Difference in corn kernel moisture content between pre-and postharvest

2021-06-02LlLuluMlNGBoXUEJunGAOShangWANGKeruXlERuizhiHOUPengLlShaokun

Ll Lu-lu,MlNG Bo,XUE Jun,GAO Shang,WANG Ke-ru,XlE Rui-zhi,HOU Peng,Ll Shao-kun

Institute of Crop Sciences,Chinese Academy of Agricultural Sciences/Key Laboratory of Crop Physiology and Ecology,Ministry of Agriculture and Rural Affairs,Beijing 100081,P.R.China

Abstract The harvest method of shelling corn (Zea mays L.) kernels in the field decreases labor costs associated with transporting,drying and threshing the crop.However,it was previously found that the kernel moisture content increased after field harvest,which decreased the value of corn kernels.To identify the reasons underlying the increase,we conducted a multiyear and-area trial in the Huang-Huai-Hai Plain,China and performed a staged-harvest test at several phases of kernel dry-down.The test investigated a range of parameters such as the kernel moisture content pre-and post-harvest,the kernel breakage rate,the amount of impurities,and the moisture content of various other plant tissues.An analysis of 411 pairs of pre-and post-harvest samples found that kernel moisture content after harvest was 2.2% higher than that before harvest.In the staged-harvest test,however,a significant increase was only observed when the kernel moisture content before harvest was higher than 23.9%.The increase in post-harvest kernel moisture content was positively associated with the pre-harvest kernel moisture content,breakage rate and impurity rate.Typically,at harvest time in this region,there is a significant fraction of immature crops with a high moisture content,resulting in kernels that are prone to breakage or impurities that ultimately lead to increases in water content after harvest.Therefore,we suggest using hybrids that quickly wither late in the growing stage.Additionally,farmers should delay harvest in order to minimize the pre-harvest kernel moisture content and thus reduce breakages and impurities,thereby improving the quality of kernels after harvest and the efficiency of corn kernel farming in China.

Keywords:kernel moisture content,pre-harvest and post-harvest,corn

1.lntroduction

The practice of harvesting kernels in the field is an attractive alternative to harvesting ears by virtue of simplifying production lines,thereby reducing labor costs and streamlining the path to market (Liet al.2016,2017).However,in practice,kernel harvest leads to an increase in kernel moisture content after harvest,significantly reducing the value.Despite these important downstream effects,there is little information published on the mechanistic association between moisture and kernel harvest methods to date.

The observed difference between pre-and post-harvest moisture contents may be related to the fact that broken kernels and non-kernel impurities are often mixed together with high-quality kernels after harvest.Previous studies have extensively reported on the causes of breakages and impurities,including information on breakage susceptibility of corn kernels (Waelti 1967;Paulsenet al.1983;Martinet al.1987),kernel moisture content at harvest (Jennings 1974;Cloningeret al.1975;Plett 1994;Chaiet al.2017;Wang and Li 2017;Liet al.2018),combine harvester thresher components and parameters (Waelti and Buchele 1969;Hall and Johnson 1970;Chowdhury and Buchele 1978;Johnson 1981;Wanget al.2016),and others.In order to achieve a high-quality harvest,farmers must decide upon the best maize hybrid strain,an optimal harvest time,the walk speed of harvester,thresher settings,and a wide range of other factors.Slight changes in each of these parameters can lead to significantly different rates of breakages and impurities.Researchers have previously reported an unexpectedly high breakage and impurity rate in the Huang-Huai-Hai Plain (Liet al.2017,2019;Minget al.2018;Wanget al.2018a,b;Xueet al.2019),particularly when the plants were still green at harvest and the pre-harvest kernels had high moisture content.These conditions can actually cause the post-harvest kernel sample to take on a light green color after staining due to liquids released from the plant.To date,however,it is not understood how the moisture content in postharvest kernels is affected by breakage and impurity rates.

In this work,we conducted a multi-year and multi-area trial in the Huang-Huai-Hai Plain and a staged-harvest test at several phases of kernel dry-down to investigate the kernel moisture content pre-and post-harvest,the breakage rate,the impurity rate,and the moisture content of various plant tissues.Our objectives were to:1) identify the pre-and post-harvest differences in kernel moisture contents and 2) analyze factors that affect the differences.This work provides a foundation for future efforts to increase the efficiency of corn kernel production in China.

