基于传递熵的泵站管道振动传递路径特性分析

2021-11-26张建伟黄锦林曹克磊叶合欣李紫瑜

张建伟,杨 灿,黄锦林,曹克磊,叶合欣,李紫瑜

基于传递熵的泵站管道振动传递路径特性分析

张建伟1,杨 灿1,黄锦林2,曹克磊1,叶合欣3,李紫瑜1

(1. 华北水利水电大学水利学院,郑州 450046;2. 广东省水利水电科学研究院,广州 510635;3. 广东省水利水电技术中心,广州 510635)

泵站管道因结构复杂,产生多种振源,且振动的传递路径难以确定,对输水管道的安全运行具有较大威胁。针对此问题,以某泵站管道为研究对象,结合原型观测数据与传递熵方法识别主振源的振动传递路径;并以信息传递率为定量标准,验证管道振动传递路径的有效性。结果表明:稳定运行及开机时,叶频引起的振动为主振源,并由弯管或三通管处向其他部位传递,其信息传递率均值分别为27.2%与42%;关机时,水流脉动及管-水耦合引起的振动为主振源,且振动主要在阀门与弯管或三通管之间呈周期性传递,信息传递率均值为51.4%;稳定运行时信息传递率较低,表明在镇墩控制下,管道稳定运行时传递能量较少,但开关机时,管道阀门、弯管及三通管处仍有较大振动能量传递。本研究方法受管道结构影响较小,能准确识别管道主振源,且从能量角度识别振动传递路径,相较于传统方法更加高效、直观。研究结果有助于准确识别泵站管道主振源的振动传递路径,展现管道各工况下的危险部位,并提出减振措施,为泵站管道运行管理提供理论依据。

泵;振动;传递路径;传递熵;信息传递率;振源分析

0 引 言

近年来,随着水利事业迅速发展,大流量、高扬程梯级输水泵站的修建日益增多,能够满足跨流域供水的需求,降低水资源匮乏地区用水压力。压力管道是跨流域调水工程中不可或缺的重要组成部分,其运行状态关系到农业生产灌溉等用水问题,管道的安全稳定运行极为重要[1-4]。由于水力学的复杂特性与管道结构的自身特点,泵站管道在各工况下产生的振动十分强烈;但管道振动来源复杂,振动传递路径难以分析;管道的安全运行存在隐患,管道结构损伤逐渐积累,耐久性不断下降,进而引发安全事故[5-6]。因此,解决管道振源分析及传递路径识别问题,对农业、石油、化工等领域获得持久经济效益,极为重要。管道振动系统包括振源、振动传递路径和受振体。其中管道主振源的能量通常在全部振动能量中占有较大比例,是管道振动传递路径研究的关键[7-8]。但压力管道结构复杂,产生的振源多样且难以区分,振动传递路径更加复杂,管道主振源的振动传递路径识别存在较大困难[9],对管道的安全运行极为不利。针对此问题,王海军等[10]基于结构声强理论测得水电站厂房振动传递路径;欧阳金惠等[11]利用脉动压力测试得出抽水蓄能电站厂房振动原因;伍鹤皋等[12]通过解析计算和数值模拟相结合的方法得到水电站厂房振动传递路径;职保平等[13]基于振动基本理论、矩阵微分理论等方法分析轴流式水轮机振动传递路径。尽管上述研究在振动传递路径上取得一定成果,但大多是对水电站厂房振动传递路径识别;泵站管道结构与水电站厂房这类大体积混凝土结构不同,水电站厂房振动一般由尾水传递至支墩;而泵站管道较长且弯管、叉管较多,振动来源复杂,振动传递识别困难,并且将传递熵用于泵站管道结构振动传递路径的研究成果几乎空白。

本文以某灌区提水泵站管道为研究对象,依据原型观测数据,利用传递熵与信息传递率识别泵站管道结构振源及振动传递路径。首先通过原型试验观测数据,绘制频谱图并计算能量占比,获得泵站管道不同工况下的振源组成,并确定主振源;然后使用传递熵方法识别该泵站管道不同工况下主振源传递路径,确定振动传递方向;最后在传递熵基础上利用信息传递率定量描述泵站管道主振源的传递规律,并提出优化管道运行方法及减振措施。

