Identification of digital technologies and digitalisation trends in the mining industry

2020-12-20LarsBarnewoldBerndLottermoser

Lars Barnewold,Bernd G.Lottermoser

Institute of Mineral Resources Engineering,RWTH Aachen University,52062 Aachen,Germany

ABSTRACT Digitalisation in mining refers to the use of computerised or digital devices or systems and digitised data that are to reduce costs,improve business productivity,and transform mining practices.However,it remains increasingly difficult for mining companies to decide which digital technologies are most relevant to their needs and individual mines.This paper provides an overview of digital technologies currently relevant to mining companies as presented and discussed by mining journals,the media and insight reports of leading consultancy agencies.Relevant technologies were systematically identified using text-mining techniques,and network analyses established the relations between significant technologies.Results demonstrated that currently 107 different digital technologies are pursued in the mining sector.Also,an analysis of the actual implementation of digital technologies in 158 active surface and underground mines reveals a limited uptake of digital technologies in general and that the uptake increases with the run-of-mine production.Large-scale mining operations appear to select and apply digital technologies suitable to their needs,whereas operations with lower production rates do not implement the currently available digital technologies to the same extent.These minor producers may require other digital transformation solutions tailored to their capabilities and needs and applicable to their scale of operations.

Keywords:Diffusion of digital technologies Automation Internet of things Big data Machine learning Artificial intelligence

1.Introduction

Mining techniques and technologies have evolved and improved over time (e.g.the introduction of explosives and the use of mechanised and motorised mining equipment during the Industrial Revolution).In the past,each technical achievement and its implementation at mine sites led to better practices and strong industrial growth.Today,the mining sector faces the implementation of digital innovations,and various terms have proliferated in the media,the internet and at conferences,describing these technological advances and associated imminent changes.In this context,authors freely use the terms‘‘fourth industrial revolution”,‘‘digital revolution”,‘‘digitalisation”,‘‘digital transformation”,‘‘intelligent mining”,‘‘smart mining”,or ‘‘mining 4.0”.Unfortunately,these terms are used inconsistently,although there are noticeable differences in the original definitions.For example,‘‘digitalisation” originally refers to continuous evolution and change of particular processes and procedures based on digital technologies [1].‘‘Digital transformation” describes the overall changing process of a company or business model due to the implementation of digital technologies [2],whereas ‘‘intelligent mining”,‘‘smart mining”,and ‘‘mining 4.0” limit the digital transformation to the mining industry [3].Regardless of the slight differences in definitions,digitalisation is based on the application of digital technologies.Therefore,in this study digitalisation in the mining industry refers to the use of computerised or digital devices,methods and systems and digitised data that are to reduce costs,improve business productivity and efficiency,and transform mining practices.

To date,the general direction and structure of innovative processes and the digital technologies for the mining industry as well as the influencing factors that encourage the implementation of trends have been identified[4,5].Others have discussed specialised digital technologies that are particularly relevant for mineral processing and beneficiation [6–8].However,an appraisal of current digitalisation trends(i.e.the general direction in which the mining sector is adopting digital technologies) and of the implementation of digital technologies in the mining sector does not exist.Hence in this study,digital technologies relevant for the mining industry have been identified and their implementation in active mining operations of different production rates established.By providing such information,the study aids in identifying digital technologies relevant to mining operations and provides insights into the acceptance of digital technologies by mining operations of different production scales.

2.Method

In order to identify digital technologies,their importance and implementation in the mining industry,co-word analyses and text-mining techniques with suitable algorithms were applied.Co-word analysis establishes the multi-and co-occurrence of words (i.e.content relation of two keywords) and correlates the relevance of these [9,10].Text-mining extracts from readable textual datasets hidden knowledge and semantic information [11],with most text mining programs using mathematical vectors and matrices.The unstructured readable text is thereby converted into structured datasets that consist of individual tokens stored in single-column vectors.Tokenisers generate these tokens by using fixed splitting characters as punctuations or even letter sequences[12].In this study,text-mining was performed on a textual database,and the generated vectors were treated as standard data sets and processed using a sequence of algorithms.The latter algorithms were developed using the data mining software ‘‘Rapidminer” on a standard PC with 4 cores @ 3.4 GHz and 32 GB.

2.1.Textual database

Initially,global consulting companies perceived by the business magazine ‘‘Forbes” as leading in the mining sector were identified(n=13),and then their insight reports were taken as the first data source(n=26).This text database was extended to include papers published in industry magazines,peer-reviewed journals as well as conference proceedings and abstracts (obtained through onemine.org).Text searches were limited to information in English,digitally available and published after 2010.In total,over 2400 textural data items were identified.All materials were stored as PDF files and converted into XML files using the software La-PDFText.Detailed information about the functionality of the program and structure of XML files is provided by [13].The text searches revealed that published materials on emerging technologies were limited.Consequently,Wikipedia was used as an additional text source,because it offers networked hyperlinks on article pages (internal links,redirects,or categories),making it an indirect powerful text collection [14,15].

2.2.Co-word analysis and text-mining

2.2.1.Step 1—manual review of reports

In the first step,insight reports (n=26) of global consulting companies were studied whether they contain digital technologies as keywords.The sole criterion for selection was the term ‘‘digital technology” representing a software or hardware.Identified technologies were stored as keyword vector vkand used in all five following steps as keywords.

