Effects of annealing treatment on microstructure and tensile behavior of the Mg-Zn-Y-Nd alloy

2020-12-18ShengDuHuQioXioWngXuZhengXi

L.Y.Sheng,B.N.Du,Z.Y.Hu,Y.X.Qio,Z.P.Xio,B.J.Wng,D.K.Xu,Y.F.Zheng,T.F.Xi

a Shenzhen Institute,Peking University,Shenzhen 518057,China

b Jiangsu University of Science and Technology,Zhenjiang 212003,China

c Institute of Metal Research,Chinese Academy of Sciences,Shenyang 110016,China

d Shenzhen Yezhan Electronics Co.,Ltd,Shenzhen 518110,China

Received 11 June 2019;received in revised form 27 July 2019;accepted 29 July 2019 Available online 7 June 2020

Abstract In the present study,the Mg-4Zn-0.6Y-0.5Nd alloy was hot extruded and annealed at 200°C,225°C and 250°C for different time to optimize microstructure and mechanical properties.The results exhibit that the dual-size grain structure and linearly distributed secondary phase are the main feature of the as-extruded Mg-Zn-Y-Nd alloy,which can be described as the elongated grain is surrounded by the fin equiaxed grain.Moreover,the as-extruded alloy shows strong{01¯10}fibe texture feature,especially for the large elongated grains.The annealing treatment results in static recrystallization,which increases fin equiaxed grains but decreases large elongated grains.In addition,the equiaxed grains formed during the annealing treatment demonstrate relative random orientations,which weaken the{01¯10}fibe texture of the alloy.Moreover,during the annealing at 225°C and 250°C,the extension twins begin to form in the alloy and weaken the{01¯10}fibe texture of the alloy further.The annealing treatment has little influenc on the linearly distributed secondary phase but promotes the coarsening of small precipitates at 250°C.The annealing treatment could increase the yield and ultimate strength,but the elongation decreases,especially at higher temperature.Such a variation can be ascribed to the evolution of texture,grain structure,twinning and precipitation during the annealing treatment.© 2020 Published by Elsevier B.V.on behalf of Chongqing University.This is an open access article under the CC BY-NC-ND license.(http://creativecommons.org/licenses/by-nc-nd/4.0/)Peer review under responsibility of Chongqing University

Keywords:Annealing treatment;Mg-Zn-Y-Nd alloy;Microstructure;Tensile property.

1.Introduction

Mg has attracted much attention because of its attractive features such as low density,high specifi strength,low elasticity modulus[1,2].Therefore,it has be thought as one of most competitive materials in field of aerospace,automobile and biomedical implant,etc[3,4].However,the relative low ductility and strength of Mg have handicapped its widely application,so improving its mechanical properties is necessary.In general,alloying has been thought as one of most convenient way to increase the mechanical property,and Zn,Al,rare earth(RE)etc have been applied to develop new Mg alloys[5-7].The research of Nˇemec et al.investigated the microstructure and compressive properties of the Mg alloys with different Zn addition[8].The results exhibited that the increased Zn content would increase the quantity of precipitates and the compressive strength.Zhang et al.[9]had revealed that the hot extruded Mg-6Zn(wt.%)alloy could obtained better mechanical properties with tensile elongation and strength of 18.8% and 279.5MPa,respectively.However,more addition of Zn in the Mg-Zn binary alloy would promote the formation of coarse grain which was detrimental to the mechanical performance[10,11].The previous studies[12-14]showed that the rare earth elements is beneficia to the grain refinemen effectively.The study of Lee et al.[12]exhibited that the Mg-Zn alloy with appropriate Y addition could obtained refine grain structure with I-phase,which strengthened the alloy obviously.Furthermore,the strengthening effect is correlated with the Zn/Y ratio.when the Zn/Y ratio is 2.5,the strength of the Mg-Zn-Y based alloy would reach the highest value.Moreover,Wang et al.[13]demonstrated the Mg-Zn-Mn-Ca alloy with minor addition of Nd could obtain fin microstructure.The Li et al.[14]exhibited that the synergistic effect of Nd and Y could decrease the dendrite size and promote the formation of semi-continuous intergranular phase in as-cast Mg-Zn-Zr alloy,which favors the ultimate strength and elongation.From the previous researches,it could be summarized that the Mg based alloy with reasonable Zn,Y and Nd addition could obtain good mechanical properties.

Besides,hot working is another important way to improve mechanical properties of Mg based alloys by refinin precipitates and grains,which is also beneficia to the element and microstructure homogenization[15,16].However,it is generally reported that the formed texture and incomplete recrystallization during hot working would influenc the mechanical properties.The X.Zeng et al.[17]on rolled Mg-2Nd-1Zn alloy sheet showed that the cold rolling could form strong texture in the rolling direction but weak texture in the transverse direction.However,the investigation of D.Zhang et al.[18]had demonstrated that the predeformation on Mg-Y-Nd-Zr alloy led to the basal planes perpendicular to the predeformation direction and improved its strength obviously.In addition,the C.Barrett et al.[19]revealed that the Y would segregate along the grain boundary in Mg matrix and then weaken the texture during its deformation.Despite of the effect of texture,the following heat treatment on Mg alloy could help to optimize its mechanical properties and microstructure[20,21].Zhang et al.[20]studied the influenc of heat treatment on the as-extruded Mg-2.7Nd-0.2Zn-0.4Zr alloy and exhibited that its ductility was improved with a little reduction of strength.In addition,the heat treatment promoted the precipitation of fin and dispersed particles,which contributed to the strength and homogeneous corrosion.Yuan et al.[22]conducted aging treatment at different temperatures on the as-extruded Mg-Gd-Y-Nd-Zr alloy and exhibited that the alloy aged 225°C for 72h obtained the high strength and creep property.

Therefore,the Mg based alloy with Zn,Y and Nd addition was prepared and hot extruded in the present research.After then,the annealing treatment was performed to optimize its microstructure and mechanical properties of the hot extruded Mg-Zn-Y-Nd alloy.The microstructure and tensile properties of the as-extruded and annealing treated alloys were analyzed,and the effect of annealing treatment on microstructure and tensile properties was discussed.

2.Experimental procedures

The alloy with designed composition of Mg-4Zn-0.6Y-0.5Nd(wt.%,Mg-Zn-Y-Nd for short)was melted from Mg-25Nd(wt.%)master alloy,pure Zn and Mg-25Y(wt.%)master alloy in the electric resistance furnace at 760°C under a CO2/SF6(100:)protective atmosphere.To ensure the homogeneity of the cast alloy,the liquid melt was stirred and then cast into a mild steel crucible heated to 220-300°C to obtain the alloy ingot with diameter of 130 mm.Before the hot extrusion,the heat treatment of 500°C/2h was carried out on the alloy ingot.Then the heat treated alloy ingot was hot extruded into a bar with diameter of 50 mm at 460°C.After that,the as-extruded alloy bars were annealing treated at 200°C,225°C and 250°C for 1h,5h,8h and 12h,respectively.

