Microstructure evolution and mechanical property of Mg-3Al alloys with addition of Ca and Gd during rolling and annealing process

2020-12-18YunZhangHaitaoJiangQiangKangYujiaoWangYonggangYangShiweiTian

Yun Zhang,Haitao Jiang,Qiang Kang,Yujiao Wang,Yonggang Yang,Shiwei Tian

Institute of Engineering Technology,University of Science and Technology Beijing,Beijing 100083,China

Received 9 April 2019;received in revised form 24 October 2019;accepted 4 November 2019 Available online 24 June 2020

Abstract The formability of magnesium alloys at ambient temperature can be enhanced by alloying additions such as Ca and RE elements,which is ascribed to the weakened basal texture.To produce magnesium alloy sheets with excellent comprehensive performance,the evolution of texture characterization during fabrication process and subsequent effect of texture on mechanical properties are vital controlling factors.In this investigation,three experimental Mg-3Al series alloys were hot rolled and annealed to sheets with 1mm thickness.The microstructure evolution during rolling and annealing process was investigated.Furthermore,the influenc of texture on tensile properties along different tensile directions was also studied.The results show that weakened basal texture and refine grains were achieved with the co-addition of Ca and RE element.However,strengthening of mechanical properties wasn't obtained.During hot rolling process,microstructure was refined second phase particles broken,and basal texture was increased.While basal texture was weakened during annealing process.Recrystallization behavior influence by formation of second phase was dominated to attenuate basal texture.Tensile deformation behavior was controlled by basal slip and followed Schmid factor criterion.Moreover,the weakened basal texture and activation of non-basal slips during hot rolling process can contribute to diminish the anisotropy of tensile properties.© 2020 Published by Elsevier B.V.on behalf of Chongqing University.This is an open access article under the CC BY-NC-ND license.(http://creativecommons.org/licenses/by-nc-nd/4.0/)Peer review under responsibility of Chongqing University

Keywords:Magnesium alloys;Microstructure evolution;Texture;Anisotropy.

1.Introduction

Magnesium alloys have promising prospect in industrial applications such as automotive,aerospace and electronics,due to their advantageous performance containing low density,high specifi strength,high specifi stiffness,outstanding electromagnetic shielding effectiveness and retrievability[1-3].However,the further development is restricted,because of the poor formability at ambient temperature.The poor formability is originated from the lack of adequate active slip systems resulted from the nature of hexagonal close-packed(hcp)structure.Meanwhile,an intensive basal texture at sheet plane(RD(rolling direction)×TD(transverse direction))can be obtained after traditional hot rolling process.Hence,low formability and significan anisotropic mechanical properties are obtained due to the intensive basal texture.Finally,the application of second processing such as sheets metal forming is restricted[4-6].

The formability of magnesium alloy sheets can be promoted by some suitable methods which can refin grain size and attenuate basal texture[7,8].Compared with progressive rolling processes such as asymmetrical rolling and cross rolling[9-11],alloying method with addition of RE and Ca elements is considered to be effective and practicable,which can optimize basal texture and improve formability.Moreover,mechanical properties can be improved by solution strengthening and precipitation strengthening due to the formation of second phase particles and dissolving in the matrix[12-17].For example,our previous study[18]found 0.2% RE elements have a positive effect on room temperature formability of Mg-1.5Zn alloy,especially for Gd element as alloy-ing component which makes IE values increase from 2.6 to 7.0mm.Some investigations studied the phenomena of weakened basal texture in Mg alloys contained Ca and RE elements,and summarized that the weakened mechanisms were ascribed to the influenc of alloying elements on SFE,nonbasal slip systems and recrystallization behavior[19,20].Ding[21]revealed the texture weakening of extruded Mg-2Zn alloys with addition of Ca or RE elements is originated from decrease of c/a axis ratio and stacking fault energy(SFE).Therefore,understanding the microstructure evolution during hot rolling and annealing process is helpful to analyze the texture variation and related influenc mechanism.Moreover,the anisotropy of mechanical properties from different tensile directions is propitious to indicate the influenc of grain orientation on mechanical properties.In this investigation,microstructure evolutions during hot rolling process and annealing process have been studied.Concomitantly,effect of coaddition of Ca and RE elements on texture characterization and evolution has been analyzed.Furthermore,relationship between grain orientation and tensile properties has also been discussed.

