Effect of three tree species on UV weathering of wood flour-HDPE composites

2020-05-19VanDinhNguyenTatThangNguyenAihongZhangJianxiuHaoWeihongWang

Van Dinh Nguyen · Tat Thang Nguyen · Aihong Zhang · Jianxiu Hao ·Weihong Wang

Abstract Eucalyptus urophylla, Acacia mangium, and Pinus caribaea are the primary species for the wood industry in Vietnam. Wood residues of these species were used to reinforce high-density polyethylene (HDPE) composites. The flexural or bending property, impact strength and surface color were evaluated after exposure to accelerated ultraviolet weathering up to 2000 h. The weathered surface was characterized by scanning electron microscopy(SEM) and Fourier transform infrared (FTIR) spectroscopy. The results indicate that A. mangium/HDPE composites had the lowest color change and least fading,and remained stable after 1500 h exposure. FTIR spectroscopy showed that the oxidation of the composites increased in parallel with duration of exposure by assessing the concentration of carbonyl groups on the surfaces.SEM showed that all three species reinforced composites exhibited similar severe cracks after 1000 h; however, at the end of the weathering test,E.urophylla and P.caribaea composites were more severely cracked than A. mangium composites. A. mangium also had the highest flexural strength, impact strength and crystallinity during weathering. A. mangium is the most preferable among the three species to reinforce HDPE.

Keywords Eucalyptus urophylla · Acacia mangium ·Pinus caribaea · Polyethylene · Weathering · Color ·Mechanical property

Introduction

The production of wood-plastic composites (WPC) has rapidly increased, especially in China, Europe, and North America due to major advantages of significant biological and weathering resistance and dimensional stability compared to wood-based products(Haider and Eder 2010;Eder and Carus 2013). In 2012, the production of WPC reached 1,100,000 t in North America, 900,000 t in China, and 260,000 t in Europe. Together, these regions represent the majority of annual production worldwide (Eder and Carus 2013;Carus et al.2014).These composites are widely used for outdoor decking,fencing,automobile interior parts,and furniture (Pritchard 2004; Smith and Wolcott 2005;Markarian 2008; Kumar et al. 2011; Madhoushi et al.2014).

The wood material used in WPCs is often a post-industrial residue such as sawmill trimmings, waste urban and demolition wood, and logging slash. Vietnam has a total forest area of 14.4 million ha, a coverage of 41.2%,including natural and planted forests.However,most of the natural forest is overexploited. Therefore, Vietnam has started to implement protection policies for natural forests along with establishing industrial forest plantations and developing high efficiency wood utilization. Currently,plantations are primarily Eucalyptus urophylla S.T.Blake,Acacia mangium Willd., and Pinus caribaea Morelet(Mard 2017). In 2015, the output from plantation forests was 8.7 millionm3logs for the processing industry which increased to 16 millionm3in 2016 (Goviet 2017). Sixty percent of each log is waste (10% is saw-dust, 50% wood chips,slabs and edgings).The total amount of wood waste from the wood industry was 6.7 million tons,including 5.6 million tons of scrap wood and 1.1 million tons of sawdust.Reinforcing recycled thermoplastics is an effective way to utilize these wood residues.

However,changes in WPC due to weather exposure has been of great concern to consumers (Smith and Wolcott 2006;Yang et al.2015b).The combination of UV radiation and water penetration leads to mechanical loss and color changes of WPCs. Moreover, the surface is eroded from water spraying which in turn, creates a new surface for degradation(Stark and Matuana 2010;Liu et al.2013).The natural or accelerated weathering of WPC materials can change their color and decrease mechanical properties(Stark and Mueller 2008; Butylina et al. 2012; Chen et al.2016). Research has been carried out to understand the aging process when WPCs are weathered (Kiguchi et al.2007; Wei and McDonald 2016). Photochemical reactions in wood are initiated by UV radiation, causing the formation of free radicals and the degradation of lignin and photooxidation of cellulose and hemicelluloses, leading to wood discoloration(Matuana et al.2011;Peng et al.2014).During exposure to weathering, the polymer matrix is degraded by the action of UV rays,thereby enabling water to penetrate and reach the wood particles(Stark 2006).The wood fibers swell after absorbing moisture and cracks are created in the plastic matrix, leading to the loss of composite modulus of elasticity(MOE) and strength. Moisture also damages the appearance of the wood component of the WPC and reduces the efficiency of stress transmission from the matrix to the fibers (Rangaraj and Smith 2000; Wei et al.2013).Although there is considerable literature on the weathering of WPC, research on the effect by tree species is limited. Kim et al. (2009) explored the influence of 10 species on water absorption, biodegradation, and metal corrosion as well as color changes of WPC exterior. Their results showed that the inherent characteristics of the wood filler can affect the properties of WPCs.The use of durable wood species in WPCs could result in products with improved endurance. Fabiyi and McDonald (2010) compared the influence of hybrid poplar, Douglas-fir, black locust,white oak,and ponderosa pine,and found that color change, thermal stability and mechanical properties of WPCs were species-dependent. The best species was hybrid poplar.

