竹集成材钉节点力学性能的试验研究

2020-08-12于云飞杨文琪徐振东

陈 国,周 通,于云飞,谈 闯,杨文琪,徐振东

竹集成材钉节点力学性能的试验研究

陈 国,周 通,于云飞,谈 闯,杨文琪,徐振东

(南京林业大学土木工程学院,南京 210037)

为研究现代竹构建筑中钉节点的受力性能和变形性能,对85个竹集成材钉连接节点试件进行单调加载试验,研究不同钉子端距、中距、边距、行距对钉节点的承载性能、变形特性和破坏机理的影响。试验结果表明,节点的力学性能主要取决于端距和中距,而边距和行距的影响较小。加载初期的钉孔间隙导致节点初期的刚度较低。当端距和中距小于6(为钉子直径)时,节点的承载力随着端距和中距的增加而呈增大趋势,当端距和中距大于等于6时,节点的承载力将不再增大。钉节点的破坏形态与钉子的布置密切相关。当端距或中距小于6时,分别以端部剪切破坏和纵向劈裂破坏为主;当边距小于4或行距小于3时,分别以劈裂和块剪破坏为主。当钉子的端距、中距、边距和行距布置满足最小容许要求时,钉节点以销槽承压破坏模式为主,表现出较好的延性特征。试验结果的回归分析表明,Folz模型能较好地反映钉节点在各个受力阶段的荷载-位移本构关系,而基于Foschi和Hassanieh模型预测的弹塑性阶段的钉节点荷载-本构关系结果偏于保守,但明显高估了破坏阶段的受力变形性能。研究结果可为竹集成材钉节点的设计与应用提供参考。

竹;钉子;竹集成材;钉连接;构造要求;荷载-位移模型

0 引 言

中国拥有极其丰富的竹材资源,种类、蓄积量和产量均居世界首位。对竹子进行改性并应用于工程领域有利于降低对不可再生建筑材料的依赖[1-3]。竹集成材(Laminated Bamboo Lumber,LBL)是以3~5年生的毛竹为原料,加工成一定规格的矩形竹片,再经干燥、蒸煮、炭化、涂胶、组坯后热压而成的一种型材[4-5]。与圆竹相比,LBL克服了原竹的材料缺陷和尺寸变异性,力学性能明显优于速生木材[6],目前主要应用于家具、地板和装饰等非结构领域。尽管LBL在桥梁[7]和房屋[8-9]结构中也有一定的应用,但其设计和建造主要采用国内外的木结构设计标准,严重制约了LBL在土木工程领域的推广应用。突破LBL的局限性,拓展其应用范围,在国内具有重要的现实意义。

节点是影响竹木结构抗震性能的重要部件,直接关乎结构的安全。常见的节点形式包括榫卯节点[10-12]、齿板节点[13]、螺栓节点[14-16]和钉节点[17]等。其中,钉连接具有施工方便、安全可靠、价格低廉的特点,是一种最常见的连接方式。国内外学者对木结构钉节点的力学性能进行了大量的试验研究和理论分析。Porteous等[18]研究了端距、边距、中距、行距等对木材-钢夹板钉节点力学性能的影响并提出了设计计算方法。Meghlat等[19-20]认为钉节点的破坏形态与钉子间距影响密切,其中端距和中距的影响最显著。GB 50005-2017《木结构设计标准》[21]和Breyer等[22]对木结构钉节点的构造要求进行了严格限制,并提出了相应的设计计算方法。

木结构钉节点承载力低,不适合应用于大跨度和重型木结构中;另一方面,中国实施了数十年的天然林保护工程,木材的采伐和利用严重受限,迫切需要寻找另一种可持续绿色建材。为解决上述问题,研究人员[23-26]提出了“以竹代木”,并成功将其应用于工程领域。Ramirez等[27-28]认为主材和侧材的销槽承压强度对钉节点力学性能有着显著的影响的影响,竹集成材的销槽承压强度明显优于木材。Li等[29]对胶合竹-木钉连接节点进行了有益的探索,但未考虑钉子间距对组合节点的影响。更为重要的是,迄今为止国内外尚未有结构用LBL的相关规范或标准,且LBL钉节点的研究亦未见文献报道。

已有研究表明[21],竹木材料顺纹方向的力学强度最高,斜纹次之,横纹向最低。因而,实际工程中主要选择其顺纹方向使用。本文设计了85个LBL钉节点顺纹向受力的试件,进行单调加载试验,研究其破坏机理和抗剪性能,讨论钉子端距、中距、边距和行距对受力性能的影响,在试验的基础上,研究钉节点荷载-位移本构模型,为此类LBL钉节点的设计和有限元分析提供技术依据。

1 材料与设计

1.1 材料性能

本研究涉及的材料包括LBL和钉子。其中LBL由东莞湘楠竹木制品有限公司提供,材性试验依据ASTM D143-14[30]和ASTM D5764-97a[31]进行,测得其抗拉强度为107.7 MPa,抗压强度为56.3 MPa,弹性模量为11 GPa,密度为870 kg/m3,含水率为9.2%。销槽承压强度是衡量LBL在销类连接件作用下抵抗自身破坏的能力,销槽承压强度与销类连接件的直径密切相关[32],当销直径为2.5 mm时,LBL顺纹向销槽承压强度为73.71 MPa。根据GB 50005-2017《木结构设计标准》[21]规定和当前工程实践,钉连接常采用直径为2.5 mm、长度D为50 mm的普通光圆铁钉,参照ASTM F1575-17测得其抗弯强度平均值为705.2 MPa。

