The Role of an Independent Netherlands Laboratory in the Trade and Industry of Edible Oils and Fats

2020-07-22MarVerhoeff

Mar Verhoeff

(Dutch Agrolab Group Company,3024 AC Rotterdam,Zuid-Holland,Netherlands)

Abstract: The task of an independent laboratory within the trade of edible oils and fats is to determine the quality of shipped goods.Samples of the cargo are taken upon loading and discharge of a vessel and tested for the contractual quality specifications.The testing is performed according to contractual agreed methods of analyses.The laboratory should be recognised by the trade organisations and be tested every year on its performance.Also there is an increasing demand for analyses on contaminants,e.g.pesticide residues.This is enforced by national and international legislation.Therefore,the laboratory should be equipped with the newest analytical instruments in order to detect the requested low levels of contaminants and should keep up with the latest methods of analyses.A brief introduction of the independent laboratory in the Netherlands,the main analytical indexes agreed in the contract in the oil and fat trade,the important quality parameters,the key pollutants (including pesticide residues,polycyclic aromatic hydrocarbons,mineral oil,phthalate,dioxin,monochloropropane,etc.) are summarized in this paper,in order to make readers understand the quality control and technical progress of the goods in the oil and fat trade by the International Organization for Standardization (ISO) and the European Union (EU),provide some references for facilitating technology exchange.

Key words: independent laboratory; edible oils; trade; main indicators; quality parameters; key contaminants;Netherlands

