Dynamic Response of Shipbuilding Sandwich Plates with Functionally Graded Soft Core Subjected to Impulse Loading

2022-06-18hoZHAO

-,-ho,,ZHAO N,-,

(a.School of Naval Architecture and Ocean Engineering;b.School of Science,Jiangsu University of Science and Technology,Zhenjiang 212003,China)

Abstract: A novel refined multi-layer dynamic model is presented in this paper for calculation of the dynamic response of functionally graded material (FGM) soft sandwich plates under impulse loading and for capturing of the micro-deformation of functionally graded soft core. The Navier's solution and Runge-Kutta method were used to solve governing equations. The accuracy of the present theory and solution were validated by comparing with FEM and open literature results. Then, a series of paramet⁃ric (impulse loading, skin/core thickness ratio and volume fraction distribution) studies were carried out to investigate the influence of the dynamic response,providing a theoretical basis for structural de⁃sign and application of functionally graded sandwich panels with soft FGM cores.

Key words:sandwich plate;soft FGM core;refined multi-layer dynamic model;impulse loading;dynamic response

0 Introduction

Functionally graded materials (FGMs)are novel multi-functional materials which were first in⁃troduced in 1984[1],gaining wide interest in various areas ranging from macro-scale (i.e.,ships,sub⁃marines, aircraft, vehicles, nuclear reactors, space-station structures, biomedical engineering, etc.)to micro- and nano-scales (i.e., shape memory alloys, atomic force microscopes, micro/nano-elec⁃tro-mechanical systems),due to material tailor ability,revolutionary properties,and enhanced func⁃tionality[2-3]. Sandwich structures with soft core have an excellent performance due to their ultralight weight, higher stiffness and strength to weight ratios, and energy absorption capability under blast/impact loading[4-5]. Generally, sandwich structures with FGM skin/core can be classified in⁃to three types:Type-A,sandwich structures with FGM skins and homogenous core[6];Type-B,sand⁃wich structures with homogenous skins and FGM core[7-8]; Type-C, sandwich structures with FGM skins and FGM core[9].In this study,analytical solution for dynamic response under impulse loading of Type-B sandwich plates are investigated.

Various studies have investigated mechanical properties,impact/blast response and energy ab⁃sorption capability of a wide range of engineering structures.Five types of theoretical models are of⁃ten used to analyze the dynamic mechanical behaviour of sandwich/FGM plates: equivalent singlelayer theory (ESLT), 3D elasticity theory[10-11], layer-wise theory (LWT)[12-13], von Kármán large de⁃flection theory[14-15]and other mixed theory[16~18]. The ESLT can be divided into three main catego⁃ries: classical plate theory (CPT)[19-20], first-order shear deformation theory (FSDT)[21-22], higher-or⁃der shear deformation theories (HSDTs)[23~26]and refined higher order shear deformation theories(RHSDTs)[27].In addition to theoretical research,there is a great deal of experimental and numerical research work.

Balkan and Mecitoğlu[28]investigated dynamic response behavior of a viscoelastic composite sandwich plate subjected to a non-uniform blast loading by theoretical,experimental and numerical study. Liu et al[29]investigated dynamic response and blast resistance of all-metallic sandwich plates with functionally graded close-celled aluminum foam core based on finite element simula⁃tions, which have a superior blast resistance. Chen et al[30]investigated dynamic response and de⁃sign optimization of clamped sandwich panels with two aluminum alloy skins and a layered-gradi⁃ent closed-cell aluminum foam core under impulse loading.Wang and Sun[31]performed experimen⁃tal and numerical study of sandwich panels with homogeneous and graded foam cores under blast loading to optimize and improve the blast resistance of graded core sandwich panels. Li and Wang et al[32]investigated dynamic response of metallic sandwich spherical shells with graded aluminum foam core under inner blast loading, the deformation of spherical shells, the energy absorption of each core layer, and propagation characteristic of stress waves in the foam core layers by finite ele⁃ment simulations. Xiang et al[33]investigated impulsive response of fully clamped rectangular metal sandwich plate with graded foam core by theoretical and finite element method, the analytical pre⁃dictions indicated that the negative graded design of the sandwich structures had a better impulsive resistance than uniform graded design, while the positive graded design was the worst. Ye et al[34-35]investigated energy absorption capability and anti-penetration performance of sandwich plate with aluminum foam core, along with dynamic response of aluminum foam core by experimental and fi⁃nite element method. Zhang et al[36]addressed the dynamic response of sandwich steel plates with three kinds of corrugated core arrangements consisting of identical core density subjected to dynam⁃ic air pressure loads by finite element model and a series of experiments. Xue et al[37]studied influ⁃ence of the panel thickness on the underwater impact resistance performance of the pyramid lattice sandwich structure based on the SPH-FEM method. The energy-absorption rate and the influence of the panel thickness on the impact resistance were studied in detail.