1.2 试件设计

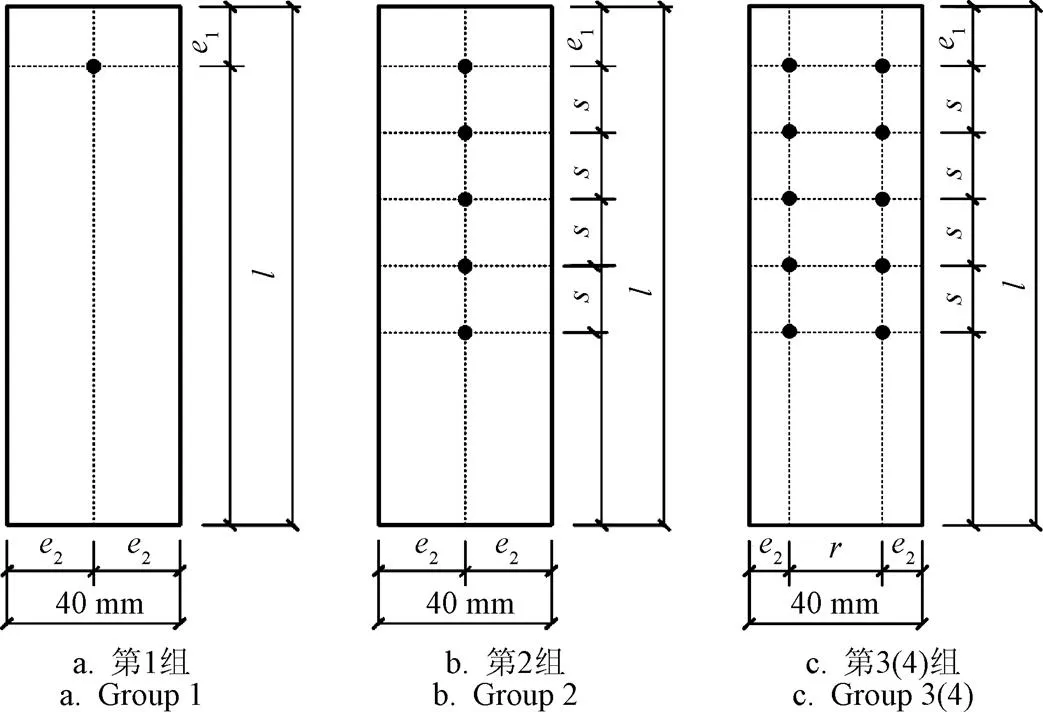

参照目前国内外常见木结构钉节点的尺寸,设计的LBL钉节点试件[17-18]由两块侧材和一块主材组成,侧材和主材通过钉子按一定间距连接。主材和侧材的厚度分别为40和20 mm,截面宽度均为40 mm,同组试件的主材和侧材长度相等,不同组主材和侧材的截面示意图参见图1。钉节点的受力性能、变形性能和破坏机理主要取决于钉子的端距、中距、边距和行距等构造参数。85个LBL钉节点试件,分为4个组共17个系列,每系列5个重复试件。各组分别考虑端距、中距、边距和行距对钉节点荷载-位移曲线、承载力和延性的影响,如表1所示。已有研究表明[24],直接钉入竹集成材易发生劈裂破坏,因而采用预钻孔的方式钉入钉子,钻孔深度约等于钉子长度的90%,钻孔直径约为钉子直径的80%。为消除主材和侧材间的摩擦力对节点抗剪性能的影响[33],试件制作时,首先在主材和侧材之间嵌入1 mm厚的薄钢片,然后从节点侧面垂直钉入铁钉,直至钉帽与侧材表面平齐,最后再拔出薄钢片,试件制作完毕后10 min内开始进行单调加载试验。

注:e1为端距,mm;e2为边距,mm;s为中距,mm;r为行距,mm;l为主(侧)材长度,mm。下同。

表1 钉节点试件参数

注:为钉节点行数;为钉节点列数;为钉子直径。下同。

Note:is number of rows of nails;is number of lines of nails;is diameter of nails. Same as below.