The samples for microstructure and phase analysis were cut from the as-extruded and annealing treated bars and prepared by conventional methods of mechanical grinding and chemical etching with a solution of 5ml acetic acid+5g picric acid+10ml distilled water+100ml ethanol.The Xray diffraction(XRD)measurement was conducted on the Rigaku D/mac-2400 diffractometer with Cu Kαradiation.The microstructure observation was carried out on the Phenom Pro scanning electron microscope(SEM).The electron backscattered diffraction(EBSD)was used to characterize the local microstructure and texture of the as-extruded and annealing treated alloys.The sample for EBSD analysis was grinded,polished and ion beam etched through a LEICA EMRES101 ion beam milling system.

The tensile specimens with gauge dimensions of 3mm×4mm×20 alloys were cut from the annealing treated and as-extruded bars.After then they were polished by sandpaper down to the metallurgical grit of 1200.The INSTRON 5582 testing machine was employed to conduct the tensile test and the initial rate was 1×10−3mm/s.After the tensile test,the samples near the fracture surface were cur from the fractured tensile specimens and polished by the conventional metallographic methods.The SEM was used to observe the fracture surface and the microstructure near the crack to analyze the fracture mechanisms.

3.Results

3.1.Microstructural characterization

The typical microstructure and phase constituent of the as-extruded Mg-Zn-Y-Nd alloy were analyzed by SEM and XRD,and the results are displayed in Fig.1.Clearly,the as-extruded alloy is mainly composed of fin equiaxed grain and large elongated grain,as shown in Fig.1(a).The length of the large elongated grain is about hundreds of microns and its width is tens of microns.The equiaxed grain has the size of about 10-30μm and should be formed by the dynamic recrystallization.However,due to the short extrusion processing time,the dynamic recrystallization could not proceed thoroughly in the alloy,thus there are still large original grains that are heavily deformed and elongated along the extrusion direction(ED).Besides,the hot extrusion has broken the secondary phases into small ones which are linearly distributed along the ED.Additionally,some ultrafin particles could be observed in the grain or along grain boundary.The XRD analysis in Fig.1(b)shows thatα-Mg and W phase are the main constituent phases in the as-extruded alloy.Furthermore,the hot extrusion has promoted the crystal preference along the(1000)crystal plane.

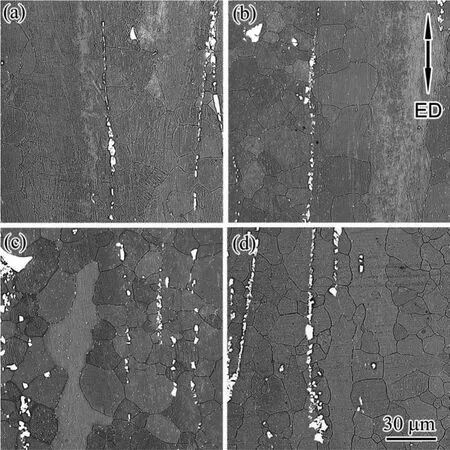

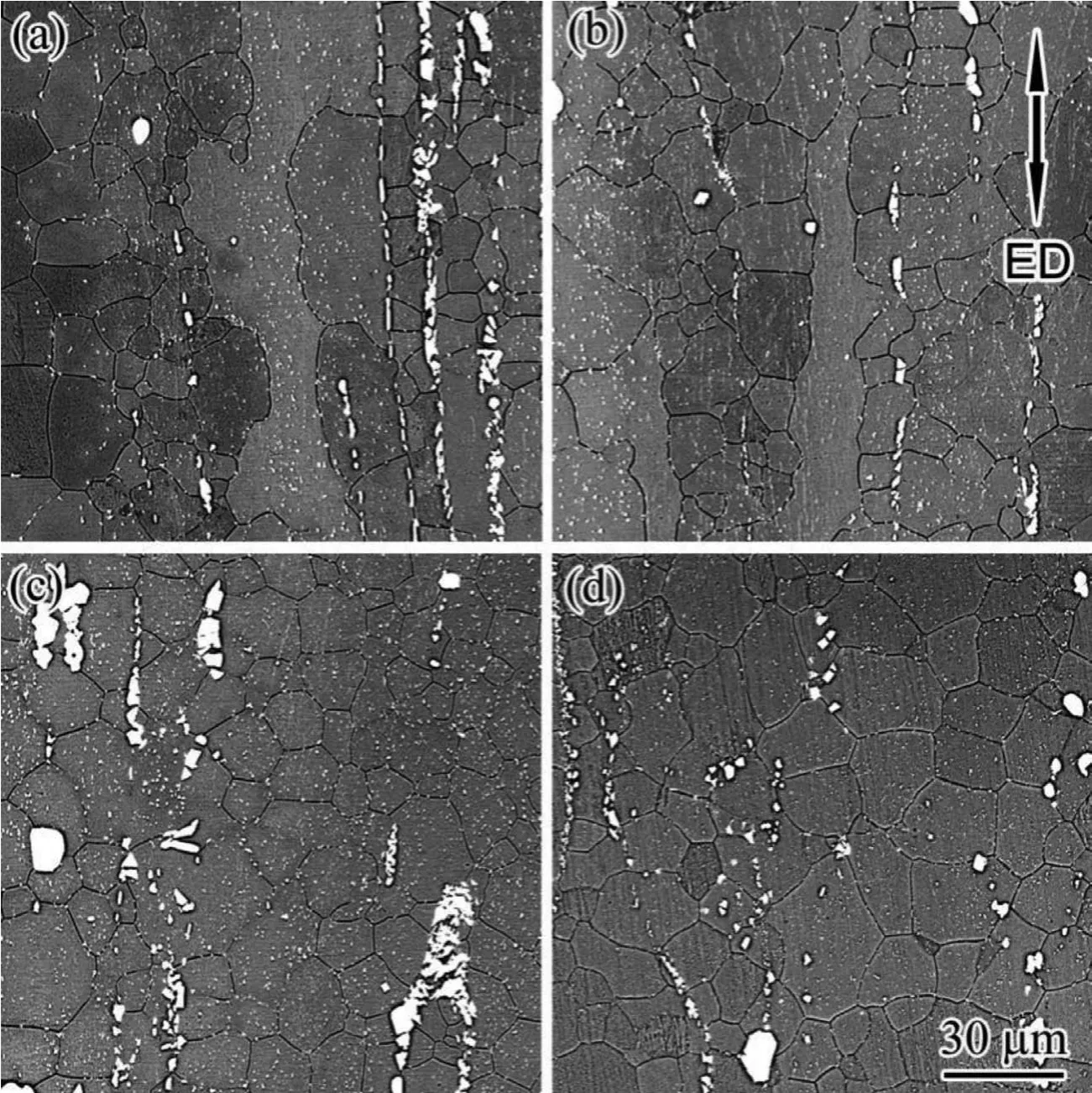

The annealing treated Mg-Zn-Y-Nd alloys at 200°C,225°C and 250°C were observed by SEM and their typical microstructure was exhibited in Figs.2-4 respectively.Obviously,the annealing treatment at 200°C has exerted little influenc on the alloy,as shown in Fig.2(a)-(d).The elongated grains still exist in the alloy,and their sizes almost have no change.Even though the annealing treatment time extends to 12h,the change of the microstructure is still not obvious,which indicates almost no static recrystallization occurs in such a heat treatment.The secondary phases remain linearly distribution along the ED and their size shows no obvious change.The nanoscale precipitates can also be found to disperse in the matrix,while their size and quantity are essentially similar to those in the as-extruded alloys.Such a phenomenon should be ascribed to the low annealing temperature that cannot provide enough energy.

