Microfluidic assisted 90%loading CL-20 spherical particles:Enhancing self-sustaining combustion performance

2023-05-06LingfengYngXinruiShiChunzhiLiBoWuChonghuPei

Ling-feng Yng ,Xin-rui Shi ,b ,Chun-zhi Li ,Bo Wu ,* ,Chong-hu Pei ,*

a State Key Laboratory of Environment-friendly Energy Materials,Southwest University of Science and Technology,Mianyang,621010,PR China

b Xi'an Modern Chemistry Research Institute,Xi'an,Shaanxi,710065,PR China

c Luzhou North Chemical Industries Co.,Ltd.,Luzhou,646003,PR China

Keywords:Microfluidics Hexanitrohexaazaisowurtzitane Spherical particles Thermal behavior Self-sustaining combustion

ABSTRACT The performance of the chemical fuel determines the altitude,range and longevity of spacecraft in air and space exploration.Promising alternatives (e.g.,hypergolic ionic liquids or high-energy composites)with high-energy density,heat of formation and fast initial rate are considered as potential chemical fuels.As the high-energy density material,hexanitrohexaazaisowurtzitane (CL-20) often serves as secondary explosive with poor self-propagating combustion behaviors.Herein,90% loading CL-20 microspheres with uniform particle sizes are precisely prepared by microfluid method,which exhibit unique hierarchical structure.The morphology,thermal behaviors,as well as combustion performance were further investigated.The results demonstrated that as-prepared spherical particles exhibit prominent thermal compatibility,and the enhanced self-sustaining combustion performance.This work provides an efficient method achieving the uniform high-energy density particles with excellent self-sustaining combustion performance.

1.Introduction

Exploring high altitudes and space has been the pursuit of human beings since ancient times,which relying on primitive technology.As the power source of rocket and spacecraft,the chemical energy released by the propellant affects their altitude,range and lifetime.With the development of modern technology,highperformance fuels have attracted a lot of attention.The current hypergolic liquid propellants primarily derived from the hydrazine and its derivatives,for instance monomethylhydrazine(MMH)and unsymmetrical dimethylhydrazine (UDMH) [1].Nevertheless,these hydrazine-based fuels still suffer from some issues such as highly toxicity,expensive storage and handling procedures,as well as high cost for safety precautions[2].Some serious accidents have happened over the history of spaceflight,causing severe pollution and billions of dollars in losses.The discovery for green advanced rocket fuels as replacements of volatile hydrazine-based fuels is highly desired.Recently,environment-friendly hypergolic ionic liquids [3—5],laser-ignited composites films [6],and high-energy propellants have been provided extensive alternatives from chemistry and material community.Among them,composite propellants have been widely applied in the fields of spacecraft,satellite attitude control systems [7,8],and microelectromechanical systems (MEMS) [9,10]owing to their simplicity,ease of preparation,and reliability.To meet the requirement of environmentally friendly and high energy output,it is urgent to hunt for promising fuels and the corresponding adjustable combustion with highenergy density,heat of formation and fast initial rate.

As the most powerful energetic material,hexanitrohexaazaisowurtzitane(HNIW or CL-20)possesses high-energy release rate and favorable oxygen balance (-11%) [11,12],which was expected to be the excellent choice for composite fuels.Usually,they serve as secondary explosives,which indicates that its poor selfpropagating combustion behaviors hinders its growing development as fuels.Some strategies have been employed for enhancing the self-sustaining combustion performance of CL-20.For example,doping the cellulose energy-containing aerogel [13]and 3D hierarchically ordered porous carbon[14]with CL-20,which effectively improved the thermal properties of CL-20.Adding hydrocarbon polymers change the decomposition mechanism of CL-20 from a single-step process to a multistep and greatly mitigate the decomposition process of CL-20[15].The combustion performance of CL-20 is greatly enhanced by embedding-CL-20 particles in a graphene oxide(GO)matrix,forming a relay-domino-like reaction film[6].Confined CL-20 and ammonium perchlorate(AP)in a selfstanding carbonized butterfly wing scales (CWs) matrix.The CWs with multi-channeled hierarchical porous structure enhanced heat and mass transfer from synergistic reactions,obtained excellent combustion performance [16].It is noteworthy that the inner hierarchical porous structure also plays a significant role in tuning the combustion performance of composites fuels based on CL-20,besides the components.These porous structures were used in confined CL-20 and found that via shortened diffusion paths effective compensated the heat and/or pressure loss,improved energy release and combustion performances,which inspires us to develop an energetic composite material with 3D porous structure to improve the self-sustaining combustion of CL-20.

