diagram of the fiber-matrix interaction of the CF/PEEK composites in Fig. 15 is similar to the other studies [38]. The flattened crystalline lamellar chains with high crystallinity in the interfacial region enable more polar components to interact functionally with the fiber surface.The adhesion of the interfacial region is increased,which affects the mechanical properties of the composites,such as improving shear performance. In contrast, holding for a longer time at a lower molding temperature reduces the viscosity of the molten PEEK matrix. Due to the crosslinking of PEEK, the mobility of crystallizable unit molecules is further reduced,which affects the nucleation mechanism and slows down the crystal growth. Thus, the PEEK matrix is unable to develop strong bonds with the fiber surface,as shown in Fig.15(b),which is fabricated at 360◦C,0.25 MPa,40 min.

Fig.15. SEM of fracture surface and schematic diagram of fiber-matrix interaction of CF/PEEK composites under different molding process conditions: (a) SEM fracture surface of high crystallinity specimen (XC = 32.41%); (b) SEM fracture surface of low crystallinity specimen (XC = 23.54%).

The DSC test results of CF/PEEK composites under different processing parameters are calculated and drawn in Fig.16(a).It can be seen that the crystallinity of the CF/PEEK composites fabricated by the orthogonal process ranged from 23.5 to 33.6%.The molding temperature affects the destruction of the pre-existent crystalline entities and the formation of new nuclei, but since the molding temperature mainly affects the number and size of crystalline entities, it does not affect the final crystallinity of the CF/PEEK composites. Therefore, the degree of crystallinity remains relatively constant as the molding temperature increases, as shown in Fig.16(b).Molding pressure and holding time are as well important for the crystallization behavior of CF/PEEK composites.The molding pressure orients the polymer melt and induces nucleation, which leads to a higher crystallization rate.However,the slight difference of each molding pressure in the thermoforming process leads to an unobvious effect of the molding pressure on the crystallinity, as shown in Fig. 16(c). As the holding time increases, the chain oxidation and crosslinking of the PEEK matrix leads to a decrease in the molecular mobility of crystallizable units in the melt, which influences the nucleation mechanism and slows down the crystal growth process, as shown in Fig.16(d), and a similar trend is proposed in other literature[46].In addition,appropriately increasing the holding time can generate transverse crystals on the carbon fiber surface [42], thus increasing the stiffness of the composites,but extremely short and extremely long holding time would reduce the transverse crystals [47].

Fig. 16. Relationship between crystallinity and molding process parameters of CF/PEEK composites: (a) Orthogonal test results of crystallinity; (b) Contour map of molding temperature and molding pressure; (c) Contour map of molding pressure and holding time; (d) Contour map of holding time and molding temperature.

