浙江青瓷和它引领的风流

2020-07-20郑建明

郑建明

浙江青瓷在明代之前一直居于窑业中心的地位。无论是越窑还是龙泉窑,不仅技术高超,生产规模亦十分庞大,远非国内其他任何一个窑场可以相比。

瓷器是中国古代最伟大的发明之一,而浙江又是瓷器的故乡,是古代浙江人对世界文明的伟大贡献。

一部陶瓷史,半部在浙江。

浙江的制瓷业从夏商时期开始,延及明清,其主流发展过程包括先秦时期的原始瓷、汉六朝时期的早期越窑、唐宋时期的越窑、宋元明时期的龙泉窑。此外杭州的南宋官窑、浙北的德清窑、浙中西地区的婺州窑、浙东南地区的瓯窑亦各领风骚。同时,受江西、福建地区影响,在浙西、浙南一带亦有相当数量的青白瓷、黑瓷、青花瓷等窑址的存在,如临安地区以生产青白瓷为主兼烧黑瓷的天目窑等。这些窑口与窑场,构成了浙江古代完整的制瓷业画面。

在纷繁复杂的窑业中,以先秦时期的原始瓷、汉六朝时期的早期越窑、唐宋时期的越窑、宋元明时期的龙泉窑与南宋官窑构成主体,前后相续,形成一浪高过一浪的发展进程,引领着中国制瓷业的发展。

因此,所谓的浙江青瓷,主要是指这四个发展进程中的五大窑口:他们以青瓷为绝对主流,产品面貌相对一致,烧造技术不断精进,产品行销全国乃至全世界,技术辐射整个东亚、东南亚以及西亚、北非地区,在中国制瓷史上占据主导地位。

浙江是瓷器的故乡

瓷器的起源是一个漫长的过程,它先后经历了先秦时期原始瓷的起源与发展以及汉六朝时期成熟青瓷的起源与发展两个过程。

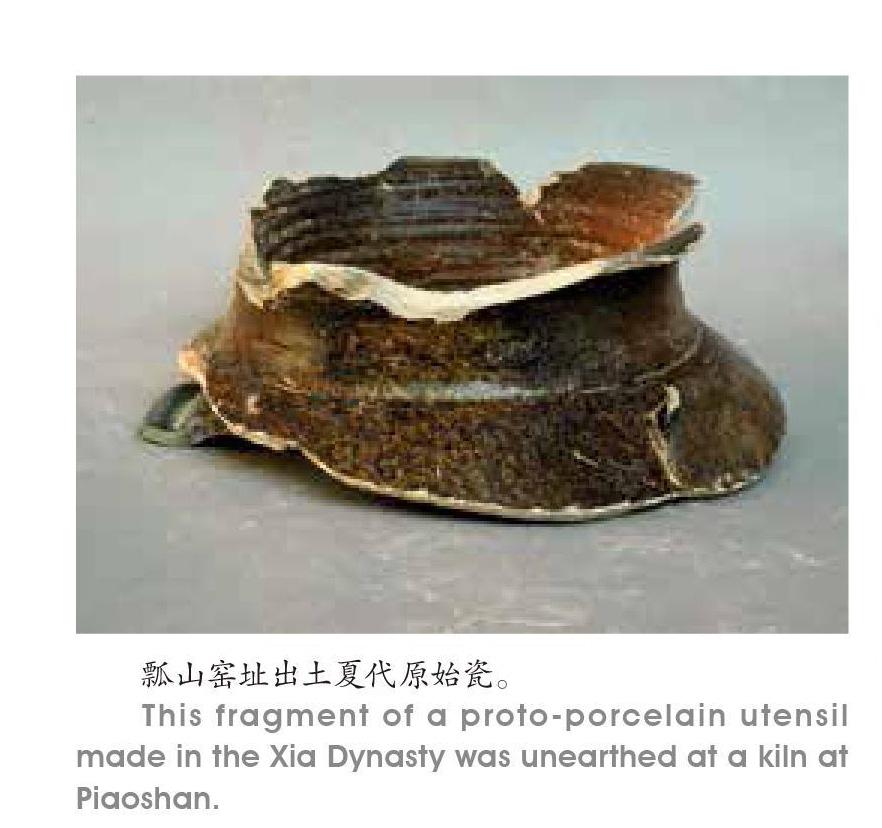

制瓷史上的两个里程碑式技术跃进——原始瓷的起源与成熟青瓷的出现,均发生在浙江,浙江不仅在夏商时期发明了原始瓷,而且在东汉时期成功烧造出了成熟青瓷。同时,这一伟大的技术成果,造就了先秦与汉六朝时期浙江作为全国乃至全世界制瓷中心的地位。