1.3 试验方法

1.3.1 加载方案与量测内容

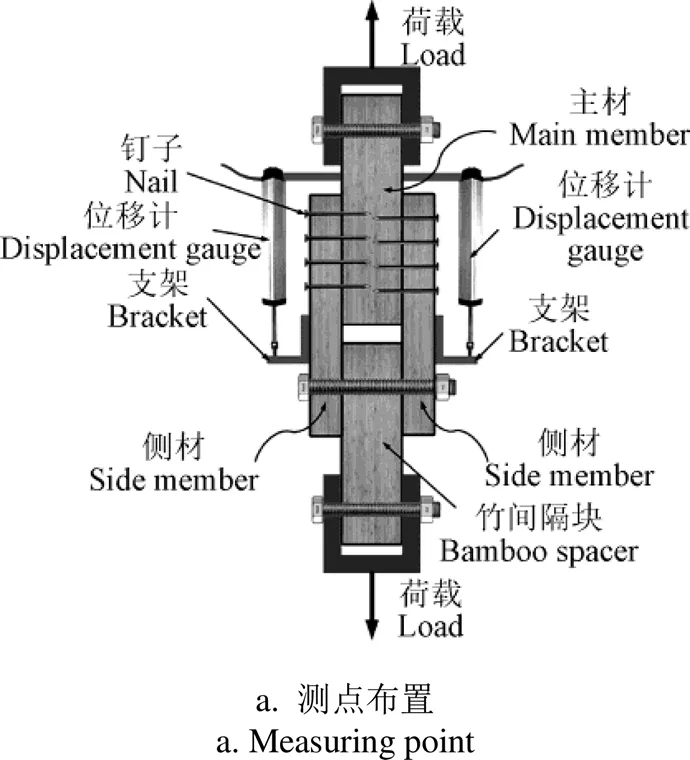

单调加载试验在DDL5电子万能试验机上进行,试验机的最大加载值为50 kN。试验加载装置和测点如图2所示,侧材底部与40 mm × 40 mm × 150 mm的竹间隔块通过M20螺栓连接以形成夹持段,主材顶部和竹间隔块底部的夹持段分别通过M 20螺栓和U型夹具相连。试验时拉力荷载使用万能试验机上的刚性夹头在试件两端的U型夹具加载,确保试件始终处于轴心受力状态。加载过程中,在试件侧面布置2个位移计实时监测主材和侧材的竖向相对位移值,通过试验机高精度力传感器实测荷载。所有的位移和荷载均由东华DH3820静态应变测量系统自动采集并存入电脑记录,采样频率为1 Hz。

参照《木质结构材料用销类连接件连接性能试验方法》LY/T 2377-2014[34],正式加载前进行预加载,从而消除试件和夹具之间的缝隙并检验仪器设备是否工作正常,初始加载为预估极限承载力的15%。正式加载采用位移加载,速度为2 mm/min,保证试件在10 min左右达到极限荷载,当荷载降至极限荷载的85%左右时,认为试件破坏,结束加载。

1.3.2 参数计算

屈服荷载y采用“5%钉子直径”法[34]确定,如图3所示。对照实测的荷载-位移曲线线性段,沿横坐标向右平移钉子直径5%的位移,再绘制一条与其平行的直线,取该直线和荷载-位移曲线交点与起始点之间的极限荷载作为屈服荷载y。如果该直线未与荷载-位移曲线相交,则取曲线极限荷载m作为y。由于钉连接节点的初始刚度较低,根据Zheng等[20]的研究成果,取0.1m和0.4m对应位移量的斜率作为刚度0。试件发生破坏时的位移与屈服位移Δ之比值为其延性系数[35]。

式中Δ为相应于y的屈服位移,mm;Δ为试件最终发生破坏时的位移,取荷载下降至85%m时对应的位移值,mm。

注:Fy为屈服荷载,kN;Fm为极限荷载,kN。下同。

2 结果和分析

2.1 试验结果

2.1.1 荷载-位移曲线

以dj3试件的荷载-位移曲线为例(图4),分析试件的相对变形过程,其大致可分为4个阶段:1)初始滑移阶段,荷载从0到10%m,钉节点发生了较大滑移,但荷载增长非常缓慢,这主要是因为钉子和孔壁间存在间隙,使得钉子未能充分发挥其承载能力,类似的现象也发生在木结构钉连接试验中[19];2)弹性阶段,当荷载不大于40%m时,荷载-位移曲线保持较好的线性关系,节点处于弹性工作阶段;3)弹塑性阶段,荷载继续增加,但增速明显变缓,节点破坏缓慢发展,荷载-位移曲线出现多个峰值;4)破坏阶段,荷载达到m后,进入破坏加速阶段,曲线开始显著下降,试件丧失承载力,试验结束。

图4 dj3试件荷载-位移曲线

2.1.2 承载能力

试件的主要试验结果取平均值及变异系数V如表2所示,试件的极限荷载和屈服荷载与钉子的端距1、中距、边距2和行距密切相关。

当1<6(dj1和dj2)或<6(zj1、zj2和zj3)时,屈服承载力和极限承载力随钉子端距和中距的增大而增加,但屈服荷载的增长幅度明显低于极限荷载的增长幅度。但当1≥6(dj3、dj4和dj5)或≥6(zj4和zj5)时,承载能力不再增大,趋于恒定值。当2<4(bj1)或<3(hj1)时,承载力随钉子边距和行距的增大而增加,但当2≥4(bj2和bj3)或≥3(hj2、hj3和hj4)时,承载能力将不再增大。边距和行距对试件承载能力的影响较小,这主要是因为边距2和行距为横向的钉间距,垂直于LBL的受力方向。因此,LBL钉节点的最小端距1和中距应取6,最小边距2和行距的构造要求分别取4和3。LBL顺纹向受力的钉子最小间距,应符合表3的要求。GB 50005-2017《木结构设计标准》对木结构钉节点的最小容许距离做出了严格的限制,但未充分考虑钉子的钉入方式对钉子最小距离的影响,钉间距采用统一的要求。Breyer等[22]认为端距和中距的最小容许距离随着主(侧)材密度的增大而呈减小的趋势,而边距和行距的容许距离与主(侧)材的密度没有必然的联系。当木材的密度大于600 kg/m3,应采用预钻孔的方式以避免木材劈裂,因而钉子的最小距离应细分为预钻孔和非预钻孔两种情况,采用预钻孔加工的钉间距略小于非预钻孔。LBL的密度大于木材的密度,因而LBL钉节点的端距1和中距的要求均小于国内外木材的要求,而LBL的最小边距2要求大于国内外木结构的要求,最小行距要求则介于《木结构设计标准》[21]和Breyer等[22]的要求之间。

