Study on effect of TiB2 reinforcement on the microstructural and mechanical properties of magnesium RZ5 alloy based metal matrix composites

2020-12-18ArabindaMeherManasMohanMahapatraPriyaranjanSamalPanduVundavilli

Arabinda Meher,Manas Mohan Mahapatra,Priyaranjan Samal,Pandu R.Vundavilli

School of Mechanical Sciences,Indian Institute of Technology Bhubaneswar,Odisha 752050,India

Received 8 November 2019;received in revised form 3 March 2020;accepted 23 April 2020 Available online 6 June 2020

Abstract A self-propagating high-temperature synthesis route is adopted for the fabrication of TiB2-reinforced magnesium RZ5 alloy-based in-situ metal matrix composites.Ti-B is used according to the appropriate stoichiometry to obtain 4,6 and 8 wt.% TiB2 reinforcements.The base alloy and cast composites are solutionised to enhance the mechanical properties of the materials.A microstructural study of the composites is carried out using optical microscopy and f eld emission scanning electron microscopy(FESEM)and revealed near-uniform distribution of TiB2 particles in the magnesium RZ5 alloy matrix.X-ray diffraction revealed the formation of the TiB2 reinforcement along with the transient phase TiB and MgB7.The hardness of the RZ5 alloy-based composites increases by 7.12%,17.06% and 32.07% with the addition of 4,6 and 8 wt.% TiB2 reinforcements,respectively.The ultimate tensile strength of the as-cast composite increases by 30.47% with the addition of 8 wt.% TiB2.The tensile strength and ductility of the materials is improved by using the solutionising heat treatment.The heat-treated composite containing 8 wt.% TiB2 results in an ultimate tensile strength of 178.7 MPa.The tensile fracture surfaces are analysed using FESEM.The wear loss of the materials decreased from 25.826 mm3 to 22.949 mm3 by the adding 8 wt.% TiB2 for the sliding distance of 2000 m.Micrographs of the worn surfaces obtained from FESEM of both the base alloy and composites are also studied which indicate delamination,wear groove and oxide formation.© 2020 Published by Elsevier B.V.on behalf of Chongqing University.This is an open access article under the CC BY-NC-ND license.(http://creativecommons.org/licenses/by-nc-nd/4.0/)Peer review under responsibility of Chongqing University

Keywords:In-situ composites;Magnesium RZ5 alloy;Heat-treatment;Tensile strength;Wear resistance.

1.Introduction

Metal matrix composites(MMCs)are being increasingly used in industry because of their higher strength,stiffness and wear resistance compared to other conventional materials[1].The desired properties of the composites can be achieved through the proper combination of the matrix and the reinforcement by different fabrication processes.Different matrix materials used for the fabrication of MMCs include aluminium,magnesium,copper,titanium,iron and their alloys[2,3].Cast magnesium alloy-based MMCs are used in the automobile and aerospace industries due to their highstrength for structural applications and high strength-to-weight ratio.A literature study reveals that replacing the aluminium parts with magnesium can increase fuel efficien y by 20-30% in automobiles[4].Particulate-reinforced MMCs can be processed by various processing routes,such as stir casting[5,6],squeeze casting[7],preform infiltratio[8],powder metallurgy[9,10]and self-propagating high-temperature synthesis(SHS)reactions[11,12].Composites developed byex-situmethods are generally characterised by low interfacial bonding strength and poor wettability,which may result in interfacial defect propagation.Hence,ex-situcomposites are not preferred for fluctuatin or cyclic loading conditions.In thein-situprocess,the reinforcement is synthesised inside a liquid melt by an exothermic chemical reaction,which is thermodynamically stable and less degradable at elevated temperatures[13].Researchers have endeavoured to develop TiC-,TiB2-,SiCNO-,ZrB2-and carbon nanotube-reinforced magnesium-basedin-situMMCs using different techniques for many aerospace and automobile applications[14,15].

Very few investigators have worked on self-propagating high temperature synthesis route forin-situfabrication of TiB2reinforced magnesium matrix composites.TiB2is considered as one of the most potential reinforcement due to properties like high melting point,high hardness,good thermal stability and excellent wear resistance[16].Matin et al.fabricated the TiB2reinforced magnesium-based MMCs using potassium boron tetrafluorid(KBF4)and potassium titanium hexafluo ride(K2TiF6)salt.When the salt was mixed and stirred at 450 rpm after melting the magnesium(above 1023 K),resulted in formation of TiB2by a series of reactions[17].Peng et al.also conducted the chemical reaction between KBF4and K2TiF6salt along with aluminium to fabricate Al-20 wt.% TiB2master alloy.The master alloy and alloying elements were added to molten magnesium at 750°C to fabricate TiB2reinforced magnesium AZ91 based composite.It was observed that,TiB2extracted from the master alloy were uniformly distributed in magnesium AZ91 alloy matrix with the particulate size of 50-300 nm.Also,the grain refinemen of composites occured due to the presence of TiB2particle as it acts as a grain refine.Ductility of the material along with other mechanical properties were observed to have improved[18].Wang et al.synthesized TiB2/Mg composite by SHS route taking Al,Ti and B powders.Preform was prepared by blending the powders using ball mill for 8 hours followed by the compaction at 70 MPa and drying of the compact.Preform was added to the magnesium melt at a temperature of 860°C which is slightly above the exothermic reaction temperature.The uniform distribution of TiB2in magnesium matrix was observed[19].Fang et al.fabricated AZ31/TiB2composite by SHS reaction using coupled fiel treatment and noticed that addition of TiB2in the magnesium AZ31 alloy matrix acts as a grain refine.It was also observed that due to the coupled fiel treatment strength as well as ductility of the composite improved[20].

Studies describing the synthesis of TiB2-reinforced rareearth-basedin-situmagnesium matrix composites are rare.The purpose of the present investigation is to developinsitumagnesium RZ5 alloy(Mg-Zn-Zr-RE)based MMCs with TiB2reinforcements using SHS reaction.The effect of the TiB2reinforcement on the mechanical properties,including hardness,strength and wear resistance of the magnesium matrix composites is studied.The effect of heat treatment on the mechanical properties of both the base alloy and cast composites is also investigated.

2.Experimental procedure

2.1.Synthesis of in-situ RZ5-TiB2 composites

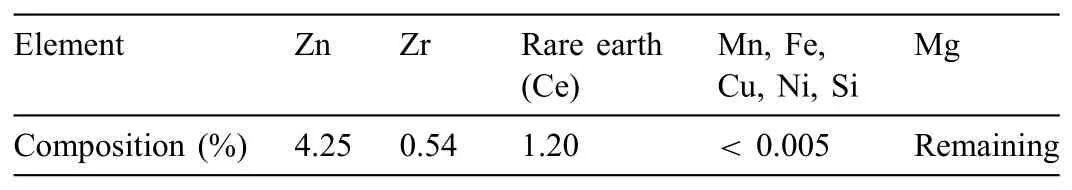

In this study commercial grade magnesium RZ5 alloy cast plate was used as the base material,which was procured from Foundry and Forge Division,Hindustan Aeronautics LimitedBangalore,India.The elemental composition of the cast magnesium alloy is depicted in Table 1.