Owing to the high packing density,good particle gradation,and well homogeneity of particles,spherical composites show great potential in composite propellants.Common method preparing particles of high-energy materials,for instance ball milling method[17],emulsification recrystallization [18]and spray dry [19—21],always suffer from the safety issue,uneven size and irregular shape.The microfluidic system has significant advantage of the homogeneous preparation,non-hazardous and precise preparation,which brought a turnaround to achieve homogeneous particles.At the micron length scale,the fluid inertia is usually negligible,providing a controlled environment for droplet production.Accordingly,it has become a more reliable alternative method for generating monodisperse emulsions than the traditional emulsification method[22].In addition,the high ratio of surface to volume and the small hold-up volumes of less than liter prevent the accumulation of heat[23].

Herein,we used microfluidic techniques employing passive coflow microfluidic chips to prepare 90% loading CL-20 spherical particles with tens to hundreds of microns.The morphology,thermal properties and combustion behavior of CL-20-based microspheres were further investigated.Benefiting from the synergistic effect of the three-dimensional ordered porous PVDF/NC framework,the resulting CL-20 spherical composites exhibit excellent self-sustaining combustion performance.The PVDF/NC hybrid framework demonstrated remarkable catalytic activity for the thermal decomposition of CL-20.

2.Experimental

2.1.Materials

Raw CL-20 was supplied from the Chinese Academy of Engineering Physics.Nitrocellulose(NC)was provided by Sichuan North Nitrocotton Co.,Ltd.Poly(vinylidene fluoride)(PVDF),Ethyl acetate(EA),N,N-Dimethylformamide (DMF) and polyvinyl pyrrolidone(PVP) were purchased from Chengdu Kelong Chemical Co.Ltd.

2.2.Characterization

The particle size,morphology and structure of CL-20 microspheres were observed by ZEISS Gemini SEM 450 field emission scanning electron microscope.Particle size was measured by a Keenes digital microscope VHX-7000,with more than 300 particles sampled,and calculate the particle size distribution.

DSC-TG measurements were performed by a differential scanning calorimeter equipped with a NETZSCH STA 449F5.For each measurement,approximately 0.5 mg of the sample was placed in an aluminum crucible and tested for its thermal decomposition properties under a high-purity argon atmosphere with a purge rate of 50 ml/min at heating rates of 5,10,and 15°C/min.DSC-TG-FTIR measurements were performed by NETZSCH STA 449F5 and Bruker VERTE X80 infrared spectrometer.The experiments were performed in high-purity argon at a purge rate of 50 ml/min.About 0.8 mg of the sample was placed in an aluminum crucible.The sample was heated at 10°C/min from 25 to 500°C.TG mass and temperature calibration (indium) were performed prior to the experiment.

To evaluate the self-sustaining combustion performance of CL-20 composites,the Ti3C2MXene membrane was cut into small pieces larger than 25 mm2and covered on top of the sample.The film side of the sample was directed toward the incident laser.The samples with a diameter of 7 mm and a thickness of 1 mm were prepared by pressing~20 mg particles.A 1064 nm diode pumped solid state laser (MFSC-10,Maxphotonics Co.,Ltd.,China) with a spot size of~4 mm was used to ignite the samples.Snapshots of the laser ignition were recorded with a high-speed camera (VEO410L,Photron).

