Experimental study on dynamic mechanical properties of carbon fiber reinforced polymeric concrete

2023-02-24BAIErleiWANGZhihangYANGNing

,BAI Erlei,WANG Zhihang,,YANG Ning

(1.College of Aeronautical Engineering,Air Force Engineering University,Xi’an 710038,P.R.China;2.Air Force Guangzhou Engineering Design Office,Guangzhou 511458,P.R.China)

Abstract:To further elucidate the mechanical properties of fiber-reinforced concrete,carbon fiber was added to modify polymeric concrete,and the impact resistance of polymeric concrete reinforced by various contents of carbon fiber was studied.Impact compression test was carried out using a split Hopkinson pressure bar(SHPB)test system to investigate the influence of carbon fiber content on the impact resistance of polymeric concrete in terms of the stress-strain curve,strength,deformation characteristics and impact toughness.The results show that with continuous increases in carbon fiber content,the impact resistance of the polymeric concrete first increases and then decreases.When carbon fiber content increases to 0.2%,the dynamic compressive strength of the concrete,as well as the deformation capacity under high strain rate compression load,is at the maximum.Consequently,0.2% is the optimal content of carbon fiber.

Keywords:carbon fiber;redispersible latex powder;composite concrete;dynamic compressive strength;deformation performance

1 Introduction

At present,concrete is utilized for most buildings and public infrastructure facilities due to its accessibility,as well as the abundance of raw materials to make it.However,there are some disadvantages of concrete,e.g.,low tensile strength,poor impact resistance,and vulnerability to brittle fracture[1].Carbon fiber(CF)is an environmentally safe new fiber material that has superior advantages within its mechanical properties,e.g.,high strength,low density,and high-temperature resistance[2].CF can not only carry loads as part of a structure,but can work as a functional material.The tensile strength of carbon fiber can reach 3 500-6 000 MPa which is much higher than any other inorganic fiber such as steel and ceramic fiber[3].Therefore,CF can be added to modify concrete to improve its impact resistance.CF can restrain the expansion of microcracks in concrete,improve crack and permeability resistance of concrete,further improve the physical and mechanical properties of concrete,and enhance the seismic performance of the structures[4-5].

There have been many studies on the dynamic and static test design methods and relevant theories concerning the performance of ordinary concrete reinforced by CF that achieved excellent results[6-13].However,there are still few theoretical studies on concrete mixed with both CF and a polymer.Chen et al.[14]was the first to propose the addition of a polymer to act as the CF dispersant.The results show that the dispersant significantly improved the toughness and compressive strength of the CF concrete.Wang et al.[15]studied the influence of mixing fiber and latex powder on the mechanical properties of cement mortar and found that the flexural strength and toughness of the mortar improved significantly when the admixture of fiber and latex powder was used.The crack resistance of the cement mortar increased when 1% glass and 2%latex powder were added to the concrete.Mei et al.[16]studied the effects and performance of fiber and styrene-butadiene concrete mortar emulsions and found that the addition of the fiber significantly improved the impact resistance of the styrenebutadiene emulsion mixture.The styrene-butadiene emulsion improved the cohesiveness between the fiber and the matrix,thus,the combination of the two was superior to any of the constituents alone.

At present,the studies on carbon fiber reinforced polymeric concrete are limited to the strength,deformation,durability and crack resistance under a static load with few studies investigating the concerns regarding the compressive mechanical properties of dynamic impact.Therefore,in this study,a polymeric latex powder was selected to aid in the dispersion of CF with CF content used as the variable.The reinforced concrete was then tested using a shock compression test,stress-strain curves,dynamic compressive strength test and peak toughness were obtained to further explore the influences of varying CF content on the impact resistance of polymeric concrete.