Fig.3.Microstructure of the Mg-Zn-Y-Nd alloy with annealing treatment at 225°C for different time:(a)2h;(b)5h;(c)8h;(d)12h.

Fig.4.Microstructure of the Mg-Zn-Y-Nd alloy with annealing treatment at 250°C for different time:(a)2h;(b)5h;(c)8h;(d)12h.

Fig.5.Inverse polar figur of the as-extruded and annealing treated alloys at different temperatures:(a)the as-extruded alloy;(b)the annealing treated alloy at 200°C for 8h;(c)the annealing treated alloy at 225°C for 8h;(d)the annealing treated alloy at 250°C for 8h.

When the temperature of annealing treatment increases to 225°C,the changing of grain structure in the Mg-Zn-Y-Nd alloy becomes more obvious.As the increasing of annealing treatment time,the equiaxed grains increase and grow,which narrows the large elongated grains gradually,as shown in Fig.3(a)and(b).That is because static recrystallization promotes the transformation of subgrains into grains during the annealing process.Due to the greater deformation in the margin of elongated grain,the new equiaxed grains tend to invade the large elongated grain from the grain boundary,and then the elongated grains are narrowed and separated gradually.It can be found that the width of the elongated grain decreases to less than 30μm after its annealing treatment for 8h,as shown in Fig.3(c).However,when the annealing time increases to 12h,the elongated grains become so smaller and its width is almost equal to that of the equiaxed grain,as shown in Fig.3(d).Compared with the as-extruded alloy,the static recrystallization process could form a more uniform grain structure.Whatever the change of matrix,the size and distribution of the secondary phases change little at such an annealing temperature.In addition,the nanoscale precipitates dispersed in the alloy also show no obvious variation during the annealing treatment at 225°C.

When the annealing treatment temperature rises to 250°C,the microstructure of Mg-Zn-Y-Nd alloy experiences obvious evolution.Even with 2h annealing treatment,the fin equiaxed grains start to form along elongated grain boundaries,as shown in Fig.4(a).With the annealing treatment proceeding,the equiaxed grains grow up,which encroaches the large elongated grain gradually,as shown in Fig.4(b).Clearly,the elongated grains have almost disappeared,when the annealing treatment time exceeding 8h,as shown in Fig.4(c)and(d).Comparatively,the equiaxed grains in the alloy with longer time annealing treatment have bigger size than those with short time annealing treatment.It means that the as-extruded Mg-Zn-Y-Nd alloy with annealing treatment at 250°C has experienced the fully static recrystallization.However,the observation also reveals that the distribution and size of the linearly distributed secondary phases have little changes at this temperature,but some original nanoscale particles become coarse.

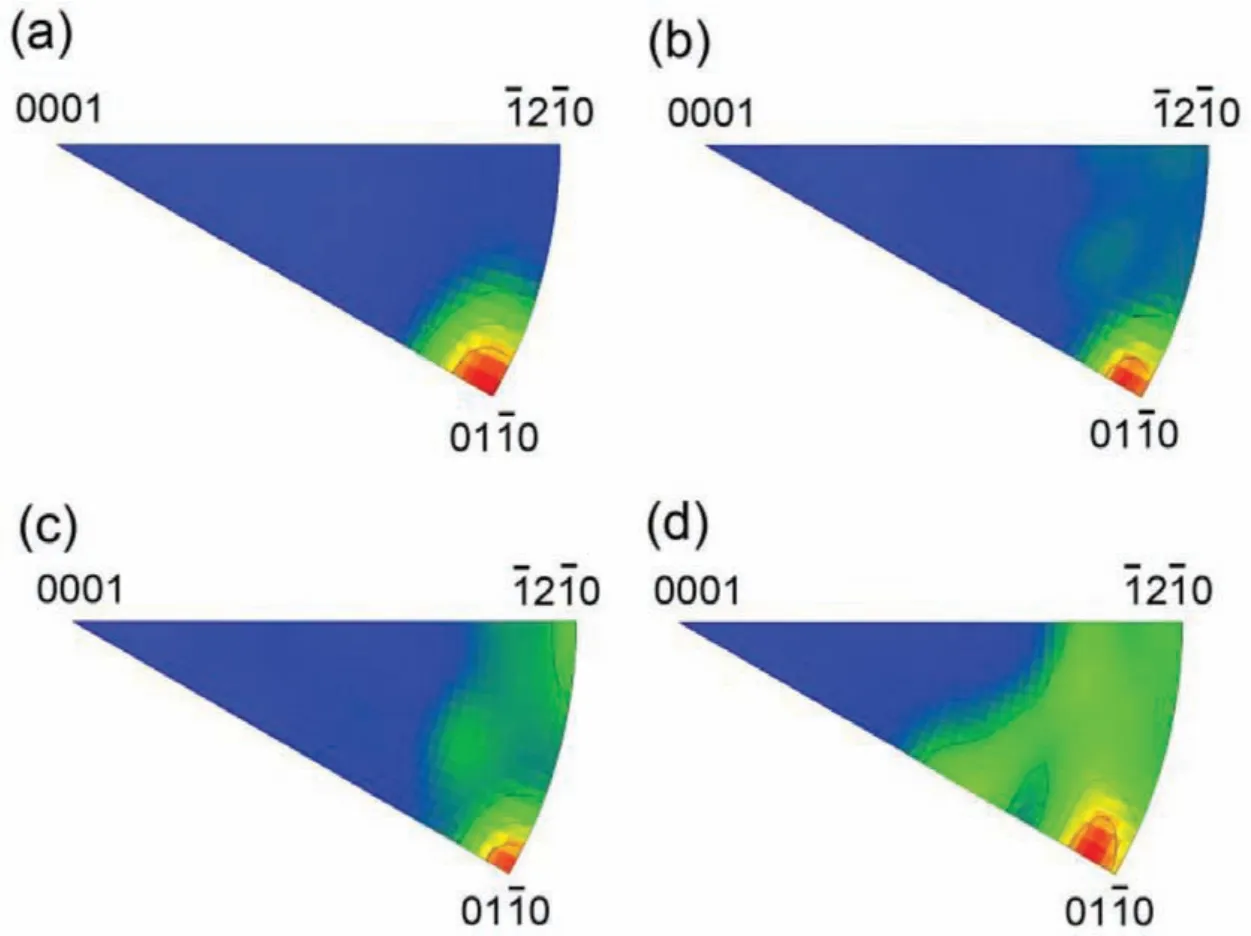

To investigate the texture evolution and the effect of annealing treatment,the EBSD analysis was carried out on the as-extruded and annealing treated Mg-Zn-Y-Nd alloys and the obtained inverse polar figur along ED is exhibited in Fig.5.Clearly,the as-extruded alloy demonstrates strong{01¯10}fibe texture feature,as shown in Fig.5(a).However,the annealing treatment could weaken the fibe texture of the alloy,especially at high temperature.As exhibited in Fig.5(b),the alloy annealing treated at 200°C for 8h shows almost the similar strong{01¯10}fibe texture with the as-extruded alloy.With the annealing temperature increases to 225°C,the same time treatment weakens the{01¯10}fibe texture of the alloy obviously as shown in Fig.5(c).When the annealing temperature rises to 250°C,the{01¯10}fibe texture of the alloy is weakened significantl,as shown in Fig.5(d).