2.3.Preparation of spherical CL-20 microspheres

CL-20/NC/PVDF (mass ratio 90:5:5) was dissolved in the mixed solvent(the mass ratio of EA/DMF was 3:1),which was selected as the dispersed phase(DP).PVP was dissolved in water as continuous phase (CP).The dispersed phase was injected through a needle in the center and flows co-currently with the continuous phase in the main channer at the temperature of 25°C.The flow rate ratio of the dispersed phase to the continuous phase was adjusted to obtain droplets of different diameters.In the channel,the droplets gradually crystallize and form spherical particles.Rinse with a large amount of deionized water after entering the collect,then dry in an oven at 45°C to obtain CL-20 spherical particles.The irregular CL-20/PVDF/NC composite was prepared by solvent non-solvent method.

3.Results and discussion

3.1.The assembly strategy of the composite

In order to prepare spherical composite particles,it is essential to achieve a high loading of CL-20 and impart self-sustaining combustion performance at same time.Necessarily this implies that the CL-20 should be assembled with a binder and satisfied both compatibility and structural requirements.Nitrocellulose has been reported to be a commonly energetic binder with good compatibility and self-sustaining combustion properties [24],and its unique 3D mesh structure may help CL-20 to obtain self-sustaining combustion properties through effectively shortening the heat propagation diffusion path.Theoretical studies have found that,PVDF,as a fluoropolymer,can effectively improve the mechanical properties when compounded with CL-20 [15,25,26],and its unique H…F,H…O hydrogen bonding may provide interesting active sites for the crystallization of CL-20,resulting in a uniform loading of CL-20.Attempt to construct the porous mesh framework as in Fig.S1(a),the 5 wt.%PVDF/NC mixture solution was prepared into microspheres by microfluidic technique.The result validated the structure of the PVDF/NC composite framework,and Fig.S1(b)and (c) revealed that PVDF/NC complexes can constitute a 3D porous framework.In this work,a 3D framework with PVDF/NC as binder was prepared to construct CL-20/PVDF/NC spherical composite with 90% CL-20 loading.The microfluidic technology is utilized to provides an excellent formation environment for the continuous preparation of composite microsphere particles.In microfluidics system,inertia begins to lose its influence on the liquid flow.Viscosity dominates over inertia resulting in the predictable laminar flow.This shift is represented by dimensionless Reynolds numberRe:

where ρ is the density of the continuous phase,ν is the average velocity of the continuous phase,η the viscosity of the continuous phase,andDis the equivalent diameter.The dispersed phase is injected through a needle in the center and flows co-currently with the continuous phase in the main channer.Dispersed phase droplets are generated into the channel under Rayleigh-Plateau instability.In this predictable laminar flow,the solvent exchange in the microchannel always takes place by steady diffusion.The relationship between the mass transfer time (t),the mass transfer distance and the diffusion coefficient in a microfluidic chip channel can be approximated by Einstein's equation:

wherelis the mass transfer distance(e.g.,microchannel width),Dis the diffusion coefficient.The transition from droplets to solid particles in microfluidic systems is a complex and rapid process.In order to accurately prepare CL-20-based composite microspheres with a PVDF/NC framework,the transformations of droplets to composite microspheres is detailed,including emulsification,polymer crystallization,and CL-20 crystallization are detailed described in Fig.1.The droplet of disperse phase,once post the initial creation of an interface with the continuous phase,began to solvent exchange and shrink.The laminar flow around the droplet allows for continual replenishment without disruption of the interface and exposure of the polymer to the continue phase.Next,as shown in Fig.1(a),the dilute solution undergoes a liquidliquid extraction by which the polymer concentrated-phase droplets form.The PVDF and NC concentrated phase droplet starts to crystallize and entangled with each other at this moment[27—30].The formation of the PVDF/NC polymer framework provides the active site for CL-20 crystallization and induces the orderly crystallization of CL-20 crystals within the droplet (Fig.1(b)).Along with the gradual diffusion of the solution,the well-soluble CL-20 crystals in organic solvents are also locally oversaturated at the liquid-liquid interface and start to crystallize,and attach to the 3D mesh structure formed by the polymer under hydrogen bonding[31].The droplets shrink dramatically and solidify rapidly [32].Lastly,spherical CL-20/PVDF/NC composite particles are formed(Fig.1(c)).