In China and Europe,the wood used in WPC production is poplar and pine, respectively, and their performance has been reported. However, there are no studies on the weathering of E. urophylla, A. mangium, and P.caribaeaused in Vietnamto produce reinforced thermoplastic composites. Therefore, the aim of this study is to determine the effects of E. urophylla, A. mangium, and P.caribaea on the weathering of WPC. Mechanical properties,color change,surface characteristics of the composites before and after weathering treatment are analyzed.

Materials and methods

Materials

High density polyethylene (HDPE; grade 5000 s, melting flow index of 0.8-1.1 g/10 min at 190 °C, and density of 0.949-0.953 g cm-3) was purchased from Daqing Petrochemical Co. Ltd., Daqing, China.

Wood flour (WF) of E. urophylla, A. mangium, and P.caribaea was purchased from Truong Thanh Furniture Corporation, City, Vietnam. The moisture content was 18-20%,and the size could pass through a 40-mesh screen.

Maleic anhydride-grafted polyethylene(MAPE;grafting percent of 0.9%), used as a coupling agent, was purchased from Shanghai Sunny New Technology Development Co.Ltd., Daqing, China. Wax and polyethylene wax were added for lubrication.

Preparation of composite samples

The process of preparing WF/HDPE composites is similar to industrial manufacturing (Du et al. 2010; Yang et al.2015a).The wood flour was oven dried at 105 °C for 24 h to reduce moisture content to less than 3% (based on dry weight)before mixing with HDPE.The composite formula was 60 parts WF, 40 parts HDPE, 3 parts MAPE, 1 part wax,and 1 part polyethylene wax.The material was mixed for 10 min and fed into a twin-screw extruder for compounding at 150-175 °C. The extruded melt mixture was cooled and reduced into small particles containing wood flour and HDPE and fed into a single-screw extrusion system to produce continuous lumber with a crosssection 4.0 mm × 40.0 mm.

The boards were cut and conditioned at 23 °C and 50-60% relative humidity for one week before testing and weathering treatment.

Accelerated weathering treatment

Composite samples were put in an accelerated weathering tester(QUV/Spray,Q-Lab Co.,city,state USA)and treated according to ASTM G154-12a (2012) (Standard Practice for Operating Fluorescent Ultraviolet (UV) Lamp Apparatus for Exposure of Nonmetallic Materials). Each 12-h weathering cycle consisted of 8 h of UV exposure at 60 °C,followed by 4 h of condensation exposure at 50 °C without radiation. UV irradiance was 0.89 W m-2at 340 nm wavelength.Changes in surface color,surface morphology,flexural properties and impact strength of at least five samples were evaluated after weathering periods of 500,1000, 1500, and 2000 h.

Characterization

Colorimetric analysis

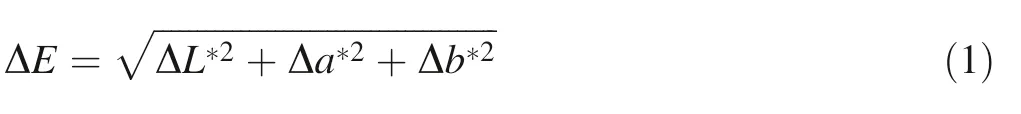

Surface color of the samples was measured using a NF333 photometer(Nippon Denshoku Co.Japan)according to the CIE L* a* b* color system. Lightness (L*) and chromaticity coordinates (a* and b*) were measured for ten replicate samples. An increase in L* signifies that the sample has faded. The total color change (ΔE) was calculated using Eq. 1 according to ASTM D 2244-02(2003)(Standard Practice for Calculation of Color Tolerances and Color Differences from Instrumentally Measured Color Coordinates):

where ΔL*, Δa*, and Δb* are the differences between the initial and final values for L*, a*, and b*, respectively.