According to comprehensive literature survey,anti-impact and anti-explosive performance re⁃search of sandwich plates with FGM skins or core has attracted research attention in recent years.Most of the research work has focused on foam graded core, and the main research methods focus on original shear deformation theories, numerical simulation and a few experiment. In this paper, a novel refined multi-layer dynamic model for dynamic response of sandwich plate with soft function⁃ally graded core is presented; the Navier’s solution and Newmark method were used to solve gov⁃erning equations.The new model yields an accurate estimate of the dynamic response of functional⁃ly graded soft sandwich plate under impulse loading and can capture the micro-deformation of func⁃tionally graded soft core. The accuracy of the present model was validated by compared with FEM and open literature results.Then,a series of parametric study were carried out to investigate the dy⁃namic response, providing a theoretical basis for structural design and application of functionally graded sandwich panels with FGM soft cores.

1 Theoretical formulation

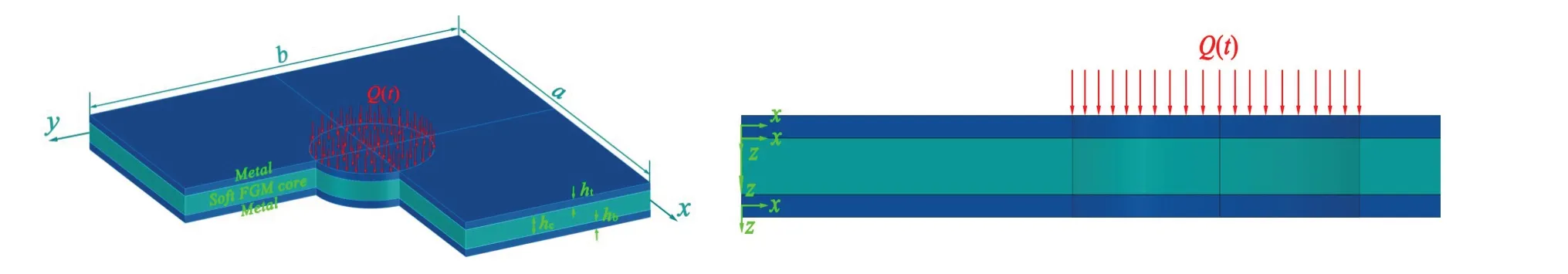

The global and local Cartesian coordinate system of a sandwich plate with soft FGM core is giv⁃en in Fig.1,which includes three local Cartesian coordinate systems and one global Cartesian coor⁃dinate system. The planez=0 coincides with the mid-plane of the sandwich plate in global Carte⁃sian coordinate system. The mathematical model was presented to solve frequency and deformation of sandwich plates with soft FGM core and isotropic skins.

Fig.1 Geometry and coordinate system of sandwich plate with soft FGM core

1.1 Sandwich plate with a soft FGM core and isotropic skins

The material properties for the soft FGM core vary through the core thickness with a power law distribution,which is given below:

wherePdenotes the effective material property,PuandPddenote the property of the top face and bottom face of the core,respectively,and‘p’is the exponent index.The effective material property is soft FGM core Young’s modulus in this study.

