光伏-环路热管/热泵热水系统在不同气候区性能对比与优化

2020-03-03王美芳

李 洪,王美芳,张 曼

光伏-环路热管/热泵热水系统在不同气候区性能对比与优化

李 洪,王美芳,张 曼

(燕山大学建筑工程与力学学院,秦皇岛 066004)

为改善传统太阳能光伏/光热热水系统运行性能,拓展空气源热泵热水系统应用范围,该文针对一种太阳能光伏-环路热管/热泵热水系统开展了其在3种不同气候区运行性能对比及优化研究。分别选择北京、上海和广州作为寒冷、夏热冬冷和夏热冬暖地区典型气候代表城市,依据所建数学模型,模拟比对系统在3个地区的全年运行性能,分析了集热/蒸发器的朝向与安装倾角对系统运行性能的影响,并对其进行了优化;以传统空气源热泵热水系统为基准,采用全寿命周期成本计算方法分析了系统的经济可行性。结果表明,相同安装倾角正南朝向时,系统在广州的太阳能综合利用效率最高、节能性最佳;各地区理想安装倾角下,北京和上海正南朝向时系统节能效益最优,广州则南偏东30°时节能率最高;与传统空气源热泵热水系统相比,系统在北京、上海、广州的全寿命周期成本分别降低了58.75%、49.83%及53.09%,经济效益显著。

太阳能;热泵;效率;气候条件;运行性能

0 引 言

传统化石能源的应用促进了经济的增长和生产力水平的提高,但同时导致能源危机以及环境污染问题日益严重[1-2]。因此,太阳能作为一种可持续清洁能源,受到越来越广泛地推广应用。太阳能光伏光热(photovoltaic and thermal,PV/T)技术一直是太阳能研究领域中备受关注的方向之一,以其良好的节能性、环境友好性等优势引起众多学者的研究兴趣[3-4]。目前所涉及的研究内容主要包括设计更加高效的系统形式[5-6]、研究分析系统的经济性与可行性等[7];研究方法包含数值模拟[8-10]、搭建试验台进行试验研究等[11-13]。通过学者们的不断探索和研究,太阳能PV/T技术日臻完善。

环路热管(loop heat pipe,LHP)是一种高效的两相传热设备,具有优良的传热性能与结构特性,能够在小温差、长距离的情况下传递大量热量,同时具有良好防冻性能,基于以上特性,部分学者提出将PV/T技术与LHP相结合的供热系统[14-16]。研究表明,该类系统能够提升太阳能光热效率与光电效率,具有良好的光电光热综合利用性能[17-20]。此外,Zhang等[21-22]将PV/T集热/蒸发器、环路热管以及热泵技术相结合,通过环路热管与热泵循环串联连接的方式进一步提升太阳能光热转换效率。张龙灿等[23]及Li等[24-25]则通过环路热管与热泵环路并联的方式,实现多模式相互切换的太阳能环路热管热泵热水系统,以更高效地满足建筑生活用水需求。本课题组所提系统将太阳能PV/T技术与环路热管及太阳能/空气源热泵相结合,不仅继承了太阳能热泵的优点,同时解决了热泵运行所需部分电力,减少了能量的输送环节,提高了太阳能综合利用效率及其节能效益[25]。相关研究表明,太阳能PV/T系统及其与热泵相结合的复合系统运行性能受气候条件、设计参数及安装位置等因素影响显著[26-30]。因此,在前期研究的基础上,本课题组将针对文献[25]中所研究系统,进一步分析比对其在不同气候区的运行性能及变化规律,同时研究分析太阳能PV/T集热/蒸发器的安装倾角和朝向对系统运行性能及其经济性的影响。

1 系统描述

光伏-环路热管/热泵热水系统(图1),主要包括光伏-环路热管(PV-LHP)和热泵2个环路。PV-LHP环路主要由PV-T集热/蒸发器和垂直螺旋管沉浸式冷凝器组成,水箱容积为150 L。热泵环路中蒸发器采用无玻璃盖板平直翅片平板式太阳能集热器,冷凝器与热管环路共用;压缩机采用滚动转子式。开启阀门1和2,关闭阀门3和4,系统在PV-LHP模式下运行,PV/T集热/蒸发器吸热管中液态工质吸收太阳热能并蒸发为汽态工质,汽态工质沿蒸汽上升管到达冷凝器,在冷凝器内冷凝液化将热量传给水箱中的冷却水,液态工质在重力作用下,沿凝液下降管回到PV/T集热/蒸发器,完成一次循环。同时,集热/蒸发器表面间隔铺设的光伏板接收一部分短波辐射转化为电能。关闭阀门1和2,开启阀门3和4,系统则以热泵模式运行。系统主要设备结构参数见文献[25]。

图1 光伏-环路热管/热泵热水系统原理图

用户需求水温设定为45 ℃,系统优先以PV-LHP模式运行,考虑到热管启动负荷需求,并达到最大程度利用太阳能、节约传统能源的目的,其运行时段设定为8:00—14:00。该运行模式结束后若水温不达标,则启动热泵模式继续加热。