Table 1Elemental composition of magnesium RZ5 alloy

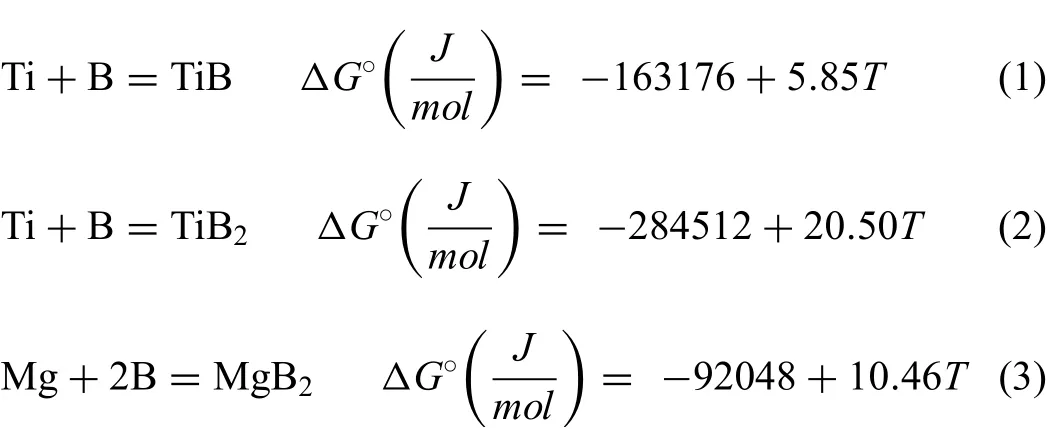

To develop the magnesium RZ5 alloy based metal matrix composites,a coal-fire pit furnace was used and a stirrer arrangement was made with a speed controller.Infra-red temperature reader(Extech-VIR50)was used to measure the temperature of the molten metal.The schematic representation of the casting setup is shown in Fig.1.In this study,high purity Ti mesh(99 % pure)and boron powder(99.5 %pure)were used with a molar ratio of Ti:B=1:2 to develop the TiB2reinforced metal matrix composites.The amount of Ti and B was added according to the stoichiometry of the required amount of reinforcement(i.e.4,6 and 8 wt.%)with the magnesium RZ5 alloy matrix[21].The SHS reaction between Ti mesh and boron powder led to the formation of TiB2reinforcement.In order to prevent oxidation,proper argon shielding was provided throughout the casting process.

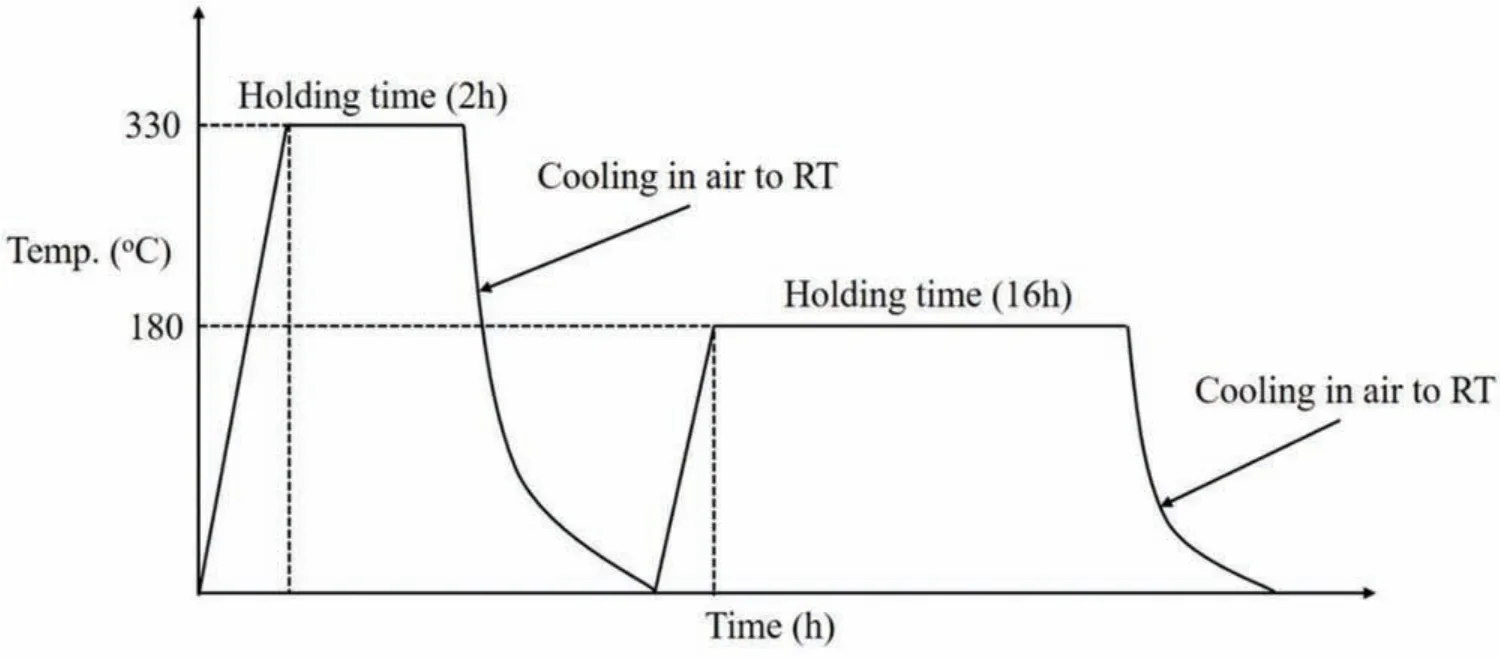

The Gibbs free energy for the formation of a solid solution phase can be determined by the following relations given in Eq.(1)-(3).

As per the thermodynamics data,the value of Gibbs free energy(ΔG◦)is more negative for TiB2as compared to that of TiB and MgB2.So the probability of TiB2formation is more as compared to other phases during the synthesis of magnesium matrix composites[17].

For casting,the titanium mesh was heated to 1400°C in a high temperature ceramic crucible at which the mesh structure gets converted into the powder form.The preheated boron powder was wrapped in an aluminium foil and was added into the crucible in an argon protective atmosphere.The mixture of titanium and boron was stirred continuously for 15 min to get a uniform distribution.After holding the mixture at 1400°C for about 10 min Ti-B mixture turns into a semi-solid slurry.Magnesium RZ5 alloy was melted in another crucible at 750°C.The Ti-B mixture was added to molten magnesium and stirred continuously for 20 min at 350 rpm.The diffusion between titanium and boron was initiated at this temperature[22].During this periodin-situreaction between titanium and boron took place inside the magnesium melt which resulted in the formation of TiB2.Then the liquid molten composite was poured into the pre-heated(500°C)steel mould.

Fig.1.Schematic representation of casting setup.