3.2.Morphology characterization

The composite spherical particles of CL-20/PVDF/NC with three particle sizes were prepared by varying the flow rate ratios of dispersed phase and continuous phase.Fig.2 shows the morphology and particle sizes distribution of samples (a),(b) and(c).These microspheres show uniform size distribution and high sphericity,and the average particle sizes were 68.3 μm,185.4 μm,and 316.6 μm.The presence of small particle sizes was thought to be caused by microsphere fragmentation.It can be seen from Fig.3(a) that the resulting composite microspheres have a dense surface.The internal structure of composite microspheres is observed in Fig.3(b) after crushing,and the internal of microspheres are mainly assembled by 3D mesh structure and submicron particles.The X-ray diffractogram (Fig.S2) exhibited the crystal diffraction peaks of the composite.The multi-stage structure was formed by PVDF and NC construction (Fig.S3).These results highlight the excellent effectiveness of PVDF with NC as a binder for the spherical assembly of CL-20 crystals.Such hierarchically porous and 3D structure can provide a model architecture for loading of high-energy fuels and achieving high-performance combustion by compensating the heat and/or pressure loss.

3.3.Thermal behavior

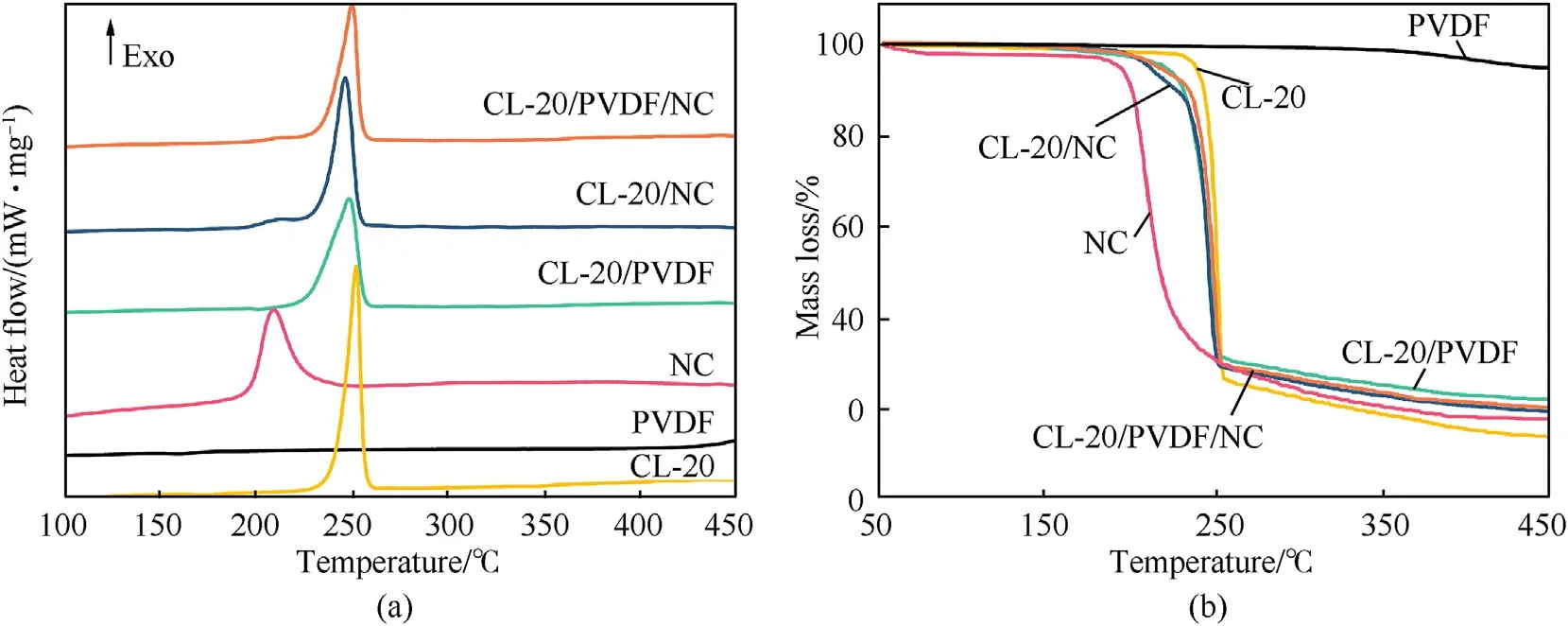

The thermal compatibility and stability of CL-20,PVDF and NC were investigated by DSC analysis.The DSC curves in Fig.4(a)illustrate the thermal behavior of CL-20 and its complex with PVDF and NC.From the DSC curves,only one decomposition peak can be observed for the CL-20,CL-20/PVDF composites and CL-20/NC,CL-20/PVDF/NC composites show a weak decomposition peak of NC and a strong decomposition peak of CL-20.All four products decomposition were produced in a narrow temperature range of 220—259°C.However,the initial decomposition temperature of the composite was significantly earlier than that of raw CL-20 with the addition of PVDF and NC.The decomposition peak temperatures(Tp) of CL-20/NC,CL-20/PVDF and CL-20/PVDF/NC are 247.0,247.2 and 249.3°C,respectively,which are 4.2,4.0 and 1.9°C lower than that of raw CL-20.The decomposition peak temperature of all the composites have been decrease at different level compared with raw CL-20,which seems to suggest that both two polymers have unexpectedly catalytic