2.2.2.Step 2—extracting and quantifying keywords

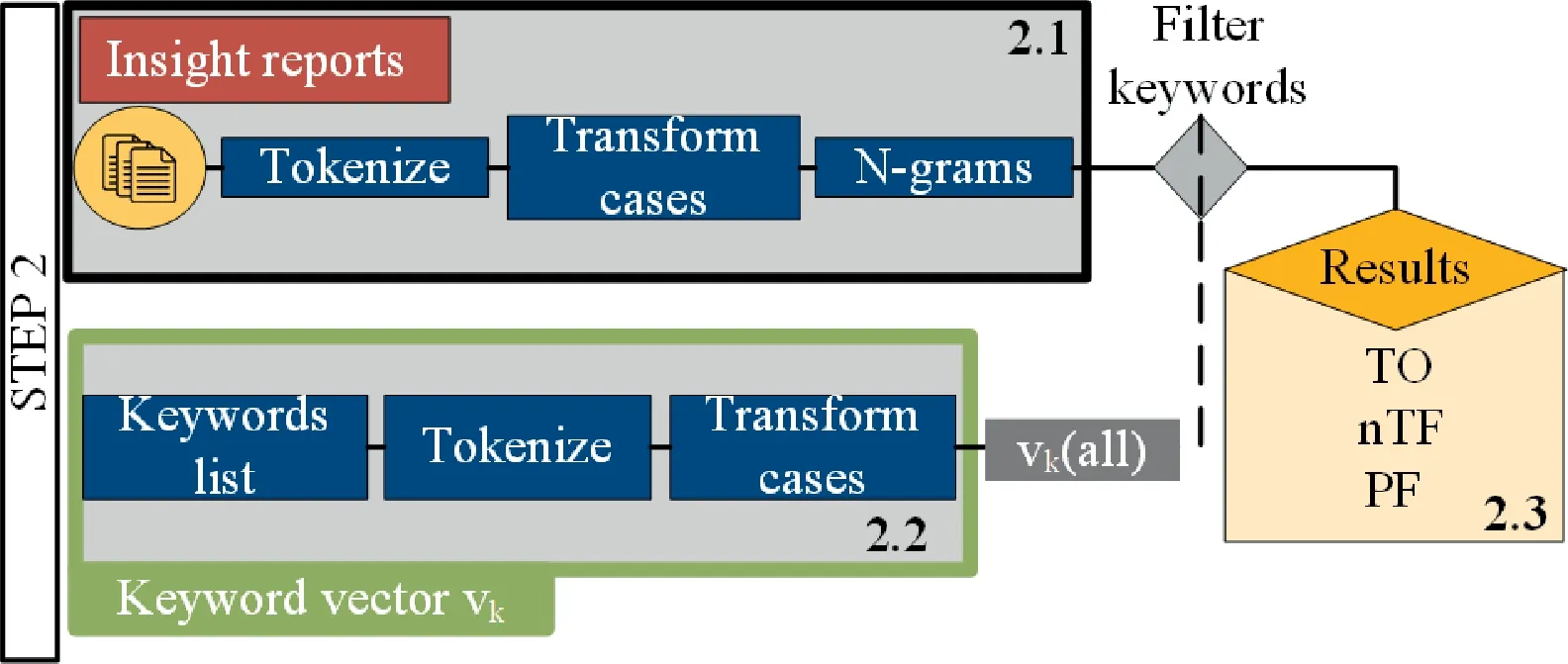

Fig.1.Flow chart for extracting and quantifying keywords (Step 2),comprising Step 2.1:structuring insight reports,Step 2.2:structuring keyword list,and Step 2.3:filtering and quantifying the occurrence of keywords.

In the second step,a text-mining algorithm (Fig.1) filters the previously identified keywords out of the insight report collection and quantifies the occurrence as a result.The algorithm first turns the insight report collection into structured data by tokenising the text(Step 2.1,Fig.1).The tokeniser splits the text into single words by using all non-letter as splitting points.All tokens were transformed into small cases because the following steps are case sensitive.The filtering engine cannot detect keywords consisting of multiple words.Therefore,words were combined to one token,by using the n-gram model G(wn)(see Eq.(1))as described by[16].A keyword list was prepared for the filtering process (Step 2.2,Fig.1) by tokenising and transforming the tokens in small cases.This resulting vector vkwas used for the filtering process.Finally,keywords were counted according to their occurrence in a single paper (term occurrence (TO)),and the total number of words was established in the respective paper,which resulted in the cumulated term frequency (Step 2.3,Fig.1).From these data,the nominal term frequency (nTF) was determined,which in turn allowed comparing different TF values with variable paper lengths.The paper frequency(PF)is defined as the percentage of all articles,in which the keyword was mentioned.

where g is the final n-gram; w a single word; and n the number of words.

2.2.3.Step 3—identifying semantic relatedness from the insight report database

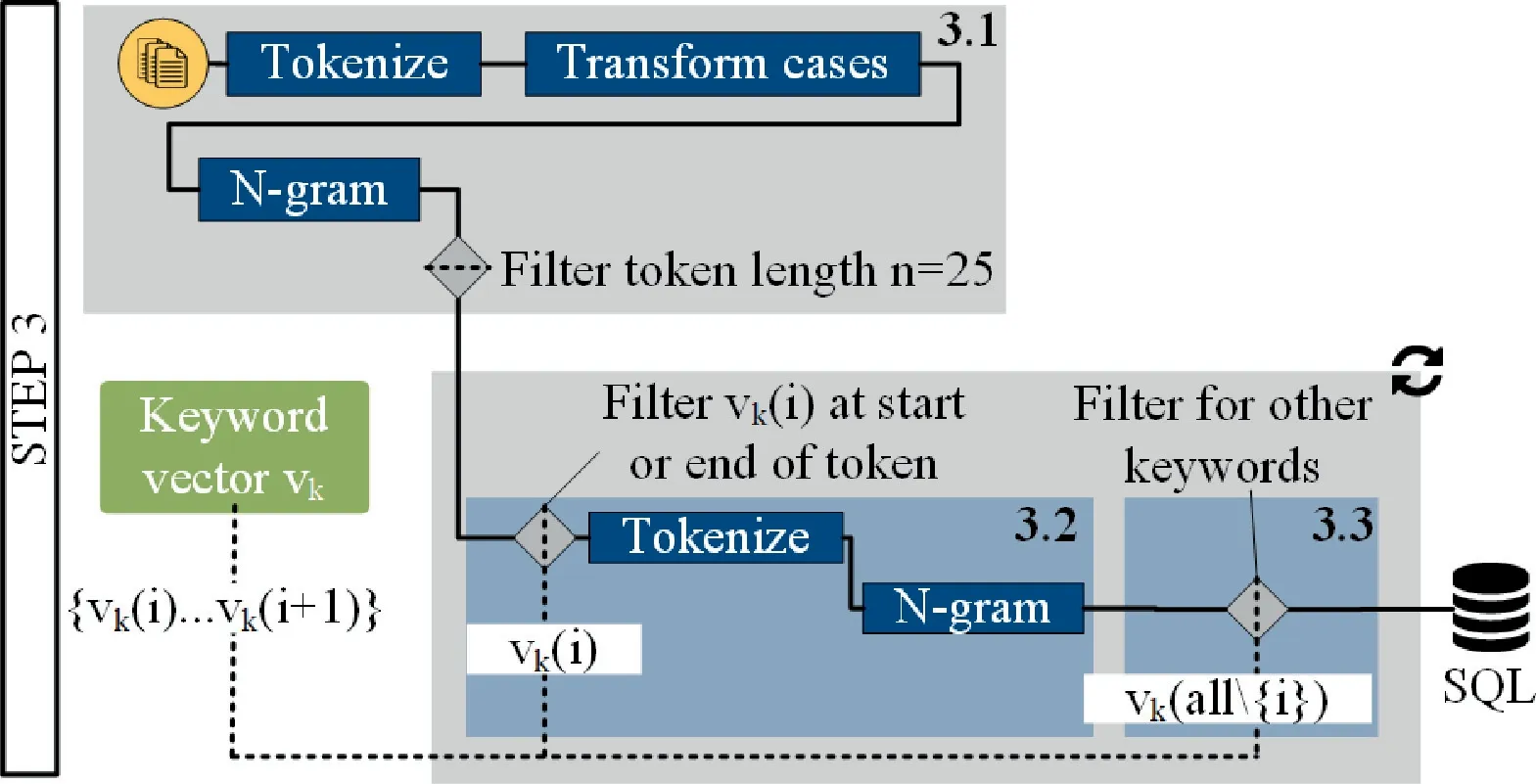

In the third step,the insight reports database was examined for identifying semantic relatedness between keywords.Relatedness between individual keywords helps to classify these and draw a superordinate picture of all relations of digital technologies[17,18].The insight reports were investigated for interrelations by using the order of words to draw a conclusion on which keywords co-occur.For this purpose,the algorithm searches the immediate vicinity of a keyword text passage for additional keywords and stores the results in a relational SQL database (Fig.2).

As a first step,the unstructured papers were tokenised by nonletters and cases were standardised (Step 3.1,Fig.2).The cumulative n-gram function then processed the word vector with 25 semantic ordered words and directly filtered for the exact token length of 25 words as shown in Eq.(2).This filtering pattern consisted of a regular expression(RegEx),which is often used for filtering or in searching algorithms as described by [19].

Fig.2.Flow sheet for identifying semantic relatedness from the insight report database (Step 3),comprising Step 3.1:structuring data,Step 3.2:filtering tokens with vk(i) at start/end,and Step 3.3:filtering for keywords.

where x={n -1}; and n is the number of the token length.

Every element of the pre-processed word vector from Step 3.1 was searched and filtered by the keyword vector vkin an iterative process (i) (Steps 3.2 and 3.3,Fig.2).The function under Step 3.2 filters all n-grams,where vk(i) is at the start or end of the n-gram token.The filtered n-grams were tokenised and filtered by the RegEx in (i=3) for other keywords from the vector vk(Step 3.2,Fig.2).Eq.(3) is based on an alternative branch syntax (a|b).