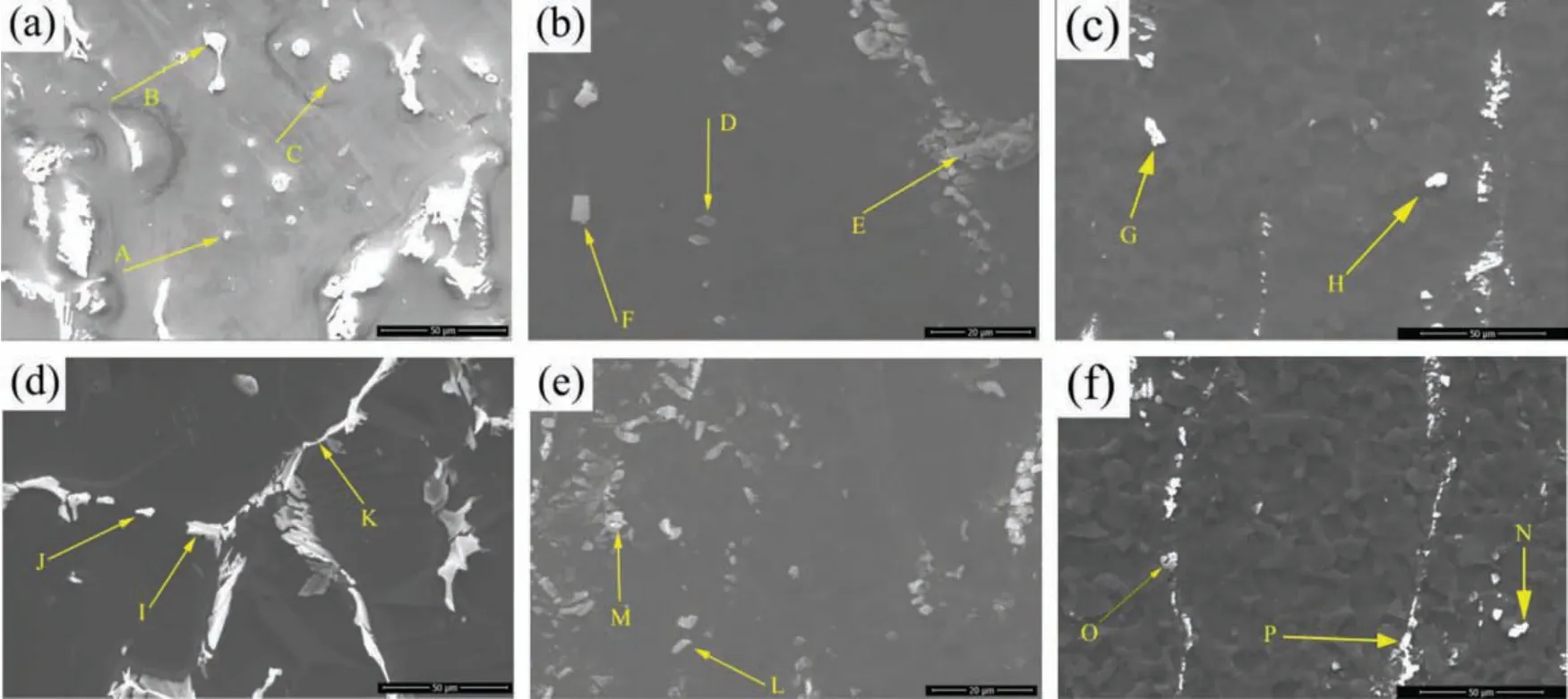

Table 1Chemical composition of the experimental magnesium alloys in weight percent.

2.Experiment procedures

In the present work,Mg-3Al series alloys with three different chemical compositions(free addition of other elements,individual Ca addition,and co-addition of Ca and Gd)were investigated.The ingots were prepared using pure Mg,pure Al and master alloys(Mg-20wt.%Ca,Mg-30wt.%Gd)with high purity.The raw materials were melted in a medium frequency induction furnace under 1%CO2-99%SF6protection gas atmosphere.After homogeneous stirring at 750°C for 30min,melts were transferred into steel mold which preheated at 350°C,then the ingots with dimension ofΦ120×150mm were smelted.The actual composition components of these alloys were detected by inductively coupled plasma atomic emission spectrometry(ICP-AES)and the results are presented in Table 1.The corresponding denoted designations were also shown in Table 1 for convenience.

In the present investigation,the slabs with thickness of 10mm were machined from ingots,and subsequently preformed to homogenization treatment at 450°C for 12h.Then,slabs were conducted to hot rolling at 400°C to fina sheets with thickness of 1.0mm by multi-passes,and reduction per pass was controlled at about 20%.To ensure permanent rolling temperature,re-heated processes were carried out between all two passes for 5∼10min.The as-rolled sheets were annealed at 350°C for 1h to obtain strain-free condition which is suitable to perform tests of mechanical property and formability.Meanwhile,hot rolled sheets with total reduction of 60% and 90% were selected to analyze the microstructure evolution during rolling process.

Microstructural characterizations were observed by optical microscopy(OM-Zeiss AX10),field-emissio environmental scanning electron microscope(SEM-Qutanta FEG 450)equipped with energy-dispersive X-ray spectroscopy(EDS),field-emissio SEM(Zeiss-Ultra 55)equipped with Electron Back-Scattered Diffraction(EBSD)dector,X-ray diffractometer(XRD-Panalytical X‘pert MRD)and field-emissio highresolution transmission electron microscopy(HRTEM-Tecnai-G2-F20).Metallographic specimens were grinded with SiC papers and subsequently polished with nitric acid solution(10%HNO3+90%alcohol),finall etched in acetic picral solution(5g picric acid+5ml acetic acid+100ml alcohol+10ml distilled water).The grain sizes and particle sizes were determined by intercept method(¯d=1.74L,Lis linear intercept size[22]).To obtain texture characterization and distribution of grain orientation,the samples for XRD and EBSD were immersed in chemical polishing solution comprising 10% nitric acid solution and further were electropolished with ACⅡsolution,applying voltage of 15V and current of 0.4A for 60s.For TEM analysis,discs with diameter of 3mm on RD×TD plane were grinded to 50μm in thickness and then thinned by twin-jet electropolishing using an electrolyte of 3vol.%perchloric acid in absolute ethanol.

The tensile testes for annealed sheets were conducted by SANS-CMT5105 tensile testing machine with tensile rate of 1mm/min at room temperature.The tensile specimens with gage length of 25mm and gage width of 6mm were machined along three directions,where the angles between loading direction(LD)and RD were 0°(RD),45°(45°)and 90°(TD).Moreover,the tests for tensile properties were performed at least 3 times for every direction.Based on power law regression,n-value(σ=K·εn)which means strain hardening exponent was calculated by data of strain range between yield strain and ultimate tensile strain from corresponding true tensile stress-strain curves.

3.Results and discussion

3.1.Microstructure evolution

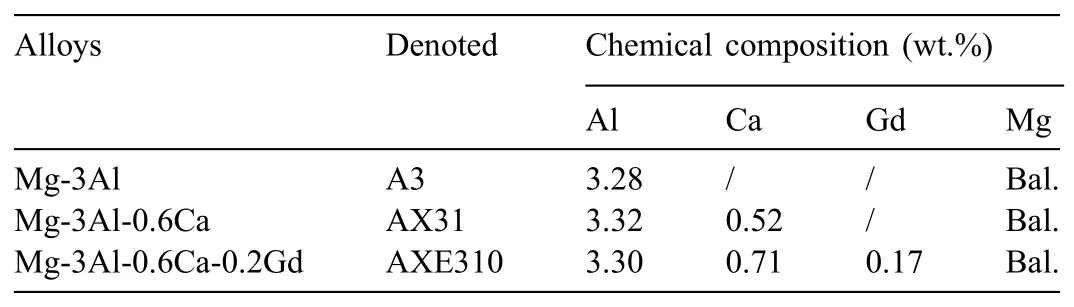

Fig.1.The optical microstructure of experimental alloys at different process conditions:(a)A3 homogenized;(b)AX31 homogenized;(c)AXE310 homogenized;(d)A3 as-rolled 60% total reduction;(e)AX31 as-rolled 60% total reduction;(f)AXE310 as-rolled 60% total reduction;(g)A3 as-rolled 90% total reduction;(h)AX31 as-rolled 90% total reduction;(i)AXE310 as-rolled 90% total reduction;(j)A3 annealed;(k)AX31 annealed;(l)AXE310 annealed.