Scanning electron microscopy (SEM)

The surface structure of the WF/HDPE composite samples was analyzed by SEM (FEI QUANTA 200). The surfaces were sputter-coated with gold and analyzed at a working distance of 25 mm, voltage of 12.5 kV, and probe current 6 × 10-10A (high vacuum, detectors of ETD, and spot size of 6.5).

Fourier transform infrared (FTIR) spectroscopy

Surfaces of weathered and unweathered WF/HDPE composites were analyzed using attenuated total reflectance(ATR,MAGNA-IR560,Thermo Nicolet).Sixty-four scans were recorded in absorbance units from 4000 to 650 cm-1.Three spectral measurements were carried out on each sample to study the functional groups on the surface of composites.

Mechanical tests

Flexural properties and impact strengths of the weathered and unweathered composite specimens were determined with the unweathered specimens as the reference. The flexural tests were carried out with a universal testing machine (RGT-20A, Shenzhen Reger Instrument Co., Ltd.Shenzhen China) according to ASTM D 790-03(2010)(Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials). The specimens were 80 mm × 13 mm × 4 mm with a span of 64 mm. A loading speed of 2 mm min-1was used, and the specimens were broke in 2.5 min.

The unnotched impact strength was determined with an impact testing machine (XJ-50Z, Chengde Precision Testing Machine Co.Ltd.,Chengde,China)on the basis of GB/T 1043.1(2008)(Plastics,Determination of Charpy Impact Properties, Part 1: Non-instrumented Impact Test). The specimens 80 mm × 10 mm × 4 mm with a span length of 60 mm. The striking velocity was 2.9 m s-1and the pendulum energy was 2 J. Six specimens of each sample were tested to determine the impact strength.

The data were subjected to an analysis of variance(ANOVA) and individual means compared using Tukey’s Least Significant Difference Test (α = 0.5).

Results and discussion

Color change of WF/HDPE composite surface during weathering

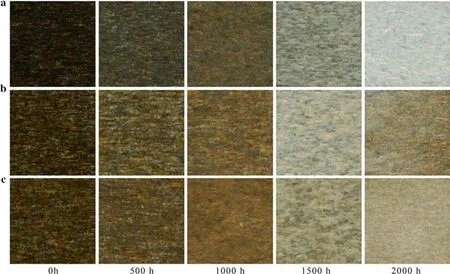

Significant discoloration of the composites occurred during weathering, with ΔL* used to note the degree of fade of weathered composites relative to their original color(Fig. 1). The lightness value ΔL* and total color change ΔE*for A.mangium and P.caribaea composites increased significantly upon weathering up to l1500 h,and thereafter there was little change. These results are consistent with other WPC weathering studies (Fabiyi et al. 2008; Fabiyi and McDonald 2010).The E.urophylla WF composite had similar lightness and color change levels as that of P.caribaea with a 500-h exposure, and thereafter changed faster in ΔL* and ΔE* (Fig. 1).

The increase in lightness suggests the degradation of substances that reflect yellow and red light bands (Fig. 2),causing a bleaching effect and surface oxidation of the composite samples (Wei et al. 2013). The color changes may be the photodegradation of structures in the wood components, especially lignin. E. urophylla contains approximately 31.2% lignin, higher than A. mangium and P.caribaea(25.7-27.0%)(Nguyen et al.2010).At the end of 2000-h exposure, the color change and the fade degree of the three composites ranked as follows: A. mangium <P. caribaea <E. urophylla. With these testing results, A.mangium is a preferable species for improving WPC color performance.

Fig. 1 Change in color parameters: a ΔL* and b color change (ΔE*) of all groups of composites as a function of weathering time

Fig. 2 Images of WF/HDPE composites as a function of weathering time for a Eucalyptus urophylla,b Acacia mangium,and c Pinus caribaea

Surface morphology

Surface morphology of the WPC composites also changed significantly due to weathering. SEM micrographs after accelerated UV weathering for 500,1000,1500 and 2000 h reveal coarsening of the initially smooth surfaces (Fig. 3).The effects were visible after 1000 h on all samples, and the coarsening was followed by matrix cracks and interfacial defects after extending the weathering to 2000 h.