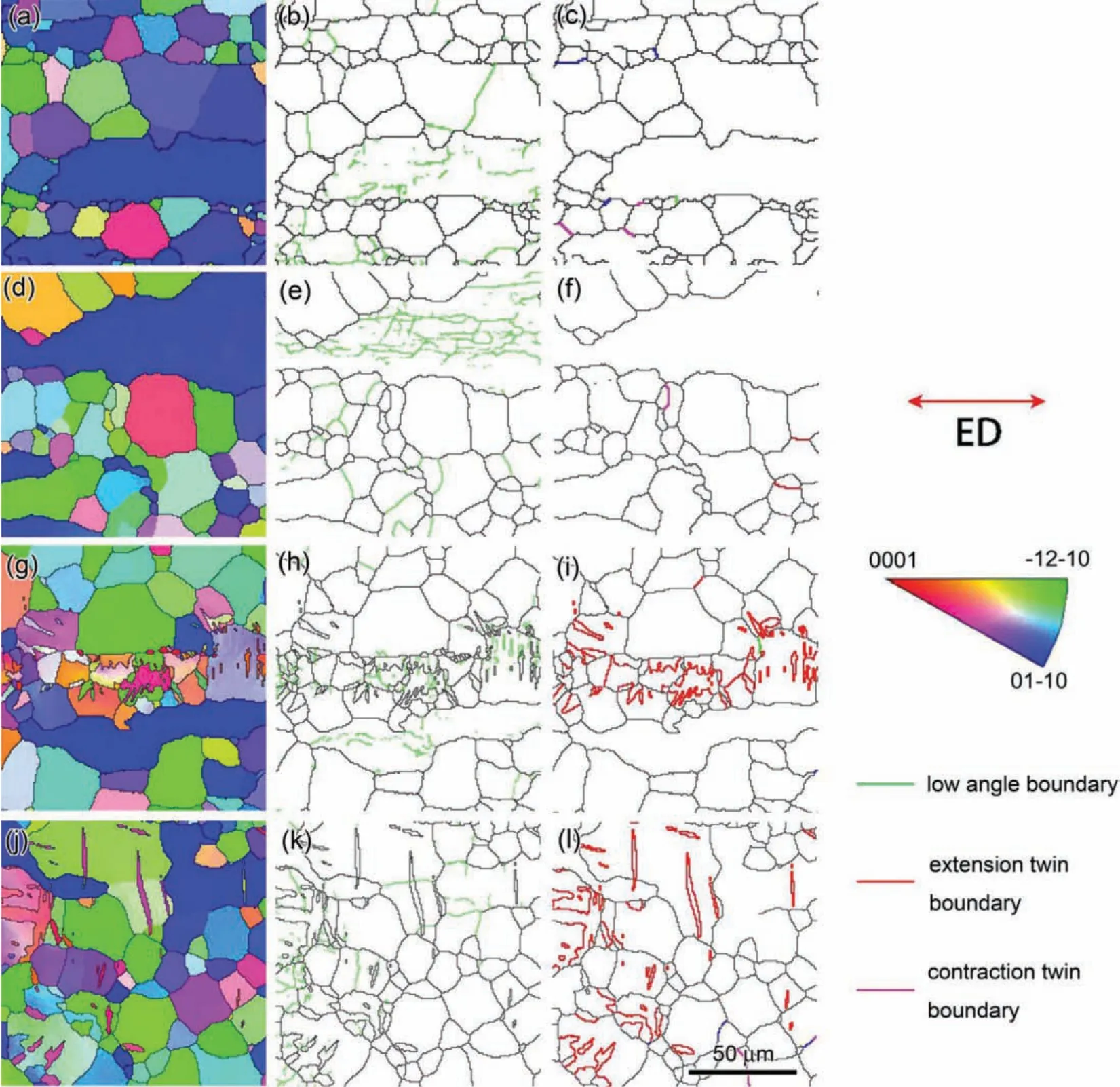

Fig.6.EBSD results of the as-extruded and annealing treated alloys:(a)-(c)the as-extruded alloy;(d)-(f)the annealing treated alloy at 200°C for 8h;(g)-(i)the annealing treated alloy at 225°C for 8h;(j)-(l)the annealing treated alloy at 250°C for 8h;(a)(d)(g)(j)Inverse polar map;(b)(e)(h)(k)Grain boundary map;(c)(f)(i)(l)Twin map.

The inverse polar map,grain boundary map and twin map of the as-extruded and annealing treated alloys were also obtained through EDSD analyzer,and the results are shown in Fig.6.It can be found from the inverse polar maps that the large elongated grains exhibit{01¯10}fibe texture,while the equiaxed grains show various orientations.As exhibited in Fig.6(a),the as-extruded alloy shows strongest{01¯10}fibe texture feature,because it has high volume fraction of elongated grain.In addition,it also demonstrates that the large elongated grains contain large numbers of low-angle boundaries,while the quantity and density of low-angle boundaries in the equiaxed grains decrease significantl,as shown in Fig.6(b).Moreover,almost no twin could be found in the as-extruded alloy,as shown in Fig.6(c).The distributions of grain orientation,low-angle boundary and twin of the alloy with annealing treatment at 200°C for 8h are similar to those of the as-extruded alloy,as indicated in Fig.6(d)-(f).With the annealing temperature increasing to 225°C,the static recrystallization begins to encroach the large elongated grains,and thus the{01¯10}fibe texture is weakened,as shown in Fig.6(g).Simultaneously,the annealing process has reduced the low-angle boundary content in the large elongated grains.However,some extension twins appear in the alloy which is annealing treated at 225°C for 8h,as revealed in Fig.6(i).After annealing treatment at 250°C for 8h,the large elongated grains almost disappear,and the quantity of low-angle boundary decreases further in the alloy,but more extension twins appears in the alloy,as exhibited Fig.6(j)-(l).Based on the inverse polar map in Fig.6(g)and(j),it is found thatthe extension twins formed during annealing treatment prefer to grow along the orientation of<0001>which is parallel to the ED.Such an evolution would contribute to weaken the{01¯10}fibe texture of the alloy.

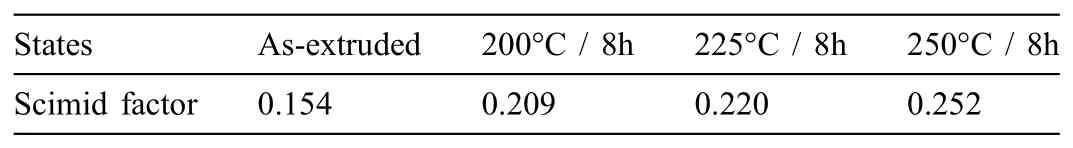

Table 1The Scimid factor of{0002}〈11¯20〉basal slip in the as-extruded and annealing treated alloys

Moreover,based on the EBSD results,the average Schmid factors of{0002}<11¯20>basal slip in the annealing treated and as-extruded alloys were calculated when the stress is applied along ED,and the values are shown in Table 1.It can be found that the Schmid factor of the as-extruded alloy is only 0.154.While the Schmid factor in the annealing treated alloy increases with the annealing temperature increasing,which indicates the reduction of the resistance to basal slip.