1 泵站管道振源识别设备及方法

1.1 泵站管道振动测试设备及参数

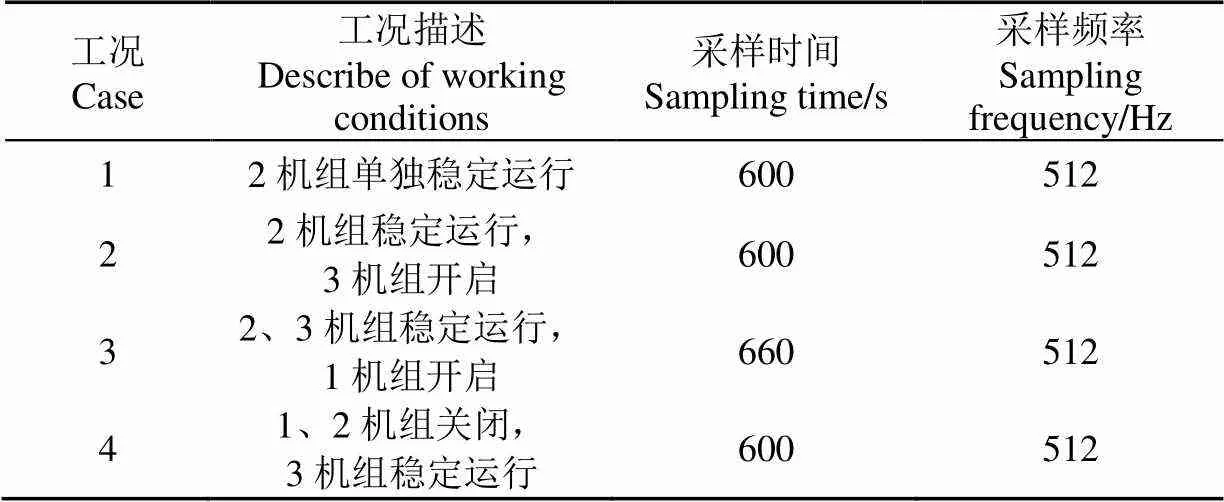

由于该灌区提水泵站管道的铺设方式具有代表性,并且便于检测,能够得到精确的原始数据。以7泵站管道作为试验对象,管道平面布置如图1所示。管道共连接3台机组,额定转速均为600 r/min;在泵站管道关键位置布置10个测点,每个测点均放置3个拾振器(、、方向),分别位于支管、主管及两者交汇处,如图1a所示。由工程经验可知,管道开关机时管道振动剧烈,且为与稳定运行工况对比,在原型试验测试4种工况,工况、采样时间及频率见表1。

1.2 泵站管道振源测试及分析方法

通过拾振器在泵站管道上采集数据,对所有测点振动信号进行频谱图分析,获得各测点振动主频。由于泵站管道结构、边界条件,机械条件,水力条件复杂多样,泵站管道产生振动的原因难以确定。根据以往研究可知,振动主要从3个方面进行分析:水力方面、机械方面和电磁方面[14-18]。由于泵站管道不同结构产生的振动特性各不相同,在计算管道内各振源及其所占比例时可采用式(1)。

式中为不同振源的能量,J;为总能量,J;x为不同振源能量所占比例。

表1 管道原型试验测试工况

1.3 泵站管道振动传递路径识别方法

1.3.1 传递熵方法

泵站管道内部结构复杂、边界条件、水体与管道的耦合作用,使其振动传递路径识别产生困难。而传递熵作为度量不同时间序列之间的耦合关系以及信息传递关系的熵函数,是一个动态过程关于另一个动态过程所产生的传递信息。传递熵的计算,不需要考虑物体的结构,而是从振动过程中不同位置振动信息传递熵值的大小,判断信息之间相关程度,来揭示振动传递的方向。传递熵计算方式简单、识别敏感性与可靠度较高、适用于线性与非线性数据,对解决管道振动传递路径识别问题具有较大优势。

