Gliding arc plasma adjusting pre-combustion cracking products

2022-12-23FeilongSongYunWuShiXuXingkuiYngJinpingZhouXinChen

Fei-long Song ,Yun Wu ,b,*,Shi-d Xu ,Xing-kui Yng ,Jin-ping Zhou ,Xin Chen

a Science and Technology on Plasma Dynamics Laboratory,Air Force Engineering University,Xi'an,710038,China

b Institute of Aeroengine,Xi'an Jiaotong University,Xi'an,710049,China

Keywords:Plasma adjustment Pre-combustion cracking Kerosene Detonation

ABSTRACT In view of the difficulty of kerosene-air detonation faced by the application of rotating detonation to aviation engines,in order to improve the kerosene detonation activity,the atmospheric pressure gliding arc plasma is used to conduct secondary adjustment of the pre-combustion cracking products.The results show that the components with larger molecular weight in the pre-combustion cracking products,such as ethylene and methane,can be cracked into highly active species of hydrogen and acetylene by gliding arc plasma.With the increase of the fuel ratio of pre-combustion cracking,the plasma has a more significant effect on the adjustment of high active components.However,as the flow rate of the cracking gas treated by plasma increases,the adjustment effect is obviously reduced.

1.Introduction

In recent years,rotating detonation has been extensively studied because of its higher thermal cycle efficiency[1,2],and has great potential in aerodynamic applications.However,the current research of rotating detonation is still in the basic research of gaseous fuel[3-5].As an aviation propulsion device,liquid kerosene should be preferred[6,7].Due to the slow atomization and evaporation of kerosene,poor mixing effect and insufficient activity of mixture,kerosene-air initiation is very difficult[8,9],which can only be realized by adding hydrogen[10],oxygen[11-13]or heating air[14].In addition,many published documents show that plasma also has good application prospects in improving ignition[15-17]and assisting combustion[18-22]for low activity reactants.In response to tow-phase detonation problem,our research team used plasma cracking of hydrocarbon fuel in the early stage to improve fuel activity,and adopted two types of discharge:dielectric barrier discharge[23,24]and gliding arc plasma[25,26].Although the cracking products contain highly active species such as hydrogen and acetylene,the overall cracking rate is low and the plasma processing capacity is limited.

After a long period of difficulties,we have innovatively changed our research ideas.Combined with the application background of aero-engine,we proposed the technical approach of precombustion cracking[27,28].A small part of kerosene is burned to provide a high temperature environment,and most of the remaining kerosene is injected into the high temperature zone to realize cracking and reforming.The experimental results are exciting,and the concentration of active species in the product is significantly higher than that of adopting plasma technology alone.The application of pre-combustion cracking scheme in kerosene-air rotating detonation has achieved positive results,which can significantly reduce the oxygen content from 50 %[11,12]to 30 %[29,30].

With the development of research,it is found that there are some limitations in pre-combustion cracking.Due to the small controllable temperature range of the pre-combustion flame,the effect of changing refueling position and residence time on the concentration of cracking products is small.The cracking rate can be significantly changed by changing the fuel ratio.Unfortunately,for applications,it is expected that less kerosene will be consumed for pre-combustion and more kerosene can be involved in cracking.That is to say,a high fuel ratio is required,while the cracking rate is very low at this time,and the concentration of active components in the corresponding cracking gas is also very low.In order to overcome this difficulty,we combine the two schemes of precombustion cracking and plasma cracking,and adopt the scheme of plasma adjusting cracking products described in this paper to further improve the concentration of active components.