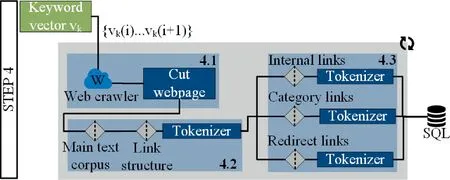

2.2.4.Step 4—extracting keywords from Wikipedia HTML

To analyse and use Wikipedia HTML structures,the following step was designed iteratively.For every single keyword vk(i)the filtering process was processed,and the results were stored in a SQL database(Fig.3).In the first step,the HTML document of the specific keyword was downloaded by a web crawler (Step 4.1).To reduce the workload for the algorithm,and to limit the ‘‘standard word error rate”[20],content extraction was used to delete unnecessary HTML parts by the RegEx in Eq.(4) (Step 4.2,Fig.3):

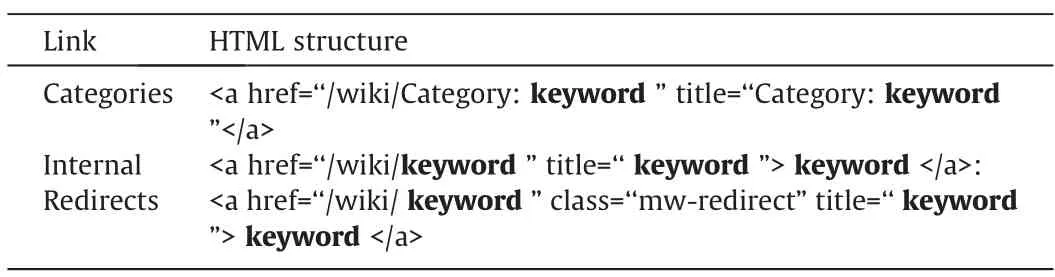

From this,the categories and internal and redirect links were extracted (Step 4.3,Fig.3).The specific link structure of the items is shown in Table 1.The mentioned keywords were filtered using RegEx expressions.This resulted in keyword connections with the same structures as created in Step 3.The results were merged with the results from Step 3 from the insight reports.

2.2.5.Step 5—analysing keywords structure by using network analysis

Keywords and the interconnections between keywords can be perceived as a vast network.The open-source program Gephi was used to visualise the network and to highlight links between keywords in the network structure.Nodes and edges are the essential elements.Here,nodes represent the specific keywords and edges show the relation between two keywords [18].A forceddirected visualisation algorithm (ForceAtlas2 [21]),which takes attraction and repulsion of the single keywords and their connections in consideration,was used to design the network.The resulting complex was further investigated in networking analyses,by focusing on key parameters (i.e.weighted degree WD,closeness centrality CC,and betweenness centrality CB),which are discussed by[22,23].In particular,the centrality of a vertex indicates the relevance of a node (x) to its dependence on other nodes.Important centrality indicators are:

Fig.3.Flow sheet for extracting keywords from Wikipedia HTML (Step 4),comprising Step 4.1:downloading HTML,Step 4.2:filtering necessery HTML parts,and Step 4.3:extracting keywords from links.

Table 1HTML structure of relevant elements from the Wikipedia HTML code.

(1) Closeness centrality(CC),which indicates how central a node is positioned in a network.CCis calculated by the average length of the shortest path (dsp) to all individual nodes (y)as shown in Eq.(5).

where x is the regarded node; dspthe shortest path;and y the connected node with x.

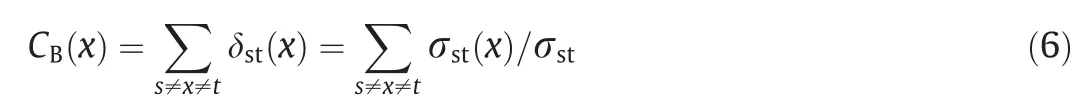

(2) Betweenness centrality(CB),which allows a statement about the relevance and importance of this node in the network.CB(x) is calculated by adding all pair dependencies (δst) of the network that contain x as a node,as shown in Eq.(6).

where σstis the number of shortest paths;s and t the corner nodes of σst; and σst(x) the number of shortest paths containing x.

2.2.6.Step 6—implementation of digital technologies at operating mines

This step determined the actual application of digital technologies at operating mines based on text extracts from the onemine.org database.The algorithm in Step 6 (Fig.4) filters the text database for keywords and searches additionally for the names of operating mines,which are named in the text.The results are stored together in a relational SQL database.

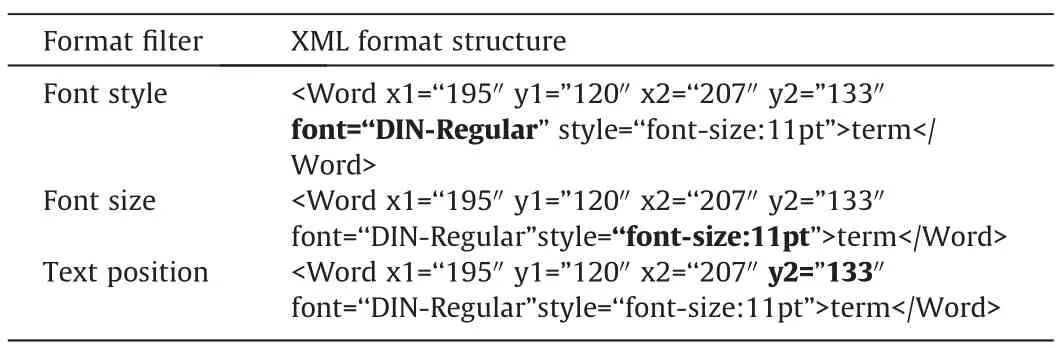

Typographically,the name of a mine begins in English with a capital letter.In this study,the PDFs from the paper collection were processed by the algorithm from Step 2 to detect the digital technologies within individual papers (Step 6.1,Fig.4).To reduce the‘‘error rate”,structural elements with further capitalisation (e.g.headings,names,and places within references and at the start of records)were filtered and deleted.Due to missing format information,PDF files had their in-text references deleted(Step 6.2,Fig.4),by tokenising the text,which resulted in vector w1.The correspond XML file,with all word-specific formatting and position information,was used to identify headings,which resulted in vector w2(Step 6.3,Fig.4,Table 2).The intersection of both vectors (w1and w2) was checked for proper names of mining operations by filtering words for uppercase formatting (Step 6.4,Fig.4).The resultant list was linked to the identified digital technologies and stored in the SQL database.

Fig.4.Flowsheet for identifying the implementation of digital technologies at operating mines(Step 6),comprising Step 6.1:processing Step 2,Step 6.2:filtering in-text references,Step 6.3:filtering structural elements,and Step 6.4:extracting words with capitals.

Table 2XML format structure.

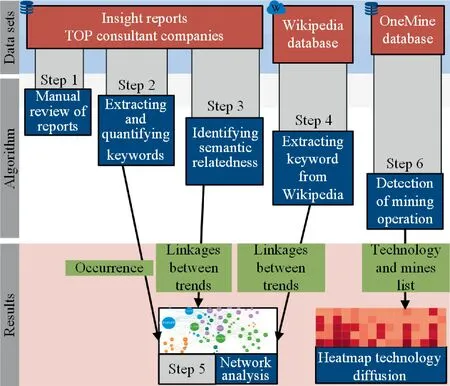

2.3.Overall methodology

All six aforementioned steps build an overall methodology to identify essential keywords from the scalable database and to draw conclusions about the acceptance of digital technologies in the mining industry (Fig.5).Steps 1 and 2 identify and quantify relevant keywords from the insight reports and results as nodes in the network structure.Step 3 evaluates linkages from the insight reports and represents the edges from the network.Step 4 adds linkages from Wikipedia,which completes the results from Step 3.Step 5 analyses and visualizes the final network structure.Step 6 links keywords with mining operations,which are mentioned together in the onemine.org database.The results are finally visualized in heatmaps.