2.Materials and methods

2.1.The multi-year and-area trial

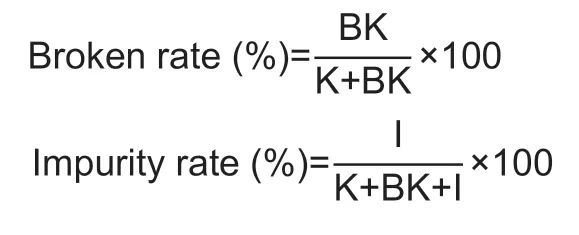

We conducted a multi-year and-area trial across 26 cities/counties of five provinces including Henan,Hebei,Shandong,Anhui,and Jiangsu in the Huang-Huai-Hai Plain from 2013 to 2017.Details of the experimental sites,harvest dates and harvesters are listed in Table 1.The hybrid strains reported herein were common strains used within China or new strains released by the Crops Variety Approval Committee.Hybrids and their numbers varied widely among experimental sites,and are not described in this paper.

A total of 411 pairs of pre-and post-harvest corn kernel specimens were collected.On the harvest day,pre-harvest kernel moisture content was measured using a PM8188 moisture meter (KETT,Japan).For each hybrid,a total of five ears were picked,threshed and then mixed.The kernel moisture content was averaged by taking the closest three values from 3–5 measurement replicates.After harvest,samples were removed from the harvester bin to measure moisture content with the same meter.

2.2.The staged-harvest trial

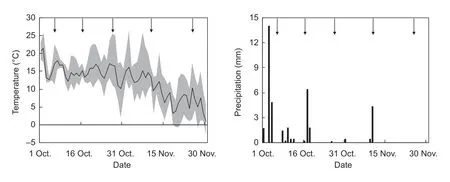

In 2017,a staged-harvest trial was conducted at several phases of the kernel dry-down process at the Comprehensive Experimental Station of Chinese Academy of Agricultural Sciences in Xinxiang,Henan (35°10´N,113°47´E).On 17 and 18 June,2017,a total of 28 hybrids were sown at a density of 67 500 plants ha–1,where each hybrid had a planting area of 600 m2with 10 rows and each row had a length of 100 m.There were five harvests,on 6 Oct.,16 Oct.,27 Oct.,10 Nov.,and 25 Nov.,that all used the same combine harvester (Lovol GE50) and the same harvester driver to reduce bias.Daily air temperature and precipitation during harvest are shown in Fig.1.

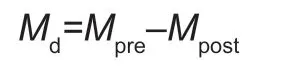

In the staged-harvest test,the kernel moisture contents at pre-harvest (Mpre) and post-harvest (Mpost) at each timepoint were measured using the same method as described above.The difference (Md) was calculated as:

The relationship betweenMdandMprewas determined by fitting a bi-linear model:

whereais the difference value whenMpre<Mjoint,bis the rate of change of the difference whenMpre≥Mjoint,andMjointis the cut-off point between the two lines.

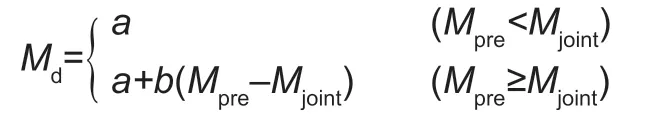

After each harvest,about 2 kg sample were taken out from the harvester bin to investigate the breakage rate and the impurity rate.Each sample was divided equally into three parts,and each part was hand-sorted into three components:high-quality kernels (K),broken kernels (BK)and non-kernel impurities (I) which included pieces of leaves,stalk,cob,husk,or ear-pedicel.Each component was weighed using an electronic scale.The breakage rate and the impurity rate were calculated as follows (Xieet al.2014):

Table 1 Characteristics of the experimental sites and harvesters in the multi-year and multi-area trial

Fig.1 Daily air temperature and precipitation from 1 Oct.to 30 Nov.in 2017.Arrows indicate the five harvest dates.The shadowed area in left represents the daily maximum temperature and the daily minimum temperature.