2 Test methods

2.1 Materials

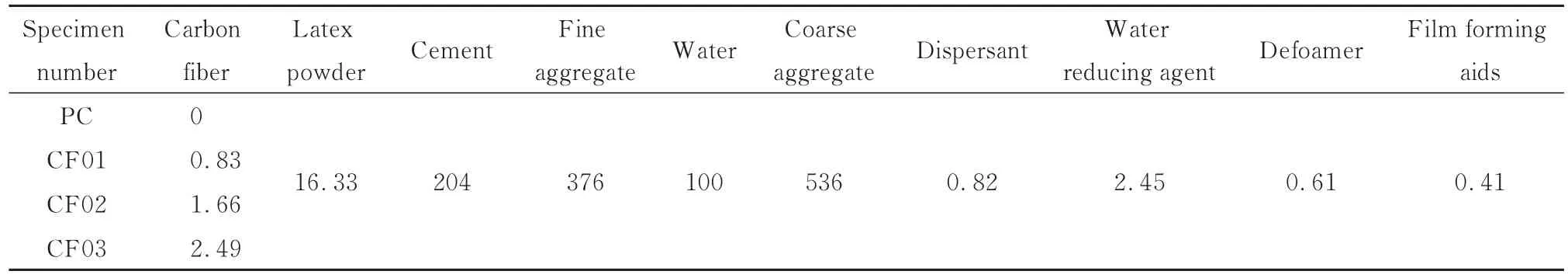

The primary raw materials used for preparing the modified concrete are as follows:cement,sand,gravel,water,re-dispersible latex powder,CF and aid.For the cement,common Portland cement(P.O)was used,fine aggregate,natural sand from Bahe,coarse aggregate limestone gravel with a particle size of 5-20 mm;common tap water,VINNAPAS® 5044N re-dispersible latex powder manufactured by WACKER CHEMIE AG,Germany(volume fraction:8%)[17];chopped PAN based CF manufactured by TORAY,Japan(Fig.1),with carbon fiber concentrations of 0.1%,0.2%,and 0.3% of the concrete volume.For the water reducing agent,STHPC-03A model FDN superplasticizer mother liquor manufactured by Hebei Shengtong Building Materials Technology Co.,Ltd.was used,NOPCO NXZ metal soap defoaming agent manufactured by NOPCO,Japan,and DN-12 coalescing agent manufactured by Jiangsu Tianyin Chemical Co.,Ltd..The mix ratio for the test concrete was based onDesign Specification for Mix Ratio of Common Concrete(JGJ 55-2011)[18]Finally,the mass ratios of the components are shown in Table 1.

Fig.1 Carbon fiber

Table 1 Concrete mix design kg/m3

2.2 Specimen preparation and test equipment

2.2.1 Specimen preparation process The mixing process of the investigated concrete involved 6 steps:weighing,fiber dispersion,polymer dispersion,mixing,molding,and curing.The concrete was mixed according to the mix and stir ratios.Followed by loading the mixture into a long cylindrical steel die 2-3 times.To ensure complete contact between the specimen and the rod interface,a cylinder with a diameter of 98 mm was selected.Next,the mixtures were vibrated using a shaking table and a plug-in vibrating rod,then transferred to a room for curing.Then,the die was removed after 1 day and allowed to cure for 28 days under standard conditions.Next,the specimen was taken out and cut intoϕ98 mm×50 mm short cylindrical pieces and the two ends of each piece were polished.Finally,the pieces were clean and dried.The prepared pieces are shown in Fig.2.

Fig.2 Concrete mold specimen

2.2.2 Test equipment and protocol The mixer used was a HJW-60 single-horizontal shaft forced concrete mixer manufactured by Xi” an County Pengyi Construction Instruments Factory,and the magnetic vibrating table was a HZCT-80 vibrating table for concrete testing manufactured by Xi” an County Yihang Test Instrument Co.,Ltd..Considering that there were some special requirements for the pieces used for the impact compression test,a cutter was used for cutting the specimen after curing.A polisher was used to polish both ends of the concrete pieces.