The optical micrographs of experimental alloys at different conditions including homogenized,as-rolled with total reduction of 60% and 90%,and annealed are shown in Fig.1.After homogenization treatment,the microstructures of A3,AX31,and AXE310 alloys(Fig.1(a-c))exhibit equiaxial feature originated from occurrence of static recrystallization(SRX)stimulating under high temperature for long period,and the average grain sizes of three experimental alloys are 142.71μm,125.25μm and 115.34μm,successively.Moreover,second phase particles tend to be more apparent with alloying addition.Amount second phase particles occur in the vicinity of grain boundaries under homogenized condition of AX31 and AXE310 alloys,as shown in Fig.1(b,c).During multi-passes hot rolling process,microstructures of experimental alloys show a combination of equiaxial grains and deformed grains which contain twins,as presented in Fig.1(d-i).The grains exhibit bimodal nature when the total reduction is 60%,there are many fin recrystallized grains surrounded by deformed grains which possess twins in the matrix.It is obvious that the appearance of fin equiaxial new grains is attributed to dynamical recrystallization(DRX).When the total reduction reaches 90%,microstructures of the three alloys turn to more uniform and the grain size decrease.It indicates that rolling process can effectively refin grain size and improve microstructure homogeneity.During annealing process,recovery and recrystallization occur,and result in disappearance of deformed grains and formation of fully recrystallized microstructure,which are depicted in Fig.1(j-l).Average grain sizes of A3,AX31,and AXE310 alloys after annealing treatment are 13.2μm,12.4μm and 10.5μm,respectively.It is significan that micro co-additions of Ca and Gd elements play an important role on refinin grain size.