effect on the thermal decomposition of CL-20.Different decomposition stages are clarified as mass loss rate peaks in TG-DTG curves.As can be seen from TG-DTG curves(Fig.4(b) and Fig.S4) a rough constant weight of pure PVDF is inspected in the temperature range of 50—450°C and composites have mass loss in the temperature range of 50—450°C,which is agreement with their DSC results.These results shown excellent thermal compatibility of CL-20/PVDF/NC composites.

Moreover,Kissinger fitting method was used to reveal the thermal decomposition kinetics of CL-20,NC,as well as CL-20/PVDF/NC composite microspheres.The activation energies are obtained by the Kissinger equation[33],which is presented as follows.In this equation,Eais the apparent activation energy,β is the heating rate,Ris the gas constant,Tpis the peak temperature,andA0is the pre-exponential factor.

Fig.2.The SEM,digital microscope pictures and the particle size distribution of CL-20/PVDF/NC: (a)(b)(c) low resolution;(a1) (b1) (c1) high resolution.

Fig.3.(a) Surface morphology of CL-20/PVDF/NC microspheres and (b) inner morphology of the microsphere after crushing.

Fig.4.(a) The DSC curves and (b) TG curves of CL-20,CL-20/NC,CL-20/PVDF,CL-20/PVDF/NC at 10 °C/min.

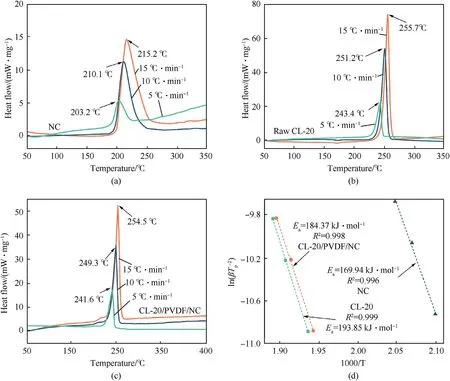

where from Fig.5(a),(b) and (c),the decomposition temperature gradually increased with the increase of the heating rate and the decomposition temperature of the CL-20/PVDF/NC composite was slightly lower than that of raw CL-20.Meanwhile,the initial decomposition temperature of the CL-20/PVDF/NC composite is also earlier than raw CL-20.The activation energies results are presented in Fig.5(d),and the linear relationship between the decomposition temperature and ln(β/T2)exhibited that all samples have a similar reaction order.Also,all linear correlation coefficients are close to 1,which indicates reliable results.The activation energy(Ea) of CL-20/PVDF/NC composite microspheres is 184.37 kJ/mol,which is lower than that of raw CL-20.Comprehensive analysis of the thermal decomposition behavior and the kinetics of the thermal decomposition showed that the presence of the PVDF/NC reduced the activation energy of the composite,and maintained a thermal decomposition temperature that was close to the raw CL-20.The CL-20/NC/PVDF microspheres show great thermal stability.