For the dynamic compression test,aϕ100 mm SHPB test unit was adopted and depicted in Fig.3.The unit is composed of the main equipment and the energy and measurement systems.The main equipment includes an emitter,an accelerating tube,a bullet,a damper,a member bar,an adjusting bracket,and a console.The energy system is composed of an air compressor,a high-pressure vessel,and a pipeline.The measurement system is made up of a bullet velocity and a dynamic strain test system.

Fig.3 SHPB test device

By adjusting the air pressure in the pneumatic pump,several strain rates of the CF reinforced polymeric concrete in the range of 10-102s-1were obtained to investigate the impact deformation behavior of the concrete.A total of five pressure values(0.2,0.25,0.3,0.35 and 0.4 MPa)were tested.Under each pressure,the test was repeated in triplicate,and the test results were averaged.

3 Test results and relevant analysis

3.1 Analysis of the stress-strain curves

Stress-strain curves may reflect the mechanicalproperties of the material.Fig.4 shows the stressstrain curves for groups of pieces under similar strain rates(10-102s-1).Each curve corresponds to a group of concrete pieces,i.e.,the five curves correspond to five different strain rates.

According to Fig.4,the relevant rules are summarized as follows:1)For the initial rise stage,the groups of the concrete pieces were similar,i.e.,similar slope curves and similar strains corresponding to the same stress,indicating that the addition of CF did not significantly improve the elastic modulus of the polymeric concrete during the initial deformation elastic stage.2)With the increase of strain rate,the peak of stress-strain curves of the concrete specimen increased,and the descending stage gradually shifted to the right,indicating that the addition of CF caused significant strain rate effects for the peak strain of the polymeric concrete.3)When the latex powder was added alone,the top of the stress-strain curve for the concrete specimen was sharp,and the descending stage fell rapidly.After the addition of CF,the decreasing trend or the descending stage slowed,indicating that the addition of CF into the polymeric concrete increased its ductility.

Fig.4 Stress-strain curves of CF reinforced polymeric concrete

3.2 Strength and deformation characteristic analysis

Impact compression strength refers to the peak stress of specimen.It is an important index characterizing the strength of CF reinforced polymeric concrete under an impact load.The influence of the average strain rate on the impact compression strength of polymeric concrete with different CF content is shown in Fig.5(a).

Fig.5 Compression strength of CFRP concrete

According to Fig.5(a),1)The impact compression strength of CF reinforced polymeric concrete with the same CF content was positively correlated with the average strain rate,therefore,the impact compression strength of the concrete increased with the strain rate.2)When the strain rate remained unchanged,the addition of CF improved the impact compression strength of the polymeric concrete,and when the content of CF was 0.1% and 0.2%,the concrete pieces performed similarly during the impact compression strength test,with an 18% increase in impact compression strength compared to that of the concrete pieces without CF reinforcement.When the content of CF exceeded 0.2%,the impact compression strength of the concrete decreased,indicating that 0.2% is the optimal CF content for polymeric concrete.

The Dynamic Increase Factor(DIF)[19-21]was introduced to further clarify the relationship between impact compression strength and strain rate.The formula for calculating DIF is as follows:

Wherefc,dis the dynamic strength of concrete specimen,fc,sis the static strength of the concrete specimen,respectively.

The static compressive strength of different contents of the CF reinforced polymeric concrete pieces is shown in Fig.5(b)and the DIF of the concrete pieces can be calculated based on these parameters.The relationship between DIF and the average Log strain rate for the groups of pieces is shown in Fig.6.

Fig.6 DIF and fitting diagram of CF reinforced polymer concrete specimens

Since the DIF of concrete with the same CF content increased linearly with the average Log strain rate,i.e.,lġ,the DIF is expressed as:

Wherekandbare constants for the material,which are related to the content of CF(Table 2).