4.4. The relationship between molding process parameters,crystallization and mechanical properties

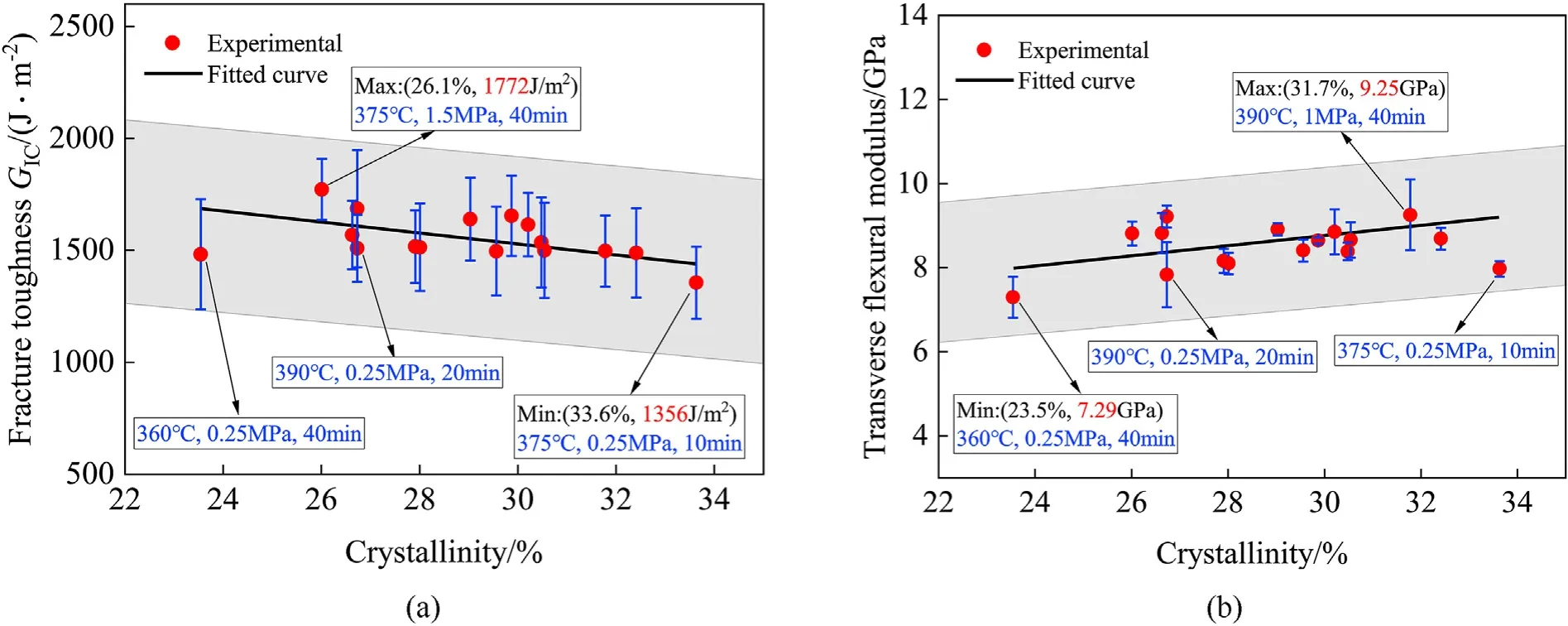

In the above Sections, the influence mechanism of processing parameters on the mechanical properties and crystallinity of CF/PEEK composites is discussed, respectively. However, it has been reported that the crystallinity of resin has a significant effect on mechanical properties [31], clarifying the inherent relationship between process parameters, crystallization and mechanical properties can further optimize the manufacturing process of thermoplastic composites. Schematic diagrams of deformation in the crystalline and amorphous domains of the DCB and the threepoint bending specimens are shown in Fig.17 and Fig.18. Due to the macromolecular chains in the crystalline domain aligning in better order and owning stronger intermolecular forces, resulting in higher strength and rigidity [48,49], the matrix becomes more stiff and brittle after crystallization,as shown in Fig.17 and Fig.18.Thus,the higher crystallinity enhances the bending performance of CF/PEEK composites, as shown in Fig.18. However, the ductility of the matrix plays a dominant role in the crack extension of the DCB specimen. As the crystallinity increases, the percentage of ductile amorphous domains decreases, which reduces theGICof CF/PEEK composites,as shown in Fig.17.

Fig.17. Schematic diagram of mode-I delamination of semi-crystalline CF/PEEK composites specimen.

Fig. 18. Schematic diagram of semi-crystalline CF/PEEK composites specimen deformation under bending load: (a) Schematic drawing of the bending test; (b) Deformation of crystalline and amorphous domains under bending load.

Fig.19. Trend graph of mechanical properties changing with crystallinity: (a) Mode-I interlaminar fracture toughness; (b) Transverse flexural modulus.

Fig. 20. SEM micrographs of spherulitic structures of the specimen are fabricated at 405 ◦C,1.5 MPa, and 20 min.

Molding temperature has a slight effect on matrix crystallinity,but higher molding temperatures can reduce molten PEEK viscosity and improve fiber-matrix infiltration,thereby increasing theGICof CF/PEEK composite laminate.Molding pressure affects theGICof CF/PEEK composites from two aspects. On the one hand, the higher molding pressure increases the crystallinity of the matrix PEEK due to stress induction. The higher crystallinity means a higher percentage of brittleness in the material, while the ductility of the matrix plays a dominant role in the crack extension of the DCB specimen.On the other hand,increasing the molding pressure can effectively improve the infiltration of high-viscosity resin with fibers and lead to a denser laminate, thus improving theGIC.Therefore, for theGICof CF/PEEK composite laminate, there has a competitive relationship between the crystallinity and the molding quality (infiltration, porosity, etc.). According to the data of DCB range analysis results (Fig. 6),GICincreases with the increase of molding pressure, which means that high-quality laminates fabricated under higher molding pressure contribute more to theGICof CF/PEEK composites. The crystallinity decreases with increasing holding time, therefore a longer holding time is beneficial to improve the matrix ductility and thus theGICof CF/PEEK composites, which is consistent with the range analysis results(Fig. 6) of the DCB test data.

The effect of molding temperature onEyyof CF/PEEK composites is similar to that ofGIC,whereEyyincreases with increasing molding temperature. It is worth noting that it is easier to generate welldefined spherulites and columnar crystalline structures at higher molding temperatures,resulting in increasedEyy. Due to the effect of stress-induced crystallization, increasing the molding pressure not only improves the crystallinity but also improves the molding quality, thus improvingEyy. The holding time affects theEyyof CF/PEEK composite laminate from two aspects. On the one hand,increasing the holding time reduces the crystallinity, which is not conducive to improvingEyy.On the other hand,although the proper increase of holding time can improve the molding quality, due to the degradation and crosslinking of resin at higher temperatures,which makes too long holding time is not conducive to the molding quality. The above conclusions are consistent with the range analysis results (Fig.10) of the three-point bending test data.