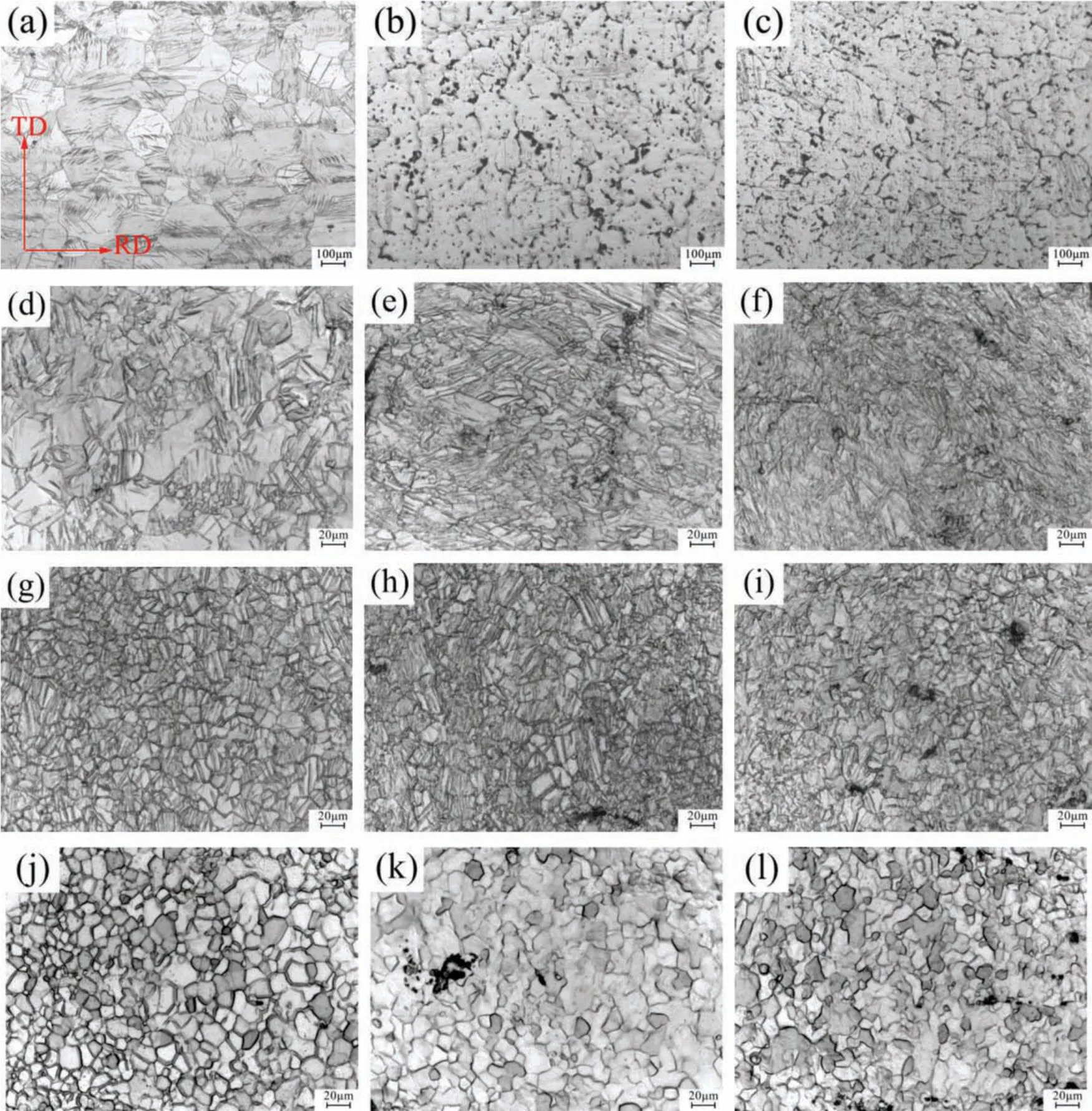

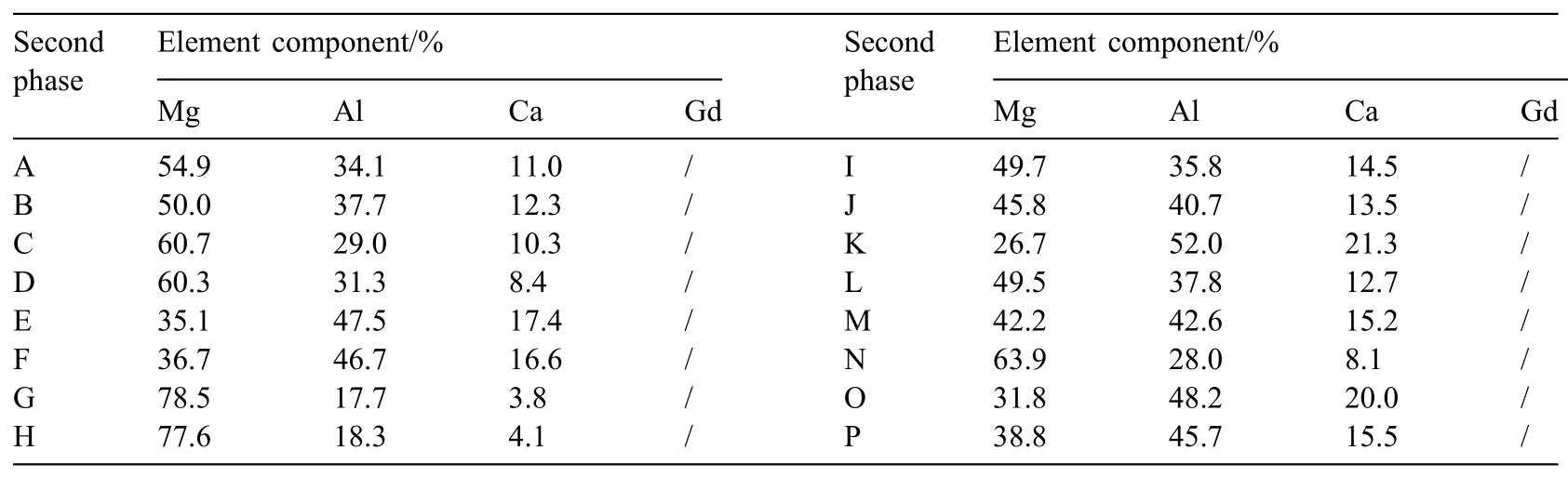

Some second phase particles detected by SEM under various processing conditions are exhibited in Fig.2,and related chemical compositions of second phase particles points A-P analyzed by EDS are presented in Table 2.Under homogenized condition,lamellar,rod,block and spherical compounds can be observed and exhibit an aggregation state.The average lengths of second phase particles in AX31 and AXE310 alloy are about 6.94μm and 4.24μm,respectively.During hot rolling,second phase particles get broken under rolling pressure and turn to more regular shape.After rolling process,the sizes of second phase particles decrease and the average lengths of AX31,and AXE310 alloys are 2.28μm and 1.80μm,respectively.However,the distribution of second phase particles remains coalescence.After annealing treatment,second phases exhibit excellent thermal dimensional stability,the coarsening of second phase particles do not occur,and remain nearly 2μm in size.

Fig.2.SEM images of second phase particles:AX31(a)homogenized;(b)as-rolled reduction of 90%;(c)annealed;and AXE310(d)homogenized;(e)as-rolled reduction of 90%;(f)annealed.

Table 2EDS analysis of the second phases particles(at.%)shown in Fig.3.

The component analysis of second phase particles by EDS from Table 2 indicates that the main components in second phase particles of AX31 and AXE310 alloys are Mg,Al and Ca elements.Gd element cans not detected by EDS in second phase particles,and may exists in Mg matrix as dissolved elements.Our previous study demonstrated that the second phase particles of the two investigated alloys are both identifie as Al2Ca by indexing the diffraction spots in TEM[23].As the stable phases due to the higher melting point than Mg matrix[24],Al2Ca particles do not dissolve and can be broken during hot rolling process.In magnesium alloys,particles with different dimension play diverse influenc on recrystallization[25,26].Second phase particles with size of micron scale can promote nucleation of recrystallization grains,while,particles with size of nanometer level hinder grain growth by Zener pinning effect.In conclusion,the second phase particles in AXE310 alloys play an important effect on recrystallization behavior.

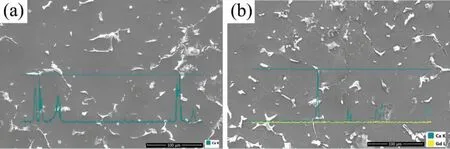

The solid solubility of Ca and Gd elements in magnesium alloys decreases dramatically with temperature decreasing,and Ca or Gd elements as solid solute may affect the c/a axis ratio.Moreover,the line scanning micrographs of Ca and Gd elements in magnesium matrix of AX31 and AXE310 alloys at homogenized condition are exhibited in Fig.3.Some peaks of Ca elements exist at the position without second phase particles.Compared with Mg and Al atoms,Ca and Gd atoms exhibit larger atoms radius[27,28].The inevitable elastic interaction is formed between the pressure on the matrix,induced by the solute and the volume difference.Furthermore,the elastic interaction is favorable to make atoms of Ca and Gd evolve clustering tendency in Mg-Al series alloys.Meanwhile,the clustering is beneficia for the decrease of the size misfi energy in the matrix and result in distortion of lattice[29].

Fig.3.Line scanning maps of Ca and Gd elements in matrix:(a)AX31;(b)AXE310.

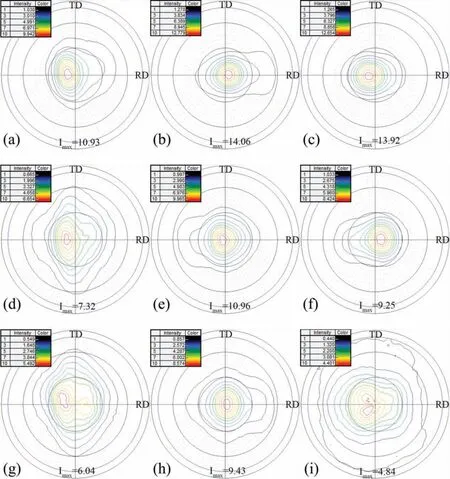

Table 3Lattice constant of experimental alloys.

Microstructural observations during rolling process reveal that the grain size significantl decreases by rolling pressure.The fin equiaxial grains appear at grain boundaries,which mean DRX is activated during hot rolling.Moreover,rolling at temperature of 400°C is propitious to stimulate proliferative dislocations,which is beneficia for dislocations rearrangement in the vicinity of grain boundaries and release of stress concentration[30].Intergranular coordinated deformability is enhanced by dislocation climb and cross-slip as the non-basal slips can be easily activated under high temperature conditions.Besides,second phase particles and alloying element clustering at the matrix and grain boundaries can block the movement of dislocations and grain boundaries.Due to the characteristics with high dislocation density and large orientation gradient,constituent particles can act as ideal heterogeneous nucleation sites for DRX[31,32].Therefore,DRX behavior arises easily,and it is positive to form equiaxial grains.During annealing treatment,solute drag effect can be achieved by the addition of solid solution Ca and Gd elements,and mobility of dislocation,twinning and grain boundaries are restricted[13,33].Moreover,nucleation rate of SRX increases under the role of heterogeneous nucleation sites from lattice defects such as Al2Ca particles.Eventually,co-addition of Ca and Gd is advantageous to induce grain size refinemen during annealing process under the roles of solute drag and heterogeneous nucleation of recrystallized grains.