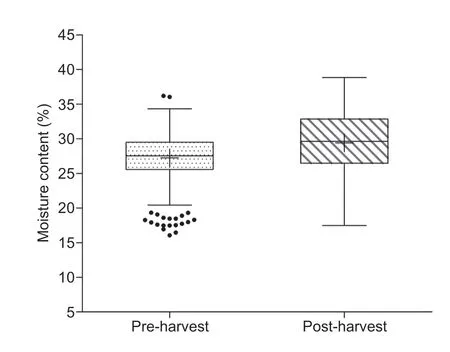

To measure the moisture content in plant tissues at each harvest,the fresh weights of the cob,husk,ear-pedicel,all the kernels from an ear,leaves,and the stalks from three nodes (the ear node,the first-upper-ear node and the firstsub-ear node) were measured using an electronic scale.The dry weights were determined after drying them in a forced-air oven at 85°C for 48 h.Then,the moisture contents of each tissue were calculated as follows:

2.3.Data analysis and figure

All mathematical calculations were carried out using Microsoft Office Excel 2010.Statistical analyses were performed in IBM SPSS Statistics 22.0.Figures were produced in Microsoft Office Excel 2010 and GraphPad Prism 5.0.

3.Results

3.1.Difference in the kernel moisture contents between pre-and post-harvest

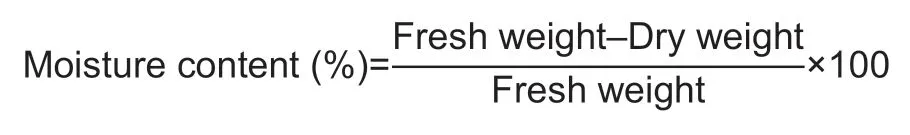

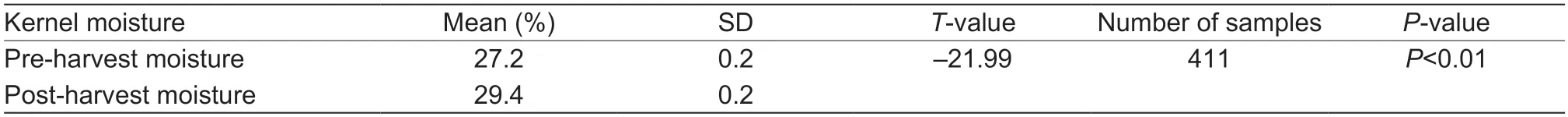

The analysis of the 411 couples of samples showed that,from 2013 to 2017,kernel moisture content after harvest was 29.4% on average with a regional range from 16.1 to 36.2%,and was 2.2 percentage points higher than that at pre-harvest-27.2% on average (Fig.2).Paired samplesT-test confirmed that there was a significant difference in kernel moisture content between pre-and post-harvest kernel samples (Table 2).

Fig.2 Kernel moisture contents of pre-and post-harvest samples in the multi-year trial.The box represents the interquartile range (IQR),containing the middle 50% of samples in the Box-whisker Plot (from the lower quartile to the upper quartile),with the solid line in the box denoting the sample median,the whiskers were drawn according to the Tukey method,extending to the data point that was closest to 1.5 times the IQR below the lower quartile and above the upper quartile.•,outliers more than 1.5 times below or above the 1st or 3rd quartiles;+,the sample mean.

3.2.A significant association between pre-and postharvest kernel moisture

In the staged-harvest test in 2017,the kernel moisture content of pre-harvest samples ranged from 13.9 to 37.6%,and there was a significant increase in moisture content after harvest (Fig.3).For example,on 6 Oct.,the preharvest moisture of 28 samples ranged between 31.1 and 37.6%,but the post-harvest moisture content was too high to measure using the moisture meter (the maximum limit of detection was 40%).These excessive values were not included in the rest of the analyses of this study due to a lack of quantitative measurement.When the pre-harvest moisture content was low,the difference in kernel moisture content between the pre-and post-harvest was insignificant.When the pre-harvest moisture content was high,there was a significant difference between the pre-and post-harvest moisture content.This indicated that there might be a cutoff point for pre-harvest moisture content above which there was likely to be a measurable increase in kernel moisture content after harvest.