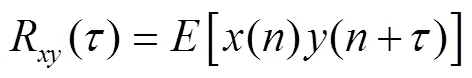

按照Schreiber定义的传递熵[19],如果在与这两个稳定的传递过程中,对的作用影响概率为,这个过程表示为式(2)。为了减少计算传递熵时繁琐的高维概率密度函数,在不影响利用传递熵判断传递的方向和关联程度的前提下,Nichols等[20]和Overbey等{21]假设过程和过程均为一阶马尔可夫过程,即==1。式(2)可以化简为式(3)。

其中:

1.3.2 信息传递率方法

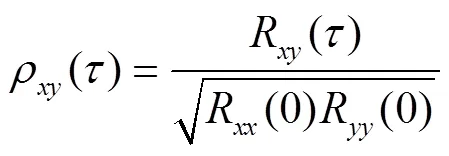

为了更全面地描述管道振动的传递路径,利用信息传递率[21](Information Translate Rate,ITR),ITR来计算管道振动能量传递效率。信息传递率通过两点传递熵值计算,对振动信号之间的传递效率进行定量描述,可以更进一步描绘管道振动传递路径。对于管道振动传递过程和,信息传递率计算过程为式(7),其中(y→x)与(x→y)与式(2)相同,表示与两点间的传递熵:

式中ITR为信号到的传递率;|(y→x)(x→y)|为到的振动信息净传递量。

2 泵站管道振源分析及振动传递路径识别结果

2.1 振源分析

泵站管道在开关机时振动较为剧烈,可以检测到具有代表性的振动频率,本文以开关机工况时靠近泵站机组的两测点为例,方便检测更全面的频率。图2为工况2和工况4下两拾振器信号频谱图。由图2a知,3机组开机时,7#拾振器幅值最大为59.38 Hz,是引起管道振动的主频,69.25、29.69 Hz等为次频;同理可知,1、2机组关机瞬间,其主频为39.63、69.38 Hz。

统计泵站管道4种工况下各测点振动主频出现次数并列表,表2为4种工况下主频出现次数统计。由表2可知,测点频率在0~2、9.9、19.8、29.7、39.6、49.5、59.4及60 Hz以上均有分布。

由式(1)结合振动信号频谱图与表2,参考已有研究[22]计算得出泵站管道振源。总结如下:1)低频成分。泵站管道稳定运行时,低流速的水流冲击管道引起的低频脉动, 频率在10 Hz以下;2)叶频、转频。泵机运行时,高速水流与机组叶片摩擦,使管道产生中高频振动,由泵机参数计算,该泵站机组叶频为60 Hz左右,属于中高频率,存在管道各种工况下所有位置,多为振动主频,且比较突出;3)管-水耦合产生的高频。泵站开关机瞬间,由于水锤作用,管道内产生高速水流冲击管道产生高频振动。

表2 各工况主要频率出现次数统计表

在研究该灌区提水泵站管道的振源对管道的影响时,参考Zhang等[23-24]对管道振动的研究,结合上述振源实测分析与振源组成计算,得出7 泵站管道不同工况下影响管道振动的主振源:1)机组稳定运行时,叶频、转频倍频产生的振动能量占比最大,是管道振动的主振源。2)机组开机时,叶频仍是主振源。3)机组关机时,低频水流与管-水耦合引起的高频振动占比最大,为管道主振源。

2.2 管道振源传递路径识别

2.2.1 传递熵识别管道振动传递路径

在泵站管道中,弯管及三通管、阀门等应力集中部位与水流作用产生强烈激振力,引起弯管及三通管处产生汽蚀和空蚀,加大管道表面摩擦力,进而增强弯管及三通管处振动;并且在机组开关机时,流体流速变化较大,管道内形成水锤,产生压力波与反射波,在阀门与其余部位产生具有一定周期的振动,沿着管道传递。