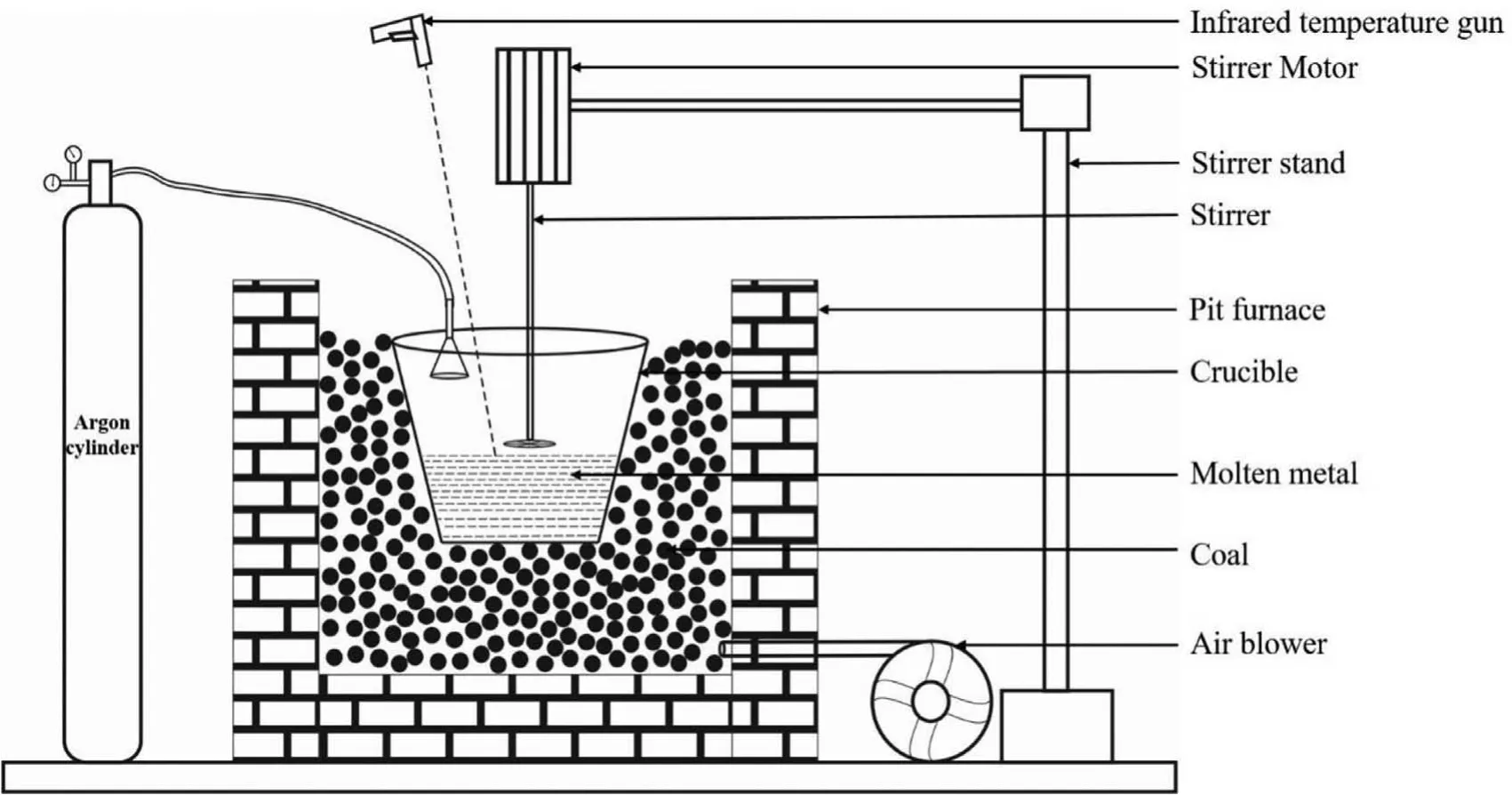

Fig.2.Schematic representation of the heat treatment process.

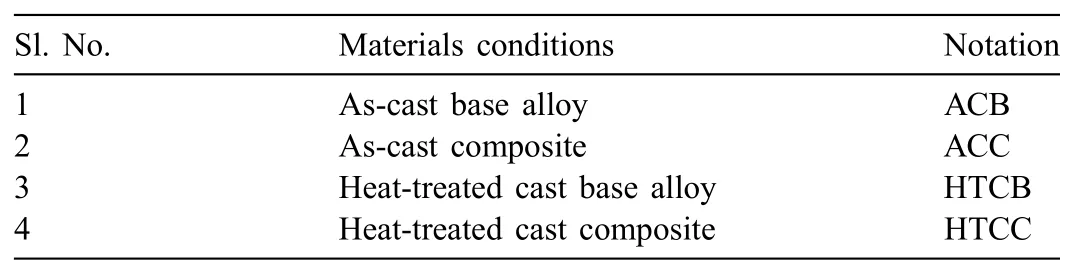

Table.2Notation of different materials

As the cast magnesium RZ5 alloy is brittle in nature so the heat treatment of the base alloy and the cast composites was carried out as per ASTM B661-12[23].The schematic representation of the heat-treatment process of the material is shown in Fig.2.The mechanical properties of the materials were characterized in the following four categories as given in Table 2.

2.2.Material characterization

For the metallographic study,a standard procedure was followed to prepare the samples[24].Etching of the samples was done by the etchant acetic picral(10 ml acetic acid+4.2 g picric acid+10 ml distilled water+70 ml ethanol).To know the different phase formations during thein-situsynthesis of the materials,phase analysis of the materials was performed by using BRUKER D8 Advance x-ray diffractometer with Cu Kα(λ=1.542 °A)radiation.X-ray diffraction was measured within the scan range of 10° to 90° with a scan speed of 0.5°/min.Micro-structural characterization of the composites was done using LEICA DMI3000 M optical microscope and ZEISS MERLIN Compact fiel emission scanning electron microscope(FESEM).

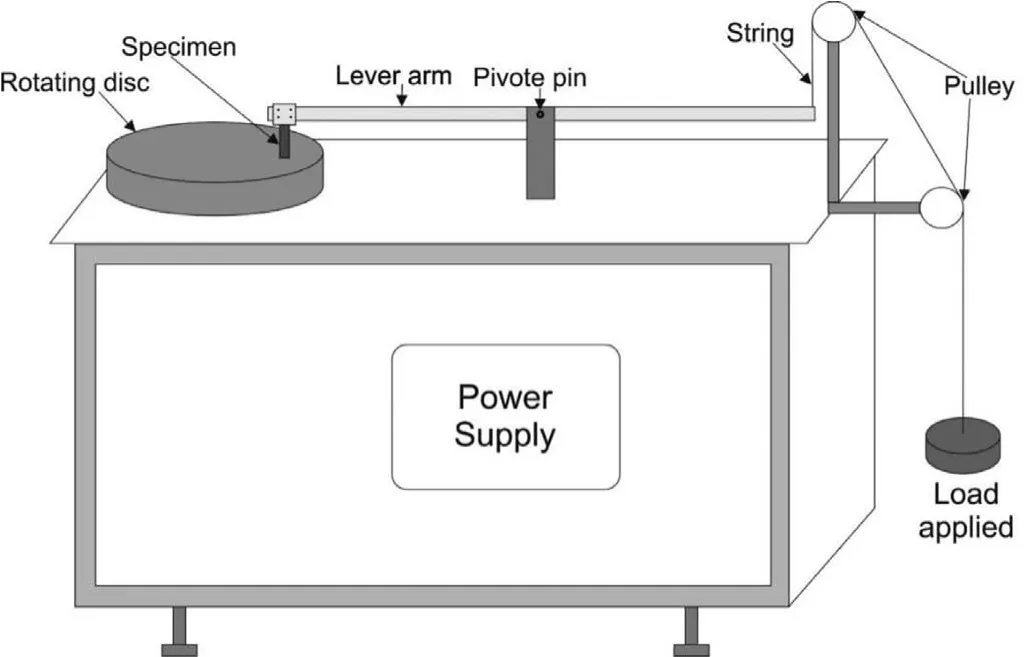

Fig.3.Schematic representation of wear testing setup.

The mechanical behaviour of the base alloy and 4,6 and 8 wt.% TiB2-reinforced magnesium matrix composites under both as-cast and heat-treated conditions was studied.The microhardness test of the materials was carried out by an Omnitech semi-automatic micro-hardness tester applying a load of 500 gf and a dwell time of 10 s.The indentation was taken at f ve different points to obtain the average hardness value along with the standard deviation.The tensile strength of the composites was measured using an INSTRON 5982 universal testing machine.The tensile strength test samples were prepared according to the ASTM E8/E8M-13a standard[25].The tensile test was conducted with a strain rate of 0.1 mm/min.The fracture surface of the tensile test samples was studied using FESEM.A Charpy test was completed using a pendulum impact testing machine(Tinius Olsen model Impact 104).ASTM E23-07a was followed to prepare the samples for the test[26].The dimensions of the impact test specimen were 55×10×10 mm3with a single-edge v-notch of 45° with a root radius of 0.25 mm and a depth of 2 mm.For each composition,four samples were taken to obtain the average impact strength along with the standard deviation.The wear rate of the materials was found using a Ducom TR-20LE-PHM 400 wear testing machine.A schematic representation of the wear testing setup is shown in Fig.3.The wear test samples were rectangularly shaped with dimensions of 10×10×30 mm3for both the base alloy and composites.