3.Results

3.1.Identification of key digital technologies in the mining industry

Fig.5.Overview of methodology to identify the digital technologies relevant to the mining industry.

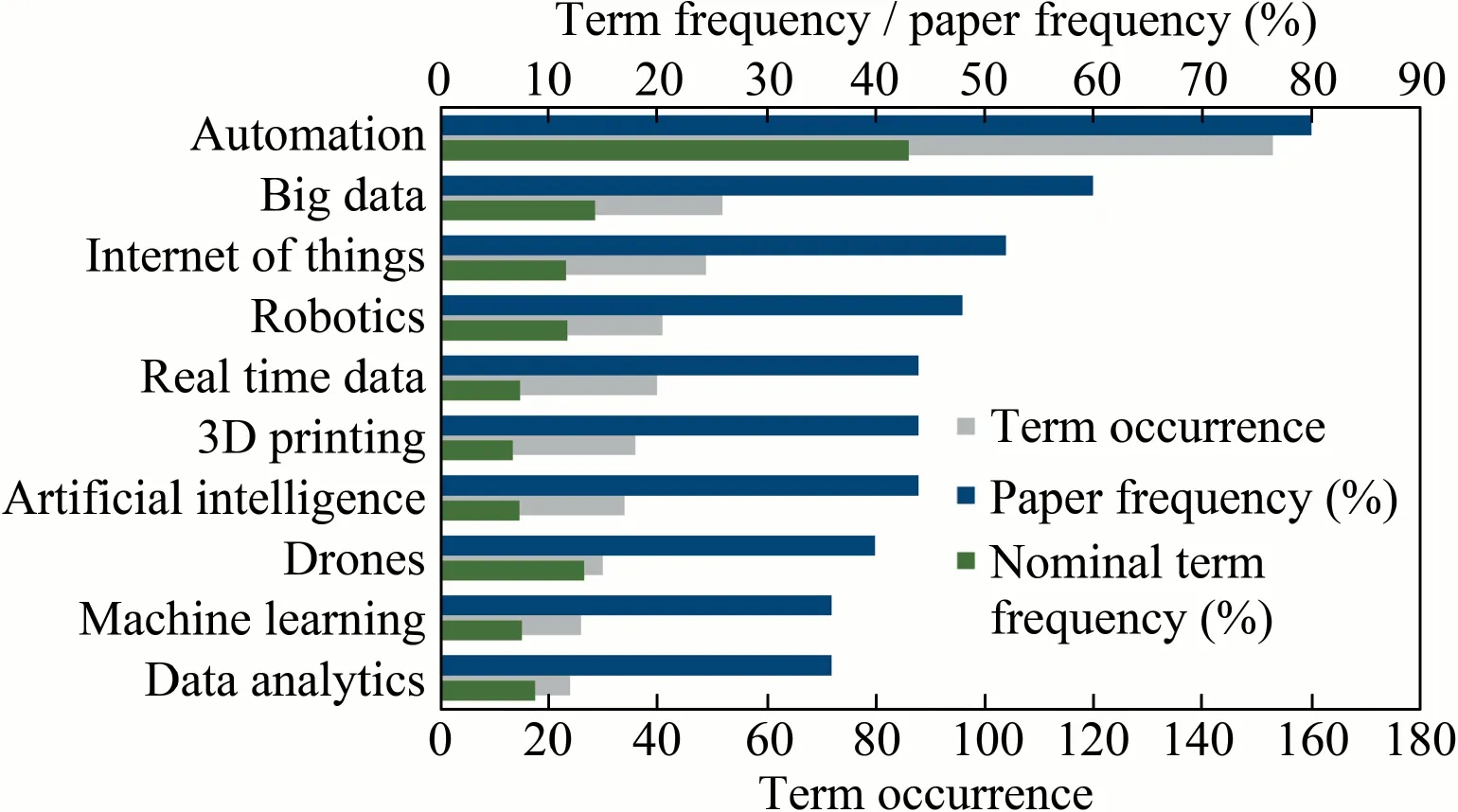

Co-word analyses and text-mining techniques with algorithms on the insight reports(n=26)allowed the recognition of 107 individual keywords,after eliminating duplicates and using uniform spelling.Term occurrences (TO) of these terms were established for each paper,whereby the 10 most frequently cited terms were referred to 820 times in total.Of these 10 terms,the most frequently stated term with the highest TO in all insight reports is‘‘automation” with 153 citations,followed by ‘‘big data”,‘‘internet of things”,‘‘robotics”,‘‘real-time data”,and ‘‘3D printing” (Fig.6).An analysis of the nominal term frequency(nTF)allows a comparison of the term occurrence with the paper length.Looking at the average nTF together with the paper frequency (PF),the TO of the identified terms can be validated(Fig.6).‘‘Automation”occurs in 80% of all papers with a high nTF value.However,‘‘big data” is mentioned in 60% of the manuscripts with the second-highest TF.Thus,there is a positive correlation between TF and PF(correlation coefficient r=0.89) in most cases,except the term ‘‘3D printing”that is mentioned in 44% of the insight reports but with an nTF of only 7% (r=0.21).