In Fig. 3, it can be seen that the composite surfaces are damaged, and surface cracks for E. urophylla/HDPE were 266 μm, A. mangium/HDPE were 116 μm, and P. caribaea/HDPE were 224 μm.As UV treatment progressed,the wood became degraded, brittle, and microcracks occurred.The decreased wood index after UV treatment confirmed a loss of wood from the composite surfaces. This is the consequence of thermal and UV treatment which caused material degradation cracks to appear in the WPC matrix and wood particles to protrude from the composite surface.The protrusion was possibly due to wood particle swelling and shrinking after repeatedly absorbing and desorbing moisture. This action results in the debonding or removal of bonds in the wood-flour-HDPE interface. At first, the surface layer was eroded and small cracks were created.The frequency and size of these cracks increased with the drying and wetting cycle.Crazing or network of fine cracks occurs more readily in the presence of water spray during weathering (Hill and Jones 1996). Finally, due to the cracks, penetration of water and light into deeper layers of the composites became possible, leading to an accumulation of water that facilitated further degradation.At the end of the weathering test, E. urophylla and P. caribaea wood flour-reinforced HDPE composites showed similar surface degradation which was more severe than A. mangium composites.

Fig. 3 SEM micrographs(500×)of a Eucalyptus urophylla;b Acacia mangium;and c Pinus caribaea WPC after accelerated UV weathering for 0 (control), 500, 1000, 1500 and 2000 h, respectively

Mechanical properties

Changes of the flexural properties and impact strength of the composites during weathering are presented in Figs. 4 and 5. All the composites decreased at a similar rate in bending strength,modulus of elasticity(MOE),and impact strength with increased weathering.After 2000-h exposure,the flexural modulus and impact strength of P. caribaea/HDPE composite decreased more quickly, with the final MOE and impact strength retention ratios of 90%and 95%,respectively. However, A. mangium/HDPE composite retained the greatest strength over the weathering period,with MOE and impact strength retention ratios of 102%and 97%, respectively. The reason might be that A. mangium wood contains more cellulose (70%) than the other two species (approximately 50%) (Nguyen et al. 2010). P.caribaea/HDPE composite had the least MOE and impact strength after 2000-h weathering, while higher flexural strength than E. urophylla/HDPE at the same duration.

In general, the mechanical properties of wood-plastic composites were influenced by the nature of the wood and plastic materials,and also by the interfacial adhesion in the composites. As high density polyethylene composites are exposed to UV radiation,chain scission,a degradation of a polymer main chain, occurs. Additionally, exposure to a humid environment causes wood particles to swell which damages the adhesion with the HDPE matrix.Both of these reduce the efficiency of stress transfer from the fiber to the matrix. For the three species in this study, although the reinforced HDPE composites cracked with a clear change in color due to weathering, their flexural properties and impact strength decreased slightly. The decreased amount is less than for other data by Stark (2003) and Lee et al.(2012). The three species demonstrated good weathering resistance for HDPE composites.

Fig. 4 a Flexural strength and b modulus of the composites as a function of weathering time