1.2 Refined multi-layer dynamic model for sandwich plates

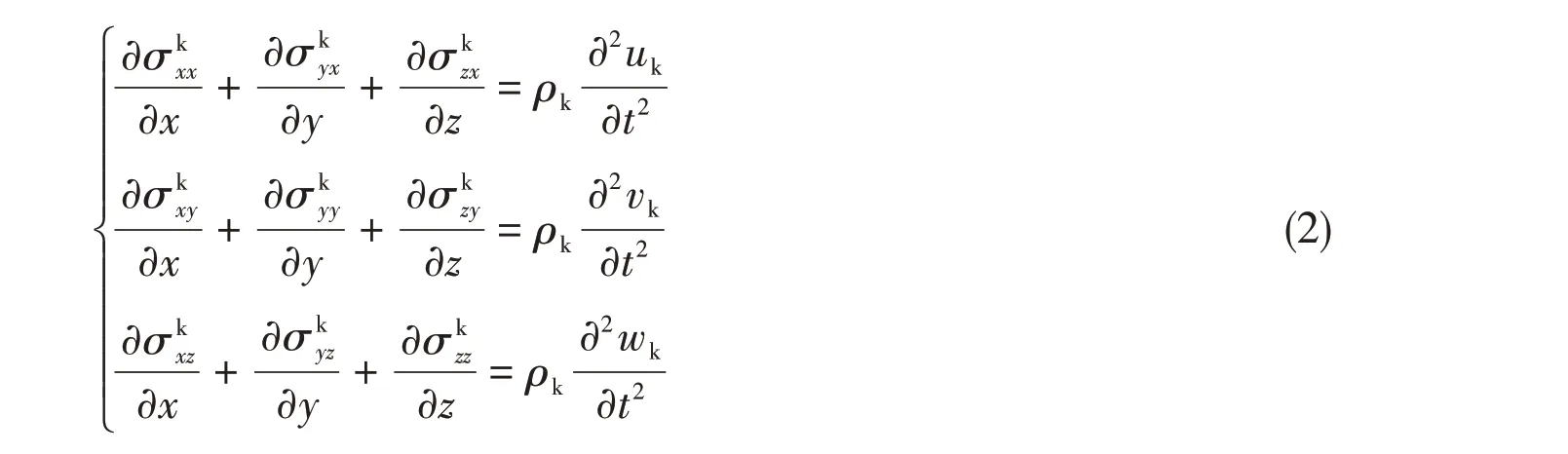

The equilibrium differential equations of the skin ply and core are governed by the following equations:

where the superscripts/subscripts k=t, c and b, stand for top, core, and bottom, respectively; (u,v,w)are unknown displacement components along the (x-,y-,z-)directions of the top,core and bot⁃tom skin plies, respectively;σxx,σyy, andσzzare the components of the normal stress; andσxy,σxz,andσyzare shear stresses.

The partial differential equations describing the equilibrium of the skin plies in Eq.(2) can be integrated as

where the superscripts/subscripts r=t and b,stand for the top,and bottom,respectively;Nxx,Nyy,Mxx,andMyyare in-plane force resultants and moment resultants,hris thickness of the skin plies,andρris density of the skin plies.