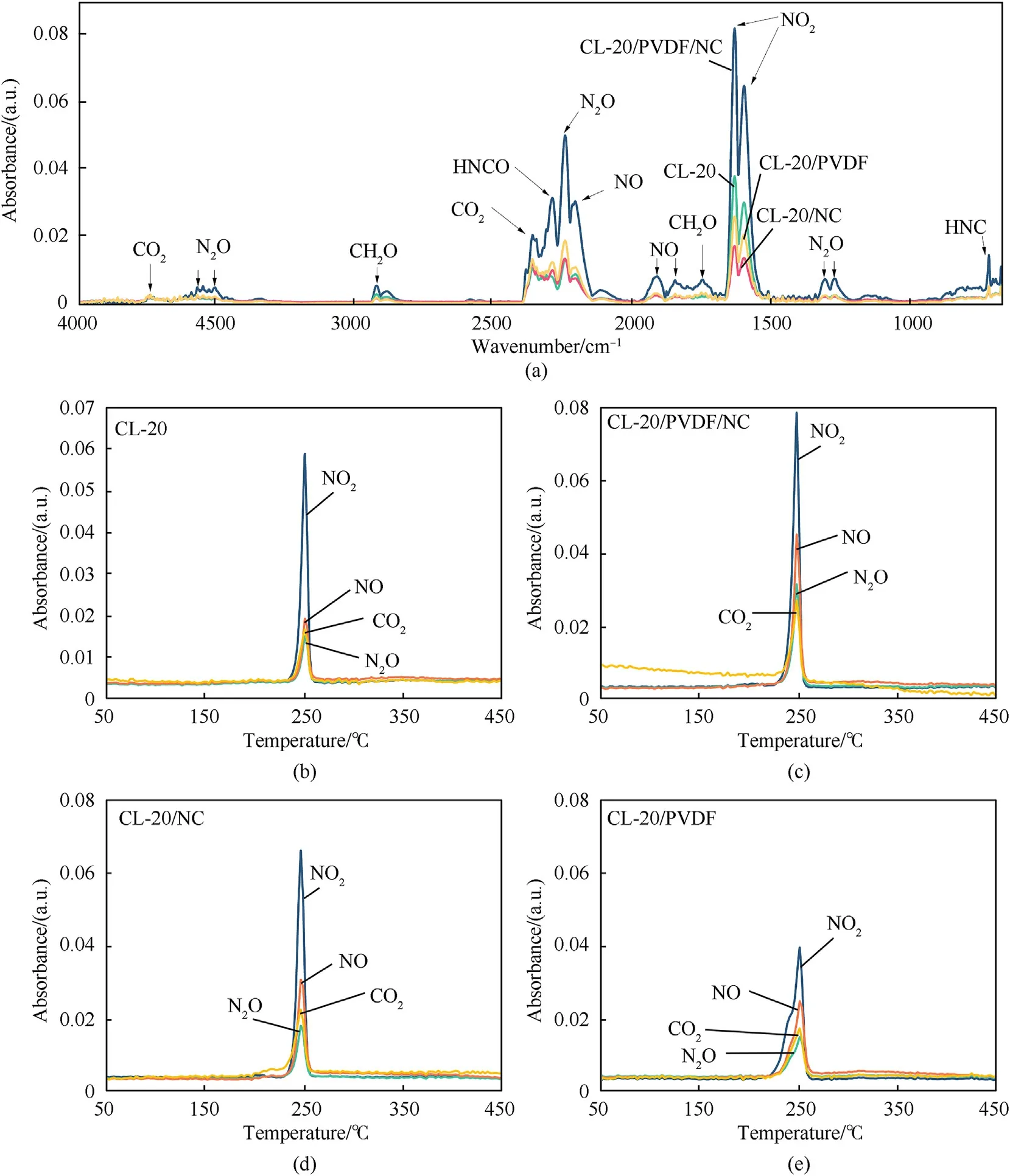

The reaction of CL-20,NC and PVDF were further investigated by Thermogravimetric-Fourier transform Infrared spectroscopy (TGFTIR) to provide evidence for the synergistic reaction of CL-20/PVDF/NC composites.Typical FT-IR spectra of gases produced during the decomposition of raw CL-20,CL-20/NC,CL-20/PVDF and CL-20/PVDF/NC composites are observed in Fig.6(a).The peaks at 1590 and 1630 cm-1are attributed to NO2,the peaks at 1842,191 and 2202 cm-1demonstrate the presence of NO,the peaks at 1270,1302 and 2238 cm-1correspond to N2O and the peaks in 2360 cm-1demonstrate the presence of CO2,and other featured peak correspond to the HNCO,HCN,CH2O and H2O.All of peaks are correspond to the main gaseous products of the thermal decomposition of raw CL-20,in agreement with previous reports[34].The primary gaseous product of the raw CL-20 sample was NO2,which is consistent with the initial thermal decomposition pathway dominated by the N—NO2homogeneous reaction.Of these,NO2will further in several ways with other cracking reactions and produce more thermodynamically stable NO and N2O in the decomposition sequence [35].Thus,the ratio of N2O/NO2and NO/NO2can indicate the extent to the decomposition reaction of CL-20 proceeds [34].The ratios of N2O/NO2and NO/NO2for raw CL-20 were 0.27 and 