Dynamic Mechanical Behavior and Constitutive Relation of Shipbuilding E36 Steel

2022-06-18,-,,

,-,,

(1.Naval Research Academy,Beijing 100161,China;2a.State Key Laboratory of Explosion Science and Technology;b.Institute of Advanced Structure Technology,Beijing Institute of Technology,Beijing 100081,China)

Abstract: The σ-ε relation of shipbuilding E36 steel under different strain rates (0.0002-3900 s-1)was studied by the MTS (materials test system) and the split Hopkinson press bar (SHPB), two im⁃proved Cowper-Symonds models and the parameters were obtained, and then the applicability of the models was investigated. The experimental results show that shipbuilding E36 steel has remarkable strain rate effect and nonlinear strain hardening effect.The dynamic constitutive model of shipbuilding E36 steel can describe the dynamic mechanical behaviors under high strain rate.

Key words:E36 steel;impact loading;dynamic mechanical behavior;Cowper-Symonds model

0 Introduction

In the whole life, warships may suffer from collision, underwater explosion[1], internal blast[2]and other loads.The prediction of the deformation and failure modes of the ship structure under var⁃ious dynamic loads by means of test and numerical simulation are the basis for the ship designers to carry out protective design. Due to the huge cost of experiments such as explosion, the United States and other western countries pay more and more attention to the role of numerical simulation in predicting the performance of warships against underwater explosion and internal blast[3-5]. In or⁃der to carry out the numerical simulation, it is usually necessary to have high-precision calculation method and accurate material constitutive relationship. Previous studies have shown that the calcu⁃lation error caused by unreasonable constitutive relation is even greater than that of grid and calcu⁃lation method[6-7].

Shipbuilding E36 steel is a kind of ship steel developed in China in the 1980s. It is widely used in frigates and other warships. Early research shows that the yield stress of steel under high strain rate is far greater than that under quasi-static loading[8]. Li et al[9-11]carried out the material mechanical properties test of shipbuilding low carbon steel under complex stress state and high strain rate, and gave the dynamic constitutive model. Zhu et al[12]studied the relationship between the dynamic stress and the strain rate of 921 steel. Yao et al[13]studied the dynamic mechanical properties of 917 steel for ship and obtained some parameters based on JC model. Li et al[14-15]car⁃ried out the dynamic mechanical properties test of 945 and 907A steel, and obtained the dynamic mechanical constitutive model and parameters. Different ship steels have different dynamic me⁃chanical properties,which cannot be described by unified parameters and models.It is necessary to carry out the static and dynamic tests of shipbuilding E36 steel, and obtain the corresponding con⁃stitutive models and parameters for supporting ship protection design.

Based on the quasi-static tensile testing machine,Hopkinson pressure bar,Hopkinson tension bars etc., experiments about mechanical behavior of E36 steel at different strain rate ranges were carried out.Two types of modified CS models were gained.

1 Experiment method

1.1 Quasi-static tensile experiments

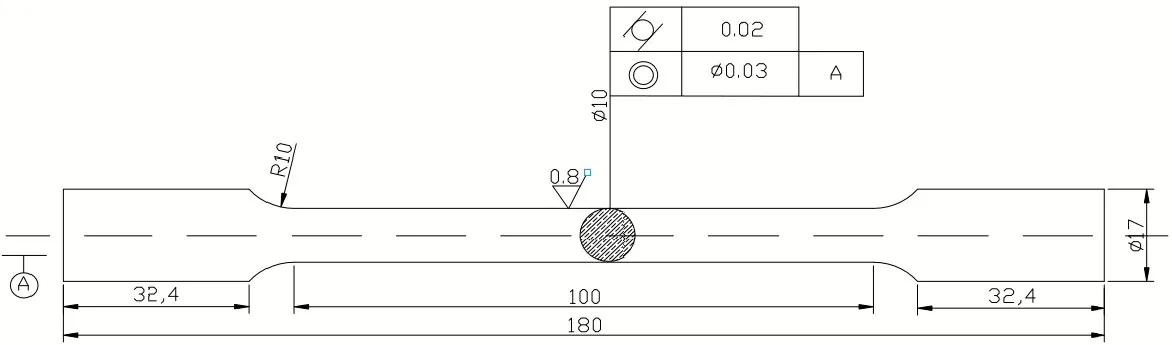

The quasi-static constitutive relation at normal temperature was obtained by uniaxial tensile test. Specimens were designed referring to GB/T228-2002, which was 10 mm in diameter and 100 mm in length, as shown in Fig.1. Experiments were carried out by using INTRON 5882 microcom⁃puter control universal material testing machine at room temperature. Testing machine loading rate was 0.6 mm/min(the strain rate was 3.3×10-4s-1).