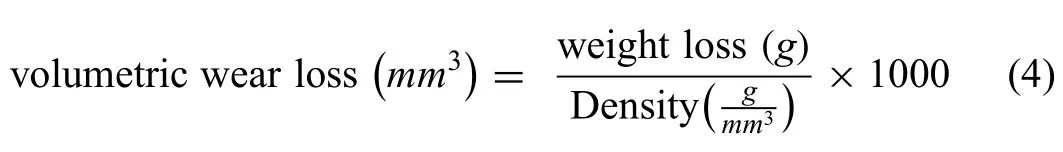

A dry sliding wear test of the materials was carried out with a rotating counter body made up of EN31 hardened steel.The volumetric wear loss of the materials was studied as a function of reinforcement content and sliding distance.The volumetric wear loss(in mm3)of the materials was measured from the weight loss of the materials due to the wear test,as shown in Eq.(4)[27,28].The microstructural variations on the wear surfaces of both the base alloy and cast composites were studied using FESEM.

3.Results and discussions

3.1.Phase analysis

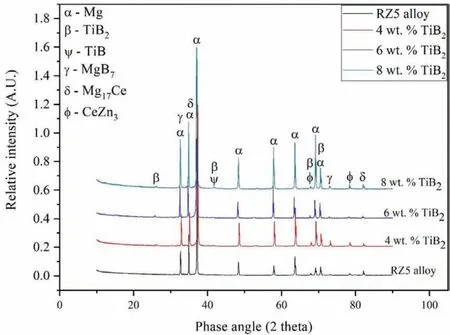

The X-ray diffraction(XRD)phase diagram shown in Fig.4 shows the presence of the TiB2phase in the composite.A few peaks of the TiB2reinforcement coincide with the peaks of the magnesium alloy.In addition to TiB2,a transient phase of MgB7and TiB(in the case of 8 wt.% TiB2)was also detected in the cast composites.The MgB7and TiB phase might have formed during thein-situreaction of the Ti and B in the magnesium melt.There was no phase formed between Ti and Mg,because as per the Mg-Ti phase diagram,no reaction takes place in this temperature range.As per the thermodynamics data available for the Gibbs free energy relation,the probability of formation of the TiB2phase is higher and it is a thermodynamically stable phase,since it has the lowest Gibbs free energy[18].Thus,TiB2particles are mostly distributed in the matrix phase.Along with Mg and the TiB2phase,other phases of the alloy,like Mg17Ce and CeZn3,were noticed in the XRD spectra.All the major peaks are identifie as per the JCPDS database.A few oxide peaks may be present that cannot be identifie by XRD due to their low intensity.

Fig.4.XRD spectra of magnesium RZ5 alloy and RZ5-TiB2 composites.

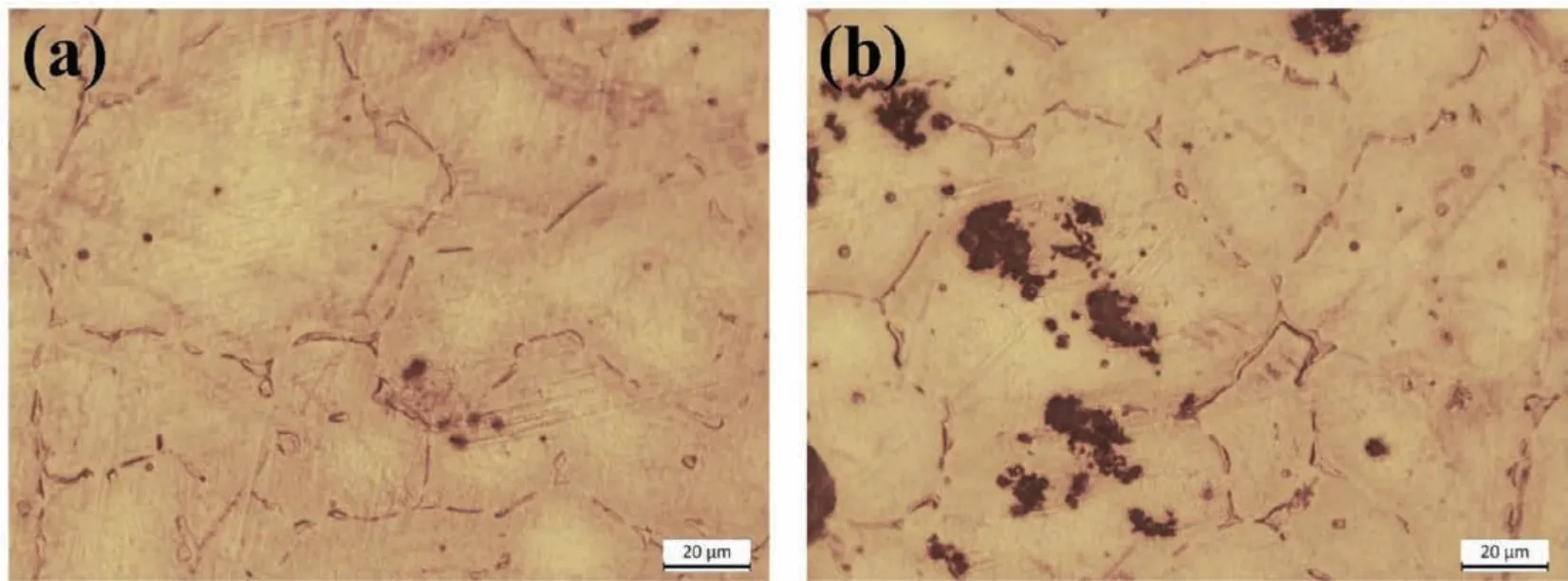

Fig.5.Optical micrograph of(a)RZ5 alloy,(b)RZ5-8 wt.% TiB2.

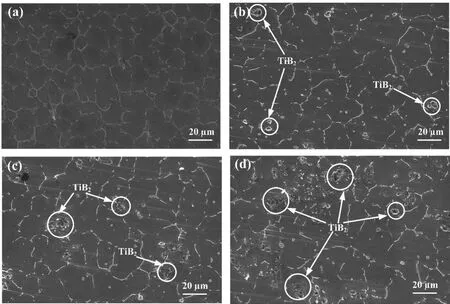

Fig.6.SEM micrograph of(a)Base RZ5 alloy,(b)4 wt.%,(c)6 wt.% and(8)8 wt.% TiB2 reinforced magnesium matrix composites.

3.2.Microstructural analysis

Fig.5 shows the optical micrograph of the base RZ5 magnesium alloy and the RZ5-8 wt.% TiB2magnesium matrix composites.It can be noticed that during the SHS process,several reinforcements develop along the grain boundaries while others form along the grain.Reinforcements are distributed near uniformly in the magnesium matrix.Wanget al.also observed a similar trend during the development of AZ91 magnesium alloy-based TiB2-reinforced MMCs.In addition,it was found that the addition of TiB2in the magnesium matrix improves grain refinemen[22].