0.28.Respectively,they increased to 0.61 and 0.31 for CL-20/PVDF composites and 0.55 and 0.40 for CL-20/PVDF/NC composites.It is indicated that NO2carried out a more complete secondary reaction in the presence of PVDF.

Furthermore,the variation of absorbance with temperature in the FT-IR spectra of four typical gaseous products,NO2,N2O,NO and CO2were also characterized in Fig.6(b).For raw CL-20,all four products were produced in a narrow temperature range of 229—259°C,typical for energetic materials.For CL-20/PVDF composites,NO2gas production starts earlier at 212°C and maintains a wide decomposition temperature,while NO,N2O and CO2remain consistent with the decomposition of CL-20.For the CL-20/PVDF/NC composites,N2O and NO were produced in the temperature range of 227—257°C,the decomposition temperature range remained narrow.The variation of the four products' absorption intensity is consistent with the variation of the DSC curves shown in Fig.4(a).The results show that the TG-FTIR characterization data all provide strong evidence that PVDF catalyzes the decomposition of CL-20,and make the decomposition of CL-20 more complete.

Fig.5.(a) The thermal behavior of NC;(b) CL-20 and (c) the CL-20/PVDF/NC composite microspheres;(d) Linear fit of plotted ln(β/Tp2) against 1000/Tp for the calculation of activation energy (Ea).