Table 2 DIF regression formula material parameters

According to Fig.6,1)No matter whether CF was added or not,the strength of the concrete can be promoted by increasing the strain rate.2)The DIF is positively correlated with the average strain rate,andbin the formula is the main factor affecting DIF.The descending order of DIF for the four groups of concrete pieces is as follows:CF02,CF01,CF03,and PC.For CF02,the maximum DIF was 2.05 and the strain rate was 140 s-1.3)R2is the index for evaluating the fitting effect of the curves and was greater than 0.98.Therefore,the fitted function curves reflected the change of DIF as a function of strain rate.With increase of strain rate,DIF increased rapidly,thus,the slope of the fitted curve enlarged.However,k,the slope of CF02,was greater than the slopes of other three concrete groups,indicating an optimal CF content for the strain rate effect of the polymeric concrete.In practical applications,in order to maximize the effect of CF,it is vital to identify the optimal CF content.

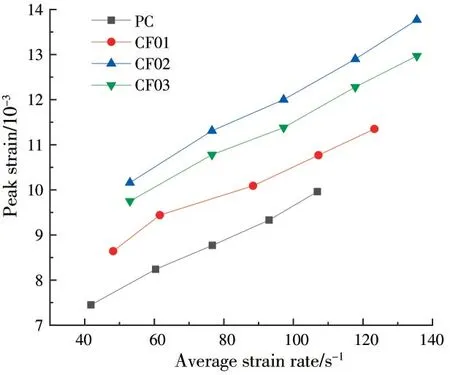

In order to further characterize the deformation of the concrete pieces,the peak strain,i.e.,the strain corresponding to the peak stress under the impact compression load was plotted.The effect of the average strain rate on the peak strain of polymeric concrete with different CF contents is shown in Fig.7.

Fig.7 Influence of average strain rate on the peak strain of CFRP concrete

As shown in Fig.7,1)the peak strain of the concrete pieces mixed with CF was significantly greater than without CF.The peak strain of the concrete pieces gradually increased with the strain rate.2)Under the same strain rate,with increasing CF content,the peak strain of CF reinforced polymeric concrete first increased,and then decreased.When the CF content was approximately 0.2%,the peak strain of the CF reinforced polymeric concrete reached a maximum.

3.3 Analysis of the polymeric concrete toughness

The toughness of concrete is a comprehensive index for the material” s ductility and strength,thus representing the material” s ability to absorb the deformation force when they are deformed.Macroscopically,toughness refers to the capacity of the material to absorb energy during loading process until damage occurs.In the impact compression test performed on concrete,peak toughness is used as an index for the impact toughness of the concrete.Peak toughness refers to the area enclosed by the stressstrain curve and the coordinate axes before the peak stress of the material appears.

Regarding the groups of concrete pieces,the peak toughness was obtained by integrating the stress-strain curve before the appearance of the peak stress within the CF reinforced polymeric concrete.The influence of the average strain rate on the peak toughness of polymeric concrete within different CF contents is shown in Fig.8.According to the relevant analysis,1)the addition of CF enhanced the peak toughness of the polymeric concrete,and the effect was relevant to the content of CF and the strain rate.2)When the average strain rate was 40-100 s-1,the impact toughness of the CF reinforced concrete gradually increased and was positively correlated with the average strain rate.When the average strain rate was greater than 100 s-1,the relationship between the impact toughness and the average strain rate was not obtained because the relevant data was very discrete.3)Under the same strain rate,with increase of CF content,the peak toughness of the CF reinforced polymeric concrete first increased and then decreased.When the CF reinforced polymeric concrete content was approximately 0.2%,the peak toughness of the CF reinforced polymeric concrete was at a maximum,indicating that as the cracks developed within theconcrete specimens,CF reinforced polymeric concrete transferred stress at both ends of the crack,absorbing and consuming part of the external energy,and thus improved the toughness of the polymeric concrete.

Fig.8 Influence of average strain rate on peak toughness of CFRP modified concrete

3.4 Microtopography analysis

Scanning electron microscopy(SEM)was used to observe the microscopic morphology of CF and the polymeric concrete pieces.The results are shown in Fig.9.