Fig.1 Tension specimen at room temperature

1.2 Experimental principle of SHPB

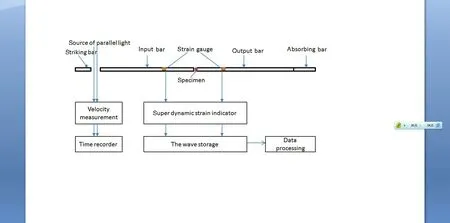

The dynamic response of E36 steel was gained by Hopkinson pressure bar[8], and verified by Hopkinson tension bar. The incident wave, the transmit wave and the reflected wave in Hopkinson bar were obtained respectively through the strain gauges pasted on the rod. The schematic of Hop⁃kinson bar diagram was shown in Fig.2.The typical incident,transmitted and reflection waves were shown in Fig.3.

Fig.2 Split SHPB equipment

Fig.3 Incident,reflected and transmitted pulse of specimen

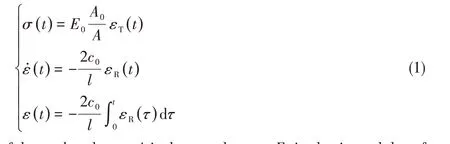

One-dimensional stress and strain uniformity are both effectiveness hypothesis Hopkinson bar. Combined with physical continuity conditions and stress balance condition, the stress, strain and strain rate of the specimens could be obtained as the calculation formula:

whereA0is the cross section area of the push rod type,Ais the sample area,E0is elastic modulus of compressive bar,lis the initial specimen length,c0is one-dimensional stress wave velocity in the compressive bar,ε̇is strain rate,εTis transmitted strain pulse,andεRis reflected strain pulse.

1.3 Design of SHPB specimen

In order to confirm specimen length to diameter ratio used in the experiment,the inertia effect of the specimen, section friction effect, two-dimensional effects, etc. should be taken into account.In order to meet the one-dimensional stress hypothesis and reduce friction between compressive bar and the specimen,the length to diameter ratio should not be too small.But in order to satisfy the homogeneity assumption and reduce volatility effects caused by the error, the specimen should be thin. Influence of the inertia effect was considered in Ref.[16], it was suggested that the sample length to diameter ratio bel/d= 3 /4. Research showed that in Ref.[17] considering influence of the strain hardening effect, the length to diameter ratio should be 0.5 or so. Considering the above factors,the final geometry size of the specimen wasΦ8 mm×6 mm.

2 Result and analysis

2.1 Experimental result

Quasi-static tensile tests(strain rate of the specimen was about 3.3×10-4s–1)were divided into three groups, and the yield stress was obtained by average method. Necking of the specimen oc⁃curred apparently in the process of the experiment,and the Bridgeman method[18]was used to modi⁃fy true stress strain curve.

Dynamic mechanical properties test was carried out by Hopkinson pressure bar of 14.5 mm in diameter. By the incident wave, reflected wave and transmitted wave signal, three wave methods were used for data processing.Eq.(1)was used to get the corresponding strain rate and stress-strain relations.The relevant experimental data was shown in Tab.1.

Tab.1 Dynamic mechanic behavior of shipbuilding E36 steel

Stress-strain curves under different strain rates are shown in Fig.4. It could be seen from the elastic stage of the stress-strain curves that the elastic modulus of E36 steel had no obvious change with increased strain rate. Under the condition of quasistatic loading, the yield strength was 430 MPa. With the increase of strain rate, the material yield stress increased. When the strain rate reached 2880 s-1,the yield stress was 598 MPa.

As shown in Fig.4, the specimen elongation under different strain rates was obviously differ⁃