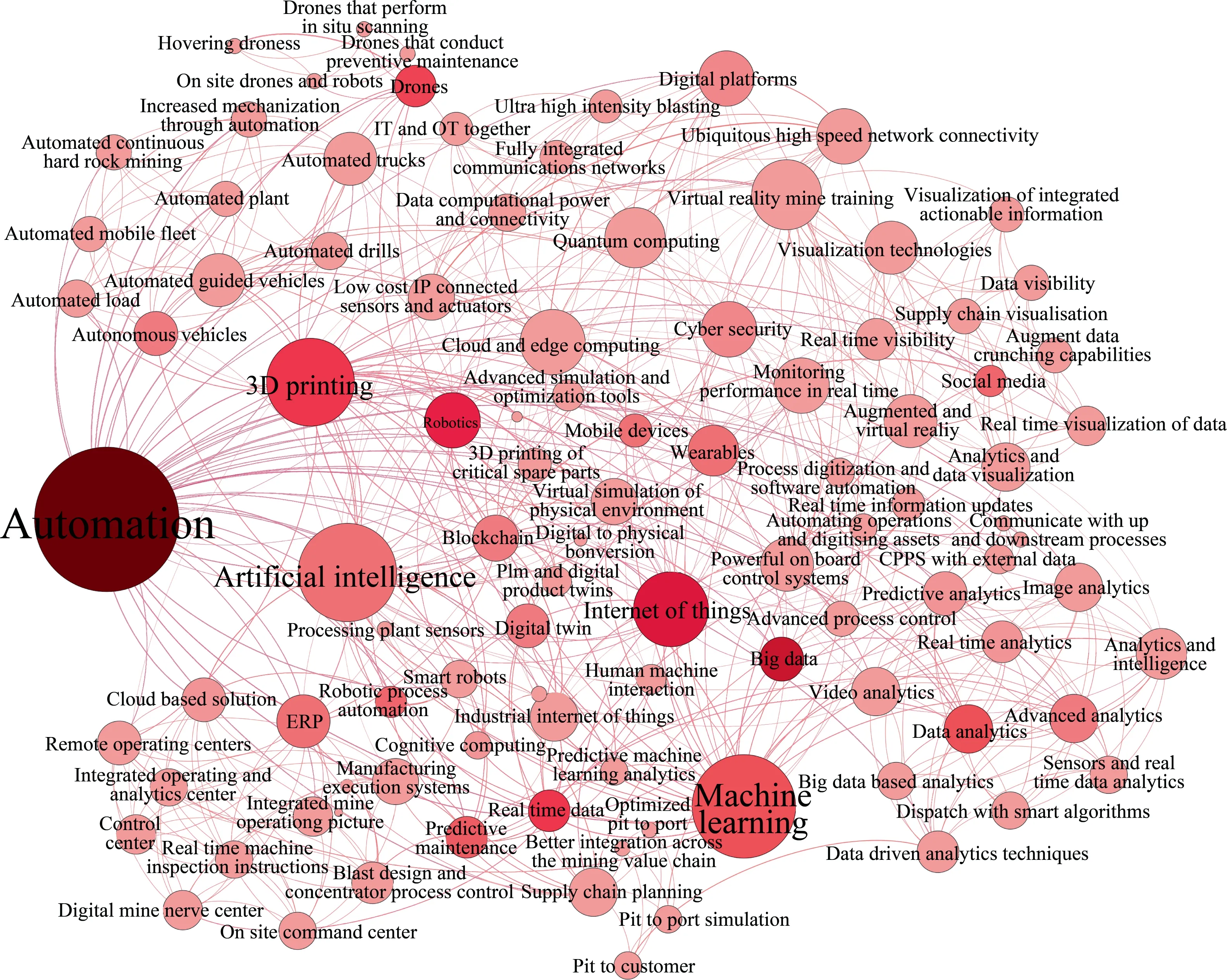

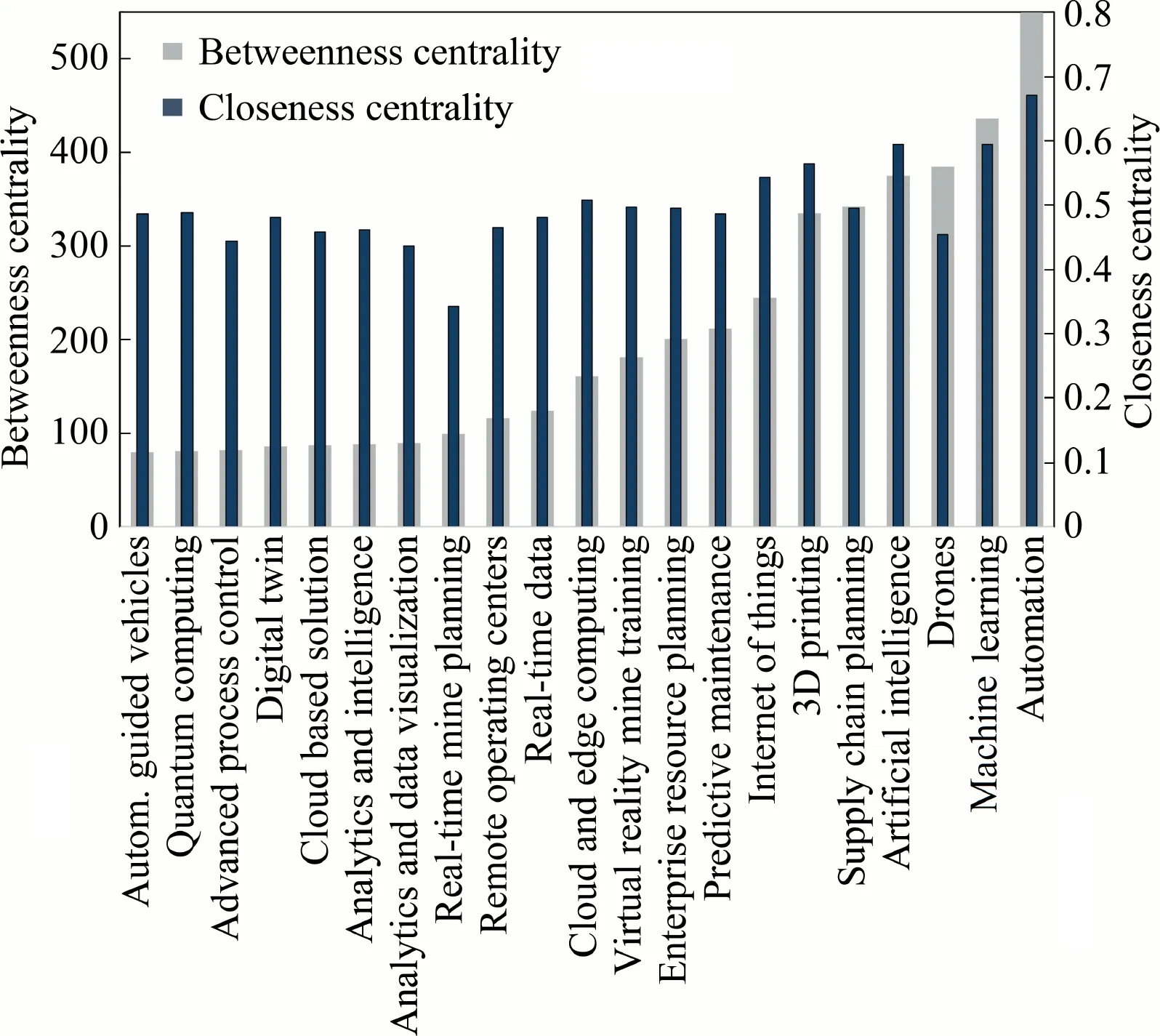

Steps 3 (semantic relatedness) and 4 (Wikipedia related links)were applied to determine the co-occurrence of key digital technology terms within the texts.These algorithms detected in total 1389 interlinkages between individual digital technology terms.The co-occurrence of terms is visualised as a network structure(Fig.7).Additional properties of the individual terms,such as weighted degree(WD)and categories of the technology are shown by their sizes and colours.The position of terms is shown as nodes(Fig.7),which in turn reflects the closeness (CC) and betweenness centrality (CB).Keywords ‘‘automation”,‘‘machine learning”,‘‘internet of things”,‘‘3D printing”,and ‘‘artificial intelligence” have the highest CBtogether with a significant CCvalue(Fig.8),however,in general,CBand CCvalues do not correlate.Again,‘‘automation”has the highest CBand CCvalues.

In addition,‘‘artificial intelligence” (WD=35),‘‘machine learning” (WD=37),‘‘3D printing” (WD=31),and ‘‘virtual reality mine training”(WD=24)have highly weighted degree values and hence can be seen as essential elements of the network.In general,a high WDvalue correlates to a central position in the network of the technologies considered in the network.From the overall network,ego-networks can be derived [24].These ego-networks consist of directly linked keywords to a focal keyword.Ego-networks were established by this study to identify relations between key digital technology terms (Fig.9).

Calculated CBvalues for the ego-networks for ‘‘artificial intelligence”,‘‘machine learning”,‘‘3D printing”,‘‘big data”,‘‘automation”,‘‘robotics”,‘‘internet of things”,and ‘‘real-time data” are illustrated in Fig.9a–h,respectively.Here,the terms have been sorted according to their highest CBvalue to highlight closely related technologies.Fig.9a–h shows at least one strongly related technology.‘‘Automation”is at the top of the diagram for‘‘artificial intelligence”,‘‘machine learning”,‘‘real-time data”,‘‘robotics” as well as ‘‘3D printing”.Fig.9f mirrors the strong correlation from‘‘big data” to ‘‘internet of things”.In turn,‘‘internet of things” is very closely linked to‘‘artificial intelligence”and‘‘industrial inter-

Fig.6.The ten most relevant digital technologies for the mining industry,rated by TO,PF and nTF.

Fig.7.Network structure of all identified technologies,whereby the nodes represent individual technologies,the node size the weighted degree and the lines the connection between two nodes.The intense colour indicates the PF of the node.