表2 钉节点主要试验结果

表3 钉子的最小容许距离

2.1.3 位移延性

延性是指结构或构件抵抗弹塑性变形的能力,一般可用延性系数来衡量。在承载力保持不变的前提下,结构或构件的变形能力越强,说明其延性就越好。Smith[36]依据延性系数的大小将木结构销连接节点的延性划分为4种类型,即脆性(≤2),低延性(2<≤4),中等延性(4<≤6)和高延性(>6)。如表2所示,钉节点的延性系数随着端距的增大而增大。当端距1大于6时,钉节点表现出高延性的特性,这与试件破坏前钉子发生明显的弹塑性变形是一致的。中距小于6的试件发生了过早的脆性破坏,破坏前无明显征兆,因而其延性系数较小。边距2和行距对试件的延性系数影响较小,大部分试件表现出中等的延性,试件发生最终破坏前LBL的销槽和钉子破坏前发生较大的变形所致。

2.1.4 试验现象

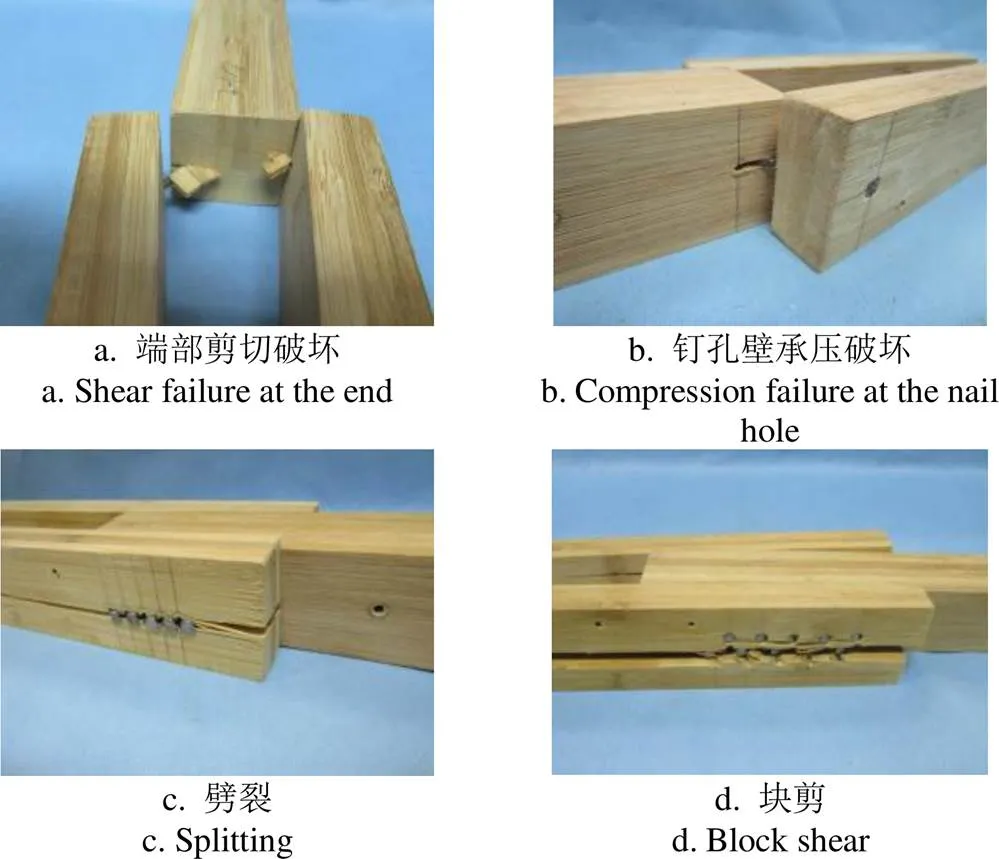

LBL钉节点的破坏现象与钉子的布置密切相关,主要观察到4种:①端部竹材剪切破坏;②销槽承压破坏;③劈裂破坏;④块剪破坏。

端距1<6的试件dj1和dj2的破坏形态为端部剪切破坏,如图5a所示,由于端部竹材对钉子的约束不足,因此靠近边缘的竹材发生过早的剪切破坏并带出竹屑,试件随即丧失承载力,但其他截面无破坏现象。随着端距1的逐渐增大,试件dj3、dj4和dj5均表现为孔壁销槽承压破坏(图5b)。

试件zj1~zj3的中距<6,裂缝首先在靠近端部的钉子孔洞处产生,随着荷载的增大,裂缝变宽变长并伴随着不断加剧的撕裂声,相邻钉子处的竹材裂缝随即发展成一条通缝,导致试件劈裂破坏(图5c)。中距≥6的试件zj4和zj5的破坏形态以销槽承压破坏为主,破坏始于靠近端部的销槽,靠近中部的销槽无可见破坏。