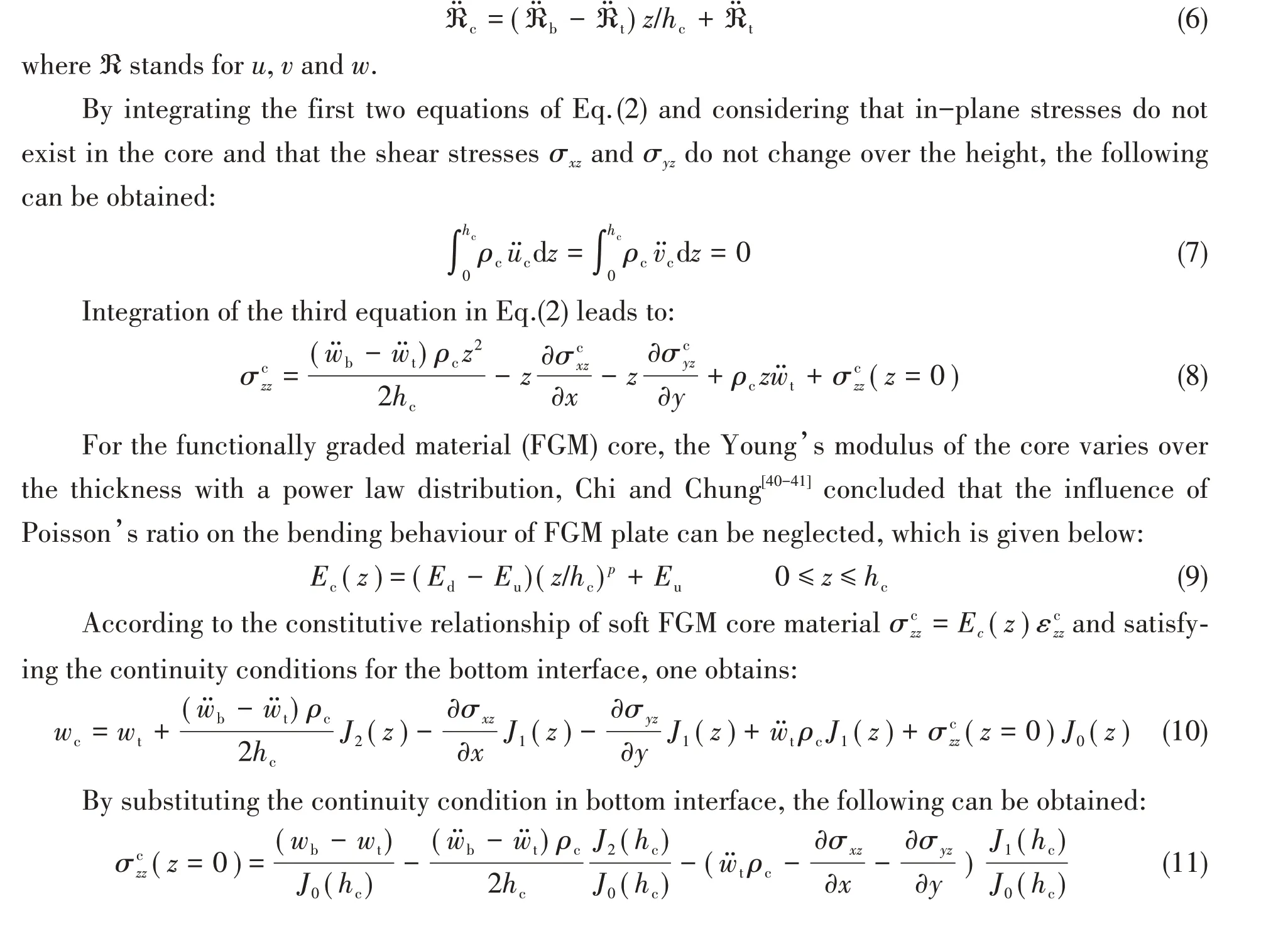

The soft FGM core was treated as a three-dimensional deformable elastic medium, and the core cross-section does not remain planar (nonlinear displacement field in the core). By using the equilibrium equations given in Eq.(2),assuming in-plane stresses of the soft FGM core are relative⁃ly small[38]and the shear stress is constant over the thickness of the soft FGM core, the horizontal and vertical accelerations of the core can be approximated by linear interpolation[39]as

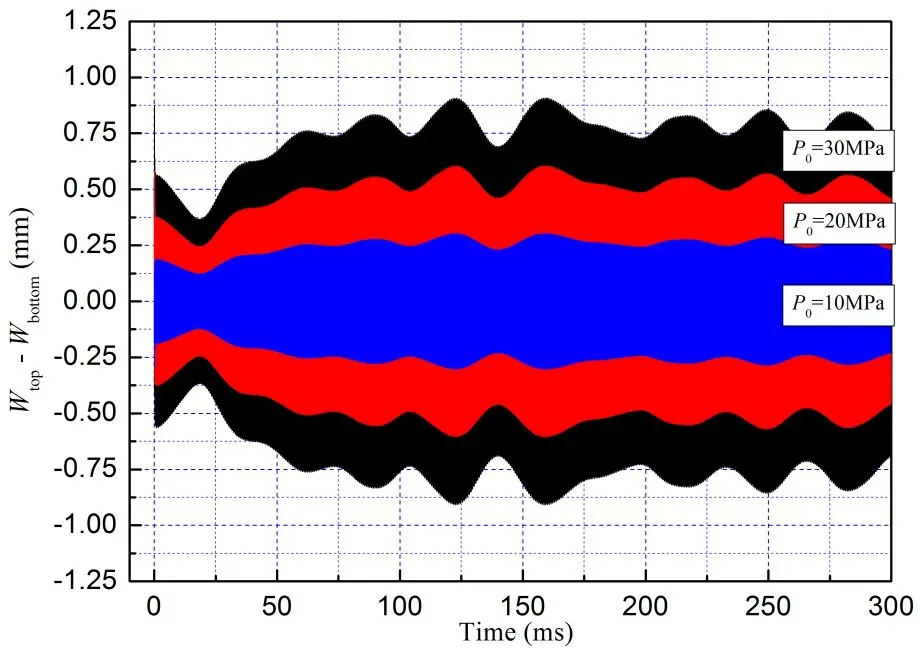

wherevobandvotare they-direction displacements of the top and bottom skins at their respective neutral axes.