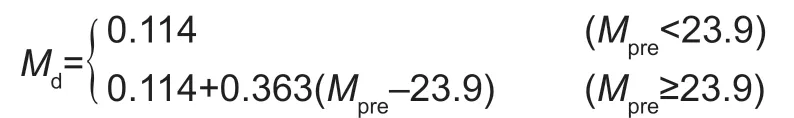

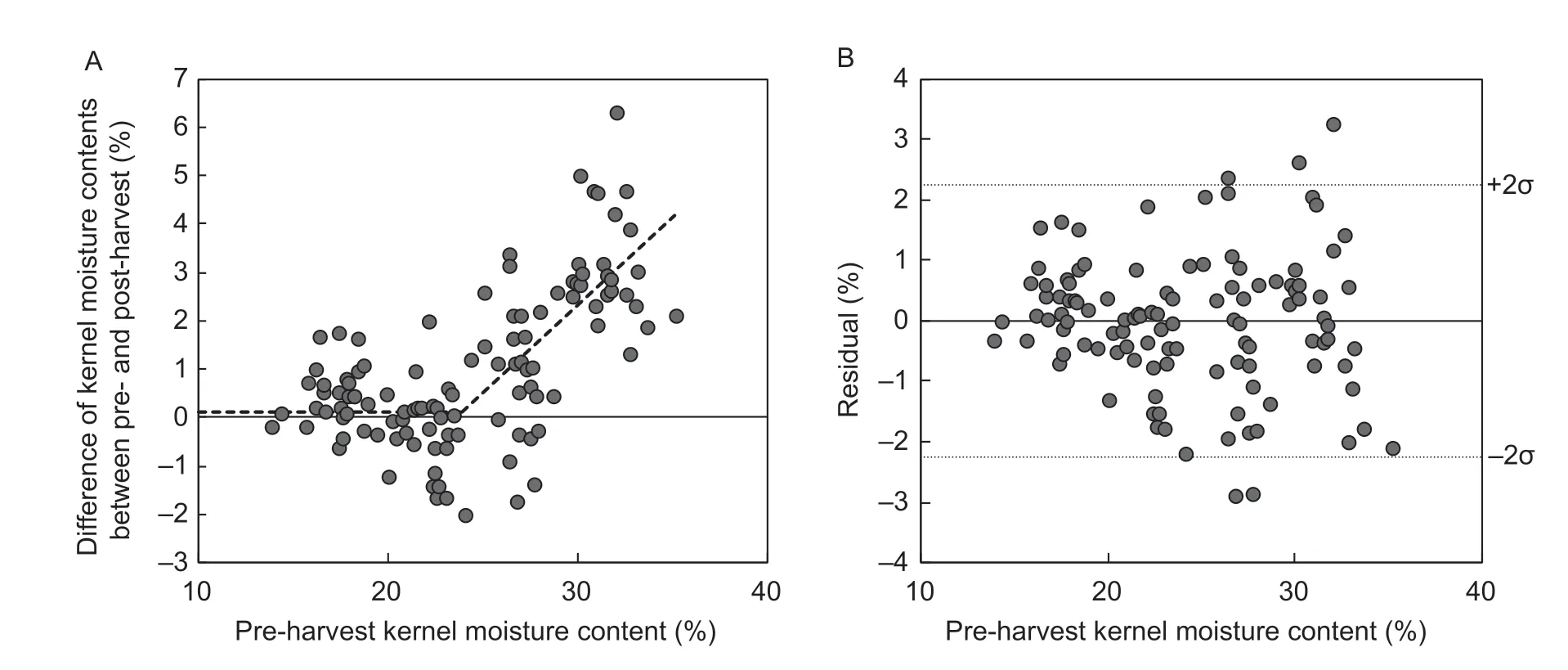

To identify the pre-harvest kernel moisture cut-off point that was predictive of a significant post-harvest difference,the relationship betweenMdandMprewas investigated by fitting a bi-linear model (Fig.4-A):

This model estimated that the cut-off point was 23.9%.WhenMprewas lower than 23.9%,Mdwas maintained at 0.114%,however,whenMprewas larger than 23.9%,Mdincreased with increasingMpreat the rate of 0.363(R2=0.516,n=111).In Fig.4-B,the residuals were mostly distributed between ±2σ in a funnel-shape,indicating that equation parameters had heteroscedasticity,possibly due to measurement errors or outliers resulting from the inherent variability in the real-world design of this experiment (Bickel 1978;Harrison and Mccabe 1979).