Fig.9 Microscopic images of CF reinforced polymeric concrete

Fig.9(a)shows that the surface of the test CF was smooth and without grooves,which is not conducive to the bonding between the CF and the cement matrix.Furthermore,in the preparation of CF reinforced polymeric concrete,due to excellent isotonicity,a method for fiber dispersion should be adopted.Otherwise,a random disordered distribution of the CF in the concrete cannot be achieved.Fig.9(b)~(d)show that after a small amount of CF was added to the polymeric concrete,the strength of the concrete was enhanced through the bonding effect of CF.However,during the concrete preparation,a large amount of CF may cause fiber agglomeration.Thus,increasing the content of CF may first increase and then decrease the impact resistance.Therefore,in practical applications,if the dispersibility of large amounts of fiber within the concrete is not sufficient,then it is impossible to improve the mechanical properties of concrete simply by increasing the fiber content.

4 The relevant mechanisms analysis

The impact resistance of CF reinforced polymeric concrete primarily depends upon the concrete matrix.However,the addition of CF and re-dispersible latex powder may effectively improve the impact resistance of composite concrete.

Relevant studies have shown that the bond between the fiber and the cement matrix is not sufficient to improve the effects of the fiber significantly;however,the re-dispersible latex powder made from a polymer emulsion via spraying and drying,after mixing with water,may form a stable polymer emulsion again.The addition of redispersible latex powder to the mortar can improve the mortar” s compressive strength,flexural strength,deformation performance and bonding performance.Therefore,the concrete containing CF and redispersible latex powder may be added to promote the bonding between the CF and the cement matrix.The primary mechanism is as follows:Latex powder can form an emulsion in water,and during the mixing process of the concrete,the emulsion may be dispersed evenly in the concrete.Furthermore,with the hydration of the cement,a polymer membrane may be formed between the polymer particles.Therefore,some of the emulsion will form a threedimensional stereoscopic structure between the CF and the cement,thus strengthening the bond between cement hydrate and CF[22-23].

The influence of CF content on the impact resistance of the polymeric concrete specimens can be analyzed by the following three aspects:First,the addition of CF may reduce the cracks within the specimens during the water loss and shrinkage stage,thus alleviating the specimen damage at the initial stage.Second,when the specimen cracks are due to external forces,the added CF in the concrete that is bonded to the matrix might aggregate across the fracture.Thus,transferring the stress from both ends of the crack consume a part of the external energy,crack development is delayed and inhibited.Third,the actual dispersion conditions of the fiber in the concrete need to be considered.Excessive CF may cause a degradation effect within the material.Therefore,the impact resistance of the concrete cannot be improved simply by increasing the CF content.However,the optimal CF content should be determined during its practical applications.

5 Conclusions

This test was carried out using a split Hopkinson pressure bar(SHPB)test system with a diameter of 100 mm to explore the effects of CF content on the impact resistance of polymeric concrete.The influence of CF content on the performance of polymeric concrete under impact loads was discussed based on the stress-strain curve,strength,deformation characteristics,toughness,as well as the microscopic morphology.Furthermore,a mechanism analysis on CF reinforced polymeric concrete was conducted.The main conclusions are as follows:

1)With the increase of CF content,the dynamic strength of CF reinforced polymeric concrete first increased and then decreased,thus,having a significant enhancement effect on the strain rate.When CF content was approximately 0.2%,the impact strength of concrete specimen was at a maximum.

2)The addition of CF to the polymeric concrete effectively improved the impact toughness of the CF reinforced polymeric concrete.When the average strain rate was 40-100 s-1,the impact toughness of the CF reinforced polymeric concrete gradually increased with the strain rate.However,when the average strain rate was greater than 100 s-1,the effect was no longer apparent.

3)A microscopic analysis show that a large amount of CF causes fiber agglomeration,thus compromising the impact resistance of the polymeric concrete.