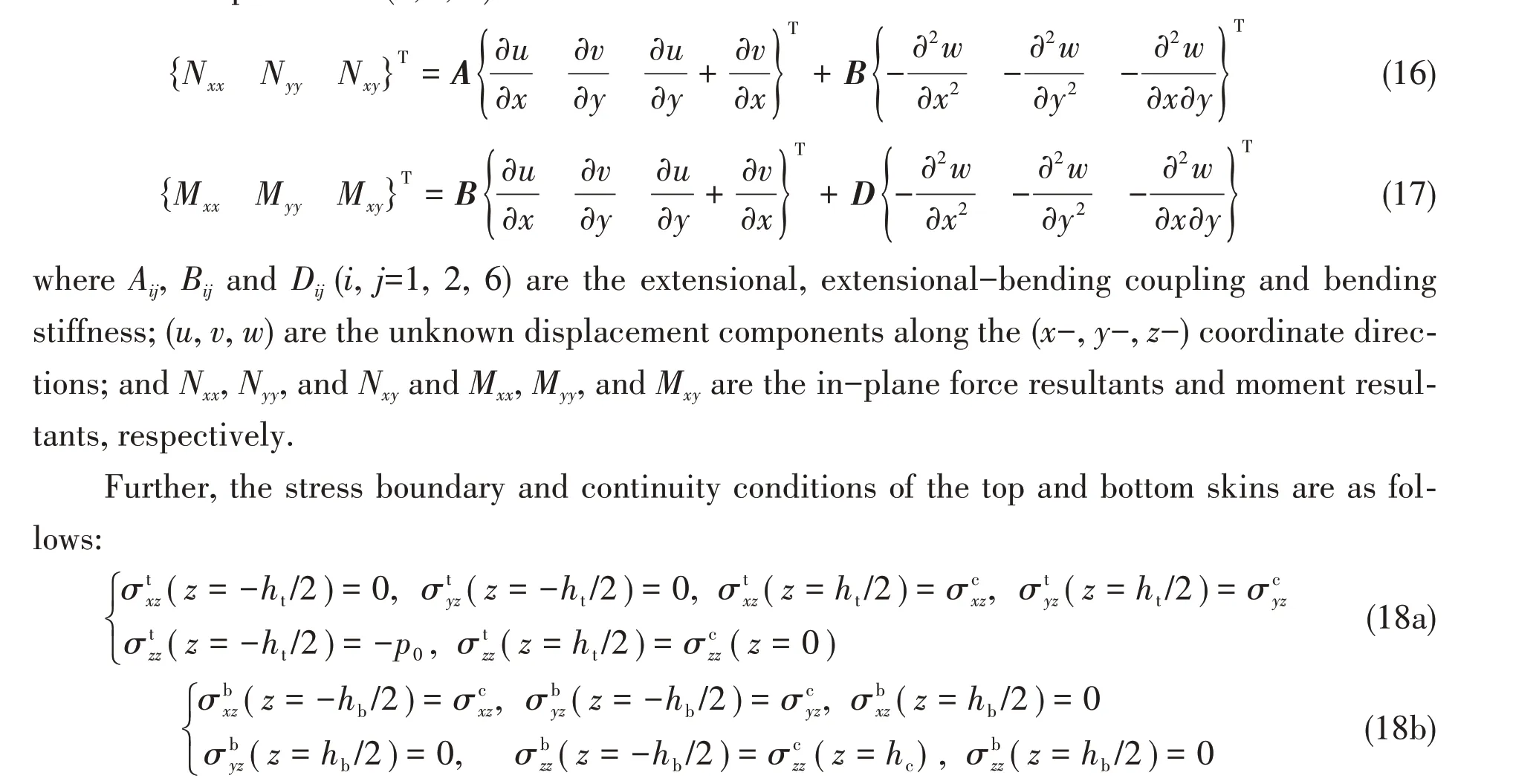

The constitutive equations of the skins due to the high stiffness and low thickness, the inplane force and moment resultants of the skins (including the bending-stretching coupling effects)in terms of displacement(u,v,w)are:

whereq0is the external loading acting on the top skin.

1.3 Governing equations of sandwich plate

The top and bottom skins in this study are composed of isotropic materials,Bij=0 (i,j=1, 2, 6),A16=A26=0 andD16=D26=0, and according to the stress resultants from Eqs.(16)-(17) and the bound⁃ary conditions from Eq.(18), the governing equations of Eqs.(3)-(5), (14) and (15) can be expressed in terms of displacements and shear stresses(uot,uob,vot,vob,wt,wb,σxz,σyz)as follows:

2 Analytical solutions

A simply supported rectangular sandwich plate with lengthaand widthbunder transverse loadqis considered. Based on the Navier approach, the following expansions of displacements and shear stress(uot,uob,vot,vob,wt,wb,σxz,σyz)are assumed as:

3 Results and discussion

In this chapter, model parameters will be studied to verify the proposed approach, then the in⁃fluence of skin/core thickness ratio and volume fraction distribution of sandwich plate with soft FGM core are investigated on dynamic response.

3.1 Validation and convergence analysis

In this section, the novel refined multi-layer dynamic model for sandwich plate with function⁃ally graded soft core is to be compared with FEM and third shear deformation theory (TSDT), in which a simply supported square sandwich plate consists of functionally graded soft core and homo⁃geneous top and bottom face sheet made of same materials. In FEM simulations, the SHELL and SOLID element of ANSYS element library is used to discretize the solution domain and the Block Lanczos scheme is applied to obtain free vibration solutions.

The following material properties are applied for the top,bottom skins and the core[8].

For the top and bottom skins:Et=Eb=70 GPa;μt=μb=0.3. The Young’s modulus of the FGM core varies through the thickness with a power law distribution,which is given in Eq.(9).