Microstructural characterisation of the TiB2-reinforced magnesium RZ5 alloy-based MMCs was carried out using FESEM.Fig.6(a-d)shows FESEM micrographs of the base RZ5 alloy and 4,6 and 8 wt.% TiB2-reinforced magnesium RZ5 alloy-based MMCs.It was noticed that the reinforcements formed due to thein-situreaction of Ti-B in magnesium melts are of hexagonal or rectangular shape.Similar microstructure was observed by other researchers during synthesis of(TiB2-TiC)/AZ91[29]and TiB2/AZ31[30]magnesium matrix composite.

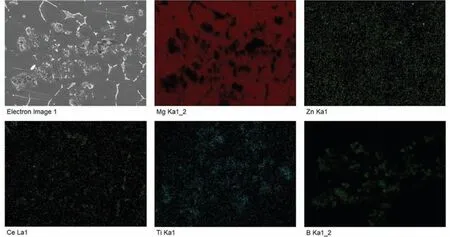

Fig.7.Elemental mapping of 8 wt.% TiB2 reinforced RZ5 alloy-based magnesium matrix composites.

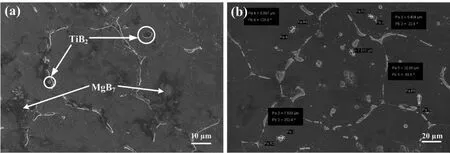

Fig.8.(a)FESEM micrograph of 4 wt.% TiB2 reinforced RZ5 composite,(b)Grain size measurement of TiB2 reinforced composites.

The FESEM micrographs reveal the near-uniform distribution of TiB2reinforcement in the magnesium RZ5 alloy matrix.From the micrographs,it is noticed that there was no macro or microporosity in the composites,which are generally observed in the composites developed by theex-situmethod.

To study the areal distribution of the TiB2reinforcement,X-ray elemental mapping of the cast 8 wt.% TiB2-reinforced composites was carried out.The elemental mapping shown in Fig.7 reveals the uniform distribution of TiB2particles along with magnesium and its alloying elements.

A transient phase MgB7was detected by XRD formed during thein-situreaction.In the FESEM micrograph,the MgB7phase formed along the grain boundary,as shown by the dark grey colour in Fig.8(a).From the micrograph shown in Fig.8(b),it was found that the average particle size of the TiB2reinforcement formed due to thein-situreaction is∼4-6μm.

3.3.Mechanical properties

3.3.1.Hardness test

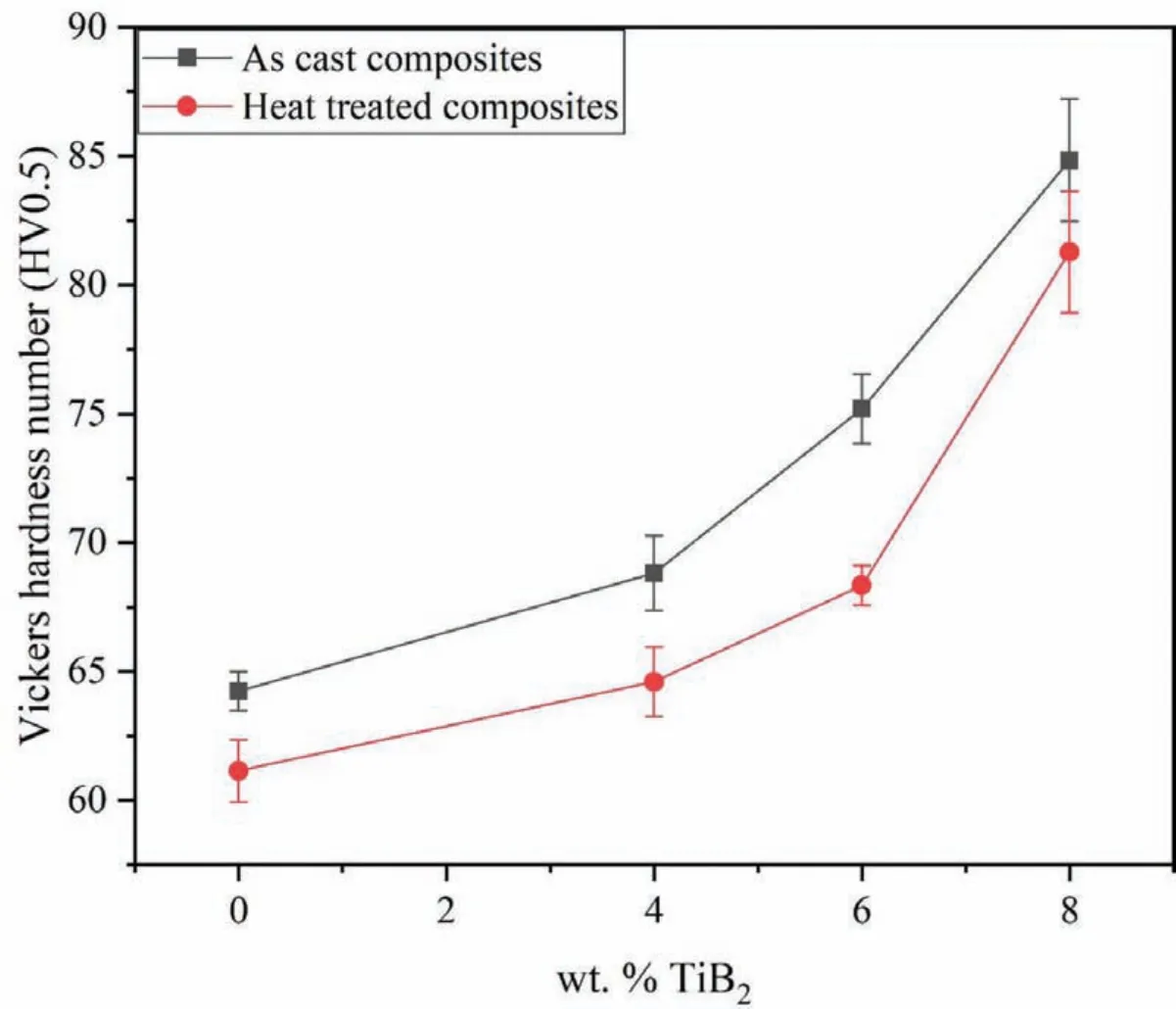

Fig.9 shows the variation of hardness with an increase in TiB2reinforcement content for the as-cast and heat-treated composites.It was noticed that the hardness of the composites increased with increasing TiB2reinforcement content.As the TiB2particles are very brittle in nature,they act as resistance to the plastic deformation.The hardness of the composites may also increase because of the grain refinemen as TiB2acts as a grain refine.From the Fig.9,it can be noticed that the hardness of the HTCC is relatively low compared to ACC because the ductility of the material increases due to the heat treatment.For the ACB alloy,the hardness value was found to be 64.2 HV,whereas for the HTCB material,the hardness was found to be 61.1 HV.A similar trend was also observed for TiB2-reinforced composites.Fig.9 shows a hardness of 85.0 HV at 8 wt.% TiB2for ACC,whereas for HTCC,the hardness value decreased to 81.3 VHN.

Fig.9.Variation of hardness with wt.% TiB2 all ACB,ACC,HTCB and HTCC materials.