Step 6 aimed to establish the actual application of digital technologies at individual mine sites.Filtering the onemine.org database with 25 keywords reduced 2400 publications in total to 164 relevant texts.In the filtered documents,proper names of mines were established,and 92 publications with a possible mine name citation were detected.By reviewing the papers again manually,65 papers describing 158 mining operations could be identified.All mines are existing projects that are currently in production,have recently been closed or are evaluated to be reopened.Among these publications,notably ‘‘automation”,‘‘real-time data”,‘‘advanced process control”,and ‘‘machine learning” show high TO values.

The recognised digital technologies were then plotted versus the Run-of-Mine (ROM in Mt/a) production for each identified mine site and versus the revenue of the parent company with multiple operations (in bn$),using a colour-based heatmap (see net of things”.The ‘‘automation” ego-network shows a clear association with ‘‘3D printing” and ‘‘machine learning”.

Fig.8.Betweenness centrality(CB)and closeness centrality(CC)values for the most significant digital technologies in the mining industry.

3.2.Application of digital technologies in the mining industry

Fig.9.Betweenness centrality (CB) values of key digital technologies within ego-networks.

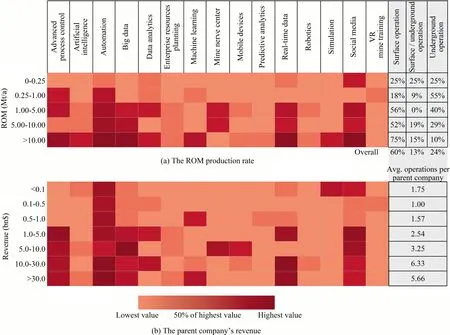

Fig.10).In Fig.10a,operations are divided into five groups according to their ROM production rate (<0.25,0.25–1,1–5,5–10,and>10 Mt/a).In Fig.10b,operations are divided into seven groups according to their revenue (<0.1,0.1–0.5,0.5–1,1–5,5–10,10–30,and >30 bn$).Colour saturation reflects the number of operations in the group,which are associated with an individual digital technology.In general,digital technologies show more saturated colours with higher ROM production in individual mines and in companies with a higher revenue.Especially those mine sites with over 10 Mt per year ROM production and companies with a revenue of over 1 bn$have the most occurrences of digital technology terms.By taking the number of average operations per parent company into account,it is visible that more digital technologies are used in mining companies with multiple operations.More than 60% of considered mines are surface operations,13% are mines with surface and underground activities,and 24%are underground mines.The share of surface operations increases with rising ROM.In situ mining operations were not considered.

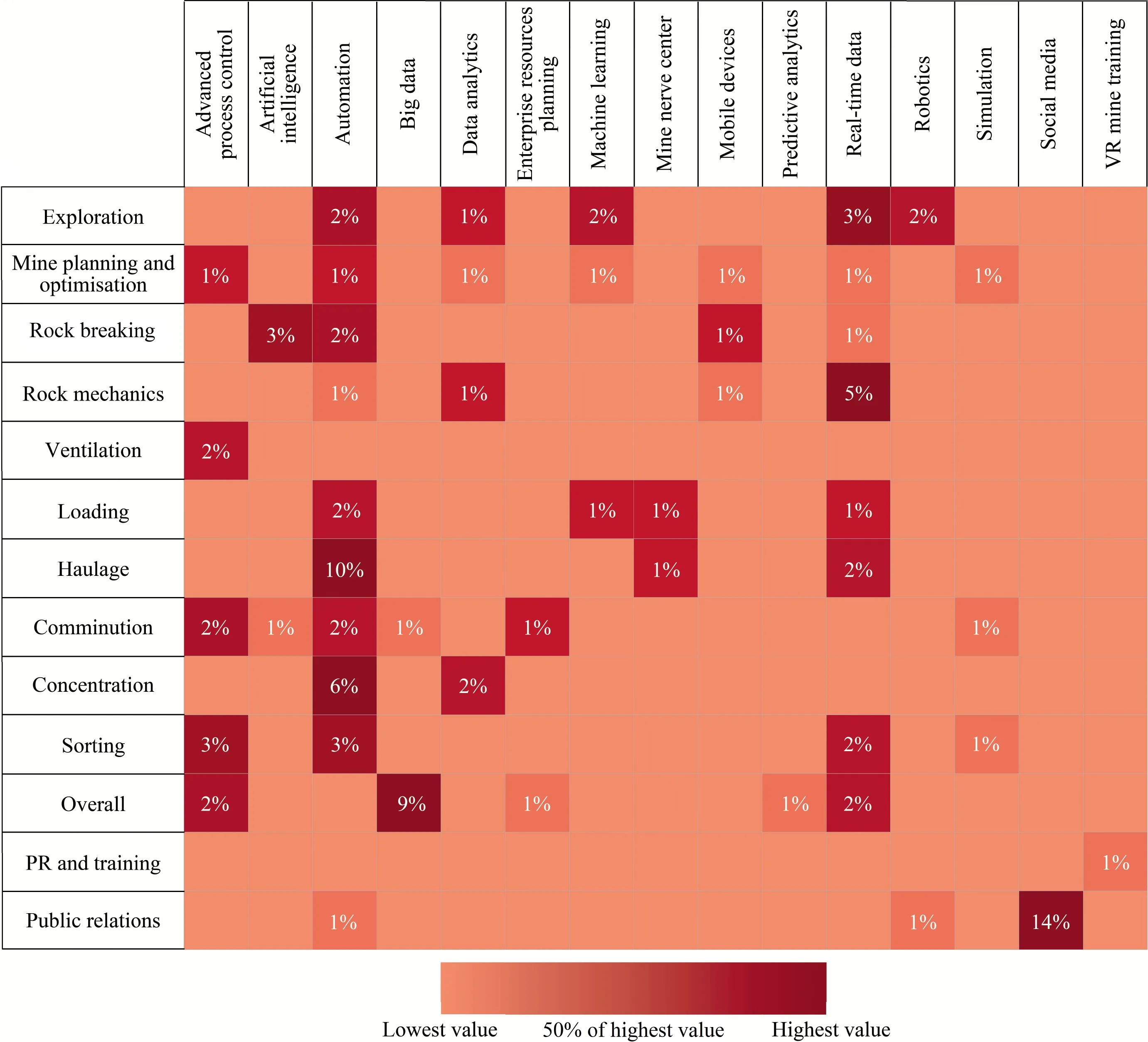

Fig.11 shows the implementation of digital technologies across the entire mining value chain.Some digital technologies could only be assigned to the entire mining process,and here the term was classified as ‘‘overall”.Related activities such as ‘‘training” and‘‘public relations” were added as well.Again,‘‘automation” shows up with implementation activities across the complete mining value chain.Especially the stages of haulage and exploration are associated with abundant digital technologies.Here,‘‘real-time data” is used in exploration activities,whereas ‘‘mine nerve centres” are used exclusively in haulage and loading,‘‘social media”is related to public relations,and ‘‘advanced process control” is mainly implemented in the processing steps,comminution,and sorting stages.Regardless,there is a general lack of colour saturation,which demonstrates that the diffusion of digital technologies in the mining industry is overall quite low.

4.Discussion

In the past,technical evolutions in the history of mining were characterised by key technologies that were designed exclusively for the mining sector(e.g.the use of dynamite)or were taken from other industries and transformed existing mining practices (e.g.the innovative use of motorised equipment).Today,a simple transfer of successful digital technologies from related industries to the mining industry is often not possible due to the unique technical and geological uncertainties and special conditions in mining operations [25].

Fig.10.Implementation of digital technologies at operating mines as a function of their ROM production rate and the parent company’s revenue,whereby a greater colour saturation indicates more adoption of the digital technology.