2.Experiment

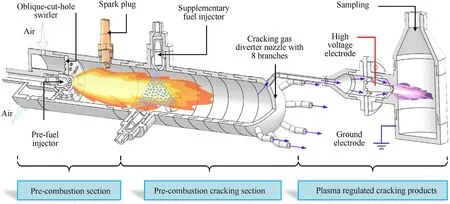

First,the fuel undergoes pre-combustion cracking treatment,and then part of the cracking gas is introduced into the gliding arc plasma cracker for further treatment,as shown in Fig.1.The swirler is a double-ring oblique-cut-hole swirler with an outer diameter of 50 mm.12 small holes with a diameter of 3 mm are uniformly distributed on the circumference of 28 mm diameter and 38 mm diameter,respectively.And the central axis of the small holes in the inner ring forms an angle of 35.94◦with the axis of the cracker,while the center axis of the small hole in the outer ring forms an angle of 44.52◦with the axis of the cracker.After going through the swirler,airflow gains a clockwise swirling effect,promoting the formation of the recirculation zone head.The swirler nozzles use Danfoss nozzles,which are equipped with a 45 μm fused copper oil filter.The igniter uses ordinary commercial spark plugs,equipped with an ignition power source with a single discharge energy of 20 J and a discharge frequency of 12 Hz.In this paper,the plasma treatment effect was compared under two fuel ratios by changing the ratio of the supplementary fuel flow rate and the pre-fuel flow rate.A diverter nozzle is installed at the end of the pre-combustion cracker,and the cracking gas is discharged through 8 branch pipes.When one branch pipe is connected to the plasma cracker with 8 branch pipes are all unblocked,the plasma can only deal with 1/8 of the total cracking gas flow.The ability to deal with the flow rate of cracking gas by gliding arc plasma was studied,in which the number of branches was changed by blocking the exhaust branch under each kind of supplementary fuel flow.The inner diameter of the used pre-combustion cracker is 50 mm,the distance from the refueling position to the pre-fuel injector is 140 mm,and to the diverter nozzle is 450 mm.The cracking gas enters the plasma discharge device through a 340 mm long gas conduit.The discharge adopts rod-ring discharge structure with a discharge gap of 1.5 mm.The pre-fuel flow rate is fixed at 2 g/s,and two supplementary fuel flow rates are set,of which the fuel ratio is 5 and 10 respectively.The flow rate used for plasma cracking is set to 5 conditions,which are 1/8,1/7,1/6,1/5 and 1/4 of the total flow rate of cracking gas.CTD-1000Z is used as plasma power supply.For sample collection,the sampling probe is placed on the central axis of the outlet of the pre-combustion cracking reactor and extends into 5 mm,of which the front end is a metal tube with an inner diameter of 1 mm.Samples are extracted by diaphragm oil-free vacuum pump(power 100 W)and detected by gas chromatography.In order to prevent soot and liquid components from contaminating vacuum pump and gas chromatography,oil-water separator is connected in series after sampling probe.The samples of pre-combustion cracking products and plasma adjusting cracking products were analyzed by Agilent 7890B gas chromatography.