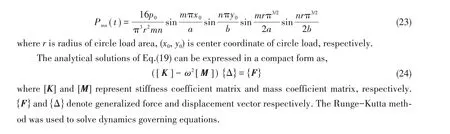

In this case,Ed=3.8 GPa,Eu=0.7 GPa,μc=0.3,ρt=ρb=2702 kg/m3,ρc=200 kg/m3,h=ht+hc+hbanda=b=5 m,hc=a/50,r=0.5 m. The natural fre⁃quency for various skins to FGM core thickness ratio valuesht/hc={1,0.5,0.1,0.05},and the pow⁃er indexp={0,0.5,1,2,3}.The natural frequency is compared with FEM results, the dynamic re⁃sponse of sandwich plate with FGM core is com⁃pared with TSDT by Reddy[42],it can be seen from Tab.1 and Fig.2 that the present results are in good agreement with FEM and TSDT.

The impulse loading is simplified as pressure and applied to the top skin of sandwich plate over a central circular region of radiusr, the exponential pressure is adopted in this paper. For the exponential load,the pressure is described by exponentially decaying time dependent history[29],as

Fig.2 Comparison of the central transverse dis⁃placements of sandwich plates by differ⁃ent theories

whereP0is the peak pressure taken as 10 MPa,20 MPa and 30 MPa,respectively,andt0is the time taken by the shock wave decay to 1/e of the peak pressure,taken as 100 μs.

Tab.1 Comparison of the natural frequencies of sandwich plates with FGM core in different modes

Fig.3 Central transverse displacement by using different terms of expansion

The central transverse displacement under 10 MPa peak pressure by using a single term ex⁃pansion (m,n=1), 9 terms of expansion (m,n=1, 3, 5), 25 terms of expansion (m,n=1, 3, 5, 7, 9),one hundred terms of expansion (m,n=1, 3, …,19) and 225 terms of expansion (m,n=1, 3, …,29) is shown in Fig.3. The results show that the Fourier series solutions using the present theory have a good convergence. For example, the 9 terms of expansion yield almost the exact solu⁃tions.