Cottom[34]reported that the decrease of c/a ratio with Mg alloy matrix accompanied by addition of RE elements can decrease the critical resolved shear stress(CRSS)of nonbasal slip systems.The crystal lattice constants of investigated Mg alloys are detected by XRD,and the values of c-axis and a-axis are calculated by Jade 6.0 software and summarized in Table 3.Results show that addition of Ca and Gd exhibits almost no influenc on c/a ratio of A3 matrix with trace addition content of Ca and Gd.It also illustrates the effect of Ca and Gd additions into A3 alloys is irrelevant to decrease of c/a ratio,instead promote recrystallization behavior.Perhaps,the low Ca and Gd addition content can't result in remarkable distortion of lattice and subsequently alter c/a ratio obviously.

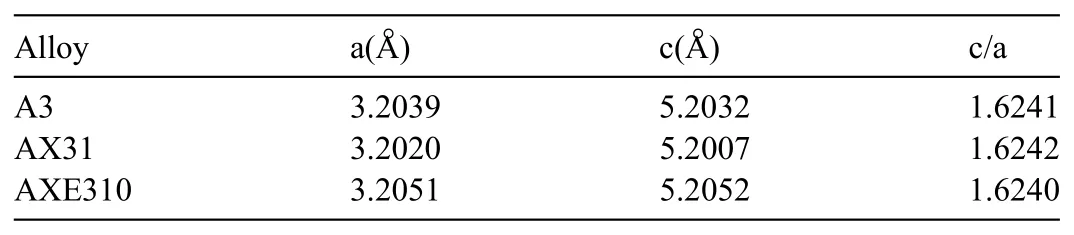

3.2.Grain orientation

The macro-scale(0002)plane pole figure of experimental Mg alloys at different processing conditions are shown in Fig.4.When the total reduction is 60%,the(0002)plane maximum intensities of A3,AX31 and AXE310 alloys are 10.93,7.32 and 6.04 MRD(multiples of random distribution),respectively.Obviously,the three experimental alloys sheets exhibit typical basal texture characteristics.However,basal textures have a slight diffusion to TD,and the maximum intensities decrease significantl for modifie AX31 and AXE310 alloys.When the total reduction is 90%,the(0002)plane maximum intensities of A3,AX31 and AXE310 alloys all increase and corresponding values are 14.06,10.96 and 9.43 MRD,respectively.It is clear that the diffusion content to TD decrease and diffusion content to RD increase with the hot rolling process progressing,and the grain orientation prefer to along RD during hot rolling process.Moreover,the maximum intensities of(0002)pole of 90% total reduction are higher than those of 60% total reduction.Though DRX occurs easily and grains of randomly distributed have an advantageous effect on attenuating basal texture.Most of newly formed recrystallized grains have a similar orientation with original grains during rolling process.Some grains which can weaken basal texture at an initial stage of dynamic recrystallization are rotated under applied loading in subsequent deformation process and transform the component of deformed texture again[35].

After annealing treatment,the(0002)plane maximum intensities of A3,AX31,and AXE310 alloys all decrease obviously and the related values are 13.92,9.25 and 4.84 MRD,respectively.Meanwhile,more obvious TD diffusion of(0002)texture can be observed with co-addition of Ca and Gd.It is clear that static recrystallization behavior is benefi cial to attenuate basal texture,though the preferred orientation behavior still exists.Shear zone,twinning,grain boundary and defects in grains are found to be preferential nucleation sites due to the characteristics with high dislocation density and large orientation gradient,and can be an advantage for the occurrence of SRX during annealing treatment[36].The generation of grains with broader orientation distribution is resulted from synergetic effect of formation of geometrically necessary dislocation and low angle grain boundary due to large orientation gradient[37].Moreover,massive non-basal dislocations formed during the rolling process merge at grain boundaries.It can promote the rotation of crystal nucleus and formation of fin static recrystallization grains in various orientations,consequently lead to distinct orientation evolution.

Fig.4.(0002)plane pole f gure of experimental alloys at different processing conditions by XRD.A3 alloy(a)Reduction of 60%;(b)Reduction of 90%;(c)Annealed,AX31 alloy(d)Reduction of 60%;(e)Reduction of 90%;(f)Annealed,AXE310 alloy(g)Reduction of 60%;(h)Reduction of 90%;(i)Annealed.