基于上述对泵站管道振源研究,结合CEEMDAN和SVD方法[25]进行主振源特征信息提取,得到泵站管道 4种工况下的主振源及其对应频率;并利用传递熵方法对各工况下相邻测点间主振源振动传递路径进行识别。泵站管道在三通管与弯管间的振动较为明显,为研究泵站管道振动传递路径规律,以工况2下16测点至13与19测点间的传递熵为例分析开机时三通管传递至直管与弯管的传递路径,以工况4下10测点至7测点、9测点至3测点分析关机时三通管传递至直管与弯管的传递路径。7泵站管道在工况2与工况4下,上述两测点之间的传递熵值随时间的变化曲线分别见图3、图4。

由图3可知:(16→19)的传递熵值明显大于(19→16);(16→13)的传递熵值明显大于(13→16)。表明在2号泵机开机期间,由叶频引起的振动通过弯管或三通管传向其余支路的信息量明显较多,可以判断泵站管道在开机状况下叶频振动由弯管或三通管传至其他部位;同理,由图 4 传递熵值关系可以得出:当1号、2号泵机关机时,水流脉动和管-水耦合振动,在关机瞬间闸门附近由于水锤使振动增强,稍高于弯管处;并在短时间内在闸门附近与弯管或三通管之间进行周期性传递。通过对泵站管道各个工况相邻测点的传递熵值进行计算分析,得出与上述结果一致结论,限于篇幅不再赘述。

2.2.2 信息传递率识别管道振动传递路径

在传递熵基础上使用信息传递率对7泵站管道相邻测点之间主振源的能量传递进行定量分析。以工况2与工况4测点的信息传递率为例,所选测点原则与计算传递熵时原因一致,不再赘述。表3为两工况不同测点之间主振源的信息传递率。

表3 工况2与工况4相邻测点之间的信息传递率

由表3可知:工况2泵站管道信号在3组测点之间的传递率分别为37.3%、44.8%与28.6%,表明弯管处很大一部分能量传至管道其余部位;工况4泵站管道信号在3组测点之间的传递率分别为59.6%、27.0%与45.6%。表明关机时,短暂时间内振动由阀门传至弯管部位,能量较高的部位在阀门附近,振动在阀门弯管及三通管之间传递。

结合表4泵站管道各工况对应的管道主要位置主振源信息传递率均值所占比例可知:泵站机组稳定运行时,叶频,转频引起的振动传递到弯管及三通管处产生了更强的耦合振动,信息传递率均值为27.2%,稳定运行时传递率相对较低,主要是镇墩、支墩等装置起到了一定的减振消能;泵站机组开机时,叶频振动主要从弯管及三通管向管道其他部位传递,信息传递率均值为42.0%,表明开机时弯管及三通管处较多能量传递至管道其它部位;泵站管道关机时,管道内低频水流脉动及由水击引起的高频振动,在阀门附近与弯管及三通管之间周期性传递,信息传递率均值为51.4%,表明阀门与弯管及三通管处较多能量传递至管道其它部位。结果证明,从信息传递率角度定量分析各工况下主振源的传递方向与传递熵值分析结果一致,表明信息传递率能有效识别泵站管道振动传递方向。

表4 不同工况下两测点之间信息传递率及其均值对比

通过上述分析可知,在管道不同工况下,弯管、三通管与阀门是振动最为剧烈的部位,在危险位置提出减振措施对管道安全运行与泵站管道结构设计尤为重要。如利用粒子阻尼为动力装置基座减振;利用磁流变减振技术控制管道低频振动。此外还可以通过增加弯管半径、减少弯头个数等方式来降低弯管、三通管、阀门的振动。且由上述研究结合表4分析可得,机组开关机时,与之相邻机组管道中,中高频振动比例及振动传递率明显增加,管道开关机会加剧多个管道之间振动的相互作用。因此可通过避免同时开启多个机组等方式来优化开关机模式。

3 结 论

通过该泵站管道原型观测资料结合传递熵与信息传递率方法对管道振动的传递路径特性进行研究,可得如下结论:

1)泵站机组稳定运行时:管道内叶频、转频倍频引起的振动为主振源,振动主要从弯管及三通管向其它部位传递,信息传递率均值为27.2%,稳定运行时传递率相对较低,主要是镇墩、支墩等装置起到了一定的减振消能。