The relationship between the mechanical properties and crystallinity of CF/PEEK composites under orthogonal processing conditions fabricated is exhibited in Fig. 19. It can be seen that the crystallinity of the PEEK matrix has an approximately linear effect on the mechanical properties.TheGICis negatively correlated with the matrix crystallinity, and conversely, theEyyis positively correlated with the matrix crystallinity. Therefore, the thermoforming process affects the mechanical properties of the composites by influencing the matrix crystallization.In addition,it is worth noting that the crystallinity of some specimens does not match their mechanical performance, mainly due to defects caused by processing parameters, as marked in Fig. 19. Indeed, the mechanical properties of composites can be affected by other factors (such as void defects), which need to be further investigated in future studies.

The elucidation of the inherent relationship between molding process parameters, mechanical properties, and crystallization is essential for the high-quality molding of CF/PEEK composites. The studies in Sections 4.1 and 4.2 show that theGICand bending performance of CF/PEEK composites are positively correlated with the molding temperature,pressure and holding time,mainly due to the degree of fiber/matrix infiltration promoted by increasing these process parameters.However,the effect of matrix crystallization on the mechanical properties cannot be ignored.Although the study in Section 4.3 shows that the effect of molding process parameters on the crystallinity of the PEEK matrix is not highly significant, but it seriously affects the crystalline morphology,which is related to the mechanical properties of CF/PEEK composites.On the one hand,the consolidation of CF/PEEK composites should be carried out at a sufficiently high temperature to destroy the pre-existing crystalline entities in the composite prepreg,thus improving the toughness of the PEEK matrix and theGICof the CF/PEEK composites[47].On the other hand, the presence of columnar crystalline structures and spherulites improves the modulus of the composites. Although PEEK resin degrades at higher temperatures, the degradation does not prevent the formation of well-defined crystalline structures,and the crystallization domain grows with the appropriate increase in holding time [42,47], thus increasing theEyyof composites. As observed for the spherulitic structures of CF/PEEK composites fabricated at 405◦C,1.5 MPa and 20 min in Fig.20.In addition,the increased molding pressure not only promotes the penetration of the resin into the fiber, but also increases the density of the crystalline domain and reduces the crystal gap. Due to the stressinduced nucleation, the crystallization rate is accelerated, thereby increasing the crystallinity and the mechanical properties of the composites. Therefore, the influence of the molding process on crystallization behavior significantly affects the mechanical properties of CF/PEEK composites.

5. Conclusions

In order to improve the molding quality of thermoplastic composites for extension and application in the cutting-edge equipment of the aerospace and defence fields, the process/crystallization/property inherent relationships of continuous CF/PEEK composites were studied in this work.The CF/PEEK composite laminates were fabricated via thermoforming, using the threeparameter four-level orthogonal test. The performance of CF/PEEK composite laminates was analyzed by mechanical characterization,crystallization characterization, and microscopic observations.The main conclusions are as follows:

(1) The mode-I interlaminar fracture toughness and transverse flexural modulus are positively related to the molding temperature, pressure and holding time. The mechanical properties of CF/PEEK composites are not only affected by the degree of matrix/fiber infiltration and molding quality, but also by potential matrix crystallization. The increased molding temperature, pressure and holding time can improve the degree of fiber/matrix infiltration and reduce molding defects such as voids, which improves mechanical properties. However, it is necessary to note that long-time high-temperature conditions can alter the viscosity and properties of the matrix due to crosslinking and degradation,thereby reducing the molding quality.

(2) The molding process parameters affect the crystallinity and crystalline morphology of the matrix, which in turn affects the mechanical properties of the composites. The results show that the crystallinity of the matrix has an almost linear influence on the mechanical properties of CF/PEEK composites. Sufficiently high molding temperature can improve the toughness and mode-I interlaminar fracture toughness of the composites by destroying pre-existing crystallites.Although increasing the holding time affects the nucleation mechanism and decreases the crystallinity due to matrix degradation, it can form well-defined crystalline structures,which increases the flexural modulus of the composites.Increased molding pressure can increase the crystallization rate due to stress-induced nucleation,and it can increase the density of the crystallization domain, which improves the mechanical properties of the composites.

(3) The above results suggest that the optimal process parameter array in certain process conditions are molding temperature of 405◦C,molding pressure of 1.5 MPa,and holding time of at least 30 min based on the thermoforming method. This processing condition ensures excellent transverse bending performance and mode-I interlaminar fracture toughness of the continuous CF/PEEK composites.

Data availability statement

Research data are not shared.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

The authors of this paper acknowledge the financial support of the National Natural Science Foundation of China (NO. 11902255,U1837601 and 52090051).

Appendix A. Supplementary data

Supplementary data to this article can be found online at https://doi.org/10.1016/j.dt.2022.04.010.

杂志排行

Defence Technology的其它文章

- A review on lightweight materials for defence applications: Present and future developments

- Study on the prediction and inverse prediction of detonation properties based on deep learning

- Research of detonation products of RDX/Al from the perspective of composition

- Anti-sintering behavior and combustion process of aluminum nano particles coated with PTFE: A molecular dynamics study

- Microstructural image based convolutional neural networks for efficient prediction of full-field stress maps in short fiber polymer composites

- Modeling the blast load induced by a close-in explosion considering cylindrical charge parameters