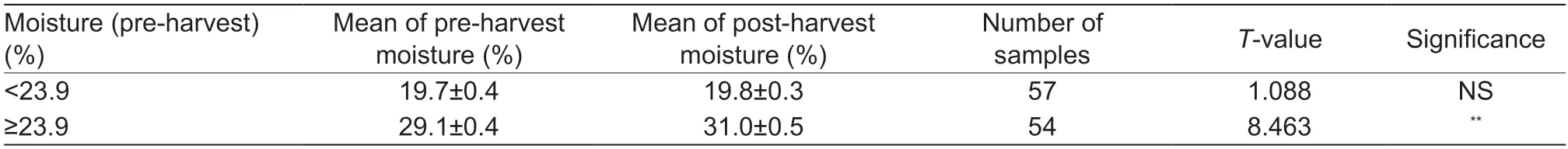

A paired sampleT-test was conducted with results shown in Table 3.It was found that post-harvest kernels had a significantly higher moisture content than pre-harvest kernels when the moisture content of pre-harvest kernels was higher than 23.9%.But the kernel moisture content was not significantly different between pre-and post-harvest when the moisture content of pre-harvest kernels was lower than 23.9%.

Table 2 Paired samples T-test of kernel moisture content in pre-and post-harvest samples from the multi-year trial

3.3.Broken kernels and non-kernel impurities’associations with increased moisture of post-harvest kernels

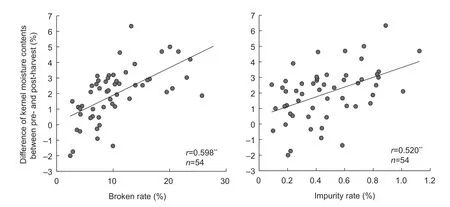

For samples with pre-harvest moisture above 23.9%,Mdwas positively correlated with the breakage rate (r=0.598**) andthe impurity rate (r=0.520**) (Fig.5).Therefore,a mixture of BK and the presence of I in cereals appeared to be associated with increased moisture of post-harvest kernels.

3.4.Differences in moisture content between various plant tissues and kernels

Fig.3 Kernel moisture content of pre-and post-harvest samples from the staged-harvest test.