3.Experimental results and analysis

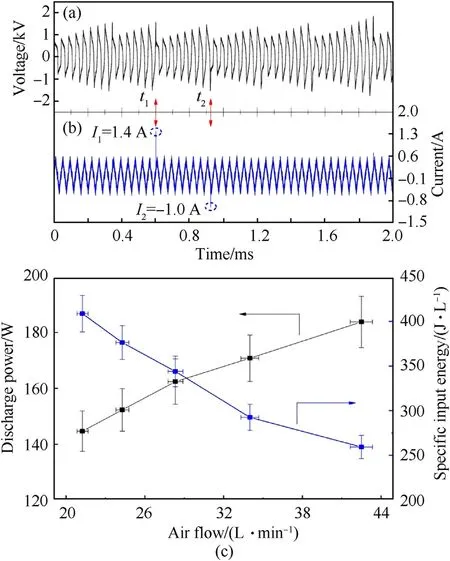

In view of the different output power of plasma discharge under different inflow conditions,an experimental test on the influence of air flow on discharge power and specific input energy was carried out separately.As shown in Fig.2(a)and(b),the voltage and current signals were collected synchronously during the discharge process.The voltage signal maintains a relatively stable stage with an envelope voltage at around 2 kV showing a saw tooth-like waveform.The current amplitude is under 0.6 A with a sinusoidal-like waveform except for times t1and t2,of which is glow-type discharge[31].However,the voltage signal peaks positively at t1,which corresponds to a current peak of 1.4 A in the positive direction,and the voltage signal peaks negatively at t2,which corresponds to a current peak of 1.0 A in the negative direction.In fact,this situation is very common in the longer time range of gliding arc discharge.After the discharge gap breaks down,the arc is elongated under the action of the air flow,resulting in an increase in plasma resistance,and the voltage required to maintain the arc gradually increases.When the arc is stretched long enough and breaks,it will re-break down at the minimum electrode gap.At this time,the corresponding loading voltage is high,and the plasma resistance instantly decreases,resulting in a peak current,which becomes a spark discharge[31].It is worth noting that the operational condition analyzed in the article is for a certain discharge power and a certain flow condition.Reasons for the discharge conversion belong to the dynamic conversion process of the gliding arc,which is caused by the occasional inter-electrode re-breakdown and short-circuit events when the gliding arc moves along the electrodes[32,33].

Fig.1.Schematic diagram of plasma adjusting pre-combustion cracking products.

Fig.2.Discharge(a)voltage and(b)current signals,as well as(c)the variation of discharge power and specific input energy with air flow.

Select the air flow range of 21-42 L/min,and the operating point corresponds to 1/8,1/7,1/6,1/5 and 1/4 of the pre-combustion air flow respectively.As shown in Fig.2(c),as the flow rate increases,the discharge power increases approximately linearly.This is because the increased air flow shortens the cycle of arc breakdownstretch-re-breakdown,resulting in an increase in the average discharge voltage.When the air flow rate is 21 L/min(1/8),the power is 145 W.When the air flow rate increases to 42 L/min(1/4),the discharge power is 184 W,with an increase of 26.9%.However,for plasma cracking,it is necessary to measure the input energy per unit flow rate than the input power.The results show that as the air flow increases,the input energy per unit volume decreases,which will have a negative impact on fuel cracking.After the air flow is increased from 21 L/min to 42 L/min,the specific input energy is reduced from 408 J/L to 259 J/L,with a decrease of 36.5 %.