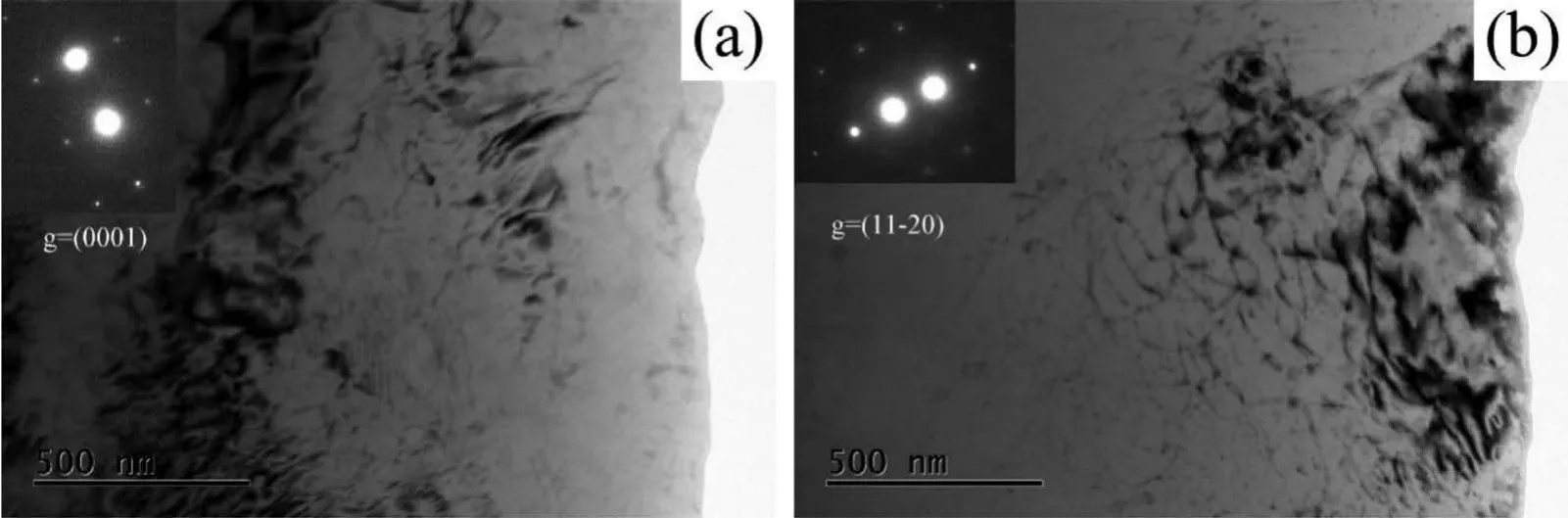

Fig.5.TEM bright-fiel images of AXE310 alloy when reduction is 90%:(a)g=0001;(b)g=11-20.

The refine grain size in AXE310 alloys is completed by the existence of Al2Ca particles which boost nucleation of recrystallization grain and block subsequent grain growth.Moreover,Agnew[38]revealed that possibility of activation for non-basal slips can be intensifie in the vicinity of grain boundaries.Then,with grain size decrease,the proportion of grain boundaries increases,which dedicates to activate nonbasal slips.Moreover,the slow diffusivity of Ca and Gd in the matrix and their clustering at dislocation and grain boundary also can slow down the movement of grain boundaries and dislocations[39].Therefore,it is undisputed that activation energies increase not only for basal slips,but also for nonbasal slip under the action of solute drag.However,as the preferential activated deformation mechanism in magnesium alloy,movements and multiplications of basal dislocations can be impeded by solute drag effect.Conversely,activities of non-basal slip can be enhanced with locally consumed of solute atoms such as Ca and Gd by dragging effect on basal slip during initial stage of hot temperature deformation.The Burgers vectors of<a>type dislocations in magnesium alloys is a/3<11-20>,the Burgers vectors of<c+a>type dislocations is(c2+a2)1/2<11-23>.Based on g·b=0 invisibility criterion,<a>type dislocations are invisible when g=(0001)and visible when g=(11-20).On the contrary,<c+a>type dislocations are invisible when g=(11-20)and visible when g=(0001).Such invisibility criterion is widely used to analyze dislocation types and deformation mechanism in some investigations of magnesium alloys[40,41].Fig.5 presents TEM bright-fiel images taken atg=(0001)andg=(11-20)of an area in AXE310 alloy when reduction is 90%.The operation vector in Fig.5(a)isg=(0001),and<c+a>type dislocations can be observed.By contrast,the operation vector in Fig.5(b)isg=(11-20),and only<a>type dislocations are visible.It is significan that the dislocations with black color in Fig.5(b)belong to<c+a>type.Meanwhile,massive<a>type dislocations are also exhibited in Fig.5(b).During hot rolling process,<c+a>type slips are activated in AXE310 alloy.

According XRD(0002)plane macro pole figur analysis results,co-addition of Ca and Gd has facilitating effect on attenuating basal texture at every processing condition.However,the(0002)plane pole figure of experimental alloys still present basal texture characteristics even after annealing treatment.For further evaluation of grain orientation,the inverse pole figure(IPF)is more intuitionistic.IPF figure of annealed experimental alloys which are detected by EBSD technique and analysed by HKL software are shown in Fig.6(a)-(c).For A3 alloy,the majority of grains are orientated with<0001>parallel to the normal direction(ND)exhibited typical basal orientation.With single addition of Ca,the grains whose crystal orientation parallels to the ND deviate away<0001>itself increase.The proportion of grains which deviate away basal texture orientation increases significantl with co-addition of Ca and Gd.The grains with blue color in Fig.6(a',b',c')mean the angle between<0001>crystal orientation of grains and itself crystal orientation which parallel to the ND is within 30° The grains of blue color occupy a percentage of total grains with 86.5%,75.7% and 55.4%for A3,AX31,and AXE310 alloys,respectively.The tendency is consistent with the results of XRD analysis and confirm the variation of grain orientation by co-addition of Ca and Gd.