图5 试件主要破坏形态

边距和行距对节点的抗剪性能具有类似的破坏特征,对于边距2<4或行距<3的试件,加载初期,荷载增加,但滑移不明显,当加载至屈服荷载后,钉子孔洞出现轻微的销槽承压破坏并伴有顺纹向微裂缝,相邻钉子之间的裂缝逐渐汇合。当达到极限荷载后,随着裂缝变宽,荷载稍有下降,滑移愈发明显,最终发生块剪破坏(图5d)。对于边距2≥4或行距≥3的试件,当加载至屈服荷载后,靠近两端的销槽处首先发生了承压破坏伴随竹材的撕裂声,之后荷载呈波浪形变化,销槽从两端向中间逐个发生破坏。当达到极限荷载后,销槽承压破坏加剧,相邻孔洞间出现微裂缝。

2.2 本构关系

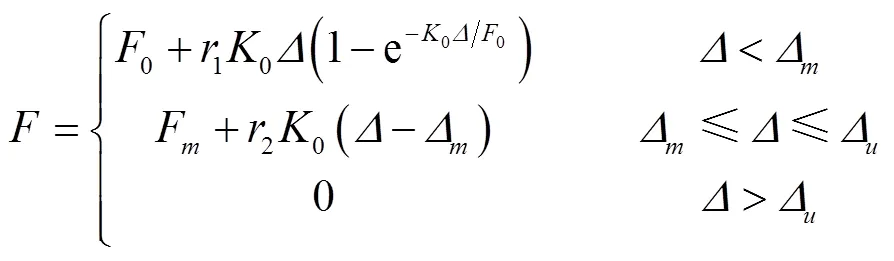

销连接的荷载-位移的本构关系主要有Foschi[37]、Folz[38]和Hassanieh[39]模型。Foschi等[37]于1974年首先提出了简化的指数模型公式,其表达式为

式中0为屈服后渐近线在轴上的截距,kN;1为屈服后刚度与弹性阶段的刚度之比(0<1<1),0为弹性阶段的刚度,kN/mm。

基于Foschi表达式,Folz提出了改进的表达式:

式中2为退化刚度与初始刚度之比(2<0);和分别为极限位移和破坏位移,mm。

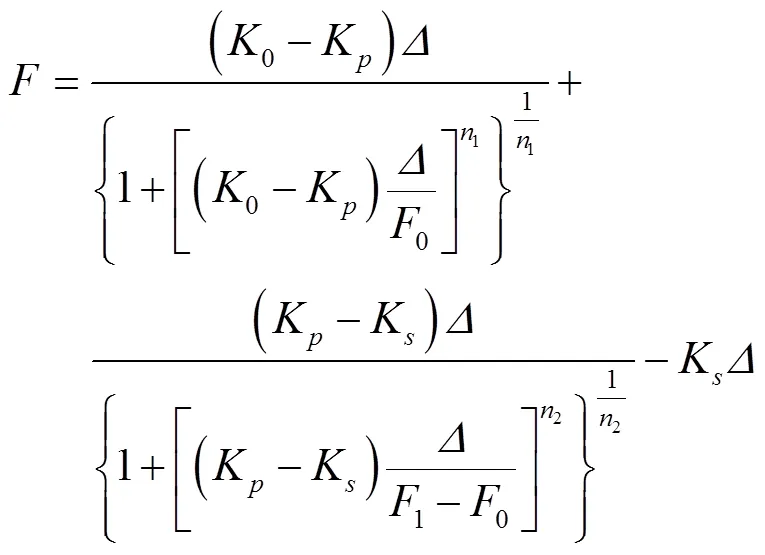

Hassanieh于2016年提出了钢夹板-木结构销连接节点的荷载-位移本构模型:

式中K和K分别为节点屈服后和破坏前渐近线的刚度,kN/mm;1为破坏前渐近线在轴上的截距,kN;1和2为常系数。

选取4个典型的钉节点试件dj5、zj4、bj2和hj2进行数据拟合,获得了理论拟合曲线和试验曲线的对比结果,如图6所示。结果表明,由于钉节点初始加载阶段发生了滑移,Fochi、Hassanieh和Folz的表达式均不能很好的模拟此阶段的荷载-位移关系。但3个理论表达式拟合的曲线能够真实的反映钉节点弹性段的受力变形性能,Fochi和Hassanieh预测值低估了钉节点弹塑性阶段的荷载-位移性能,但明显高估了破坏阶段的行为。

图6 荷载-位移关系的试验值和理论值对比

综上所述,在忽略初始滑移阶段的前提下,Fochi、Hassanieh和Folz提出的理论表达式均能如实地反映钉节点在弹性阶段的荷载-位移性能,而Folz模型能更加精确的反映LBL钉节点在各个受力阶段的荷载-位移本构关系,但表达式形式较复杂,不适合用于手算分析。相对于其他理论本构关系表达式而言,Foschi提出的指数表达式的形式简单,因而被广泛地应用于模拟木结构销类连接的变形滑移性能。本构关系的分析研究可为竹集成材钉节点的设计与有限元分析提供有益的参考。

3 结 论

通过85个LBL钉节点试件的单调加载试验,研究了端距1、中距、边距2和行距对钉节点力学性能的影响,得到以下结论:

1)LBL钉节点的屈服承载力和极限承载力随钉子端距和中距的增大而增加,但屈服承载力的提高幅度明显低于极限承载力的增幅,当端距或中距大于6(为钉子直径)时,承载能力将不再增加。而边距和行距对承载力的影响较小。