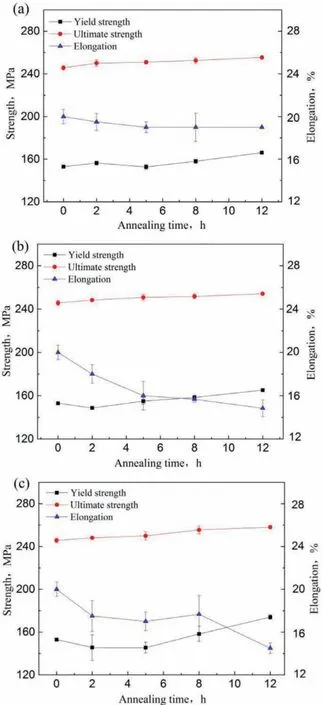

Fig.7.Tensile properties of the as-extruded and annealing treated alloys at different temperature:(a)200°C;(b)225°C;(c)250°C.

3.2.Tensile properties

To evaluate the effect of annealing treatment on mechanical property,the room-temperature tensile test was conducted on the as-extruded and annealing treated Mg-Zn-Y-Nd alloys.The detailed mechanical properties of the alloys with different states are shown in Fig.7.Before annealing treatment,the elongation,yield and ultimate strength of the as-extruded alloy are 20%,153MPa and 246MPa,respectively.When the alloy is annealing treated at 200°C,its ultimate strength and yield strength increase slowly while the elongation decreases gradually.After annealing treatment for 12h,the yield and ultimate strength of the alloy increase to 166MPa and 255MPa respectively,but its elongation decreases to 19%,as shown in Fig.7(a).With the annealing temperature increasing to 225°C,the yield and ultimate strength of the alloy vary with the time and exhibit the similar tendency with the alloy annealing treated at 200°C,but the elongation of the alloy drops obviously.After annealing treated for 12h,the alloy reaches the minimum elongation of 15%,as shown in Fig.7(b).When the annealing treatment temperature rises to 250°C,the ultimate strength rises slowly with time extending,while the elongation drops faster.Differently,the yield strength decreases a little firstl and then rises fast.As the annealing time increases to 12h,the yield strength reaches 174MPa,and the elongation obtains its minimum value about 14.5%,as indicated in Fig.7(c).

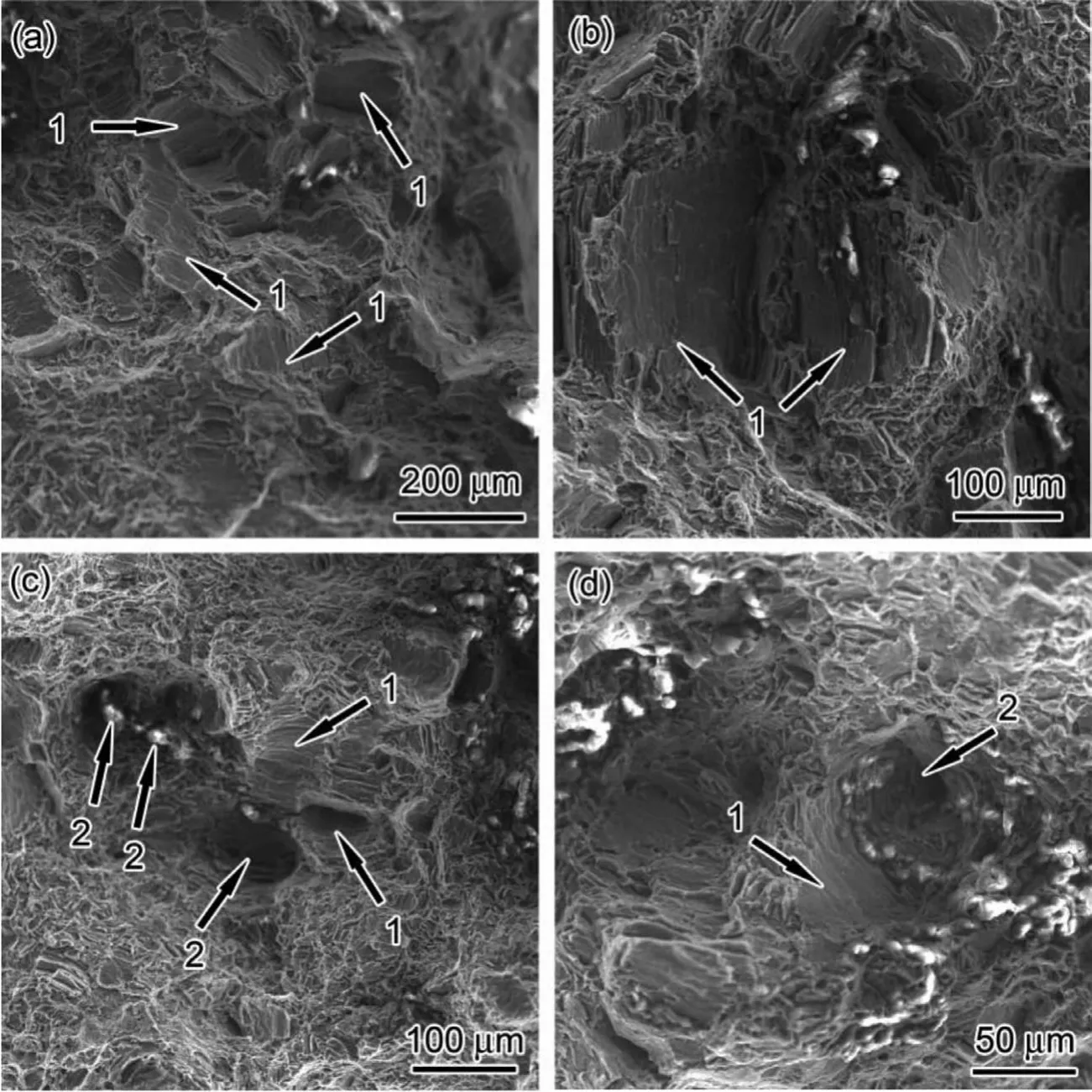

The fracture surfaces of the Mg-Zn-Y-Nd alloys with different states were observed by SEM.It is found that the fracture surface of the as-extruded alloy and annealing treated alloy at 200°C are mainly composed of smooth planes with different size and angles,as shown in Fig.8(a)and(b).With the annealing time and temperature increasing,dimples appear on the fracture surface,and the smooth planes and dimples become the main characteristics,as shown in Fig.8(c)and(d).Moreover,the sizes of the smooth planes are quite different in the alloy with different states.As can be found from Fig.8(a)and(b),the size of the smooth plane is relatively large,even more than 100μm,which is consistent with the size of the large elongated grains.While the size of the smooth planes in Fig.8(c)and(d)are about dozens of microns,which is consistent with the size of the large recrystallized equiaxed grains.Therefore,it can be deduced that for the alloy annealing treated at 200°C and as-extruded alloy,the cracks mainly initiate at the large elongated grains during tensile test.While for the alloys annealing treated at 225°C and 250°C for longer time,the large elongated grains gradually become smaller or even disappear,thus the tensile crack would initiate from the broken secondary phases and recrystallized equiaxed grains.