3.3.Mechanical behavior

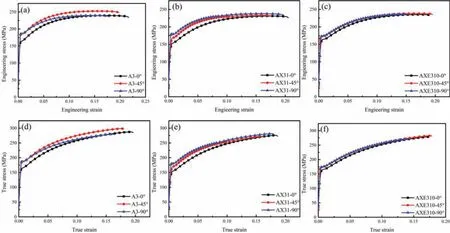

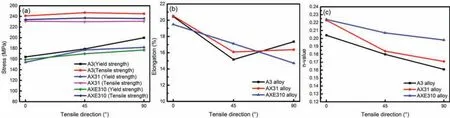

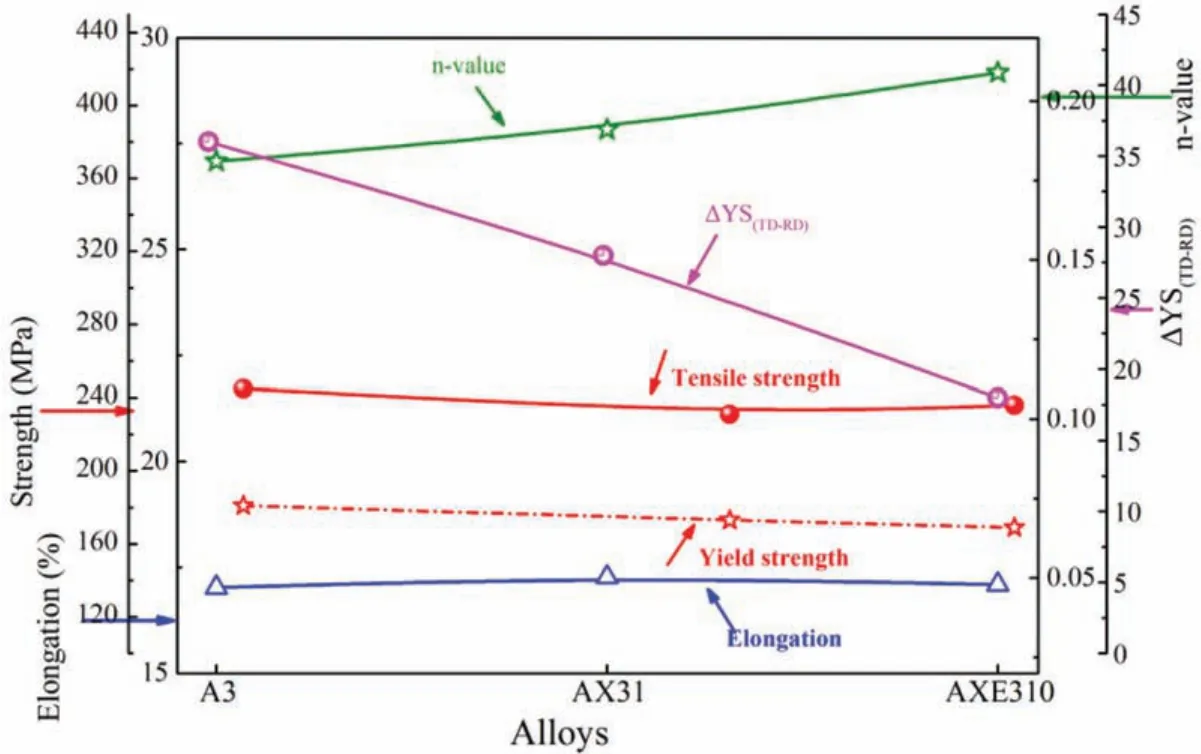

The typical engineering stress-strain curves and corresponding true stress-strain curves of experimental alloys during tensile deformation are plotted in Fig.7.Corresponding mechanical properties obtained from tensile tests are depicted in Fig.8,which contains some important mechanical parameters such as yield strength(YS),tensile strength(TS),elongation and n-value.However,mechanical parameters exhibit diverse evolution development.With sampling direction of loading direction in tensile tests deviating from RD in RD×TD plane,YS exhibits enhanced phenomenon,while n-value presents conserve behavior and difference of TS is tiny.Furthermore,the average tensile properties(X¯=(X0˚+2X45˚+X90˚)/4)are calculated to estimate mechanical properties of three investigated alloys.Average yield strengths of A3,AX31,and AXE310 alloys are 181MPa,173MPa and 169MPa,respectively.Average tensile strengths of A3,AX31,and AXE310 alloys are 245MPa,231MPa and 236MPa,respectively.Average elongations of A3,AX31,and AXE310 are 17.03%,17.27% and 17.10%,respectively.Average n-values of A3,AX31,and AXE310 alloys are 0.181,0.191 and 0.209,respectively.From comparison of tensile properties shown in Fig.9,Mg-3Al alloy exhibits higher strength,AXE310 has best work hardening capacity.However,the fluctuatio of elongation is small.The difference between yield strength along TD and yield strength along RD(ΔYS(TD-RD))are also ploted in Fig.9 for evaluating the in-plane anisotropy of mechanical property,and it illustrates that AXE310 alloy exhibits weakest anisotropy than that of other alloys.

Fig.7.Typical engineering stress-strain curves and true stress-strain curves.Engineering stress-strain curves(a)A3;(b)AX31;(c)AXE310;True stress-strain curves(d)A3;(e)AX31;(f)AXE310.

In magnesium alloys,it is convinced that solution strengthening from solute atoms,precipitation strengthening from secondary phase particles and grain boundary strengthening from grain refinemen are main and suitable ways to promote mechanical properties.Considering these strengthening mechanism,AXE310 alloy with fines grain size and most second phase and solid solution due to highest addition of Ca and Gd in three experimental alloys,should exhibit higher strength in tensile tests.However,it is Mg-3Al alloy which exhibits higher yield strength and tensile strength as shown in Fig.9.It is extensively reported that yield strength of Mg alloys is highly dependent on texture.The important Hall-Petch parameters,includingσ0(friction stress)and ky(grain boundary strengthening coefficient are confirme to be influence by texture[42,43].The plastic deformation can be activated easily due to weakened basal texture and subsequently decrease yield strength.For example,Stanford[12]revealed that the weakening of the texture contributes to a decrease in the tensile yield point in an Mg-Mn-Ca alloy.In other words,the strengthening achieved by solid solution,second phase and grain refinemen in AXE310 alloy can't offset the softening of strength due to weakened basal texture.The role of texture on mechanical properties in magnesium alloys can be reflecte by varied evolution of Schmid factors of deformation mechanisms,especially for{0001}<11-20>basal slip and{10-12}<10-11>tensile twinning at room temperature.

Fig.8.Mechanical properties of the annealed alloys along different directions:(a)Yield strength and tensile strength;(b)Elongation;(c)n-value.

Fig.9.Average mechanical properties and anisotropy of experimental alloys.

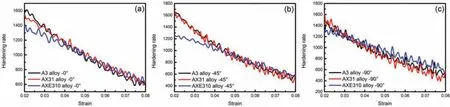

Owing relatively low CRSS at ambient temperature in magnesium alloys,basal slip and tensile twinning become two main dominant deformation modes.Other slip systems and twinning systems,such as{10-10}<11-20>prismatic slip,{10-11}<11-20>and{11-22}<11-23>pyramidal slips and{10-11}<10-12>contraction twinning,are diffi cult to play significan role during plastic deformation process due to relatively large CRSS.Tensile deformation behavior at room temperature is influence by different deformation mechanism,which results in diverse plastic hardening behavior.The hardening rate exhibits continuously decrease with the strain increasing,when the dominated mechanism belongs to dislocations slips[44].The variations of hardening rate of experimental alloys with different tensile directions during early plastic deformation stage were calculated via differentiating of the true stress-strain curves,as plotted in Fig.10.Continuously decreases tendency of hardening rate with increase in strain illustrates slip systems dominate early plastic deformation behavior.Considering the low possibility of activation for prismatic slip and pyramidal slip,the main controlling mechanism is{0001}<11-20>basal slip during incipient plastic deformation process.