2)采取预钻孔方式的LBL钉节点的最小容许端距和中距应取6,最小边距和行距的最小容许构造要求分别为4和3。

3)当端距和中距小于6时,表现出低延性的破坏特征。当端距大于6时,钉节点表现出高延性的特性,边距和行距对试件的延性系数影响较小。

4)钉节点的破坏形态有4种:端部竹材剪切破坏、钉孔壁承压破坏、劈裂破坏和块剪破坏。LBL钉节点的破坏形态与钉子间距密切相关。

5)LBL钉节点的荷载-位移关系可分为4个阶段:初始滑移阶段、弹性段、弹塑性段和破坏段。在忽略滑移阶段的前提下,Folz模型能真实的反映LBL节点受力全程的荷载-位移本构关系。

[1] 黄政华,曲妮妮,徐懿,等. 钢箍碳纤维布组合节点竹拱结构平面内稳定承载力试验[J]. 农业工程学报,2015,31(24):179-185.

Huang Zhenghua, Qu Nini, Xu Yi, et al. Test on in-plane stability capacity of bamboo arches with steel hoop-carbon fiber composite joints[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(24):179-185. (in Chinese with English Abstract)

[2] 魏洋,纪雪微,端茂军,等. 重组竹轴向应力-应变关系模型[J]. 复合材料学报,2018,35(3):572-579.

Wei Yang, Ji Xuewei, Duan Maojun, et al. Model for axial stress-strain relationship of bamboo scrimber[J]. Acta Materiae Compositae Sinica, 2018, 35(3): 572-579. (in Chinese with English Abstract)

[3] 田黎敏,靳贝贝,郝际平,等. 原竹骨架喷涂复合材料多功能组合构件力学性能试验研究[J]. 农业工程学报,2018,34(13):95-104.

Tian Limin, Jin Beibei, Hao Jiping, et al. Experimental study on mechanical properties of multi-function bamboo skeleton composite members sprayed with composite material[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(13): 95-104. (in Chinese with English Abstract)

[4] Xiao Y, Yang R, Shan B, et al. Production, environmental impact and mechanical properties of glubam[J]. Construction and Building Materials, 2013: 765-773.

[5] 苏毅,宗生京,徐丹,等. 竹集成材梁非线性弯曲性能试验研究[J]. 建筑结构学报,2016,37(10):36-43.

Su Yi, Zong Shengjing, Xu Dan, et al. Experimental study on nonlinear bending of glued laminated bamboo beams[J]. Journal of Building Structures, 2016, 37(10): 36-43. (in Chinese with English Abstract)

[6] 李海涛,吴刚,张齐生,等. 侧压竹集成材弦向偏压试验研究[J]. 湖南大学学报:自然科学版,2016,43(5):90-96.

Li Haitao, Wu Gang, Zhang Qisheng, et al. Experimental study on side pressure LBL under tangential eccentric compression[J]. Journal of Hunan University: Natural Sciences, 2016, 43(5): 90-96. (in Chinese with English Abstract)

[7] Xiao Y, Zhou Q, Shan B, et al. Design and construction of modern bamboo bridges[J]. Journal of Bridge Engineering, 2010, 15(5): 533-541.

[8] 陈国,单波,肖岩. 轻型竹结构房屋抗震性能的试验研究[J]. 振动与冲击,2011,30(10):136-142.

Chen Guo, Shan Bo, Xiao Yan. Aseismic performance tests for a light glubam house [J]. Journal of Vibration and Shock, 2011, 30(10): 136-142. (in Chinese with English Abstract)

[9] 李玉顺,张家亮,刘瑞,等. 长期荷载作用后钢-竹界面黏结性能分析[J]. 建筑结构学报,2017,38(9):110-120.

Li Yushun, Zhang Jialiang, Liu Rui, et al. Study on bond performance of bamboo-steel interface after long-term loading[J]. Journal of Building Structures, 2017, 38(9): 110-120. (in Chinese with English Abstract)

[10] 谢启芳,王龙,张利朋,等. 西安钟楼木结构模型振动台试验研究[J]. 建筑结构学报,2018,39(12):128-138.

Xie Qifang, Wang Long, Zhang Lipeng, et al. Shaking table tests on wooden structure model of Xi’an Bell Tower[J]. Journal of Building Structures, 2018, 39(12): 128-138. (in Chinese with English Abstract)

[11] 张晋,张强,柏益伟,等.燕尾榫节点梁柱式木框架抗火性能试验研究[J]. 建筑结构学报,2019,40(10):188-196.

Zhang Jin, Zhang Qiang, Bai Yiwei, et al. Experimental study on fire performance of post-beam timber frame with dovetail joint [J]. Journal of Building Structures, 2019, 40(10): 188-196. (in Chinese with English Abstract)

[12] 潘毅,袁双,郭瑞,等. 铺作层布置对古建筑木结构抗震性能的影响[J]. 土木工程学报,2019,52(3):29-40.

Pan Yi, Yuan Shuang, Guo Rui, et al. Effects of tou-kung layer layout on seismic performance of ancient timber structure[J]. China Civil Engineering Journal, 2019, 52(3): 29-40. (in Chinese with English Abstract)

[13] 何敏娟,何桂荣,倪骏,等. 轻木结构正交主轴齿板连接承载力试验及分析[J]. 同济大学学报:自然科学版,2009,37(12):1581-1585.