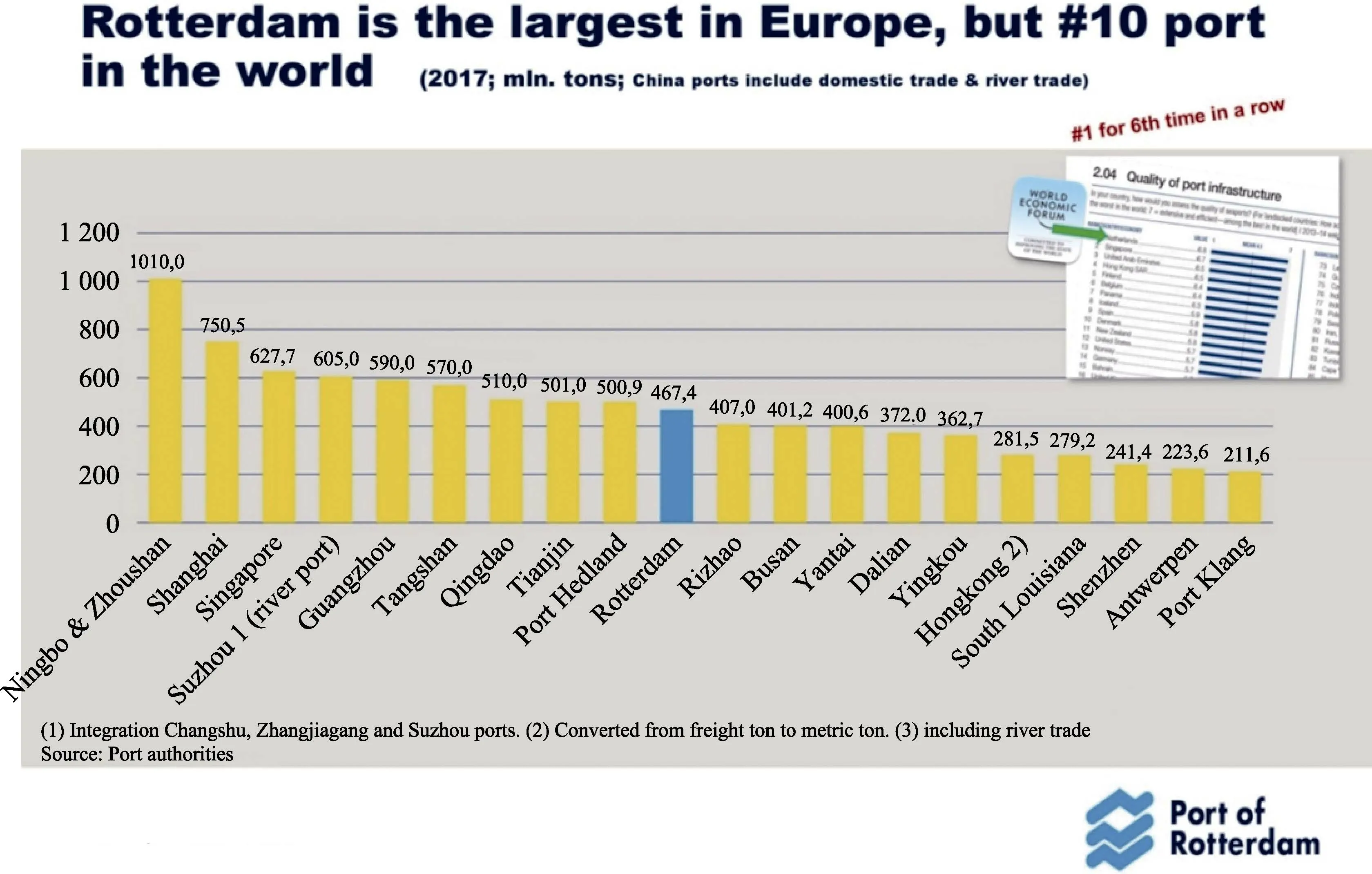

The port of Rotterdam in the Netherlands was for many years the biggest port in the world.However it was far overtaken by other ports in namely China.Today Rotterdam comes at the 10thplace,but it is still the biggest in transfer of liquid bulk cargoes(see in figure 1).

Laboratory Dr.A.Verwey was founded in 1901 and is located in the Port of Rotterdam.In 2011 it was integrated in the German Agrolab Group.The laboratory is worldwide-known for its expertise on analysing the quality of vegetable/animal oils and fats,as well as oil seeds,grains and spices.Also analyses on contaminants on before-mentioned commodities are performed.

Oils and fats are traded by means of a contract,which is agreed between seller and buyer.

Trade organisations have designed contracts for certain commodities.In these contracts basic requirements like quality and volume of a commodity are set.Also rules to be followed if a commodity does not meet the agreed requirements at arrival.

The loading and discharge procedures and volume of the cargo are checked by an independent surveying company,that also takes samples of the cargo.The quality is checked at an independent laboratory by analysing these samples.These surveying companies and laboratories need to be recognised by the trading organisations and are tested every year on their performance.Recognitions are lost if the company does not comply to the requirements of the trading organisations anymore.

Most well-known trade organisations are Federation of Oils,Seeds and Fats Associations Ltd.(FOSFA)in London,for vegetable/animal oils,fats and oil seeds and the Grain and Feed Association (GAFTA),also in London for grains and oil seed meals[1-2].

Quality aspects of commodities should be ascertained using specified methods of analyses.Both before-mentioned organisations use mainly ISOmethods[3].The same method of analysis should be used at the shipping side as well as at the receiving side.

1 Major contractual analyses

In the oils and fats trade the major contractual analyses are: Free fatty acids (FFA),Moisture and volatile matter,Insoluble impurities,Flash point at 121 ℃,Specific gravity at actual temperature.

If your majesty goes out there alone, fasting, before sunrise, and takes the middle one of the three buds, and eats it, then in six months you will bring a princess into the world

1.1 Free fatty acids

The FFA-content is an indication for the“freshness” of the oil.Free fatty acids are formed by hydrolysis of the triglyceride molecule into monoglycerides,di-glycerides and fatty acids.The lower the content of free fatty acids,the better the quality of the oil.

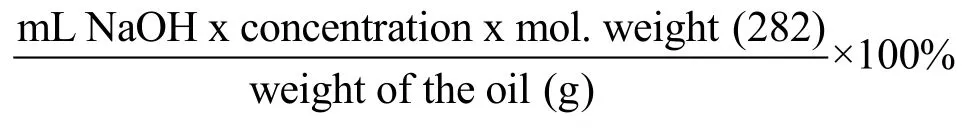

Free fatty acids are determined by dissolving a known amount of about 5 g of oil in an organic solvent,which has been neutralized before using an alkaline solution (NaOH) of known strength.The mixture is neutralized again and the amount of alkaline solution used is recorded in millilitres.The free fatty acids are calculated as follows:

The molecular weight of 282 (oleic acid) is used in the abovementioned calculation,because this is the average molecular weight of most oils and fats.However in the case of palm oil and palm oil products the average molecular weight is 256(palmitic acid).In case of coconut- or palmkernel oil the average molecular weight is 200 (lauric acid).These molecular should be used in calculating the free fatty acid content of those oils and fats.