Fig. 5 Variation of impact strength of the composites with weathering time

Fourier transform infrared spectroscopy

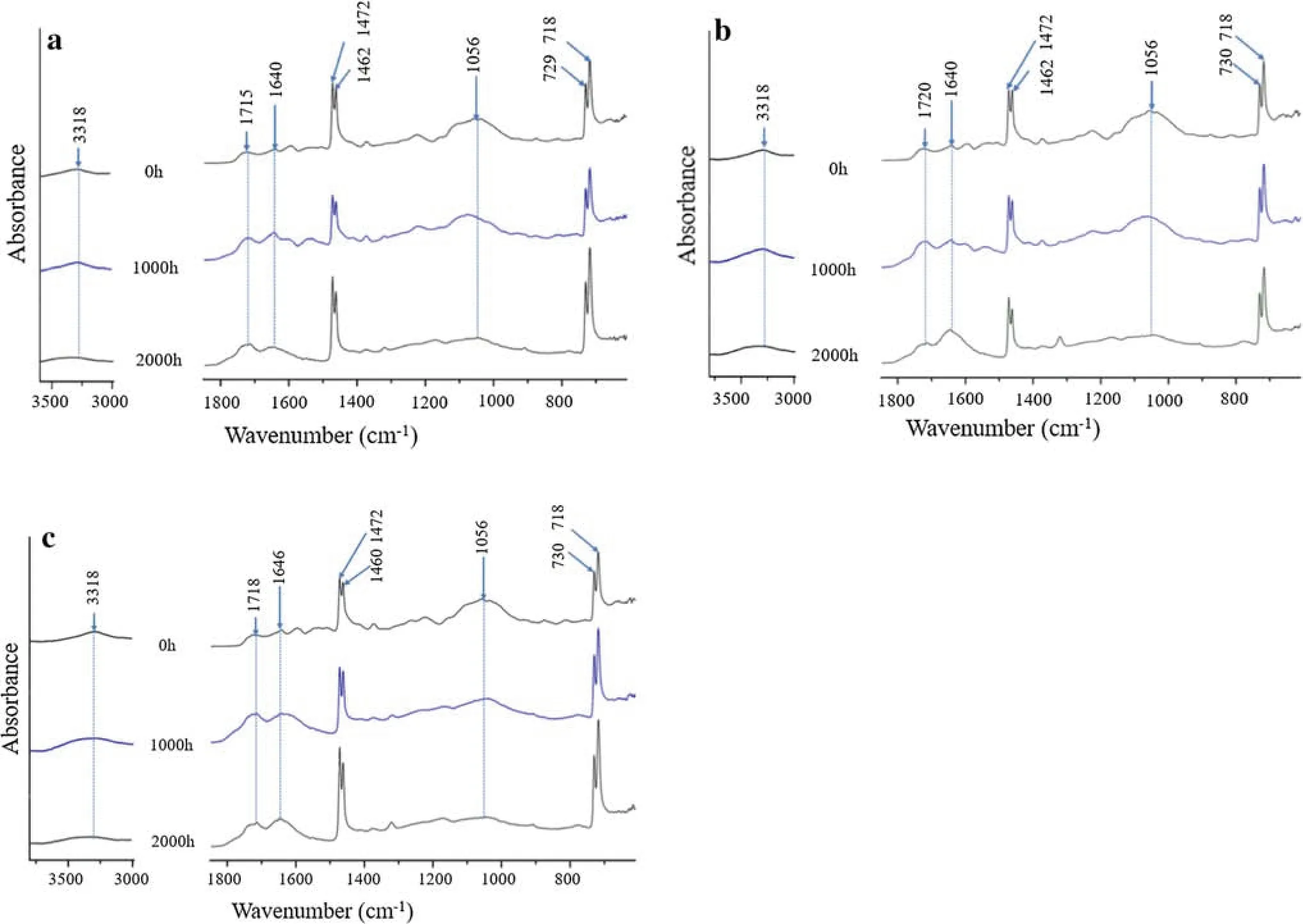

FTIR spectroscopy was used to study chemical changes on the surface of the WF/HDPE composites before and after exposure to accelerate UV weathering. The salient FTIR peaks and the corresponding groups and vibration types are listed in Table 1.

There was an increase in the peak at 1700-1750 cm-1corresponding to C=O stretching when weathered for 1000 h, which indicates that surface oxidation occurred in the first 1000 h of exposure. The increase in carbonyl group index for polyethylene after weathering is proportional to the number of chain scissions that occur in the polyethylene (Stark and Matuana 2004). Therefore, the results indicate that chain scission may have occurred upon exposure and that the number of chain scissions increased with exposure time. At the same time, chain scission decreases the density of entanglements in the amorphous phase and allows shorter molecules to migrate to the sample surface (Stark and Matuana 2007; Du et al. 2010),which may result in WPC lightening as shown in Figs. 1 and 2.

The intensity of the peaks assigned to cellulose is at 3318 cm-1(free -OH). The peak at 1056 cm-1is associated with C-O stretching in cellulose and hemicellulose(Colom et al.2003;Stark et al.2004).These peaks showed extremely high intensity in the control sample before weathering but decreased significantly after 1000 h UV weathering (Fig. 6), indicating a loss of cellulose and hemicellulose at the surface.

The peak around 1640-1646 cm-1, attributed to aromatic ring framework stretching in lignin, became clearer after 1000 h UV exposure (Fig. 6), especially for the A.mangium/HDPE composite. As shown in Fig. 3, when weathered for 1000 h, the surfaces of composites became rougher compared to the controls and exposed more woodcomponents. At 2000 h exposure, both P. caribaea and A.mangium reinforced composites presented stronger characteristic peaks of lignin than E. urophylla. This indicates that relatively more stable wood components remained on the surface.