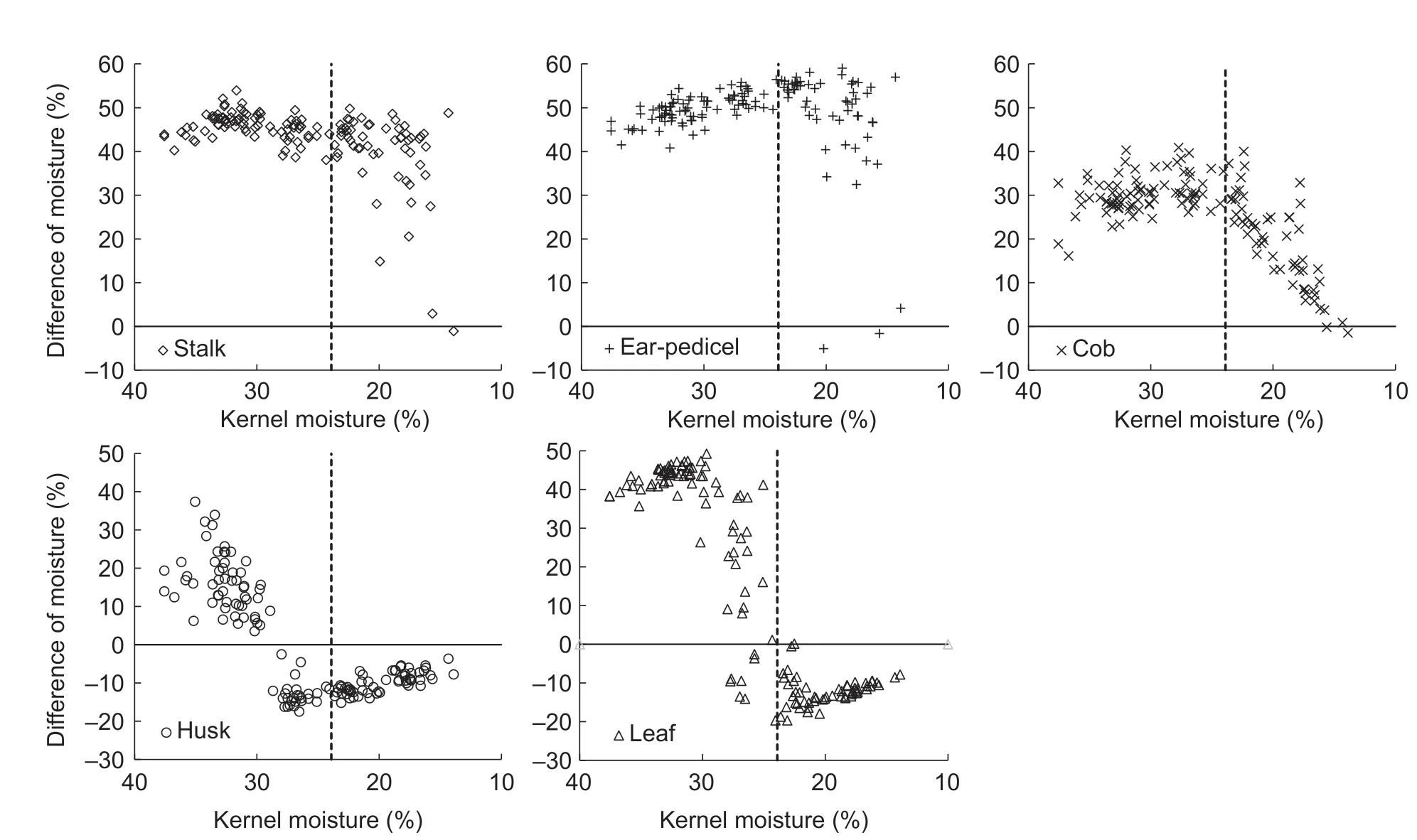

Several types of impurities were most commonly observed,including pieces of leaf,stalk,cob,husk,or ear-pedicel.Difference in moisture of the various plant tissues and kernels was shown in Fig.6.The moisture differences measured in stalk and ear-pedicel were generally positive and remained at a high level,suggesting that these parts of the plant typically have more moisture than kernels.For cob,the difference also remained positive,but first rose and then fell at a turning point of kernel moisture content being around 23.9%.For husk and leaf,the differences were first positive and then negative,changing at a turning point of kernel moisture content between 20–30%.Generally,the moisture contents of various plant tissues were higher than that of kernels,except for husk and leaf after a significant delay in harvest time (leading to dryer kernels).A generally high moisture content for these plant tissues might increase the moisture content of kernels if they are present in harvest as impurities.

4.Discussion

In a real-world study of corn kernel harvests in the Huang-Huai-Hai Plain,we found that kernels typically had an increase in apparent moisture content after harvest,which affected crop yields and sale prices.This study is the first to report a specific increase (+2.2 percentage points) in kernel moisture content after harvest and to analyze the potential causal factors of the increase,including:high moisture content of pre-harvest kernels,increased rates of BK,and the presence of I.

Fig.4 Difference of kernel moisture contents between pre-and post-harvest (A) and residual value (B) plotted against pre-harvest kernel moisture.

Table 3 Paired sample T-test of kernel moisture content between pre-and post-harvest samples in the staged-harvest test

Fig.5 Correlation between the moisture difference in the pre-and post-harvest kernels and the breakage rate and impurity rate.**,significant at the 0.01 probability level.

Fig.6 Differences in moisture content between various plant tissues and kernels as a function of kernel moisture content.