1.2 Moisture,volatile matter and impurities

Moisture,volatile matter and impurities are caused by oil crop residues remaining in the oil after the extraction process.Moisture and volatile matter is determined by heating a known quantity of oil to 130 ℃.After cooling down the loss in weight is recorded from which the percentage can be calculated.Impurities are determined by dissolving the oil in an organic solvent,e.g.hexane.The mixture is filtered and the weight increase of the filter is used to calculate the content of impurities.

1.3 Flashpoint

Figure 1 The large ports over the world

The flashpoint is a parameter to detect the presence of residues of extraction solvent.If too much extraction solvent is present the oil gives a“flash at 121 ℃”.The sample is heated to 121 ℃in a flash point tester e.g.Pensky Martens closed cup.At the moment the oil has reached this temperature a test flame is inserted and the solvent residues (if present) are ignited.If no ignition occurs the result is “no flash at 121 ℃”,which is the preferred result.

1.4 Specific gravity

The specific gravity is needed to convert the loaded or discharged volume of oil into the weight at the actual temperature.This is determined by using a so-called pycnometer.The is a calibrated glass flask of known weight and volume.The oil is poured into the pycnometer and the total is brought to the desired temperature.After stabilisation the weight of pycnometer and sample is determined,followed by calculation.A more modern and quicker method is the use of a density meter (oscillating tube).

2 Some other important quality parameters

2.1 Peroxide value

Peroxides are the first oxidation products of fatty acids (free as well as esterified fatty acids).They are mainly formed during storage,handling and transport of crude and refined oil in contact with air.In order to analyse peroxides,the sample is dissolved in an organic solvent.Potassium iodate solution is added and the mixture is stored in the dark for ten minutes.During the reaction of the peroxides,iodine is formed.The amount of iodine is determined by titration with sodium thiosulphate solution of known strength,using a starch solution as indicator.Fully refined oil with a peroxide value of below 1.0 meq/kg is considered to be of good quality,while a higher peroxide value may indicate secondary oxidation and the formation of rancid off-flavour.

2.2 Phosphorus

Phosphorus originates from the plant tissue and is present as a variety of phospholipids,generally called lecithin.Phosphorus is removed from the crude oil during “degumming” and as such is not present in refined oils anymore.Several methods can be used for this determination of which the following is an example.A small sample of the oil(0.1 ~ 10.0 g) is mixed with magnesium carbonate and combusted.The ash is dissolved in hydrochloric acid (HCl).After addition of a sulphate molybdate solution and after some time in the dark a blue colour is formed which can be measured at 720 nm.The absorbtion value is compared with a calibration curve and the quantity can be calculated.In a more automated fashion,inductively coupled plasma (ICP)is also commonly used.

2.3 Deterioration of Bleachability Index (DOBI)

2.4 Colour

Crude vegetable oils will have a colour varying from red to green via yellow and brown.These pigments are removed during the refining process of crude oils.In general the refined oils are more or less colourless.The most well-known method for colour measurement is the Lovibond Tintometer.A sample of oil is analysed using a 1 inch cuvette or a 5¼ inch cuvette.The oil is examined through the length of the cuvette (cell) and compared with standard colour glasses.The result is expressed in colour units red and yellow.Sometimes the blue colour standard is also used,but only in case the oil is “greenish”,due to the use of unripe seeds.Today also automated methods are available.

2.5 Sediment

An important test for crude sunflower seed oil.This sediment consists of oil seed residues,lecithins,wax and water.All of these items are related to the production process of sunflower seed oil.The sediment is determined by centrifuging a known quantity of sample in a calibrated tube.After separation of the sediment at the bottom of the tube the volume is recorded.