This study has shown that key digital technologies relevant for the mining sector appear to be ‘‘automation”,‘‘robotics”,‘‘internet of things”(IoT),‘‘big data”,and‘‘real-time data”(c.f.Figs.6 and 7).These terms have the highest TF scores,but such an approach disregards the relation of different terms to each other.When one considers closeness (CC) and betweenness centrality (CB) of keywords,then ‘‘automation”,‘‘machine learning”,‘‘internet of things”,‘‘3D printing”,and‘‘artificial intelligence”have the highest CBand CCvalues as Fig.8 illustrates.Thus in the mining sector,a single key technology is not discernible in the current digitalisation trend.Instead,the present innovation process consists of a complex network of remarkably diverse approaches and new technology options.Also,the diffuse context and use of the terms mentioned in Section 3 inhibits an understanding and becomes a challenge for mining enterprises [18,26].Notably,the mining industry has identified this development as a significant business risk,with >37% of leading executives having insufficient knowledge and understanding of current digitalisation trends and available options [27].Thus,important digital principles and linked digital technologies are not fully understood by and communicated to potential users.Therefore,it is of significant benefit to discuss the key digital technologies as identified by this study and to evaluate their future relevance.

4.1.Key digital technologies in the mining industry

4.1.1.Automation and robotics

‘‘Automation” and ‘‘robotics” are both an overall approach,for decoupling the human from technical machinery.‘‘Robotics” deals with the development and usage of robots,whereas ‘‘automation”defines the operation of existing machines and unattended processes without human control [28,29].The actual use of automation approaches concentrates on the processing steps,whereby automation systems have been used for decades [30].‘‘Automation” or rather autonomy technologies are actively used in the haulage process (Fig.11).Especially surface mines use automated trucks,where constant and long-lasting haulage roads and simple implementation of communication infrastructures such as GPS or LTE allow the successful implementation of automation systems.Yet,loading of ore and waste by mobile equipment is still not being automated to the same extent.The lack of automated loading practices is likely due to changing rock conditions and material positions at individual mine sites [31],which require real-time information and real-time data analysis.

As seen in the results section (Fig.6),‘‘automation” is the most-cited technology,which has already impacted on the mining industry.‘‘Automation” is affected or influenced by a variety of other digital technologies as shown by its highest betweenness centrality (CB) and closeness centrality (CC) values (Fig.8).The CCvalue reveals that automation is a central component of the network and thus a central pillar in the current digital transformation discussion in the mining sector.The ego-network‘‘automation” (Fig.9e) shows a strong correlation between‘‘robotics” and ‘‘automation” as evidenced by a high CBvalue.Similarly,the ego-networks ‘‘robotics” and ‘‘automation”(Fig.9d and e) are connected to the same technologies such as‘‘artificial intelligence”,‘‘machine learning”,and ‘‘3D printing”.Regardless,‘‘automation” is the leading key technology for the mining industry and is often seen as final vison of the digital transformation.

Fig.11.Implementation of digital technologies across the mining value chain,whereby a greater colour saturation indicates more adoption of the digital technology.The percentage results from the term occurrence related to all investigated mines (n=158).Empty block means 0%.

4.1.2.IoT

‘‘Internet of things” (IoT) is an approach whereby physical objects are interconnected and able to communicate their status over the internet and be controlled remotely from any position[32].In mining,‘‘IoT” is used in tracking the position and loading status of trucks,which helps to coordinate mobile equipment.There are also systems to track people for emergency situations[33].‘‘IoT” monitoring systems are also applied to monitor rock stability and movements in underground mines[34].In particular,‘‘IoT”allows the connection of low-cost sensors to deliver data to a central point and to act as a cross-platform system [35].The ‘‘IoT”and the ‘‘industrial internet of things” (IIoT) share the same functional principles,whereby the ‘‘IIoT” has been especially adapted for industrial purposes.The focus of ‘‘IIoT” is on permanently running,data intensive,complex systems.Aazam et al.illustrated the components of an IIoT system,where a wireless sensor network(WSN),virtual sensing,‘‘cyber-physical systems (CPS)”,and ‘‘big data” are the main pillars of such a platform [36].At mine sites,‘‘IIoT” is used for the monitoring of tailings dams,where parameters such as water level and movements of dam walls are measured[37].

Results of this study demonstrate that ‘‘IoT” is named in more than 50%of all insight reports.Also,Fig.7 illustrates a very central position of‘‘IoT”in the network with a high CCvalue,which makes‘‘IoT”a central component of the digital transformation discussion.Closely linked to‘‘IoT”is‘‘IIoT”,and‘‘automation”,‘‘artificial intelligence”,and ‘‘machine learning”,representing the cognitive level of a CPS system,are part of the ‘‘IoT” ego-network (Fig.9h).‘‘IoT”is a key technology for the mining industry(Fig.6),and the results in Fig.9h underline that‘‘IoT”,as a data-driven technology,reaches its full potential in combination with ‘‘automation”,‘‘artificial intelligence”,and ‘‘machine learning” approaches.

4.1.3.Big data and real-time data

The term‘‘big data”describes a high amount of data that cannot be handled by conventional data processing and human competencies.The term ‘‘real-time data” relates to the speed,responsiveness,and timeliness of delivering data to the user.The mining industry can significantly benefit from implementing ‘‘big data”and ‘‘real-time data” analysis.In fact,predictive maintenance systems for belt conveyors or dump trucks rely on ‘‘big data” and‘‘real-time” infrastructure,which in turn allow a better forecast of mechanical breakdowns and status as well as tracking the equipment and operators [38,39].Other possible applications include mass flow simulation and visualisation of block caving activities to understand and monitor the actual mining void [40].Time-critical atmospheric monitoring systems such as methane and carbon monoxide detection as well as measuring dust exposure uses ‘‘real-time data” to spot hazards immediately [41,42].

‘‘Big data”and‘‘real-time data”play a leading role in the current discussion (Fig.6).Both terms have a high PF with over 60% and nearly 45%,respectively(Fig.6).However,the TF of the two terms do not correlate with other digital technologies.A possible reason may be that ‘‘big data” and ‘‘real-time data” are named as underpinning technologies,which are the basis for other data-driven technologies such as ‘‘IoT”.However,‘‘big data” and ‘‘real-time data” have similar ego-networks (Fig.9f and g),with both having‘‘machine learning”,‘‘artificial intelligence”,and ‘‘automation” as related technologies.When it comes down to the analysis of multiple complex datasets,where state of the art tools and instruments reach their limits,‘‘big data” systems are a key technology for success [43].

4.1.4.Artificial intelligence and machine learning

‘‘Artificial intelligence”(AI)has been defined as techniques that allow recreating human-like cognitive abilities to automate tasks and processes [44].‘‘Machine learning” (ML) is commonly perceived as a subcategory of‘‘AI”and includes techniques that recognise patterns by learning from structured historical data [44,45].‘‘ML” methods have already successfully been applied in the mining industry.For example,structured data from infrared spectroscopy or images from drones are processed by ‘‘ML”algorithms to determine the mineralogy of exposed lithologies in mining areas [46,47].Also,mining operations use historical data together with ‘‘ML” techniques to reduce backbreaks and flyrock phenomenon in blasting operations [48,49].Predictive maintenance is done by the help of ‘‘ML” to recognize damage at mining and processing equipment to reduce unplanned downtimes and avoid fatal breakdowns [50].Yet,overall the application of ‘‘AI”in mining practices has been limited.

‘‘AI”and‘‘ML”are critical digital technologies(Fig.6),and‘‘ML”solutions are taken up by the mining industry (Figs.10 and 11).‘‘Automation” is strongly correlated to both technologies,which can be attributed to the fundamental goal of‘‘AI”and‘‘ML”to automate tasks (Fig.9a and b).Significant challenges for the mining industry are increasing complexity and amount of geological and machine data as well as the loss of skilled operators [51].This is why cognitive technologies,such as‘‘AI”and‘‘ML”are so essential in the future of mining.