支撑浙江作为世界瓷器起源地的重要证据,是大量古代瓷窑址资料,尤其是大量先秦原始瓷窑址及汉六朝时期的成熟青瓷窑址,数量庞大,时代上早于世界上任何一个地区,发展序列完整、制瓷技术高超,是探索世界瓷器起源、证明中国是瓷器起源地的最重要与最直接材料。

先秦时期浙江原始瓷窑址,主要分布在浙江北部以德清县为中心的东苕溪流域。这一窑区具有以下特点:

首先,是出现时间早、持续时间长,是目前国内已知出现时间最早、持续时间最长的先秦时期窑区。其次,是窑址密集、生产规模大。第三,是产品种类丰富。第四,是产品质量高超。第五,是窑业技术先进。第六,是独立窑区的出现。

因此,以德清为中心的东苕溪流域的商周时期窑区,无论是从生产时间、窑址规模,还是窑址产品种类、产品质量、烧造工艺等方面,在全国都是独一无二的,是中国制瓷史上的第一个高峰,为汉代成熟青瓷的出现打下了坚实的技术基础。

成熟青瓷的起源及其第一次兴盛,主要在上虞的曹娥江流域完成。

上虞曹娥江流域成熟青瓷的起源过程十分清晰:在该区域内发现的数十处东汉时期窑址群中,大致可以划分成以生产硬陶与原始瓷器为主的窑址、原始瓷与成熟青瓷合烧的窑址、以及純烧成熟青瓷的窑址等多个类型。这些不同类型的窑址中,原始瓷比例由高到低,成熟青瓷的比例则由低到高,代表了成熟青瓷起源的完整发展过程。最终以上虞小仙坛窑址为代表,完成了成熟青瓷的起源过程。

成熟青瓷起源后,在东汉晚期、三国、西晋时期迎来了制瓷业的大发展。其产品种类丰富多样,装饰华丽,包括烧成温度、吸水率等在内的理化测试数据,甚至超过许多唐宋时期的产品。这些高质量的器物,目前仅发现于南京及其周边地区的高等级墓葬中,是身份与地位的重要象征。同时由于龙窑技术的改进,使这一时期的产量有了巨大的提升,瓷器走进寻常百姓人家成为了可能。

因此上虞曹娥江流域汉六朝时期窑址群,代表着当时最高的制瓷技术水平和最大的生产规模,引领着中国成熟青瓷制瓷业的发展。

引领明代之前窑业发展

唐代之前的中国制瓷业,基本集中在浙江地区,浙江制瓷史几乎等同于中国乃至世界的制瓷史。进入隋唐以后,由于北方白瓷的发明,从而在唐代中晚期形成南(方)青(瓷)北(方)白(瓷)的基本格局,但是以越窑为代表的唐宋时期浙江制瓷业,在技术上仍一直居于时代的巅峰。

越窑是我国古代烧制青瓷器的名窑,位于浙江省慈溪市的上林湖是其核心产区,兴盛于唐代晚期至北宋早期,南宋早期仍旧为宫廷烧造瓷器,其产品种类丰富,造型优美,釉层滋润如玉。部分器物形制巨大而复杂,质量高超,是我国唐宋时期生产宫庭用瓷的主要窑场。其创烧的秘色瓷代表了薄釉青瓷的最高水平,是制瓷技术上的巨大突破,同时亦成为唐以后历代最高等级青瓷的代名词。

宋元明时期的龙泉窑是我国文化内涵庞杂、生产地域广阔、规模十分壮观的青瓷窑业系统,也是中国历代青瓷工艺技术发展的集大成者,在中国陶瓷史上占有极其重要的地位。它主要分布于浙江境内的瓯江流域,其主体遗存和瓷业生产中心位于瓯江上游的龙泉市,目前保存窑址近400处。其开创的粉青、梅子青厚釉青瓷,以失透如玉的效果,在古代瓷器中独树一帜,形成了自己独特的风格,并由此进入了古代名窑的行列。而这一时期南宋官窑,是目前能确定的最早官窑遗址,代表了这一时期最高的制瓷水平。