Fig.8.SEM image of the tensile fracture surface of the Mg-Zn-Y-Nd alloys with different states:(a)the as-extruded alloy;(b)the annealing treated alloy at 225°C for 5h;(c)the annealing treated alloy at 225°C for 8h;(d)the annealing treated alloy at 250°C for 8h(1 represent the smooth planes and 2 represent dimples.).

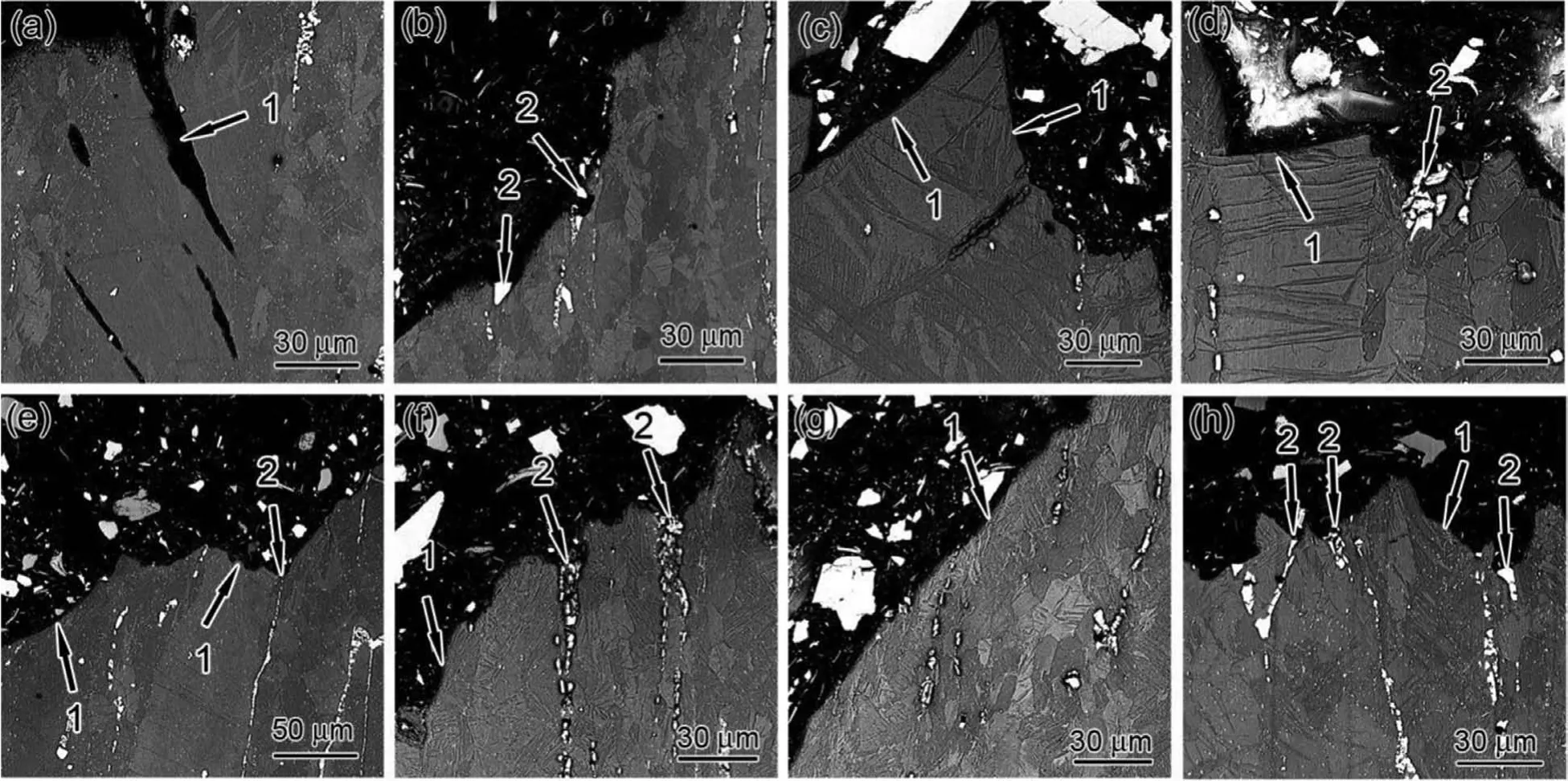

Fig.9.SEM image of the longitudinal section of the tensile fractured specimens:(a)(b)the as-extruded alloy;(c)the annealing treated alloy at 200°C for 2h;(d)the annealing treated alloy at 200°C for 8h;(e)the annealing treated alloy at 225°C for 5h;(f)the annealing treated alloy at 225°C for 12h;(g)the annealing treated alloy at 250°C for 5h;(h)the annealing treated alloy at 250°C for 8h.

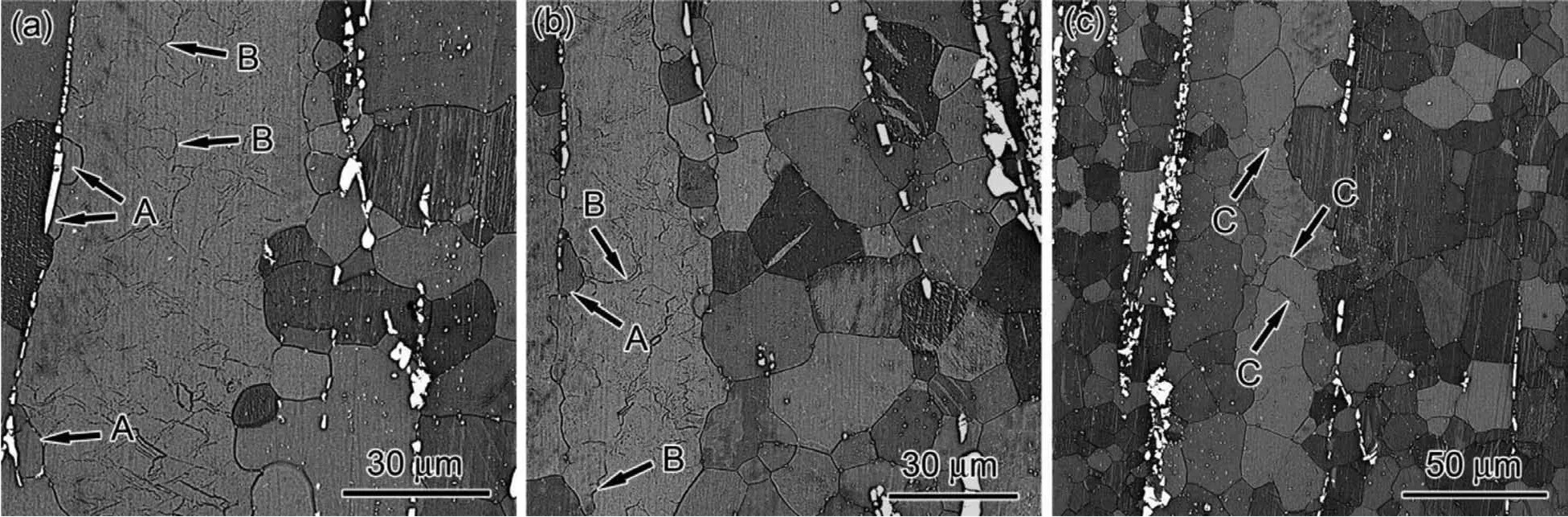

Fig.10.SEM image of the annealing treated Mg-Zn-Y-Nd alloy at 225°C and 250°C showing the static recrystallization process:(a)225°C/2h;(b)225°C/12h;(c)250°C/8h(A represents for the newly recrystallized equiaxed grain,B represents for the low-angle boundary that changing into high-angle boundary,C represents for the newly formed high-angle boundary).