The hardness of the materials also depends on the strengthening mechanism during synthesis and further processing of materials.The strengthening mechanism of RZ5 alloy is governed by the elemental composition(Mg-Zn-Zr-RE)and heat treatment(solutionize at 330°C for 2h followed by aged at 180°C for 16h).In case of RZ5/TiB2composites,it is known that during in-situ synthesis,magnesium doesn't form any phase with titanium.However,it forms a phase of MgB7,which indicates the better interfacial bonding.To further enhance the mechanical properties of the composites,solution strengthening regime is applied.The hardness of the materials mainly depends on the distribution of the TiB2reinforcement in the magnesium RZ5 alloy matrix.The hardness of the materials also depends on the holding time during heat treatment(solutionizing and aging).The heat treatment of the material affects the dislocation density,as the difference between the coefficien of thermal expansion of magnesium(26.5×106K−1)and TiB2(7×106K−1)is high[31].So,VHN of the composites depends on the presence of precipitated MgB7phase which helps in formation of strong interfacial bond and difference in the coefficien of thermal expansion between reinforcement and matrix phase.

3.3.2.Tensile strength

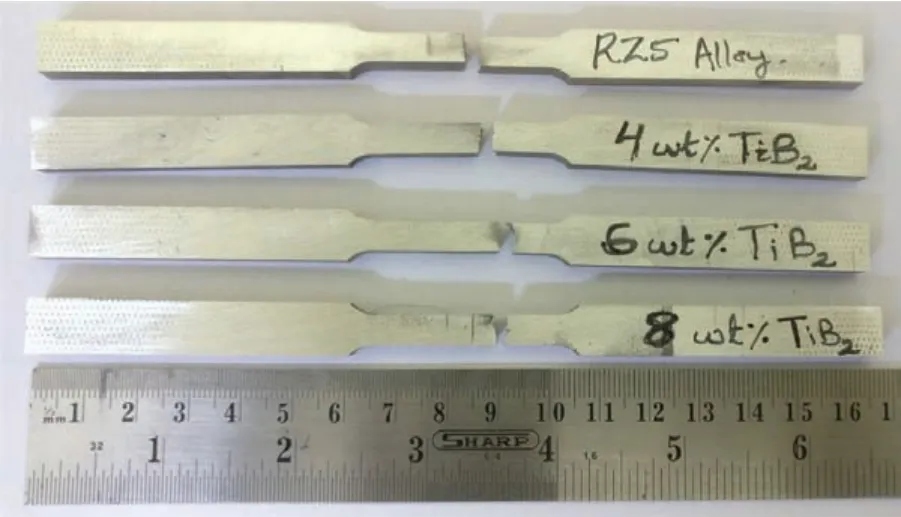

The stress-strain behavior of base alloy andin-situTiB2reinforced MMCs was studied at room temperature(27°C).The tensile strength properties of the magnesium RZ5 alloy based MMCs were examined by varying the TiB2reinforcement contents.The gauge length of the samples was prepared as per ASTM E8/E8M-13a standard.Fig.10 shows the typical image of the samples after the test.

Fig.10.Typical image of tensile samples after the tensile test.

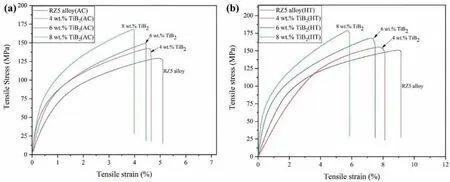

The stress-strain curve for ACB and ACC is shown in Fig.11(a),it was noticed that with an increase in TiB2reinforcement content,both yield strength(YS)and ultimate tensile strength(UTS)improved.For the as-cast magnesium RZ5 alloy,the YS and UTS was found to be 91.3 MPa and 129.05 MPa respectively.With the addition of TiB2reinforcement by 4,6 and 8 wt.%,the UTS of the composites increased by 10.48 %,15.77 % and 30.47 % respectively.For the composite containing 8 wt.% of TiB2,the UTS value was found to be 168.31 MPa.It was observed that solutionize heat treatment enhanced the tensile strength and ductility of the material.

Fig.11.Engineering stress-strain curve(a)ACB and TiB2 reinforced ACC and(b)HTCB and TiB2 reinforced HTCC.

From the engineering stress-strain curve of HTCB and HTCC shown in Fig.11(b),it was noticed that HTCB condition UTS is 150.93 MPa which indicate that the UTS of the material increased by 16.95 % via heat treatment as per ASTM B661-12.As the heat treatment was conducted in two steps,i.e.solutionizing followed by aging,the ductility of the material improved significantl.For the base RZ5 alloy,the ductility improved by 79.85 % post heat treatment.Sahooet al.also observed the significan improvement in strength and ductility due to the heat treatment of magnesium AZ91 alloy and TiB2/TiC reinforced composites[32].It was also found that the UTS and ductility improved by 6.31 % and 47.24 % respectively in case of 8 wt.% TiB2reinforced magnesium matrix composites.Fig.11(a and b)shows the reduction in ductility as the TiB2reinforcement content increases.The enhancement in strength and reduction in ductility depends on the distribution of the TiB2reinforcement particle in the magnesium matrix.

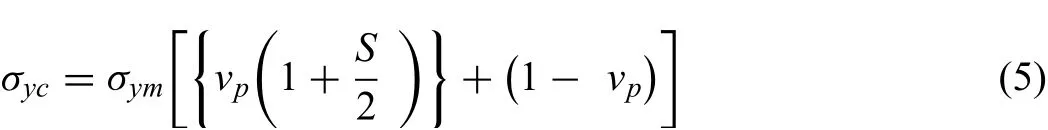

The improvement of the tensile properties of the composite by the addition of TiB2reinforcement is based on two approaches.One is,continuum mechanics indicating the transfer of load and bonding between TiB2reinforcement and matrix during loading.Another is,strengthening effect of the composites based on the yield strength of the material[33,34].Nardoneet al.established a formula for estimation of the theoretical yield strength of discontinuously reinforced ceramic particle in a metal matrix which is based on the modifie shear-lag model for the particulate reinforced composites[35],as shown in Eq.(5).

Whereσycandσymare the yield strength of the composite and the matrix phase respectively,vpis the volume fraction of the particulate reinforcement andsis the aspect ratio of the reinforcement particles.The overall strength of the MMCs improved due to the strong interfacial bond between TiB2particle and RZ5 alloy matrix.With the increase in TiB2reinforcement content(vp),both YS and UTS increased whereas tensile strain of the material decreased.

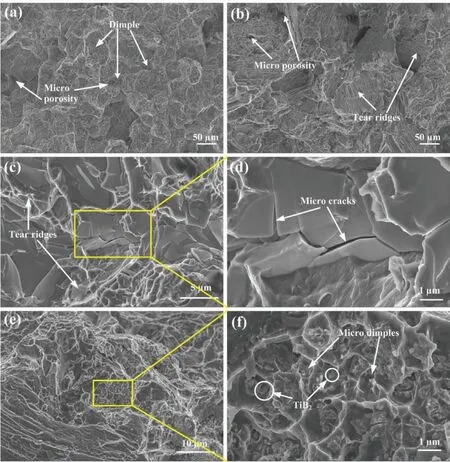

3.3.3.Tensile fracture surface

The morphology of the tensile fracture surface of the base RZ5 alloy andin-situTiB2reinforced composite is shown in Fig.12.From Fig.12(a)it was observed that in case of base RZ5 magnesium alloy,deep equiaxed dimples throughout the surface which indicates the ductile mode of fracture.Few micro voids were also noticed on the fracture surface where the cracks may have initiated.Also,the dimple type of structures remains on the surface.