He Minjuan, He Guirong, Ni Jun, et al. Experimental and statistical analysis on load carrying capacity of metal plate with orthogonal oriented teeth in light wood frame construction[J]. Journal of Tongji University: Natural Science, 2009, 37(12): 1581-1585. (in Chinese with English Abstract)

[14] 魏洋,纪雪微,周梦倩,等. 销栓型竹-混凝土组合结构的力学性能[J]. 农业工程学报,2017,33(3):65-72.

Wei Yang, Ji Xuewei, Zhou Mengqian, et al. Mechanical properties of bamboo-concrete composite structures with dowel-type connections[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(3): 65-72. (in Chinese with English Abstract)

[15] 魏洋,杨超群,王志远,等. 凹槽销栓型竹-混凝土连接件的力学性能[J]. 林业工程学报,2018,3(6):135-141.

Wei Yang, Yang Chaoqun, Wang Zhiyuan, et al. Mechanical properties of notch-dowel connections of bamboo-concrete[J]. Journal of Forestry Engineering, 2018, 3(6): 135-141. (in Chinese with English Abstract)

[16] 王明谦,宋晓滨,顾祥林,等. 胶合木梁柱螺栓节点变异性分析[J]. 土木工程学报,2019,52(7):13-21,56.

Wang Mingqian, Song Xiaobin, Gu Xianglin, et al. Variability analysis of bolted glulam beam-to-column connections[J]. China Civil Engineering Journal, 2019, 52(7): 13-21, 56. (in Chinese with English Abstract)

[17] 熊海贝,曹纪兴,张凤亮,等. 轻木钉节点恢复力模型研究及参数识别[J]. 湖南大学学报:自然科学版,2017,44(11):99-108.

Xiong Haibei, Cao Jixing, Zhang Fengliang, et al. Parameter identification and research on restoring force model of nail joints in light wood structure[J]. Journal of Hunan University: Natural Sciences, 2017, 44(11): 99-108. (in Chinese with English Abstract)

[18] Porteous A, Kermani A. Fully overlapping nailed joints with steel gussets in timber structures[J]. Journal of Structural Engineering, 2005, 131(5): 806-815.

[19] Meghlat E M, Oudjene M, Ait-Aider H, et al. A new approach to model nailed and screwed timber joints using the finite element method[J]. Construction and Building Materials, 2013, 41: 263-269.

[20] Zheng W, Lu W D, Liu W Q, et al. Experimental investigation of laterally loaded double-shear-nail connections used in midply wood shear walls[J]. Construction and Building Materials, 2015, 101: 761-771.

[21] 《木结构设计标准》:GB 50005-2017[S]. 北京:中国建筑工业出版社,2017.

[22] Breyer D E, Fridley K J, Cobeen K E, et al. Design of Wood Structures-ASD/LRFD [M]. New York:McGraw-Hill, 2007.

[23] 肖岩,陈国,单波,等. 竹结构轻型框架房屋的研究与应用[J]. 建筑结构学报,2010,31(6):195-203.

Xiao Yan, Chen Guo, Shan Bo, et al. Research and application of lightweight glue-laminated bamboo frame structure[J]. Journal of Building Structures, 2010, 31(6): 195-203. (in Chinese with English Abstract)

[24] 陈国,于云飞,李祥,等. 定向刨花板加固腹板开洞竹木工字梁力学性能研究[J]. 农业工程学报,2018,34(23):260-266.

Chen Guo, Yu Yunfei, Li Xiang, et al. Study on laminated bamboo lumber-wood I shaped joist with web opening reinforced by oriented strand board plates [J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(23): 260-266. (in Chinese with English Abstract)

[25] 冷予冰,许清风,王明谦. 胶合竹木梁抗弯性能试验研究[J]. 建筑结构学报,2019,40(7):89-99.

Leng Yubing, Xu Qingfeng, Wang Mingqian. Experimental research on flexural behaviour of glued laminated timber bamboo beams[J]. Journal of Building Structures, 2019, 40(7): 89-99. (in Chinese with English Abstract)

[26] 李海涛,宣一伟,许斌,等. 竹材在土木工程领域的应用[J]. 林业工程学报,2020,5(5):109-118.

Li Haitao, Xuan Yiwei, Xu Bin, et al. Bamboo application in civil engineering field [J]. Journal of Forestry Engineering, 2020, 5(5):109-118. (in Chinese with English Abstract)

[27] Ramirez F, Correal J F, Yamin L E, et al. Dowel-bearing strength behavior of glued laminated guadua bamboo[J]. Journal of Materials in Civil Engineering, 2012, 24(11): 1378-1387.

[28] Reynolds T, Sharma B, Harries K A, et al. Dowelled structural connections in laminated bamboo and timber [J]. Composites Part B-engineering, 2016, 90: 232-240.

[29] Li Z, Xiao Y, Wang R, et al. Studies of nail connectors used in wood frame shear walls with ply-bamboo sheathing panels[J]. Journal of Materials in Civil Engineering, 2014, 27(7): 04014216.

[30] ASTM D 143-14, Standard test methods for small clear specimens of timber [S]. American society for testing and materials (ASTM), West Conshohocken, USA.

[31] ASTM D 5764-97a, Standard test method for evaluating dowel-bearing strength of wood and wood-based products [S]. American society for testing and materials (ASTM), West Conshohocken, USA.