3.4.Combustion behavior

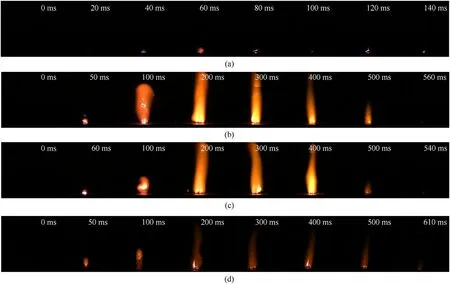

The Ti3C2MXene was used as a laser ignition generator of CL-20 and CL-20 composites to verify the self-sustaining combustion of composite materials [36].Raw CL-20 consists of inhomogeneous particle size crystals as shown in Fig.S5 (a),and Fig.7(d) is an irregular CL-20/PVDF/NC composite prepared by solvent nonsolvent method (Fig.S5 (b) and (c)).Herein,the CL-20/PVDF/NC microspheres with particle sizes of 316.6 μm and 68.3 μm correspond to the samples (a) and (c) in the previous morphology characterization.Fig.7(a) shows that the raw CL-20 powders are hard to be initiated by laser pulse (1064 nm,50 ms,79.6 W/cm2);the combustion is localized at the site where it is initiated and quenched rapidly,accompanying with brown smoke and negligible light,which exhibiting the ‘flameless burning’ [37].The low heat output of raw CL-20 combustion and high decomposition/combustion initiation threshold cannot trigger the combustion of neighboring CL-20.This phenomenon is similar to Fig.8(a),which shows the poor combustion and the acyclic heat transfer.Compared to the raw CL-20,CL-20/PVDF/NC microspheres (Fig.7(b) and (c))reaches stable combustion stage quickly after ignition burned on the holder with a bright flame and negligible white smoke with weak fire edge wobbling,which showed an efficient and selfsustaining combustion characteristic.Besides,compared with the combustion evolution of CL-20/PVDF/NC microspheres,it can be found that the irregular CL-20/PVDF/NC composite (Fig.7(d)) has longer burning duration (540—560 ms for CL-20/PVDF/NC microspheres and 610 ms for irregular CL-20/PVDF/NC composite) and dimmer flame brightness,which means low propagation speed and combustion efficiency.Namely,in terms of the flame brightness and burning rate,the CL-20/PVDF/NC microspheres sample shows the excellent combustion performance.The schematic illustration of combustion of CL-20/PVDF/NC composite are shown in Fig.8(b)and(c).The orange framework and white particles represent to the PVDF/NC and CL-20,respectively.At the laser ignition stage,the PVDF/NC decomposition firstly and generates heat to initiate the combustion reaction of CL-20 since the initiation threshold of decomposition/combustion of CL-20 is higher than that of PVDF/NC framework.Both of the exothermic reactions generate large amount of heat and feedback into the system to trigger the combustion continuously.The difference is that the CL-20/PVDF/NC microspheres have unique hierarchical porous and 3D structure,which facilitates convective heat and mass transfer,the large amount of heat generated is more efficiently feedback into the system than that of irregular composites,and result an excellent self-sustaining combustion performance.While the irregular CL-20/PVDF/NC composites exhibit inferior self-sustained combustion performance by low heat transfer efficiency and the free CL-20 particles that require high heat to trigger.These results show that the formulation of CL-20/PVDF/NC high-energy microsphere brings efficient and stable self-sustaining combustion performance.

Fig.6.(a)The typical FT-IR spectra of the gaseous products at the temperature when the intensity of FT-IR series is maximum;(b)The absorbance changes in the FT-IR spectrum as a function of temperature for NO2,N2O,NO and CO2.

Fig.7.Lateral view snapshots showing the combustion evolution of (a) raw CL-20,(b) CL-20/PVDF/NC (68.3 μm),(c) CL-20/PVDF/NC (316.6 μm) and (d) irregular CL-20/PVDF/NC ignited by laser pulse.

Fig.8.Schematic illustrations show(a)the poor combustion propagating of CL-20 particles,(b)self-sustaining combustion of CL-20/PVDF/NC microspheres and(c)irregular CL-20/PVDF/NC.

4.Conclusions

In conclusion,we have carefully fabricated 90% CL-20 loading spherical particles with different uniform sizes by droplet microfluidic.The resulting spherical particles possess outstanding dimensional uniformity and good thermal compatibility.The CL-20/PVDF/NC microspheres composited exhibited long burning time(540—560 ms) and bright flame,which indicated that their combustion performance was dramatically enhanced compared to raw CL-20.This work significantly improves the combustion performance of CL-20-based spherical particles which provides new inspiration for high-energy density composites with excellent self-sustaining combustion performance.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

This work was supported by the Project of State Key Laboratory of Environment-friendly Energy Materials,Southwest University of Science and Technology (No.20fksy18).

Appendix A.Supplementary data

Supplementary data to this article can be found online at https://doi.org/10.1016/j.dt.2021.12.004.

杂志排行

Defence Technology的其它文章

- Hardware-in-loop adaptive neural control for a tiltable V-tail morphing aircraft

- Resilient tightly coupled INS/UWB integration method for indoor UAV navigation under challenging scenarios

- Dual Attribute Adversarial Camouflage toward camouflaged object detection

- GO/HTPB composite liner for anti-migration of small molecules

- Benchmark calculations and error cancelations for bond dissociation enthalpies of X—NO2

- One-step green method to prepare progressive burning gun propellant through gradient denitration strategy