无论是越窑还是龙泉窑,不仅技术高超,生产规模亦十分庞大,远非国内其他任何一个窑场可以与之相比。因此浙江青瓷在明代之前一直居于窑业中心的地位。

浙江青瓷与“一带一路”

地处东海之滨的浙江,山清水秀,人杰地灵,以出能工巧匠以及各种名优物产而名动天下。在对外输出的物品中,瓷器占很大比例并被大量保存下来:不论是水下的沉船,还是各地的港口、城址、海防遗址,瓷器都是最为丰富的出土物,更不用说北起韩日、南及东南亚、西至东北非各个国家博物馆所藏数量庞大的历代浙江青瓷了。

浙江青瓷的输出历史相当悠久。北方出土的大部分先秦时期的原始瓷,就是从以浙江为中心的越地输入的。从三国、西晋开始,是中国真正意义上的瓷器输出时期,输出地区主要是东北亚的朝鲜半岛,产品均为越窑青瓷器;到了东晋南朝时期,不仅数量有所提高,而且窑口增加了德清窑等,产品类型也从青瓷增加到黑釉瓷器,由此形成了浙江青瓷对外输出的第一个小高潮。

伴隨着越窑青瓷在晚唐至五代、北宋早期鼎盛时期的到来,浙江青瓷也迎来了对外输出的第一个高峰,尤其是9~11世纪,除输出到传统的东北亚韩日等国家外,足迹广及东南亚、南亚、西亚以及东北非诸港口与城市,并且占中国对外输出瓷器的绝对主流。

龙泉窑作为我国最后形成的庞大青瓷窑场,对中国的制瓷业、中国文化及中外文化交流等具有重要的影响。宋元明时期,龙泉窑的制瓷技术呈放射状向外传播,除周边的丽水、金华、衢州、温州许多县市均有生产外,还远及福建、江西、两广甚至贵州一带,形成庞大的龙泉窑系,在中国制瓷史上占有重要地位。除技术外,龙泉窑的产品影响范围更大,不仅在国内有广泛的分布,而且还大量地远销日本、韩国以及东南亚、南亚、西亚、东非诸国,是中外文化交流的重要载体。

浙江是瓷器的起源地,从夏商时期创烧了原始瓷器,经历了商周至东汉初期的发展,在东汉中期前后创烧了成熟瓷器,并由此迎来了中国瓷器发展的又一波高峰,唐代之前的浙江制瓷史,几乎等同于中国的制瓷史。唐宋元明时期的越窑与龙泉窑,一直引领着中国制瓷技术的发展。浙江青瓷除满足国内市场的需求外,还大量输出到海外市场:三国西晋时期从朝鲜半岛开其风气,到唐—北宋时期,越窑形成第一个高峰,南宋元明时期的龙泉窑则成了中国瓷器对外输出的绝对主流,浙江青瓷由此构成了“一带一路”中对外输出的最大宗商品。

A Brief Overview of Celadon History

By Zheng Jianming

Zhejiang is a cradle of ceramics, one of the greatest inventions of ancient China. According to some scholars, half of the history of Chinese ceramics was written in Zhejiang. Ceramic manufacturing in the coastal province in eastern China started in the Xia (c. 2070-c. 1600BC) and the Shang (c. 1600-c. 1046), two earliest dynasties in China, and lasted up to the Qing (1644-1911).

Archaeological finds in Zhejiang indicate that kilns in the centuries prior to the Qin (221-207BC), early kilns in the Han (202BC-220AD) and the Six Dynasties (222-589), the kilns in the Tang (681-907) and the Song (960-1279), the Official Kilns of the Southern Song (1127-1279), and Longquan Kilns that operated from the Song, Yuan (1279-1368) and Ming (1368-1644), combined to be the mainstream celadon manufacturing not only in the province but also in China. These kilns in more than 2,000 years evolved and advanced step by step and their influences spread far and wide not only to the four corners of the country but also to the rest of the world. Celadon manufacturing techniques from Zhejiang were extensively copied in Asia and North Africa.

The genesis of ceramics took place slowly over a period of a long time. Temporally speaking, the proto-porcelain came into being and then became better and better in the centuries prior to the Qin. In the centuries that covered the Han and the Six Dynasties, celadon took shape and the technique became mature. The genesis of proto-porcelain and the appearance of celadon, which are two landmark technological transformations in the history of ceramics, took place in Zhejiang. The two epoch-making technologies marked Zhejiang as the center of the country and the world for porcelain making.