In case of TiB2reinforced composites shown in Fig.12(b),along with few smaller size dimples,tear ridges were also noticed on the surface.So the mixed mode of fracture has occurred in case of composites.Tear ridge on the fracture surface indicates the brittle modes of fracture.Presence of ceramic reinforcement in the composites acts as a crack arrester,which helps in improving the strength of the materials[36].Due to the presence of TiB2particles,the ductility of the material reduces.In case of composites,few micro cracks were noticed at higher magnificatio along with tear ridge surface shown in Fig.12(c)and 12(d).The tear ridge and micro-cracks may have initiated due to the presence of ceramic TiB2particle agglomeration at some points.Several smaller size dimples were noticed in RZ5-8 wt.%TiB2composites shown in Fig.12(e)and 12(f)indicate that composite follows a mixed mode of fracture.From the micrograph,it was also noticed that some TiB2particles were present on the fracture surface.As the strength of the material increases with a minimal reduction of ductility indicates the good wettability effect and strong bonding present due to thein-situformation of TiB2particle.

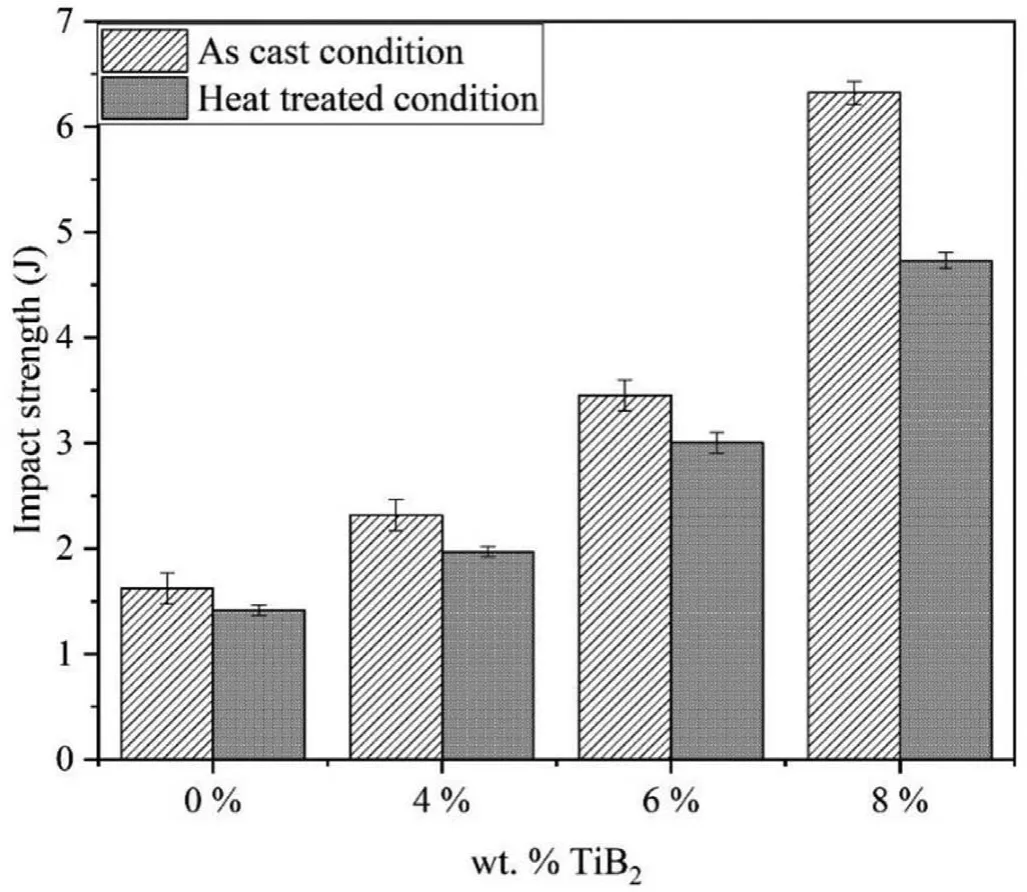

3.3.4.Impact strength

Fig.12.FESEM micrograph of tensile fracture surface(a)Magnesium RZ5 alloy,(b)Mg-8 wt.% TiB2 composite,(c)and(d)Micro-cracks and tear ridges on the surface at the different magnification of Mg-6 wt.% TiB2 composite,(e)and(f)Mg-8 wt.% TiB2 composite showing micro dimple and TiB2 particle.

Fig.13.Typical image of Impact test sample.

The impact strength of the materials was measured by the Charpy test.A typical image of the Charpy test samples along with the V notch is shown in Fig.13.The variation of the impact strength of the Charpy sample is shown in Fig.14 for the ACB,ACC,HTCB and HTCC materials.The impact strength of the materials was recorded from the energy delivered by the pendulum during the impact test.For ACB and HTCB alloys,the impact strength was found to be 1.62 and 1.41 J,respectively.Similarly,for the 8 wt.% TiB2-reinforced ACC and HTCC materials,the impact strength was found to be 6.32 and 4.73 J,respectively.It was also noticed that for all compositions of reinforcement content,the impact strength of the ACC is more than for the HTCC materials.This may have occurred as the materials were solutionize at 330°C for 2h followed by aged at 180°C for 16h.The impact strength of the materials decreases with prolong aging time as the eutectic phase of the materials get dissolved[37].The impact strength of the materials depends on the type of matrix and reinforcement,as well as on the presence of any intermetallic phase.In addition,the impact strength depends on the condition of the heat treatment of the materials because of the possibility of the formation of the precipitated phase[38].

Fig.14.Variation of impact strength with wt.% TiB2 ACB,ACC,HTCB and HTCC materials.

Fig.15.Variation of volumetric wear loss(mm3)with sliding distance(m)of HTCB alloy and HTCC materials with a load of 20 N.

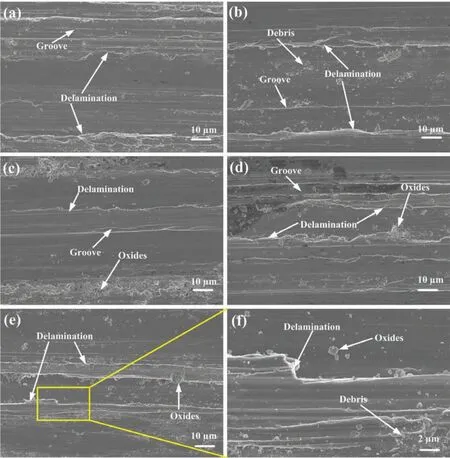

Fig.16.FESEM micrograph of(a)RZ5 alloy,(b)4 wt.%,(c)6 wt.% and(d)8 wt.% TiB2,(e)and(f)delamination of 6 wt.% TiB2 reinforced RZ5 alloy based magnesium matrix composites with a load of 20 N.

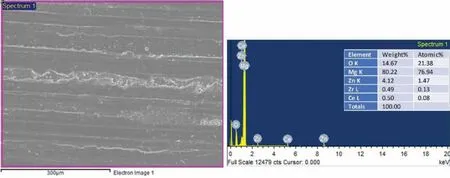

Fig.17.EDX analysis of wear surface of magnesium RZ5 alloy.