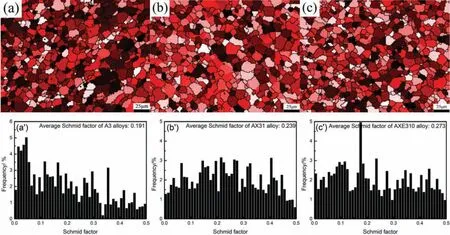

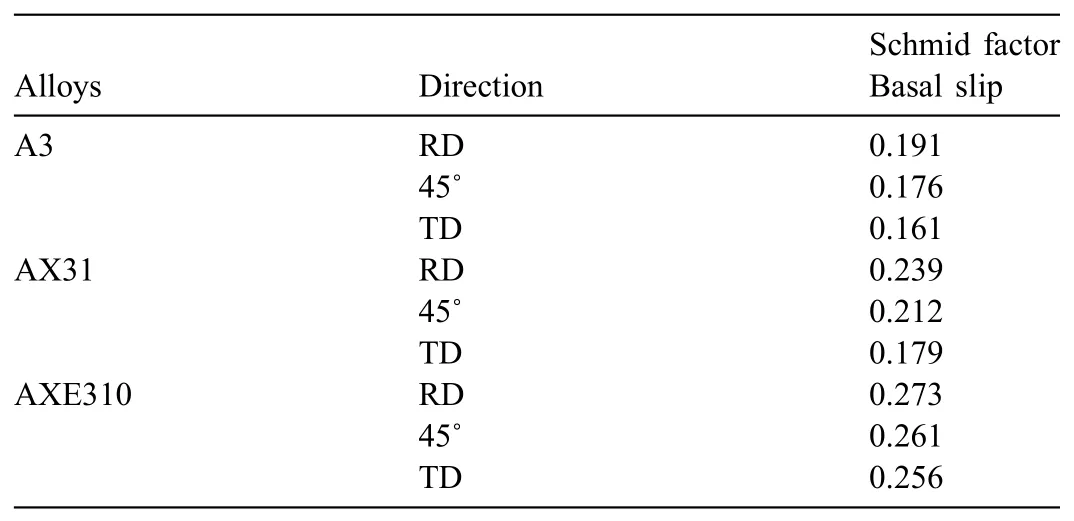

Fig.11 shows the Schmid factor images of basal slip along RD.The grains with red color(deep color)characterize grains with Schmid factor tends to 0,and the grains with white color(light color)means the Schmid factor tends to 0.5 of maximum values,the Schmid factor increases with the color from deep to light.The areas of white color increase with addition of micro alloying elements in Fig.11(a-c).The distributions of Schmid factor for basal slip along RD are shown in Fig.11(a'-c').The average Schmid factor along RD for basal slip of A3,AX31 and AXE310 alloys are 0.191,0.239 and 0.273,respectively.Moreover,the percentage of grains whose Schmid factor value larger than 0.2 of A3,AX31 and AXE310 alloys are 22.8%,34.5% and 35.3%,respectively.Obviously,A3 alloy presents most difficultl tendency for activate basal slip due to the lower Schmid factor,resulting in the highest yield strength and tensile strength among investigated alloys.

Elongation in magnesium alloys is controlled by grain size and second phase.Grain refinemen is beneficia for plasticity,while,existence of second phase is disadvantaged to plasticity.Therefore,three experimental alloys exhibit similar elongation values under interaction by two factors which are seen in Fig.9.During plastic deformation process,dislocation densities increase associated with dislocation multiplication,which make dislocation spacing decrease and result in repulsive strain fiel interactions[45].The resistance of dislocation interactions and secondary phase particles on dislocation movement becomes more pronounced with dislocation density increases.Therefore,effect of dislocation strain fiel interactions in AXE310 alloy on strain hardening is relatively higher than others,which results in a larger n-value.

Fig.10.Hardening rate curves during early plastic deformation with different tensile direction.(a)0°;(b)45°;(c)90°

Fig.11.Schmid factor imaging((a),(b),(c))and their distributions((a´),(b´),(c´))along RD:(a),(a´)A3 alloy;(b),(b´)AX31 alloy;(c),(c´)AXE310 alloy.

Table 4Schmid factors of basal slip along different tensile directions.

Table 4 presents Schmid factors of basal slip along different tensile directions.The results indicate that AXE310 alloy has lowest difference of Schmid factor under different loading directions for basal slip in investigated alloys.Obviously,it is ascribed to more uniform distribution of grain orientation due to weakened basal texture resulting from activating non-basal slip during hot rolling process,which leads to a decrease of tensile property anisotropy.However,yield strength of three investigated alloys also present significan orientation behavior in Fig.8.Annealed(0002)pole figure of experimental alloys exhibit spread component toward RD,which indicates that Schmid factor of basal slip under loading along RD is higher and results in lower yield strength[46].Hence,Schmid factors of grains for basal slip under loading along 45° and TD belong to hard orientation and exhibit higher yield strength compared with that along RD.Meanwhile,the spread diffusion of basal texture contributes to activation of tensile twinning.The distinct spread content along RD is anticipated to make tensile twinning occur easily and subsequently facilitate promotion of strain hardening[47].

4.Conclusions

The microstructure and deformation behavior of Mg-3Al series alloys during rolling process and annealing process were examined.Some conclusions are presented as follows:

(1)The basal texture is weakened and grain size is refine by co-addition of Ca and Gd elements.However,the mechanical properties aren't promoted due to the interaction of solid solution,second phase,refine grains and texture softening.

(2)The influenc of micro content addition of Ca and Gd elements on recrystallization was dominated by formation for second phase particles,which is the main reason for weakening basal texture.However,the lattice distortion by matrix is not influence due to trace addition content of Ca and Gd.

(3)Tensile deformation behaviors of three experimental alloys were dominated by basal slip,and the variations of tensile properties along different loading directions are depended on Schmid factor of basal slip.

(4)Co-addition of Ca and Gd has positive effect on decreasing anisotropy of yield strength,which is resulted from the weakened basal texture combined with activation of non-basal slips.

Acknowledgments

The authors would like to thank the financia support of Fundamental Research Funds for the Central Universities(No.2302019FRF-IC-19-018)and Aviation Science Foundation Project(No.20181174001).

杂志排行

Journal of Magnesium and Alloys的其它文章

- Microstructural evolution of Mg-Al-Re alloy reinforced with alumina fiber

- Predicting and controlling interfacial microstructure of magnesium/aluminum bimetallic structures for improved interfacial bonding

- Plasma electrolytic oxidation of AZ31 and AZ91 magnesium alloys:Comparison of coatings formation mechanism

- Effects of annealing treatment on microstructure and tensile behavior of the Mg-Zn-Y-Nd alloy

- Microstructure and performance of biodegradable magnesium alloy tubes fabricated by local-heating-assisted dieless drawing

- Comparisons of microstructure homogeneity,texture and mechanical properties of AZ80 magnesium alloy fabricated by annular channel angular extrusion and backward extrusion