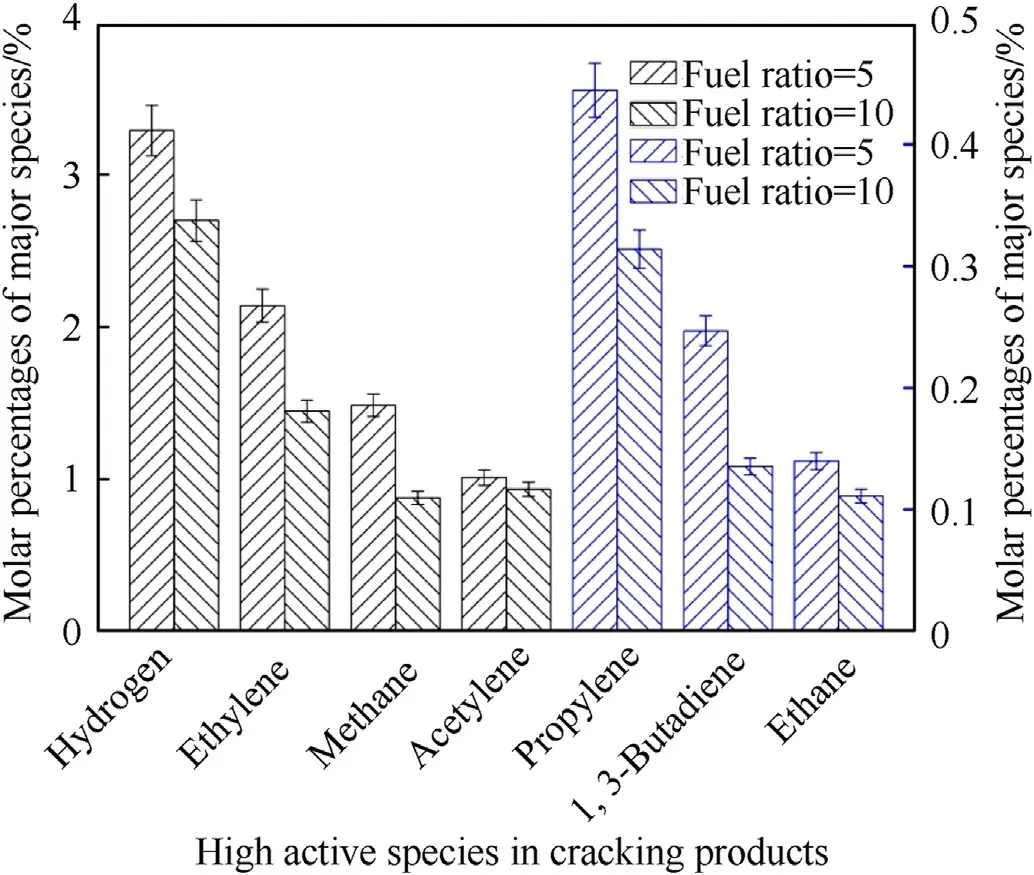

Pre-combustion cracking products with fuel ratios of 5 and 10 were analyzed.Highly active small molecules with a concentration greater than 0.1 % detected by gas chromatography include hydrogen,acetylene,ethylene,methane,propylene,1,3-butadiene and ethane,as shown in Fig.3.In addition,the cracking gas contains carbon dioxide generated by pre-combustion,nitrogen remaining in combusted pre-combustion air,carbon monoxide generated by incomplete combustion and oxygen that is not completely consumed.The results show that the main components in the cracking gas are hydrogen,ethylene,methane and acetylene,the concentrations are all greater than 1 %,of which the highest content is hydrogen.For pre-combustion cracking,increasing the fuel ratio and the concentration of cracking products will then decrease.The concentrations of hydrogen and acetylene with the smallest detonation cell size and critical ignition energy[34],which are shown in Table 1,decreased by 18%and 7.5%,respectively.This is very unfavorable for aviation applications,so the pre-combustion cracking gas under the operating conditions with high fuel ratio needs to be further treated to increase the concentration of active components.

Fig.3.Comparison of pre-combustion cracking products with fuel ratio of 5 and 10.

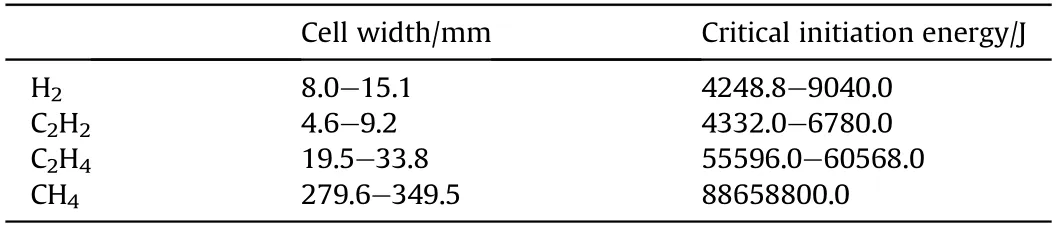

Table 1 Cell size and critical ignition energy of typical gaseous fuel[34].