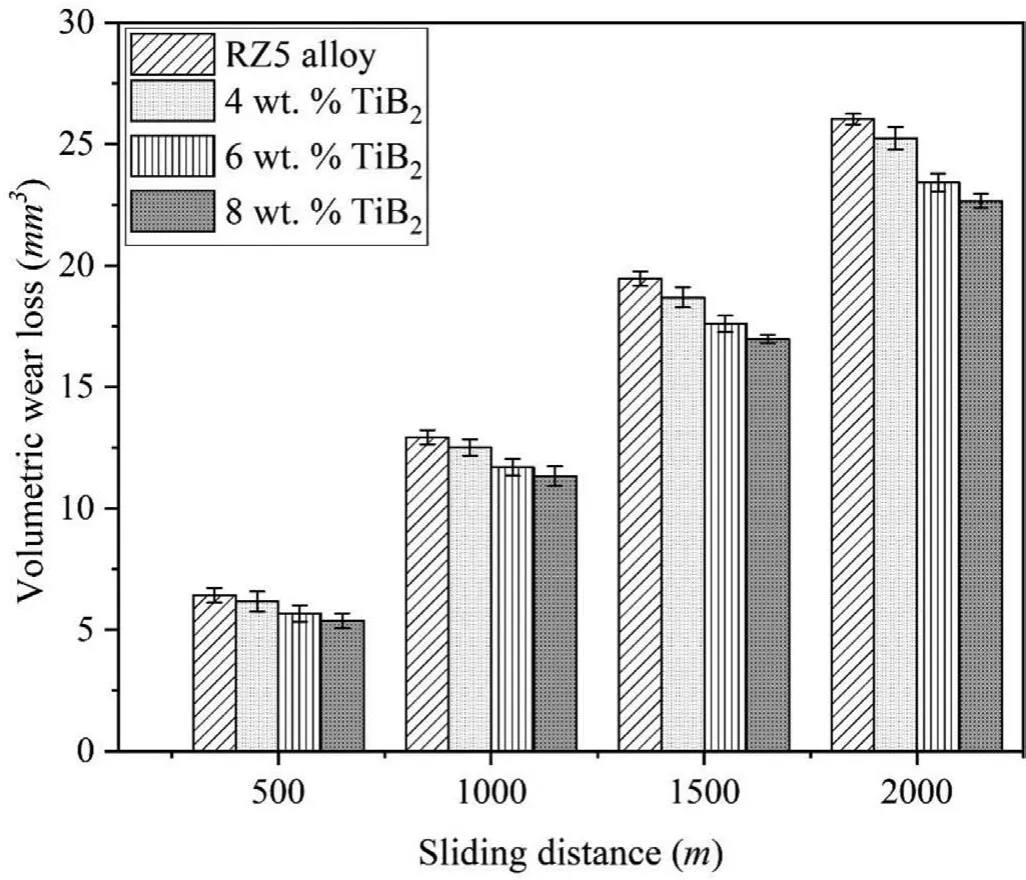

3.3.5.Wear test

Tribological behavior of RZ5 magnesium alloy and 4,6 and 8 wt.% TiB2reinforced MMCs was measured using pinon-disk wear testing setup.Fig.15 shows the volumetric wear loss(inmm3)for both HTCB and HTCC by applying a load of 20 N.For each sample,three sets of tests were performed to evaluate the actual wear loss by varying both the sliding distance and reinforcement content.From Fig.15,it can be observed that the volumetric wear loss of the materials increased with increase in sliding distance.It was also noticed that with the increase in TiB2reinforcement content wear loss decreased.Which indicates that the presence of ceramics phase TiB2is acting as the resistance to wear at the contact surface.Volumetric wear loss of 25.826 mm3was observed in case of HTCB alloy whereas that of 22.949 mm3was found in case of HTCC when reinforced with 8 wt.% TiB2for a sliding distance of 2000 m.For different sliding distances,the volumetric wear loss for TiB2particles reinforced composites observed to be lesser when compared to RZ5 base alloy due to the absence of TiB2particles on the contact surface in the softer matrix phase.For the RZ5 alloy wear loss was 6.424,12.929,19.462 and 26.019 mm3whereas in case of 8 wt.% TiB2composite wear loss was found to be 5.371,11.327,16.970 and 22.656 mm3for the sliding distance of 500,1000,1500 and 2000 m respectively.

The FESEM microstructural examination of the wear surface includes delamination,wear groove,micro-crack,wear debris and oxides.During the wear process,materials removed in the form of wear debris and wear grooves were formed due to the plastic deformation of the material at the contact surface.Due to friction,the temperature at the contact surface increases and some of the wear debris became oxides.Fig.16(a-d)shows the FESEM micrograph of RZ5 base alloy and 4,6 and 8 wt.% TiB2reinforced composites with a test condition of 20 N load and for a sliding distance of 2000 m.The morphology of the worn surface showed some wear groove formation and delamination along with wear debris and oxides.In case of composites,the presence of hard ceramic TiB2particle acts as a protective layer at the contact surface and these ceramic particles lead to the formation of heavy delamination and deep groove.In case of composites,some cracked ceramic particles were noticed on the worn surface.The wear behavior of the composite materials depends on the interfacial bond formation between the matrix and the reinforcement[39].Fig.16(e and f)shows the initiation of delamination on the worn surface of 6 wt.% TiB2reinforced composite due to the presence of hard ceramic particles at different magnifications Wear groove,delamination and oxide particles were observed clearly on the wear surface at higher magnificatio of the materials.EDX analysis of the wear surface of the material was conducted to study the formation of the oxide during the dry sliding wear.The EDX analysis of magnesium shown in Fig.17 confirm the formation of oxide during the dry sliding of the materials with the hardened EN31 rotating disc.The oxide on the contact surface formed due to the rubbing action at the contact surface.

4.Conclusion

In the present research work,TiB2-reinforced magnesium RZ5 alloy-basedin-situMMCs were successfully synthesised by an SHS route.During the synthesis of composite,temperature,holding time and casting environment were the major variables.The following conclusions can be made from the present work:

1.Optical and FESEM micrograph indicated the near-uniform distribution of the TiB2reinforcement in the magnesium RZ5 alloy matrix.XRD phase analysis confirme the formation of a stable TiB2phase along with the TiB and MgB7transient phase.

2.The hardness value of the composite increased from 64.2 to 85.0 VHN by reinforcing with 8 wt.% TiB2.The impact strength of the material also increases with increasing TiB2content.The solutionising heat treatment of ACB and ACC improved the ductility of the materials,which led to a minor reduction in hardness and impact strength.

3.A maximum increase of 30.47% was observed in the UTS by the addition of 8 wt.% TiB2in the magnesium RZ5 alloy matrix.The solutionising heat treatment further enhanced the UTS by 16.95%.The micrograph of the tensile fracture surface for the RZ5 alloy revealed the ductile mode of fracture,whereas for the composites,a mixed mode of fracture was observed.

4.Volumetric wear loss for the RZ5 base alloy was found to be 25.826 mm3for the sliding distance of 2000 m,whereas the wear loss reduced to 22.655 mm3in the case of the composite with 8 wt.% TiB2.FESEM micrographs revealed the delamination,wear groove and oxide particle formation on the contact surface.

The addition of up to 8 wt.% TiB2reinforcement in the magnesium RZ5 alloy matrix improved the mechanical properties,including tensile strength,impact strength and wear resistance,making the material more suitable for use in various components of the automobile and aerospace industries.The further addition of TiB2may lead to excessive brittleness,which may not be suitable for practical applications.

Acknowledgment

The author(s)would like to express their gratitude to Foundry and Forge Division,Hindustan Aeronautics Limited Bangalore,India for providing the magnesium alloy.

杂志排行

Journal of Magnesium and Alloys的其它文章

- Microstructural evolution of Mg-Al-Re alloy reinforced with alumina fiber

- Predicting and controlling interfacial microstructure of magnesium/aluminum bimetallic structures for improved interfacial bonding

- Plasma electrolytic oxidation of AZ31 and AZ91 magnesium alloys:Comparison of coatings formation mechanism

- Effects of annealing treatment on microstructure and tensile behavior of the Mg-Zn-Y-Nd alloy

- Microstructure and performance of biodegradable magnesium alloy tubes fabricated by local-heating-assisted dieless drawing

- Comparisons of microstructure homogeneity,texture and mechanical properties of AZ80 magnesium alloy fabricated by annular channel angular extrusion and backward extrusion