4.1.5.3D printing

‘‘3D printing”is a process that creates 3D items from digital 3D models [52].The items are produced by sequential layers of synthetic or metallic material [53].‘‘3D printing” creates physical goods and consequently differs from the other digital key technologies.In mining,a possible field of application for‘‘3D printing”is produce spare parts and custom-built components,which in turn can reduce the cost of storage,production,and delivery times.Similarly,it is possible to use geological data,pictures of drones or point clouds from laser scanners to create digital items and print those as 3D ore deposit or open pit models for illustrative purposes[52,54,55].Moreover,3D printed infrastructure models(e.g.buildings) are used to perform stress and damage tests under different geotechnical conditions [56].

‘‘3D printing”(Fig.9c)is related to‘‘automation”as well as‘‘ML”and ‘‘AI”,since a computerised production process enhances an overall automation approach.As printing spare parts are often a reaction to component failure,‘‘ML” can help to forecast failure and to start with ‘‘3D printing” in advance so that downtimes can be reduced.Also,‘‘ML”can help to improve the design of spare parts by analysing failed components.‘‘3D printing”is also related to ‘‘blockchain”,because this technology can ensure the origin of data,avoid plagiarism and count how often a component has been printed [57].Thus,on-site production of customised spare parts through‘‘3D printing”has the potential to change the logistic supply chain of mines significantly.

4.2.Diffusion of digital technologies in mining

This study has identified a number of key digital technologies(Fig.6) that can reduce costs,improve business productivity and efficiency,and transform mining practices.Many of the new technologies are yet to be adopted by the mining industry and individual mine sites as shown by the overall lack of adoption of digital technologies across the mining sector (Fig.11).Other industries are rated better in an OECD digital index study.Mining is rated low in the digital index,but industries such as ‘‘machinery and equipment” or ‘‘electrical equipment” manufacturing are rated high[58].Industries were examined in relation to the comprehensively digitized high-tech industry [59].Here,the automotive industry is rated with a 31%digitization rate and the travel industry with 50%.Where this digital frontier index is comparable to the adoption rate,these values can also be used as target values for a moderate and high adoption rate.

However,the diffusion of digital technologies in mining correlates with the ROM production date(Fig.10).Smaller mines appear to implement considerably less new technologies than bigger mines.The degree of innovation and the level of investment in smaller mines are of course less than in larger mines,but the costs for IT hardware have fallen sharply in recent years[60]so that digital systems should also be interesting and affordable for small mines.Costs alone are,therefore,no obstacle for adopting digital technologies.

The adoption rate of innovations,i.e.the diffusion of digital technologies,is characterised by the following five attributes[61]:(1) relative advantage,(2) compatibility,(3) complexity,(4)trialability,and (5) observability.These attributes help to explain why large mines appear to have a higher diffusion rate of digital technologies.

(1) Relative advantage:This term describes how beneficial a digital technology is perceived,regardless of its benefits.For example,the mining industry expects a quantifiable reduction of operational costs (15–30%) [31]; by reducing its labour costs and installing automated systems.Especially larger mines with a large workforce would benefit from the reduced labour costs,which can also be derived from the results in Fig.10,which shows that the adoption of digital technologies is higher in companies with multiple operation.For smaller mines,this effect would be reduced due to fewer pieces of equipment and a smaller workforce [62].

(2) Compatibility:This attribute focuses on the experience,needs,and values of the adopters and how the new technology fits in the existing system.Realising digitalisation in bigger mines is enhanced through the presence of already existing infrastructure (e.g.sensors and human resources).Mines are very individual systems,which are influenced by the geology and other local conditions.This does not have a direct effect on the basic digital technologies,such as‘‘automation” or ‘‘AI”.Moreover,it influences the application of the system and the final implementation process.

(3) Complexity:The term describes how difficult it is to understand or use the new digital technology.Presently,most mining industry professionals do not have the skills and knowledge to understand and use the new digital technologies.Moreover,some technologies like blockchain require specially trained staff,and small mines do not have the resources to recruit these specialists.

(4) Trialability:This indicates to what extent a technology can be tested or experimented.Bigger mining companies often have research and development (R&D) units and financial resources for testing new technologies and systems.These R&D capacities are often not present in the corporate structure of small mines.

(5) Observability:This attribute indicates whether external stakeholders realise that digital technologies are successfully applied and used by mining companies.A mining company that uses and adapts to new technologies may be perceived as role model or early adopter.This image can be crucial for global companies that are intensively scrutinised by society.Furthermore,the observability of the outcome of new digital technologies is also important for internal stakeholders,such as the management board and other decision-makers.This helps to evaluate the feasibility and benefits of an investment in digital technologies.

Therefore,there remain obstacles in the adoption of digital technologies in mining.Adoption appears to be dependent on factors such as production scale of mining operations,existing infrastructure,availability of trained staff,R&D capacities,and company willingness to lead in technology diffusion.Regardless,results of this work have shown an apparent deficit in the diffusion of technologies among smaller operations.All these factors result in a final economic consideration that significantly influences the investment in digital technologies,especially for small mining companies.With less equipment and lower production,the absolute savings are lower,so that the profitability of digital technologies is viewed critically.However,there are several mine sites that demonstrate successful and economically viable implementation of digital technologies.For example,in 2014 the Éléonore Gold Mine in Canada installed an IoT system monitoring system,which included sensors with wireless network for real-time tracking and control of the equipment (n=400) and underground processes.These technologies also allowed implementing a ventilation ondemand system,which reduced the energy cost by more than $2 million per year [63].Another example is the investment into autonomous trucks at an open-pit mine in Western Australia (Pilbara) [64].Total expenditure amounted to A$18 million,which included the autonomous trucks,operation centre,AI-or MLdriven software as well as the communication network.The mining operation benefited from this digital change through reduced labour and wearing parts costs (A$3.9 million) and an increased production value (A$22 million).Thus,there are already several business cases in the mining sector that highlight the benefits of investing into digital technologies.

5.Conclusion

This paper reviewed mining journals (onemine.org),the media(Wikipedia),and insight reports (top consulting agencies) and used text-mining techniques to identify the key digital technologies relevant to the mining industry and to establish to what extent digital technologies are currently adopted by industry.Results demonstrate that ‘‘automation”,‘‘robotics”,‘‘internet of things”,‘‘big data”,‘‘real-time data”,‘‘machine learning”,‘‘artificial intelligence”,and ‘‘3D printing” are the key technologies for the mining industry.However,in general there is a lack of technology diffusion and the diffusion of digital technologies depends largely on the ROM production rate.There is an apparent deficit in the diffusion of digital technologies among smaller operations.Larger mining operations appear to select and apply digital technologies suitable to their needs,whereas operations with lower production rates do not implement the currently available digital tools and hardware technologies to the same extent.These minor producers may require other digital transformation solutions tailored to their capabilities and needs and applicable to their scale of operations.

Disclaimer

This research did not receive any specific grant from funding agencies in the public,commercial,or not-for-profit sectors.

Acknowledgements

Comments of two anonymous referees on an earlier version of the manuscript are much appreciated.

杂志排行

矿业科学技术学报的其它文章

- Experimental and theoretical investigation on mechanisms performance of the rock-coal-bolt (RCB) composite system

- Creep characteristics of coal and rock investigated by nanoindentation

- An experimental investigation of the fracturing behaviour of rock-like materials containing two V-shaped parallelogram flaws

- Comparative evaluation of different statistical tools for the prediction of uniaxial compressive strength of rocks

- A rapid and accurate direct measurement method of underground coal seam gas content based on dynamic diffusion theory

- Optimization of gob ventilation boreholes design in longwall mining