Table 1 Wavenumbers of peaks used for FTIR analysis and the corresponding functional groups and vibrational types. Sources:Colom et al.(2000,2003),Stark and Matuana (2004) and Fabiyi et al. (2008)

Fig. 6 Fourier transform infrared (FTIR) spectra of different types of a Eucalyptus urophylla, b Acacia mangium, and c Pinus caribaea WPC before and after weathering for 0 (control), 500, 1000, 1500 and 2000 h, respectively

Under UV radiation, the degradation process of lignin begins with hydroquinone oxidation toform paraquinones(chromophore structures), which are further reduced to hydroquinones as the cycle is repeated. Hydroquinones induce WF photobleaching or loss of color, and therefore the C=O peak intensifies and the composite surfaces fade after 500 h, which further become clearer after 1000 h exposure (see Figs. 1, 2).

The double peaks at 1474-1464 cm-1and 730-720 cm-1correspond to polyethylene crystalline content(1474 and 730 cm-1) and amorphous content (1464 and 720 cm-1). The percentage crystallinity can be calculated according to Eq. 2:

where Iaand Ibis derived from the bands at 1474 and 1464 cm-1or from the bands at 730 and 720 cm-1. Zerbi et al. (1989) and Colom et al.(2000) determined that the bands at 730 and 720 cm-1were the most appropriate to study because the peak from cellulose fibers at 1430 cm-1interferes with the 1474 cm-1and 1464 cm-1peaks(Colom et al.2000).Thus,in the present study,crystallinity was calculated using the doublet peaks at 730 cm-1and 720 cm-1.

Fig. 7 Change in crystallinity of WF/HDPE composites after accelerated UV weathering. Each data point represents the average of five samples; error bars represent one standard deviation

The crystallinity of the E. urophylla/HDPE, A. mangium/HDPE, and P. caribaea/HDPE composites increased with exposure time up to 500 h, and thereafter changed by a small amount until 1500 h (Fig. 7). For A. mangium/HDPE and P. caribaea/HDPE composites, crystallinity rose from 1500 to 2000 h, but for E. urophylla/HDPE it decreased significantly over the same period. During weathering, chain scissions occur due to UV radiation,afterwards the shorter and more mobile chains recrystallize in the amorphous phase of the polymer. Therefore, an increase in crystallinity is another indication of chain scission degradation in polyethylene during photodegradation (Kaci et al. 2001; Stark and Matuana 2004).We conclude that the occurrence of this phenomenon on the composites surfaces was due to UV weathering in the first 500 h. As weathering continued, chain scissions and crosslinking in the matrix were in competition, and thus the resultant re-crystallinity became stable. However,it is possible that WF particles may physically hinder crosslinking which would allow for more chain scission degradation and a corresponding increase in crystallinity(Colom et al. 2000; Stark and Matuana 2004). After 1000 h, E. urophylla/HDPE composite decreased in crystallinity while A. mangium/HDPE composite did not change until 1500 h, and subsequently continued to increase in crystallinity.Pinus caribaea composite changed in a similar way as the E. urophylla composite before 1500 h. The higher crystallinity before and after weathering was observed for samples of A. mangium, indicating that the species is more resistant to weathering than the other two composites.

Conclusion

Three tree species commonly used in Vietnam were investigated to reinforce HDPE by studying the weather resistance properties of their composites.

UV weathering resistance of the composites is affected by the type of WF used. FTIR analysis demonstrated that there were significant changes in the surface chemistry of the composite material after exposure. After 1000 h, there was an increase in characteristic peaks of C=O and lignin,while that of cellulose decreased;

The flexural properties and impact strength of the composites declined between 0 and 2000 h of aging.Among the three composites,A.mangium/HDPE exhibited the highest flexural property and impact strength over 2000 h UV weathering. In addition, the degree of color change of the composite was the lowest.

Eucalyptus urophylla/HDPE composite had similar flexural modulus and impact strength as A. mangium/HDPE. However, its surface color and chemical characteristics changed most among the three species. Accordingly, the A. mangium/HDPE composite was considered preferable for applications in WPC where color and mechanical properties are of prime importance.

杂志排行

Journal of Forestry Research的其它文章

- Do increasing respiratory costs explain the decline with age of forest growth rate?

- At what carbon price forest cutting should stop

- Mapping the risk of winter storm damage using GIS-based fuzzy logic

- Effects of seed moisture content, stratification and sowing date on the germination of Corylus avellana seeds

- Comparison of seed morphology of two ginkgo cultivars

- De novo assembly of the seed transcriptome and search for potential EST-SSR markers for an endangered, economically important tree species: Elaeagnus mollis Diels