2)泵站机组开机时:管道内叶频引起的振动为主振源,振动主要从弯管及三通管向管道其它部位传递,信息传递率均值为42.0%,表明开机时弯管及三通管处较多能量传递至管道其它部位。

3)泵站机组关机时:管道内低频水流脉动及管-水耦合引起的高频振动为主振源,振动主要在阀门与弯管及三通管之间进行周期性传递,信息传递率均值为51.4%,表明阀门与弯管及三通管处较多能量传递至管道其它部位。

传递熵与信息传递率能准确描绘管道振动的传递路径,确定管道危险部位,且能为管道减振与优化开关机方法提出建议。

[1] 司乔瑞,唐亚静,甘星城,等. 立式管道泵进水弯管和叶轮的参数化分析与验证[J]. 农业工程学报,2020,36(17):54-63.

Si Qiaorui, Tang Yajing, Gan Xingcheng, et al. Parametric analysis and verification of curved inlet pipe and impeller of vertical inline pump[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(17): 54-63. (in Chinese with English abstract)-

[2] Kan E, Muratov A, Yusupov M, et al. Calculation of water hammer on the pressure pipeline of modernized irrigation pumping station[J]. IOP Conference Series: Materials Science and Engineering, 2021, 1030(1): 012127.

[3] Guo X, Su X, Yuan Y T,et al. A novel method for the complex tube system reconstruction and measurement[J]. Sensors (Basel, Switzerland), 2021, 21(6): 2207.

[4] Tokarev A P, Spirin S E, Godovskiy D A. Hydrodynamic causes of vibration in the pipe bend of process pipelines[J]. IOP conference Series: Earth and Environmental Science, 2021, 666(3): 032051.

[5] 张春晋,孙西欢,李永业,等. 流固耦合作用对筒装料管道车水力输送内部流场特性的影响[J]. 农业工程学报,2018,34(18):299-307.

Zhang Chunjin, Sun Xihuan, Li Yongye, et al. Effect of fluid-structure interaction on internal flow field characteristics of tube-contained raw material pipeline hydraulic transportation[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(18): 299-307. (in Chinese with English abstract)

[6] 董霄峰,练继建,王海军. 运行状态下海上风机结构振源特性研究[J]. 振动与冲击,2017,36(17):21-28.

Dong Xiaofeng, Lian Jijian, Wang Haijun. Study on vibration source features of offshore wind power structure under the operational conditions[J]. Journal of Vibration and Shock, 2017, 36(17): 21-28. (in Chinese with English abstract)

[7] Kiryukhin A V, Mil’man O O, Ptakhin A V, et al. Spatial active damping of vibrations, vibration forces, and pressure fluctuations transferred via expansion joints in liquid-Filled pipelines[J]. Thermal Engineering, 2021, 68(7): 543-555.

[8] Kulakov P A, Rubtsov A V, Afanasenko V G, et al. Influence of technical condition parameters on the period of safe operation of technological pipelines[J]. Journal of Physics: Conference Series, 2020, 1515(3): 032063.

[9] Zhang J W, Hou G, Wang H, et al. Operation feature extraction of flood discharge structure based on improved variational mode decomposition and variance dedication rate[J]. Journal of Vibration and Control, 2020, 26(3/4): 229-240.

[10] 王海军,涂凯,练继建. 基于结构声强的水电站厂房振动传递路径研究[J]. 水利学报,2015,46(10):1247-1252,1260.

Wang Haijun, Tu Kai, Lian Jijian. Research on transfer path of vibrations of hydropower house based on structural intensity[J]. Journal of Hydraulic Engineering, 2015, 46(10): 1247-1252, 1260. (in Chinese with English abstract)

[11] 欧阳金惠,耿峻,许亮华,等. 某大型抽水蓄能电站厂房强烈振动原因分析与减振措施研究[J]. 水利学报,2019,50(8):1029-1037.

Ouyang Jinhui, Geng Jun, Xu Lianghua, et al. Analysis on strong vibration cause of the powerhouse of a large-scale pumped-storage power station in China and study on its vibration reduction measure[J]. Journal of Hydraulic Engineering, 2019, 50(8): 1029-1037. (in Chinese with English abstract)

[12] 伍鹤皋,周星,石长征,等. 基于多路径传递的水电站厂房流激振动分析[J]. 华中科技大学学报:自然科学版,2020,48(3):104-109.