To investigate the failure mechanism of the Mg-Zn-Y-Nd alloys further,the longitudinal sections of the tensile fractured specimens were observed.Combining with the fracture surface observation,the initiation mode and propagation path of the tensile cracks can be found.In general,there are two different crack initiation modes of the annealing treated and as-extruded alloys during the tensile tests.The frst kind of cracks are initiated and propagated along the twins in the grains,which are quite straight and marked as 1 in Fig.9.This kind of crack is corresponding to the smooth plane on the fracture surfaces in Fig.8.The secondary kind of cracks initiate from broken secondary phases,which were marked as 2 in Fig.9.Therefore,the pulling out of the secondary phase forms dimple on the fracture surface.The fracture of all the specimens in the present research is found to be composed of these two crack initiation modes,but the proportion of the two crack initiation modes is different in the alloys with different states.For the as-extruded alloy and the alloy annealed at low temperature for short time,there are many large elongated grains that can easily produce long twins during tensile tests.The tensile cracks would initiate along these long twin boundaries,and the frst kind of crack would dominant the fracture process,as revealed in Fig.8(a)and Fig.9(a),(c),(d).However,as the annealing temperature and time increase,the large elongated grains become smaller and even disappear.Thus,the firs kind of cracks would form along the twins in the recrystallized equiaxed grains,which appear as smaller facet on the fracture surface.As is known that twins are more easily to be produced in large grains,it would be harder to produce the frst kind of cracks in the recrystallized equiaxed grains than the elongated grains.Therefore,the second kind of crack initiated from secondary phase would become the dominant fracture mode for the alloys annealing treated at higher temperature for longer time.

4.Discussions

4.1.Influenc of annealing treatment on the microstructure

The microstructure evolution of the Mg-Zn-Y-Nd alloy during the hot extrusion process has been discussed in our previous article[23],and it was found that the hot extrusion would compel the original coarseα-Mg grains to experience great deform and be elongated along the ED,which results in great internal stress insideα-Mg grain.The residual internal stress could activate basal and non-basal slip inα-Mg grains.Accordingly,a lot of dislocations would be formed and accumulated inα-Mg grains.It has been reported that the great accumulated dislocations would promote the formation of low-angle boundaries[24],so that there are large amount of low-angle boundaries insideα-Mg grains in the as-extrude alloy.Moreover,the great extrusion force would promote the rotation of crystal lattice in the elongated phase to cooperate the deformation,which results in the{01¯10}fibe texture in the elongated grains[25].Afterwards,with the proceeding of the hot extrusion,the dynamic recrystallization would frstly occur along the elongatedα-Mg grain boundary,thus forming recrystallized equiaxed grains.However,the extrusion process is short,therefore the dynamic recrystallization is incomplete,and there are still lots of highly deformed original large elongatedα-Mg grains left.As a result,the as-extruded alloy obtains dual-size grain structure of large elongated grain surround by fin equiaxed grain.Additionally,the extrusion process breaks the brittle secondary phases and forms the linearly distributed small secondary phases along the ED.

The previous research has reported that the annealing treatment after hot working would cause static recrystallization in the Mg alloys[26].In the present research,the large elongated grains in the as-extruded Mg-Zn-Y-Nd alloy still contain lots of dislocations and low-angle boundaries.During the annealing process,the high temperature and the crystal defects in the large elongated grains would promote static recrystallization and form fin equiaxed grains,as demonstrated in Fig.10.Moreover,the secondary phase interface is apt to be nucleation site of the static recrystallization,and the accumulation of low-angle boundaries could promote the formation of the high-angle boundaries and then transformation of equiaxed grains which prefers to form along the secondary phase.As demonstrated in Fig.10(a)and(b),the newly formed recrystallized grains and the low-angle boundaries which is transforming to high-angle boundaries during annealing treatment are marked as A and B,respectively.Consequently,the fin equiaxed grains would increase with the annealing time increasing,and the large elongated grains are consumed gradually.Simultaneously,the low-angle boundaries are also consumed as the static recrystallization proceeding.

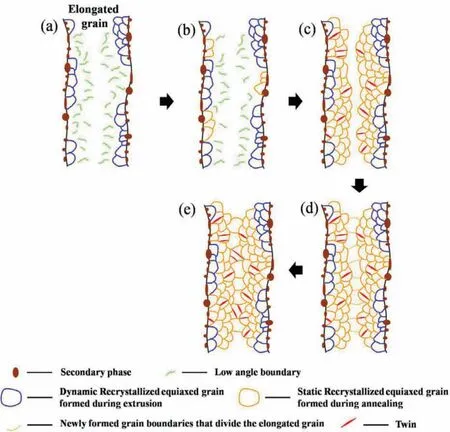

Fig.11.Schematic diagram of the static recrystallization process of the Mg-Zn-Y-Nd alloy during its annealing treatment:(a)the as-extruded alloy;(b)the early stage of the annealing process;(c)the intermediate stage of the annealing process;(d)the later stage of the annealing process;(e)the complete recrystallization structure of the alloy.

As can be found from the inverse polar maps in Fig.6(a)(d)(g)(j)that the recrystallized equiaxed grains tend to show different orientations with the large elongated grains,so that the static recrystallization process would weaken the{01¯10}fibe texture of the alloy.Moreover,during annealing treatment at 225°C and 250°C,extension twins appears in the alloy,as in Fig.6(i)(l).By comparing the inverse polar maps and twin maps,it is indicated that these extension twins tend to form in the grains with an orientation near basal texture.Since the formation of extension twin would rotate the Mg crystal to about 86°[27],these newly formed extension twins are likely to exhibit an orientation of{0001}plane which is perpendicular to the ED.The basal texture of the alloy would be weakened by the formation of this kind of extension twins.

According to the above observation,the static recrystallization process of the as-extruded Mg-Zn-Y-Nd alloy during annealing treatment can be concluded and demonstrated as schematic diagram in Fig.11.The as-extruded alloy mainly comprises large elongated grain and dynamic recrystallized grain.At the beginning of the annealing treatment,static recrystallization occurs and fin equiaxed grains prefer to form at the interface of the secondary phase in the margin of the large elongated grain,which consumes the low-angle boundaries gradually.Then as the recrystallization proceeding,the quantity of equiaxed grain rises with the narrowing of elongated grains,as shown in Fig.10(b)and Fig.11(c).Moreover,extension twins appear in some of the equiaxed grains.When the elongated grain is narrowed to the width of 20-30μm,it is approximately equal to the size of the equiaxed grains,the newly formed grain boundaries could divide the elongated grain into several equiaxed grains,as revealed in Fig.10(c)and Fig.11(d).Finally,as the annealing continues,the alloy becomes complete recrystallization structure with extension twins,as shown in Fig.11(e).

Moreover,with the annealing temperature increasing from 200°C to 250°C,the movement of the crystal defects is accelerated,which promotes the nucleation of recrystallized grains and their growth.As a result,the recrystallization process of the Mg-Zn-Y-Nd alloy becomes faster with the temperature rising.Due to the pinning effect of the nanoscale precipitates,the growth of the recrystallized grain is impeded.Therefore,the equiaxed grains exhibit similar size for the Mg-Zn-Y-Nd alloy annealing treated at different temperature for different time.