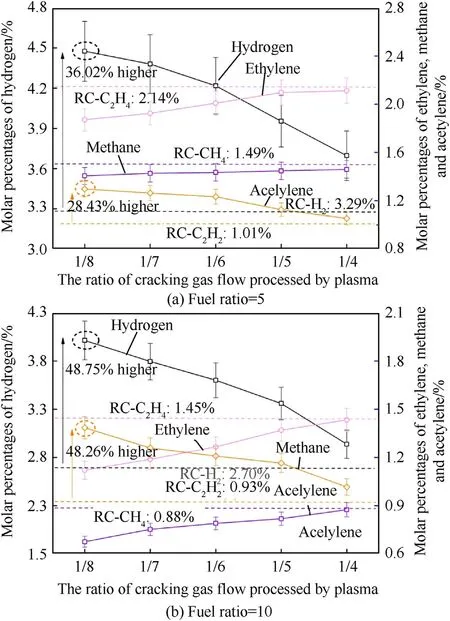

Take the concentration of pre-combustion cracking product as the reference value.When the fuel ratio is 5,the pre-combustion cracking gas with different flow rates is passed into the plasma cracker for adjustment,and the results are shown in Fig.4(a).The concentrations of hydrogen and acetylene increase from the reference value,while that of ethylene and methane decrease.When the plasma treatment flow rate is 1/8 of the total cracking gas flow rate,the component concentration changes the most,and the hydrogen and acetylene concentrations increase by 36.0 % and 28.4%relative to the reference value,respectively.The rise and fall of the concentration of the cracking product components indicate that the plasma can crack the species with larger molecular weight into hydrogen and acetylene with the smallest molecular weight,which achieves the purpose of plasma adjustment,which has important value for improving fuel activity.The conversion of products is the result of the combined effect of the hightemperature pyrolysis characteristics of equilibrium plasma and the chemical dynamics effects of non-equilibrium plasma of the gliding arc plasma[35].The result also reveals a phenomenon,that is,with the increase of the flow rate of the plasma treatment cracking gas,the decrease degree of ethylene and methane concentration decreases,while the increase degree in the concentration of hydrogen and methane weakens.It shows that when the flow rate increases,the ability of plasma adjustment weakens,which is directly related to the decrease of the specific input energy expressed in Fig.2(c)as the flow rate increases.Fig.4(b)is the product analysis result at the fuel ratio of 10.The effect of the plasma treatment flow rate on the adjustment capability is the same as the fuel ratio of 5.The difference is that when the cracking gas flow rate is 1/8 of the total flow rate,the hydrogen and acetylene concentration values increase by 48.8 % and 48.3 %,respectively.Although the increase amplitude of component prone to detonation is larger,the final concentration after adjustment is not higher than that when the fuel ratio is 5 because of the large fuel ratio and the low reference concentration.Nevertheless,plasma adjustment has shown greater potential at high fuel ratio.To a certain extent,it makes up for the defect that the degree of precombustion cracking is not enough when the fuel ratio is high.

Fig.4.Variation of cracking products adjusted by plasma with treatment flow rate under the fuel ratio of(a)5 and(b)10.

4.Conclusions

The work in this paper proves the feasibility and advantages of the plasma adjusting pre-combustion cracking products,which plays a reference role in engineering applications.However,the plasma adjusting pre-combustion cracking products is still facing severe challenges.On the one hand,it is necessary to develop a small volume plasma power supply with higher output power.On the other hand,it is necessary to further improve the upper limit of the cracking gas flow that can be processed by the plasma with better adjustment effect.Once the above two problems are solved,the transformation of results will be just around the corner.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgements

This work was supported by the National Natural Science Foundation of China(Grant Nos.91941301,91941105,52025064,51790511).

杂志排行

Defence Technology的其它文章

- Influence of local stiffeners and cutout shapes on the vibration and stability characteristics of quasi-isotropic laminates under hygrothermo-mechanical loadings

- General design principle of artillery for firing accuracy

- Data-driven prediction of plate velocities and plate deformation of explosive reactive armor

- Modeling of unsupervised knowledge graph of events based on mutual information among neighbor domains and sparse representation

- Analysis of the effect of bore centerline on projectile exit conditions in small arms

- Adaptive sliding mode control of modular self-reconfigurable spacecraft with time-delay estimation