Wu Hegao, Zhou Xing, Shi Changzheng, et al. Flow-induced vibration analysis of hydropower plant under two transfer paths[J]. Journal of Huazhong University of Science and Technology: Natural Science Edition, 2020, 48(3): 104-109. (in Chinese with English abstract)

[13] 职保平,尼玛,秦净净,等. 轴流式水轮机组振动传递路径分析[J]. 振动与冲击,2020,39(17):64-69,93.

Zhi Baoping, Ni Ma, Qin Jingjing, et al. Transmission path analysis for vibration of axial flow turbine unit[J]. Journal of Vibration and Shock, 2020, 39(17): 64-69, 93. (in Chinese with English abstract)

[14] Li W, Zhang H L, Qu W. Stress response of a straight hydraulic pipe under random vibration[J]. International Journal of Pressure Vessels and Piping, 2021,194(PA): 104502.

[15] 韩俊艳,郭之科,李满君,等. 纵向非一致激励下非均匀场地中埋地管道的振动台试验研究[J]. 岩土工程学报,2021,43(6):1147-1156.

Han Junyan, Guo Zhike, Li Manjun, et al. Shaking table tests of buried pipelines laid in inhomogeneous soil under longitudinal non-uniform seismic excitation[J]. Chinese Journal of Geotechnical Engineering, 2021, 43(6): 1147-1156. (in Chinese with English abstract)

[16] 郭强,周建旭,黄亚,等. 考虑流固耦合的厚壁输水管水锤和振动特性分析[J]. 农业工程学报,2020,36(21):137-144.

Guo Qiang, Zhou Jianxu, Huang Ya, et al. Water hammer and vibration analysis of a thick-wall pipe considering fluid-structure interaction[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(21): 137-144. (in Chinese with English abstract)

[17] Qu W, Zhang H L, Li W, et al. Dynamic characteristics of a hydraulic curved pipe subjected to random vibration[J]. International Journal of Fatigue, 2021,193: 106359.

[18] 刘厚林,明加意,肖佳伟,等. 基于稳定运行性的离心泵导叶安装位置优化试验与分析[J]. 农业工程学报,2016,32(7):93-99.

Liu Houlin, Ming Jiayi, Xiao Jiawei, et al. Optimal experiment and analysis on installation position for diffuser of centrifugal pump based on operating stability[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(7): 93-99. (in Chinese with English abstract)

[19] Schreiber T. Measuring information transfer[J]. Physical Review Letters, 2000, 85(2): 461-464.

[20] Nichols J M, Seaver M, Trickey S T, et al. Detecting impact damage in experimental composite structures: An information-theoretic approach[J]. Smart Materials and Structures, 2006, 15(2): 424-434.

[21] Overbey L A, Tood M D. Dynamic system change detection using a modification of the transfer entropy[J]. Journal of Sound and Vibration, 2009, 322(1/2): 438-453.

[22] 张建伟,江琦,王涛. 基于原型观测的梯级泵站管道振源特性分析[J]. 农业工程学报,2017,33(1):77-83.

Zhang Jianwei, Jiang Qi, Wang Tao. Analysis of vibration characteristics of pipeline of trapezoid pumping station based on prototype observation[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(1): 77-83. (in Chinese with English abstract)

[23] ZhangJ W, Li Z Y, Yan P, et al. Method for determining optimal analysis length of vibration data based on improved multiscale permutation entropy[J]. Shock and Vibration, 2021: 6654089

[24] Zhang J W, Hou G, Cao K L, et al. Operation conditions monitoring of flood discharge structure based on variance dedication rate and permutation entropy[J]. Nonlinear Dynamics, 2018, 93(4): 2517-2531.

[25] 张建伟,侯鸽,暴振磊,等. 基于CEEMDAN与SVD的泄流结构振动信号降噪方法[J]. 振动与冲击,2017,36(22):138-143.