The kilns in Zhejiang that date back to the centuries before the Qin were largely located in Deqing, a rural county in the north of the province. The kilns in this region were the earliest ones in the period and operated for the longest time. Moreover, the kilns were tightly organized in the region and constituted a large-scale production and very good quality unseen anywhere in the country. The kilns, unique in China in terms of quantity, quality, design, technology, management, manifest the first complete chapter in the history of porcelain making of China. And they laid a solid foundation for the appearance of mature celadon in the Han Dynasty.

Celadon manufacturing appeared and flourished at kilns along the Caoe River in present-day Shangyu, which is now a district of Shaoxing in eastern Zhejiang. In this region, dozens of kiln sites have been unearthed. Some kilns were exclusively engaged in producing stoneware and proto-porcelain, some manufactured a mix of stoneware, proto-porcelain and celadon, and some were dedicated to celadon production. A close look at these kilns reveals that celadon production improved and gradually yielded top-quality products whereas stoneware and proto-porcelain production gradually phased out.

From the late period of the Eastern Han to the Three Kingdoms and Western Jin, celadon manufacturing boomed. The kilns turned out a great variety of finely designed products. Modern tests indicate that the celadon products made during these centuries were even better than those made in the Tang and the Song in terms of firing temperatures and water absorption. Such top-quality celadon objects we see today are from tombs of the high-class people around Nanjing, the capital city of many dynasties during this period. It can be reasoned that the kilns along the Caoe River in eastern Zhejiang during the Six Dynasties period featured the best celadon-making technology and largest industrial scope in China.

The national porcelain making industry before the Tang Dynasty (618-907) was essentially centered in Zhejiang. In other words, the history of porcelain making in Zhejiang during that time explains the porcelain making in both China and the world. In the dynasties of the Sui (581-618) and the Tang, white porcelain appeared in the north whereas the celadon production remained strong in the south. From centuries of the Tang to the Song, the kilns in Zhejiang were technologically the most advanced.

So called kilns were represented by the kilns around Shanglin Lake in present-day Cixi, a city in eastern Zhejiang. The core of the porcelain making industry flourished in the lake zone from the late period of the Tang to the early part of the Northern Song. In the early period of the Southern Song, kilns around the lake still manufactured fine ceramics for the royal court. The kilns were a major supplier of porcelain pieces for the use of the court for the Tang and the Song dynasties. The “secret-color porcelain” represented the best of the thin glaze celadon. The secret-color porcelain was a breakthrough in porcelain making and stands for the top-class celadon from the Tang on.

The kilns in Longquan in southern Zhejiang combined to be the best celadon production system. Longquan kilns were largely scattered along the Oujiang River in the south of Zhejiang Province. The core region of this phenomenal celadon production system was in Longquan, now a city on the upper stream of the Oujiang River. There are nearly 400 kiln sites in Longquan. The thick-glaze celadon in the color of pale green and plum green invented in Longquan is the distinct feature of the celadons produced in Longquan.

In terms of technology and production scale, Zhejiang was the leader of Chinas porcelain manufacturing industry before the Ming Dynasty.

Export to Overseas Countries

Zhejiang began exporting porcelain products to the other parts of China in the centuries prior to the Qin. Most proto-porcelain pieces unearthed in archaeological sites in the north of China came from the kilns of Zhejiang. During the Six Dynasties, all the porcelain pieces China exported to Korean Peninsula were from the Yue kilns of Zhejiang. During the Eastern Jin and the Southern Dynasties, kilns at Deqing contributed a share of exportation, adding black-glazed porcelains to the celadon export. This was the first high peak of celadon export of Zhejiang.

Celadon export from Zhejiang first peaked from the 9th century to the 11th century. The celadon goods were exported to Korean and Japan as well as southeast, south and west of Asia, and north and east of Africa, as testified by archaeological finds at the port cities in these parts of the world. Celadon from Zhejiang accounted a major part of Chinas international porcelain trade during that time.

As China provided the international market with more and more celadon, celadon production no longer stayed in Longquan. There were many celadon kilns operating in neighboring regions such as Lishui, Jinhua, Quzhou and Wenzhou in the province. There were celadon kilns operating in Fujian, Jiangxi, Guangdong, Guangxi and even Guizhou. All these celadon kilns formed an extensive Longquan celadon manufacturing system, unseen in history.