3.2 Influence of peak pressure

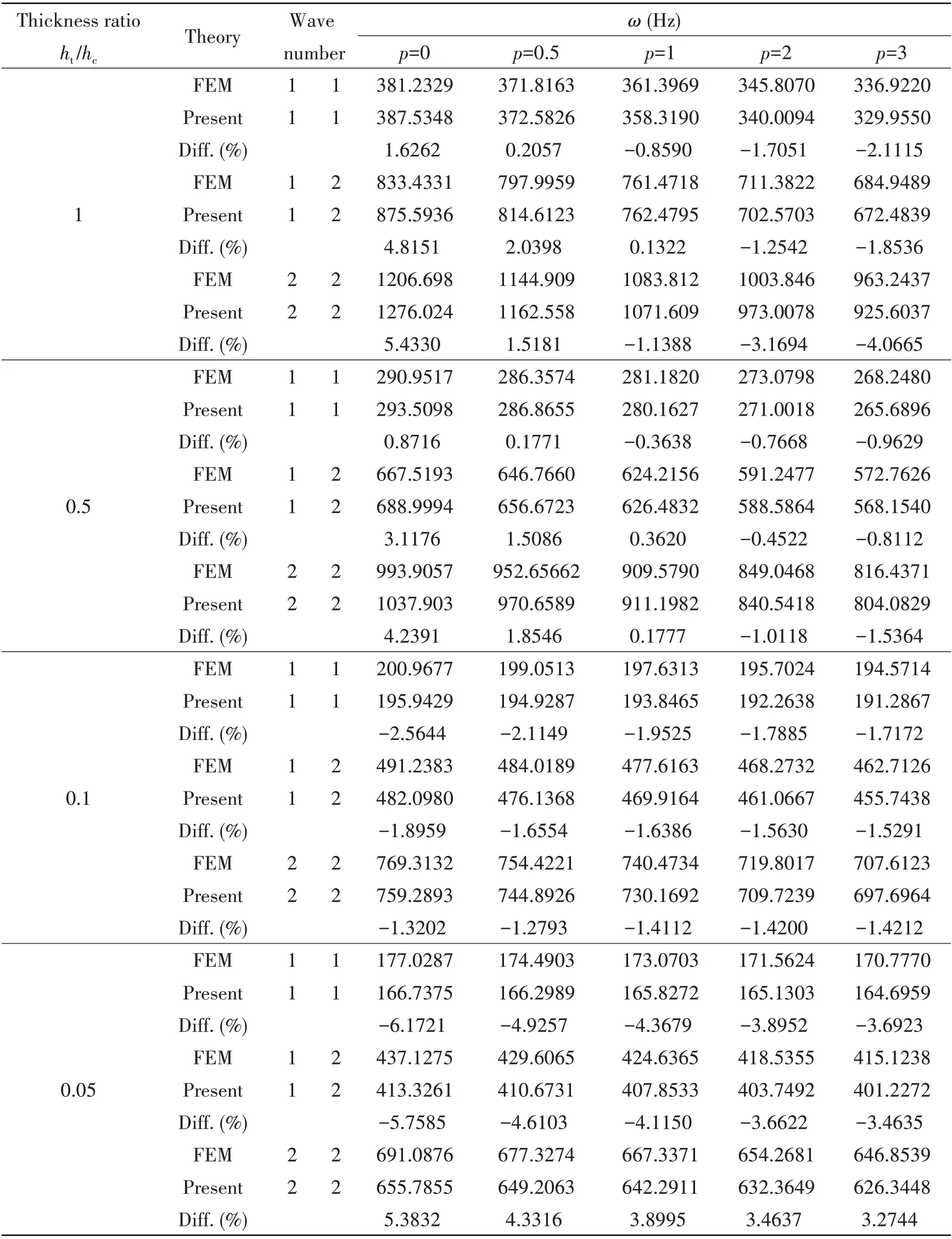

Fig.4 Comparisons of transverse displacement and velocity under different air blast loadings

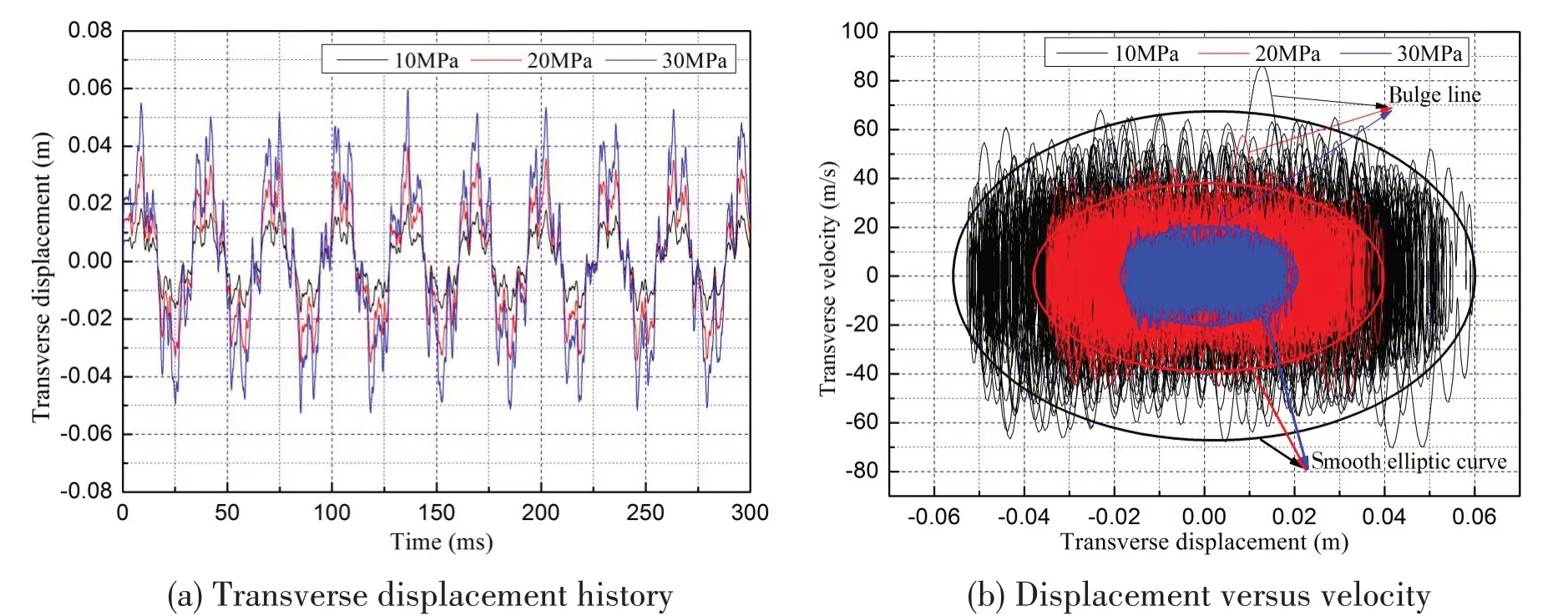

Fig.5 Difference in displacement between top skin and bottom skin history curve

The difference in displacement between top skin and bottom skin history curve of sandwich plate with soft FGM core under different air blast loadings is shown in Fig.5, it can be ob⁃served that the soft FGM core maximum com⁃pression deformation are 0.91 mm, 0.61 mm and 0.30 mm,respectively.It can be found that the present theory can accurately calculate the dynamic response of functionally graded soft sandwich plate under impulse loading and cap⁃ture the micro-deformation of functionally graded soft core. Compared with overall dis⁃placement and soft FGM core compression de⁃formation, it can be found that the former is much bigger than the latter.