Zhang Jianwei, Hou Ge, Bao Zhenlei, et al.Signal de-noising method for vibration signal of flood discharge structure based on CEEMDAN and SVD[J]. Journal of Vibration and Shock, 2017, 36(22): 138-143. (in Chinese with English abstract)

Analysis of the pipeline transfer path characteristics of pumping stations based on transfer entropy

Zhang Jianwei1, Yang Can1, Huang Jinlin2, Cao Kelei1, Ye Hexin3, Li Ziyu1

(1.,,450046,; 2.,510635,; 3.510635,)

The transmission path of vibration difficult to determine has posed a great threat to the safe operation of water transmission pipeline, due mainly to the complex structure of pump station pipeline, where there are many vibration sources. In this study, an attempt was made to analyze the pipeline transfer path characteristics of pumping stations using transfer entropy. The pipeline of 7 pump stations in an irrigation area was also taken as the research object. Firstly, a prototype test was carried out to obtain the spectrum diagram, and energy proportion, thereby analyzing the main vibration source of pipeline vibration. Then, a transmission entropy method was used to identify the vibration transmission path of the main vibration source in the pump station pipeline under various working conditions. The effectiveness of the pipeline vibration transmission path was finally verified when taking the information transmission rate as the quantitative standard. The results show that: 1) The main vibration source was caused by the blade frequency and frequency doubling in the pipeline, mainly transmitting from the elbow and tee pipe to other parts when the pumping station unit operated stably. Furthermore, the average information transmission rate was 27.2%. More importantly, the transmission rate was relatively low during stable operation, mainly because the anchor block, buttress, and other devices played a critical role in the vibration reduction and energy dissipation. 2) The main vibration source was also caused by the blade frequency in the pipeline, mainly transmitted from the elbow and tee to other parts of the pipeline, when the pump station unit starting up. The average information transmission rate was 42%. It was found that a large part of the energy at the elbow and tee was transmitted to other parts of the pipeline during startup. 3) The main vibration source was the high-frequency vibration caused by low-frequency water flow pulsation and pipe water coupling in the pipeline when the pump station unit was shut down. The vibration was mainly transmitted periodically between the valve, elbow, and tee. The average information transmission rate was 51.4%. It can be seen that a large part of the energy from the valve, elbow, and tee was transmitted to other parts of the pipeline. Correspondingly, the information transmission rate of each working condition showed that a large part of vibration energy at the pipeline valve, elbow, and tee pipe was still transmitted to other parts. Whether the machine was switched on or off, the energy transmitted by the pipeline during the stable operation was less under the control of vibration reduction measures, such as anchor block. Therefore, the prototype observation data was selected to analyze the source of vibration through the spectrum diagram and energy proportion, where quantitatively determine the transmission relationship between vibration from the perspective of energy with the help of transmission entropy and information transmission rate, as well as the direction of vibration transmission. It was more efficient and intuitive than before, indicating great advantages in the application of vibration transmission path recognition. Consequently, this research can greatly contribute to accurately identify the vibration transmission path of the main vibration source in the pump station pipeline, thereby identifying the dangerous parts of the pipeline under different working conditions, where the vibration reduction measures can be further proposed. This finding can provide a promising theoretical basis for the operation and management of the pump station pipeline

pumps; vibration; transmission path; transfer entropy; information transmission rate; vibration source analysis

张建伟,杨灿,黄锦林,等. 基于传递熵的泵站管道振动传递路径特性分析[J]. 农业工程学报,2021,37(15):47-52.doi:10.11975/j.issn.1002-6819.2021.15.006 http://www.tcsae.org

Zhang Jianwei, Yang Can, Huang Jinlin, et al. Analysis of the pipeline transfer path characteristics of pumping stations based on transfer entropy[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(15): 47-52. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2021.15.006 http://www.tcsae.org

2021-04-29

2021-08-05

国家自然科学基金(51679091);广东省水利科技创新项目(2020-18);广州市科技计划(2020-ky34)

张建伟,博士,教授,研究方向为水利水电工程。Email:zjwcivil@126.com

10.11975/j.issn.1002-6819.2021.15.006

TV93; TB53

A

1002-6819(2021)-15-0047-06