4.2.Influenc of annealing treatment on the tensile properties

According to the previous researches[28-30],the heat treatment on Mg alloys demonstrated diversifie influenc on the mechanical properties.The Gunde et al.[28]revealed that the annealing treated as-extruded Mg-Zn-Zr-Ca-Mn alloy at 360°C exhibited decreased strength but increased elongation.It was attributed to the slight grain growth and recrystallization by the relatively high temperature annealing,which would facilitate dislocation movement and decrease the deformation resistance.Zhang[29]studied the hot extruded JDBM alloy with annealing treatment at 200°C for 10h and exhibited that the ultimate and yield strength were enhanced while the elongation was reduced.Liu[30]conducted thermal aging at 225°C for 12h on the extruded WE71 alloy,and also revealed that the strength was improved while the elongation was reduced.Both Zhang and Liu attribute the changing of mechanical properties to the age hardening effect by the annealing treatment.

Actually,the mechanical property of the alloy is closely correlated with its microstructure,such as grain size,secondary phases,texture,twins,crystal defect etc[31].In the present research,the variation of tensile properties of the Mg-Zn-Y-Nd alloy during annealing treatment should be discussed in the light of its microstructure evolution.Based on microstructure observation above,it could be summarized that the influenc of annealing treatment on the tensile properties should be mainly ascribed to texture,grain structure and twining.

Firstly,according to Hall-Petch relationship[32],the effect of grain size on tensile yield strength of Mg-Zn-Y-Nd alloy could be described as following:Whereσ0andkare material constants anddis the average grain size.During annealing treatment,the static recrystallization has resulted in an increase of equiaxed grains and diminution of elongated grains.Because of the pinning effect of the nanoscale precipitates on their grain boundaries,the equiaxed grains cannot grow larger during the annealing process.Therefore,static recrystallization would cause an overall grain refinemen effect in Mg-Zn-Y-Nd alloy,which contributes to the increase of tensile ductility and strength.As the annealing temperature increase,the static recrystallization is accelerated and the recrystallized grains are increased,thus the grain refinemen effect is promoted.

Secondly,as the above analysis,the annealing treatment has weakened the{01¯10}fibe texture of the alloy because the equiaxed grains formed during static recrystallization show relatively more random orientations.It is known that for Mg alloys,the deformation modes at room temperature are dominated by extension twin and basal slip because of their low critical resolved shear stress(CRSS)values[33],and the Schmid factors of basal slip and extension twin are directly determined by the crystallographic orientation of the grains.For the grains with{01¯10}fibe texture,when the applied tensile stress is parallel to the ED,their Schmid factors of basal slip and extension twin are 0,which means that it is quite difficul to activate the basal slip and extension twin.Therefore,{01¯10}fibe texture could lead to a texture strengthening effect in the Mg alloys.As shown in Table 1,with the annealing temperature increasing,the average Schmid factor of{0002}〈11¯20〉basal slip increases,thus reducing the resistance to basal slip.The annealing treatment weakens the{01¯10}fibe texture in alloy,which would reduce the texture strengthening effect and decrease the tensile strength.

Thirdly,it is reported that the generation of{10¯12}extension twin could influenc mechanical properties signifi cantly by introducing reorient texture and twin boundaries[34].As shown in Fig.6(i)and(l),{10¯12}extension twins forms in the alloys with annealing treatment at 225°C and 250°C,which would contribute to the strength improvement by impeding the dislocation movement.However,combining with analyses of fracture surfaces in Fig.8(c)and(d)and cross-sectional microstructure of fractured specimens in Fig.9(f),(g)and(h),the twins formed in the recrystallized equiaxed grains tend to be the crack initiation sites,which is harmful to ductility of the annealing treated Mg-Zn-Y-Nd alloy.Though the annealing treatment has little influenc on the linearly distributed secondary phase,it promotes the small precipitates in the grain or along boundary.These precipitates would contribute to the strength by impeding the dislocation movement,but they are also harmful to the ductility by acting as the crack initiation,especially the precipitates along boundary,because the accumulated dislocation would increase the interface stress greatly[35,36].Therefore,it can be found that there are many cracks initiated or propagated along twin boundary,grain boundary or phase boundary.With the annealing temperature and time increasing,the quantity and size of precipitates would increase simultaneously.Then it is understandable that the Mg-Zn-Y-Nd alloy exhibits a gradually decreased ductility with annealing treatment proceeding.Therefore,it can be summarized that the combining effect of texture,grain refinement twinning and precipitation caused by annealing treatment would finall be beneficia to the yield and ultimate strength but detrimental to the ductility of the Mg-Zn-Y-Nd alloy.

5.Conclusions

The Mg-4Zn-0.6Y-0.5Nd alloy for orthopedic implant application was hot extruded and then annealing treated at 200°C,225°C and 250°C respectively.Then the microstructure and tensile property of the as-extruded and annealing treated alloys were analyzed.The results could be summarized as following:

(1)The hot extrusion forms a typical dual-size grain structure in the Mg-Zn-Y-Nd alloy,which can be described as the large elongated grain is surrounded by fin equiaxed grain with linearly distributed secondary phase.The annealing treatment leads to static recrystallization in the as-extruded alloy,thus increasing the fin equiaxed grains but decreasing the large elongated grains.

(2)The elongated grains in the as-extruded Mg-Zn-Y-Nd alloy exhibit a strong{01¯10}fibe texture feature,while the recrystallized equiaxed grains formed during annealing treatment show relatively random orientations.Therefore,the annealing treatment could weaken the{01¯10}fibe texture in the as-extruded alloy.

(3)During annealing treatment at 225°C and 250°C,extension twins form in the Mg-Zn-Y-Nd alloy and weaken the{01¯10}fibe texture.The annealing treatment has little influenc on the linearly distributed secondary phase but promotes the coarsening of small precipitates at 250°C.

(4)The annealing treatment could increase the yield and ultimate strength,but the elongation decreases,especially at higher temperature.Such a variation can be ascribed the evolution of texture,grain structure,twinning and precipitation during the annealing treatment.

Acknowledgments

The authors are grateful to the financia support from Natural Science Foundation of Guangdong Province,China(No.2018A030313950)and Shenzhen Basic Research Project(JCYJ20170815153143221,and JCYJ20170815153210359,JCYJ20170306141749970).

杂志排行

Journal of Magnesium and Alloys的其它文章

- Microstructural evolution of Mg-Al-Re alloy reinforced with alumina fiber

- Predicting and controlling interfacial microstructure of magnesium/aluminum bimetallic structures for improved interfacial bonding

- Plasma electrolytic oxidation of AZ31 and AZ91 magnesium alloys:Comparison of coatings formation mechanism

- Microstructure and performance of biodegradable magnesium alloy tubes fabricated by local-heating-assisted dieless drawing

- Comparisons of microstructure homogeneity,texture and mechanical properties of AZ80 magnesium alloy fabricated by annular channel angular extrusion and backward extrusion

- Effect of Y addition on microstructure and corrosion behavior of extruded Mg-Zn-Nd-Zr alloy