3.3 Influence of skin/core thickness ratio

In this section, comparative studies are carried out for soft FGM core sandwich plate with dif⁃ferent skin/core thickness ratios.Four different FGM skin/core thickness ratioht/hc=1,0.5,0.1 and 0.01 (hcis constant) are analyzed. The air blast loading with peak pressurep0=10 MPa is applied and the power indexp=1 in this section.The transverse displacement history curve in top skin cen⁃tral point with different thickness ratios are shown in Fig.6. It can be concluded that the maximum displacement of sandwich plates with soft FGM core decreases with the increase of the skin/core thickness ratio, because with the increase of the thickness ratio, the total thickness of sandwich plates increases,so the overall stiffness is increased.Compared with time interval of wave,it can be discovered that the bigger of the skin/core thickness ratio is, the smaller the period of sandwich plate with soft FGM core is.

The transverse displacement versus velocity curves are shown in Fig.6(b),it can be discovered that the transverse displacement versus velocity curves is close to elliptical shape,the length of ma⁃jor half axis of sandwich plate withht/hc=1,0.5,0.1 and 0.01 are 0.0017 m,0.0039 m,0.0193 m and 0.122 m,respectively.The lengths of minor axis are 2.17 m/s,5.16 m/s,20.89 m/s and 65.23 m/s,re⁃spectively. We can discover that every quasi-elliptic curve has one bulge line caused by air blast loading,and the smooth elliptic curve represents free vibration.

Fig.6 Transverse displacement history in top skin central point with different thickness ratios

3.4 Influence of the power index p of soft FGM core

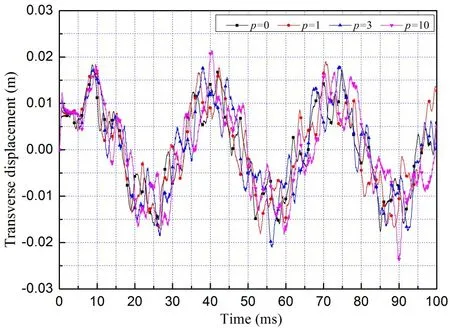

In this section, the influence of power indexpof soft FGM core is studied. The transverse dis⁃placement history curve of sandwich plates with different FGM power indexp={0, 0.5, 1, 2, 3} is shown in Fig.7.It can be seen that the overall transverse displacement is very close in different pow⁃er indexp, that is because the Young’s moduli of skins and core differ greatly, so the influence of FGM core power indexpis small.It can be discovered from Fig.7 that the maximum transverse dis⁃placement increases with the increase of the power indexp, and the natural frequency decreases with the increase of the power indexp.The difference in displacement between top skin and bottom skin history curve with different power indexpis shown in Fig.8, it can be found that the present theory can accurately calculate the dynamic compression deformation of functionally graded soft sandwich plate with different power indexp, the compression deformation increases with the in⁃crease of power indexp. In view of the relationship between compression deformation change rate and power indexp, it can be discovered that the growth rate of compression deformation increases with the increase of power indexpin a certain range of power index variation.

Fig.7 Comparison of transverse displacement histories with different power index p

Fig.8 Difference in displacement between top skin and bottom skin history with different power index p

4 Conclusions

In this paper, a novel refined multi-layer dynamic model for dynamic response of sandwich plates with soft functionally graded core was presented; the Navier’s solution and Runge-Kutta method were used to solve governing equations.In addition,a series of parametric studies were car⁃ried out to investigate dynamic performance of sandwich plates with different FGM soft cores. The following conclusions are obtained:

(1) The present model can accurately calculate dynamic response of functionally graded soft sandwich plates under impulse loading and capture the micro-deformation of functionally graded soft core with different power indexp. The presented model offers an effective and accurate predic⁃tion for free vibration modes, as well as for dynamic response of sandwich plates with soft FGM or isotropic core.

(2) The transverse displacement versus velocity curves of sandwich plates with soft FGM core is near to elliptic shape,every quasi-elliptic curve has one bulge line caused by impulse loading.

(3) It is indicated from parametric study that the maximum displacement of sandwich plates with soft FGM core decreases with the increase of the skin/core thickness ratio,the maximum trans⁃verse displacement increases with the increase of the power index p,and the growth rate of compres⁃sion deformation increases with the increase of power indexpin a certain range of power index vari⁃ation.

杂志排行

船舶力学的其它文章

- An Approach for Connector Arrangement of Very Large Floating Structures

- Structural Redundancy Verification for Side Shell Frame of Single Side Skin Bulk Carriers

- Dynamic Mechanical Behavior and Constitutive Relation of Shipbuilding E36 Steel

- Buckling Characteristics and Influencing Factors of Composite Grid Sandwich Plates with Soft Core

- Investigation on the Resistance of Planing Hulls Based on a New Mathematical Model

- Application of Computational Methods for Hydrodynamic Pressure Caused by Supercritical Ship in Shallow,Finite or Deep-depth Waters