Fig.4 The dynamic engineering stress-strain curve of experimental data

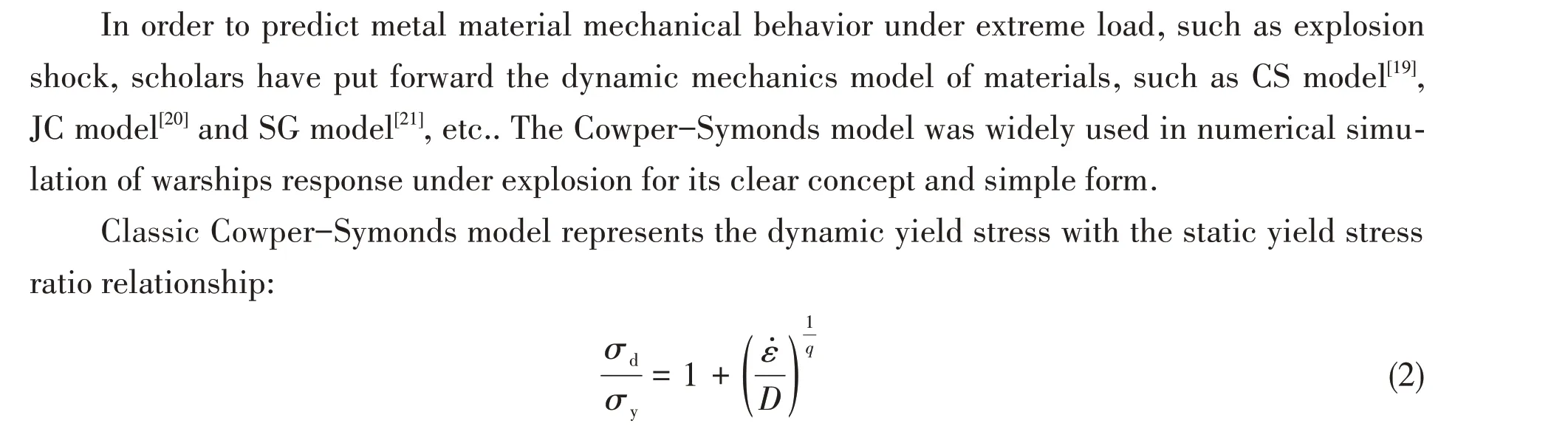

2.2 Constitutive model and parameters fitting

whereσdis the dynamic yield stress,σyis the static yield stress,ε̇ is strain rate for material,Dandqare material constants. Least square method was used for experimental data for data fitting(D=5698.7,q=1.92). The experimental data and fitting the curve were shown in Fig.5. It could be seen that CS model can effectively predict the dynamic yield stress along with the change of strain rate.

2.3 Correction and verification of the model

2.3.1 Dynamic tension test and verification

In order to verify that the results of the constitutive relation obtained by dynamic compression were suitable for dynamic tension, Hopkinson bar equipment (SHTB) was used to carry out the dy⁃namic tensile test.Specimen core section size wasΦ2 mm×4 mm.

Fig.6 shows the dynamic tensile yield stress and the strain rate. It could be seen that withD=5698.7 andq=1.92, the curve of the two parameters had good agreement with the dynamic tensile test results. Cowper-Symonds model parameters could predict E36 dynamic tensile mechanical properties of E36 steel.

Fig.5 Relationship between dynamic compress yield stress and strain rate(D=5698.7,q=1.92)

Fig.6 Relationship between dynamic ten⁃sile yield stress and strain rate

2.3.2 Strain strengthen modified

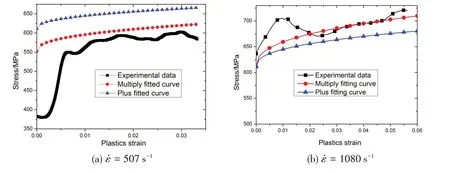

CS model was relatively accurate in predicting strengthening effect of strain rate, but not enough in predicting strain hardening. Referring to JC model, the‘multiply’formed strain harden⁃ing model was as follows:

whereσwas flow stress,σ0= 430 MPa,B= 214 MPa,n= 0.4.

It could be seen in Fig.7 that the‘multiply’formed modified CS model was more accurate than‘addition’formed one when the strain rate was lower than 1000 s-1, that could be used in low velocity crash simulation.Otherwise,‘addition’formed modified CS model was more accurate than‘multiply’formed one when the strain rate was higher than‘multiply’formed model,that could be used in near field underwater explosion.

Fig.7 Dynamic flow stress of shipbuilding E36 steel

In addition, due to the high strain rate and the large plastic deformation, metal local tempera⁃ture was easy to rise,which could not be ignored[7].In contact explosion,penetration,such as ultrahigh speed collision problem, the local strain rate is higher than the 3000 s-1, even higher than the 104 s-1,SG and ZA constitutive model could be selected,instead of CS model which ignores temper⁃ature effect.

3 Conclusions

By quasi-static tension and SHPB experiment, the dynamic mechanical properties of E36 steel were studied, and the two different strain rate models were compared. Two types of CS models were set up and compared with experiment data.Some conclusions are drawn as following:

(1) E36 steel is strain rate sensitive material, and the yield stress increases with increasing strain rate;

(2) CS model is more accurate than JC model to describe E36 yield stress under high strain rate.The values of parametersDandqare 5698.7 and 1.92,respectively;

(3) The‘multiply’formed modified CS model is more accurate than‘addition’formed model when the strain rate is lower than 1000 s-1, while‘addition’formed is more accurate when strain rate is higher than 1000 s-1.

杂志排行

船舶力学的其它文章

- Study on the Loads of Connectors for a RMRC Hexagon Enclosed Platform Model in Waves

- Numerical Simulation of Semisubmersible Accommodation Platform Going Alongside FPSO Under the Control of Dynamic Positioning System

- Behavior of Crude Oil Leakage from Underwater Damaged Hole of Oil Tank in Waves

- Dynamic Response of Shipbuilding Sandwich Plates with Functionally Graded Soft Core Subjected to Impulse Loading

- Dynamic Response Analysis of a New Semi-submersible Offshore Wind Turbine Based on Aerodynamic-Hydrodynamic Coupling

- Investigations on the Quasi-static Stability Behavior of an Innovative Subsurface Tension Leg Platform in Ultra-Deep Water(Part II)