2.6 Fatty acid composition

Every oil or fat has its characteristic fatty acid composition.Based on this,it is possible to see if an oil or fat is pure or mixed with another vegetable oil or fat.For example; during the production of crude palm oil the present palm kernels are separated.Palm kernel oil has a totally different fatty acid composition then palm oil.Characteristic is the high level of lauric acid (C12),which is about 45%.Palm oil producing companies also produce palm kernel oil.So it is possible,that during logistic operations,some palm kernel oil is mixed with palm oil.This can easily be detected by analysing the sample for fatty acid composition.If the detected level of lauric acid (C12) is above 0.25% one can conclude that there is palm kernel oil present in the palm oil.Using the fatty acid composition analysis it is also possible to differenciate between high oleic and high linoleic sunflower seed oil.

An overview of the fatty acid compositions and other characteristics of vegetable oils and fats can be found in the CODEX Standard for named vegetable oils CXS210.Named animal oils and fats are listed in CODEX Standard CXS211[4].

2.7 Total chlorine

This test is getting more and more important due to the enormous growth of vegetable and animal oils and fats intended to use for bio-energy.Especially the use of UCO,used cooking oil,has extended very much.If any chlorine is present this may end up in the bio fuel giving corrosion inside the engine because of the possible formation of hydrochloric acid (HCl).Total chlorine is determined using a microcoulometer in which the sample is combusted and the chlorine is determined by coulometric titration.

2.8 Total sulphur

Is comparable to the above,however in this case sulphur dioxide (SO2) may be formed,which is not friendly for the environment.The method of analysis used is also microcoulometry.

3 Important contaminants

3.1 Pesticide residues

Pesticides are used to protect an oil crop during growth to reduce weeds and to protect oilseeds during storage and transport.Two main groups of components are known; polar (water-soluble) and non-polar (fat-soluble).For permitted applications of pesticides,so-called maximum residue limits(MRLs) are introduced.These limits are pesticideand crop specific.They are defined on the basis of residues found after pesticides use according to good agricultural practices.The European legislation[5]can be found at: http://ec.europa.eu/food/plant/pesticides/eu-pesticides-database/public/?event=ho mepage&language=EN

Pesticide residues are determined using two major techniques,namely Liquid Chromatography with mass-selective detection (LC-MS/MS) for the polar types of pesticides.And Gas Chromatography with mass-selective detection (GC-MS/MS) for the non-polar types of pesticides.But first the compounds of interest must be separated from the matrix (the oil or fat sample).After this “clean-up”,the components are analysed using the abovementioned apparatus.

Sustainable use of pesticides (I add this content from the website above)

Directive 2009/128/EC aims to achieve a sustainable use of pesticides in the EU by reducing the risks and impacts of pesticide use on human health and the environment and promoting the use of Integrated Pest Management (IPM) and of alternative approaches or techniques,such as nonchemical alternatives to pesticides.EU countries have drawn up National Action Plans to implement the range of actions set out in the Directive.

The main actions relate to training of users,advisors and distributors of pesticides,inspection of pesticide application equipment,the prohibition of aerial spraying,limitation of pesticide use in sensitive areas,and information and awareness raising about pesticide risks.EU countries must also promote Integrated Pest Management,for which,general principles are laid down in Annex III to the Directive.

3.2 Polycyclic Aromatic Hydrocarbons (PAHs)

These are formed during the uncontrolled drying of oil seeds.Humans are exposed to PAHs by inhalation,if they are smokers,and by consumption of contaminated food.During the bleaching step in the refinery process PAHs can be removed by the use of active carbon (norit).In the European Union[5]there is legislation on the so-called PAH4,max 10 μg/kg for the sum of Benzo(a)pyrene,Benz(a)anthracene,Benzo(b)fluoranthene and Chrysene of which the Benzo(a)pyrene only should be below 2 μg/kg for consumer-ready oils.Analysing for polycyclic aromatic hydrocarbons can be done using gaschromatography with mass-selective detection(GCMS) or high performance liquid chromatography(HPLC).In Europe the most widely used technique is the so-called DACC system.This is a system of two coupled HPLCs,where the first one is doing the clean-up of the sample and the second one is performing the analysis after back-flush of the cleaned sample.