In the Huang-Huai-Hai River Plain,the winter wheat–summer corn rotation system (Huanget al.2003;Renet al.2018;Zhouet al.2019) allows for completing the entire sowing,growing and harvesting process in only about four months from late May to early October.Normally,at harvest time,the leaves and stalks of corn in this region are still fresh and green,and the kernel moisture content is very high,leading to an increased rate of kernel breakages and impurities during harvest (Liet al.2017,2019;Liuet al.2018;Minget al.2018;Wanget al.2018a,b;Xueet al.2019).In contrast,in the United States,kernel moisture content at the time of harvest is typically less than 20%,so breakages and impurities during kernel harvest are less frequent (Li 2013).As a result,in the United States,there are seldom issues with kernel moisture content after harvest.However,in China,this issue has clear economic implications.Breakages and impurities during kernel harvest may change the dielectric constant and the porosity of corn kernels (Saxena and Tayal 1981;Nelson 1982;Zoerbet al.1993;Heet al.2011),two factors that could affect the measurement of moisture content with a capacitive moisture meter (a common instrument for measuring moisture in the field).This might be the reason for the observed increase in the moisture content of post-harvest kernels.Many studies have reported that the kernel moisture content is positively associated with breakage rate and impurity rate.Specifically,higher kernel moisture at harvest is associated with more BK and I (Hall and Johnson 1970;Chowdhury and Buchele 1978;Plett 1994;Chaiet al.2017;Wang and Li 2017;Liet al.2018).This is increasingly problematic when corn is harvested while it is still considerably green;more breakage and a high rate of impurities (typically highmoisture-content impurities) would significantly increase the observed kernel moisture.Indeed,the I might include pieces of leaf,stalk,cob,husk,and ear-pedicel if kernels are harvested too early.Post-harvest kernels contain a mixture of K and BK/impurities that are not typically removed before moisture content is measured.Therefore,it is difficult to accurately estimate the moisture content of pure postharvest kernels.

When harvest begins after the leaves have turned yellow or kernel moisture content has dropped,the effect of the breakage and impurity rates on the measurement of post-harvest moisture decreases.Indeed,in the stagedharvest trial,there was no statistically significant difference in kernel moisture content between pre-and post-harvest samples when the pre-harvest moisture was lower than 23.9%.Therefore,we suggest the selection of fast-withering strains that will yellow quickly.Further,we suggest delaying harvest in order to ensure low kernel moisture content and a corresponding low rate of breakages and impurities.Combined,these strategies could reduce the moisture content of harvested kernels,thus improving grain quality and increasing the efficiency of corn kernel production in China.

5.Conclusion

In this study,we first conducted a multi-year and-area trial in the Huang-Huai-Hai Plain from 2013 to 2017.Analysis of a total of 411 pairs of samples suggested that the kernel moisture content after harvest was on average 2.2 percentage points higher than that before harvest.In addition,the staged-harvest trial found that this significant increase in moisture content was only observed when the kernel moisture content of pre-harvest samples was higher than 23.9%.In contrast,when the pre-harvest moisture content was lower than 23.9%,there was no statistically significant difference between pre-and post-harvest samples.Indeed,the increased moisture content after harvest appeared to be primarily related to the pre-harvest kernel moisture content,and the amount of broken kernels and non-kernel impurities.Therefore,choosing fastwithering hybrids and delaying harvest would allow further drying of kernels and help decrease the rates of breakages and impurities,thereby decreasing post-harvest moisture content and improving grain quality.

Acknowledgements

This work was financially supported by the National Key Research and Development Program of China(2016YFD0300110),the National Natural Science Foundation of China (31971849),the earmarked fund for China Agriculture Research System (CARS-02-25),and the Science and Technology Innovation Project of Chinese Academy of Agricultural Sciences.

Declaration of competing interest

The authors declare that they have no conflict of interest.

杂志排行

Journal of Integrative Agriculture的其它文章

- Receptor-like kinase OsASLRK regulates methylglyoxal response and content in rice

- Heredity and gene mapping of a novel white stripe leaf mutant in wheat

- Construction of a high-density adzuki bean genetic map and evaluation of its utility based on a QTL analysis of seed size

- Effects of temperature and solar radiation on yield of good eatingquality rice in the lower reaches of the Huai River Basin,China

- The effect of elevating temperature on the growth and development of reproductive organs and yield of summer maize

- High plant density increases seed Bt endotoxin content in Bt transgenic cotton