[32] 崔兆彦,王飞,徐明,等.高温下重组竹顺纹销槽承压强度试验研究[J]. 东南大学学报:自然科学版,2017,47(6):1174-1179.

Cui Zhaoyan, Wang Fei, Xu Ming, et al. Experimental study on embedding strength of bamboo scrimber parallel to grain at high temperatures[J]. Journal of Southeast University (Natural Science Edition), 2017, 47(6): 1174-1179. (in Chinese with English Abstract)

[33] Sjödin J, Serrano E, Enquist B. An experimental and numerical study of the effect of friction in single dowel joints[J]. European Journal of Wood and Wood Products, 2008, 66(5): 363-372.

[34] 木质结构材料用销类连接件连接性能试验方法:LY/T 2377-2014[S]. 北京:中国标准出版社,2014.

[35] Cabrero J M, Yurrita M. Performance assessment of existing models to predict brittle failure modes of steel-to-timber connections loaded parallel-to-grain with dowel-type fasteners[J]. Engineering Structures, 2018, 171: 895-910.

[36] Smith I. The Canadian approach to design of bolted timber connections[J]. Wood Design Focus, 1994, 5: 5-8.

[37] Foschi R O. Load-slip characteristics of nails [J]. Wood Science, 1974, 7(1): 69-76.

[38] Folz B, Filiatrault A. Cyclic analysis of wood shear walls [J]. Journal of Structural Engineering, 2001, 127(4): 433-441.

[39] Hassanieh A, Valipour H R, Bradford M A. Experimental and analytical behaviour of steel-timber composite connections[J]. Construction and Building Materials, 2016, 118: 63-75.

Experimental study on mechanical performance of laminated bamboo lumber nailed connections

Chen Guo, Zhou Tong, Yu Yunfei, Tan Chuang, Yang Wenqi, Xu Zhendong

(,,210037,)

In recent years, the building industry of China has expanded rapidly, however, construction materials such as the steel and cement are extensive used, which leads to serious environmental issues and energy consumption. As one of the fast-growing plants in the world, bamboo has been applied in civil engineering field for thousands of years. However, some disadvantages are exposed during the practice, such as thin-walled hollow and the diameter of bamboo culm decreases from the bottom to top. More importantly, the service life of bamboo structures generally does not exceed 3 years when the untreated bamboo exposure to natural environment. Recently, more and more attention are paid on the laminated bamboo lumber (LBL), which is considered as an alternative to wood because of its advantage of higher ration of strength to weight. Dowel connections including bolt, nail, screw and dowel are common types of connections in timber engineering for a large range of structural applications. Among them, nail connection is simple to produce and can be used for small as well as for large forces. Over the last decade, the use of LBL for modern bamboo structure has become increasing popular in China. LBL nailed connection which consisted of one middle member and two side members were introduced. A total of 85 specimens were tested in order to investigate the effect of parameters on capacity, deformation and failure modes of nailed connections, including end distance (1), center-to-center distance (), row spacing () and edge distance (2). It was found that the mechanical performance of nailed connections was mainly determined by the end distance and center-to-center distance of nails, and the influence of row spacing and edge distance was relative small. The initial gap between the lead hole and nails tended to result in lower stiffness. Four failure modes were recorded, including compression failure at the nail hole, splitting, shear failure at the end and block shear. For1orless than 6 times the diameter of nails (), the nailed connections failed in shear failure at the end and splitting, respectively. Forless than 3or2less than 4the connections failed in splitting and block shear, respectively. When nail spacing meet the minimum structural requirement, the nailed connections failed in compression failure of nail holes in the middle or side members, showing good ductile behavior. The ultimate load and yield load of specimens increased with the increase of nail spacing and kept constant as the nails spacing satisfied the minimum structural requirement. Many models had been proposed to quantify the load-displacement relationship of wood nailed connections, such as Folz’s, Foschi’s and Hassanieh’s model. Using the regression analysis for comparing the three theoretical models, it was found that the Folz’s model was more objectively reflected the load- displacement relationship of LBL nailed connections loaded parallel to grain. A good agreement could be observed between the Foschi’s or Hassanieh’s model and experimental results in the elastic stage, but great deviation of the theoretical results in the post-yielding stage increased gradually. The results provided useful information for modeling various bamboo structures containing LBL nailed connections.

bamboo; nails; laminated bamboo lumber (LBL);nailed connection; structural requirement;load-displacement model

陈国,周通,于云飞,等. 竹集成材钉节点力学性能的试验研究[J]. 农业工程学报,2020,36(13):291-298.doi:10.11975/j.issn.1002-6819.2020.13.034 http://www.tcsae.org

Chen Guo, Zhou Tong, Yu Yunfei, et al. Experimental study on mechanical performance of laminated bamboo lumber nailed connections[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(13): 291-298. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2020.13.034 http://www.tcsae.org

2019-12-01

2020-06-01

国家自然科学基金资助项目(51408312);江苏省自然科学基金资助项目(BK20130982);住房和城乡建设部资助项目(2018-K5-003)

陈 国,博士,副教授,主要从事现代竹木结构研究。Email:chenguo@njfu.edn.cn

10.11975/j.issn.1002-6819.2020.13.034

TU366.1

A

1002-6819(2020)-13-0291-08