3.3 Mineral oil (Mineral Oil Saturated Hydrocarbons/Mineral Oil Aromatic Hydrocarbons)

Mineral oil can be present in crude edible oils due to contamination during processing (lubricants and hydraulic oil),residues from previous cargoes during transport and storage,fraudulent adulteration and environmental pollution.

Short chain hydrocarbons (<C10) are volatile and contractually limited by the flashpoint of the crude oil (see above).

As mineral oil consists for about 75% of paraffinic hydrocarbons (MOSH) and about 25% of aromatic hydrocarbons (MOAH),the focus used to be laid on the major components,the MOSH part of the possible mineral oil contamination.However this has changed,as it was found out that the aromatic part of mineral oil is much more toxic than the paraffinic part.Today the industry is focussed on analysing both groups of hydrocarbons.FEDIOL in Brussels[6]has recommended to its members to target a maximum content of 2.0 mg/kg MOSH and 0.5 mg/kg MOAH.At this moment there is no official legislation in the European Union.Analyses are done using an on-line HPLC/GC-FID system.Method of analysis is described in EN16995.The HPLC is used for “cleaning” the sample.After cleaning the sample is analysed by the GC-FID.

3.4 Phtalates (plasticisers)

Phtalates are a group of compounds.Out of this group there are about 10 compounds chosen to be analysed of which Di Ethyl Hexyl Phtalate (DEHP)and Di Iso Nonyl Phtalate (DINP) are two examples.Main sources are e.g.packing materials/ISO containers/conveyor belts etc.Due to the extensive growth of the use of plastics,these plasticisers are all around us.Sample preparation should be done under very hygienic conditions in order to avoid contamination of the sample.A bottle of solvent left open on a laboratory table already shows an increase of phtalates content after one day.The analysis is performed using gaschromatography with mass selective detection (GCMS).A working group of ISO TC34 SC 11,France and Australia,has developed a method of analysis and is running a collaborative trial at this moment.

3.5 Dioxins,dioxin-like PCBs,non-dioxin-like PCBs

Are an environmental issue.From the out-side air these components come down on the crop.Due to the fat-solubility they concentrate in the oil after extraction of the seed.The European Union has set very strict maximum levels for food and feed.Maximum levels sum of dioxins and furans (WHOPCDD/F-TEQ),dioxins and dioxin-like PCBs(WHO-PCDD/F-TEQ),and PCB28,52,101,138,153,and 180(ICES-6) are 0.75 pg/g fat,1.25 pg/g fat,40 ng/g fat,respectively[5].Analyses are done using gaschromatography with mass-selective detection(GC-MS/MS) or high resolution gaschromatography with mass-selective detection (HRGC-MS/MS) after severe clean-up of the sample.

3.6 3-Mono Chloro Propane Diol,2-Mono Chloro-Propane Diol and Glycidyl Esters

These compounds are process contaminants,formed during the refining process of crude vegetable oil.Three methods of analyses are available in the ISO system,detailed in the part 1-3 of AOCS Cd 29a-13/ISO 18363.These methods were developed by Unilever,SGS and DGF (a German organization).A fourth method,will be absorbed in the part 4 of ISO 18363,was developed by Ralph Zwagerman at Bunge/Loders Croklaan,Wormerveer,Netherlands because there was a need to have a high-speed method available in a production facility for positive release of produced goods.This method will become an official ISO method in 2020,however it has already been approved by the European Food Safety Authority (EFSA)[7].The equipment used is GC-MS/MS with a sample preparation robot on top.It is also possible to run the method,using manual sample preparation.At this very moment the European Union (EU) has published legislation for the maximum level of GE in consumer-ready oils and fats only.However,it is expected that legislation on the other compounds will be published very soon.

4 Summary

A brief introduction of the independent laboratory in the Netherlands,the main analytical indexes agreed in the contract in the oil and fat trade,the important quality parameters,the key pollutants are summarized in this paper,in order to make readers understand the quality control and technical progress of the goods in the oil and fat trade by the International Organization for Standardization (ISO) and the European Union (EU),provide some references for facilitating technology exchange.

备注:本文的彩色图表可从本刊官网(http://lyspkj.ijournal.cn/ch/index.axpx)、中国知网、万方、维普、超星等数据库下载获取。