2 性能模拟与结果分析

根据能量守恒及热力学第一定律,分别建立了PV-LHP和热泵环路模型,PV-LHP模型主要包括PV/T集热/蒸发器和冷凝器模型,其中PV/T集热/蒸发器模型主要包括太阳能集热模型,各结构层及部件的能量平衡方程,冷凝器模型则由热管冷凝段和冷却水的能量平衡方程组成。为了简化该复合系统的模拟计算,热泵环路采用了经验拟合模型[25],模型中重点考虑了室外空气温度、冷凝器端入口水温及太阳辐射照度3个主要因素的影响。基于试验测试数据,验证了所建模型的准确性[25]。

基于所建系统模型,本文模拟分析了相同安装倾角和朝向下系统在不同气候区的运行性能,进一步分析比对了安装倾角与朝向对其节能性、经济性的影响,并对其进行了优化,为该系统的实际工程应用提供参考。

本文选取北京(40N°,116°E)、上海(31N°,121°E)、广州(23N°,113°E)为寒冷、夏热冬冷以及夏热冬暖地区的代表城市。气象参数统一引用Trnsys软件中3个城市的典型气象年参数,模拟中设定水箱初始水温相同,春秋过渡季水箱初始水温15 ℃,夏、冬两季分别取20、5 ℃。

2.1 气象条件分析

3座城市月平均空气温度及太阳辐射照度如图2所示。广州地区月平均空气温度明显高于其余两地,北京、上海、广州月平均空气温度分别在270.61~300.95、278.21~302.27及288.07~303.37 K范围内浮动,3个地区典型年最高月平均太阳辐射照度分别为544.2、499.5和529.1 W/m2,最小值分别为334.7、271.9、243.7 W/m2。

2.2 相同安装倾角和朝向

为了明确气象条件对系统运行性能的影响,拟采用相同安装倾角(35°)和朝向(正南)模拟分析系统在3个地区的全年运行性能变化规律。

图2 月平均空气温度及太阳辐射照度

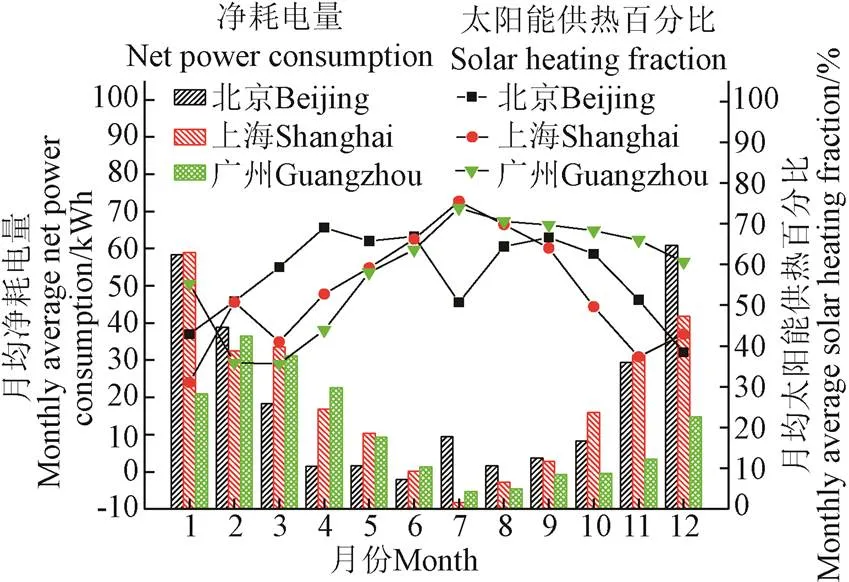

图3显示的是系统在3个地区的月均太阳能供热百分比和净耗电量。可以得出,系统在北京、上海、广州的年均净耗电量分别是229.85、233.01和128.94 kWh,年均太阳能供热百分比分别是57.42%、53.35%、58.45%。系统在广州净耗电量比北京、上海分别减少43.9%、44.7%。这是由于广州地处夏热冬暖地区,该气候区的气温年较差和日较差均小,太阳辐射照度较高,这种气象条件更有利于系统2种模式的运行。模拟结果显示,相比北京、上海,系统在广州的年均光电效率略低,年均光热效率则高出8.33%和5.72%,年均光电光热综合效率分别高出8.19%和5.58%。从太阳能光电光热综合利用的角度出发,系统在广州适用性最强,其次是上海、北京。

图3 月均净耗电量与太阳能供热百分比

2.3 安装倾角与朝向的优化

对于固定式安装的PV/T集热/蒸发器,其安装倾角与朝向对系统光电光热性能影响较大,而理想的安装倾角与朝向随气候条件变化显著。因此,有必要针对系统的安装倾角与朝向进行优化,以进一步确保系统在各气候区运行的可靠性。

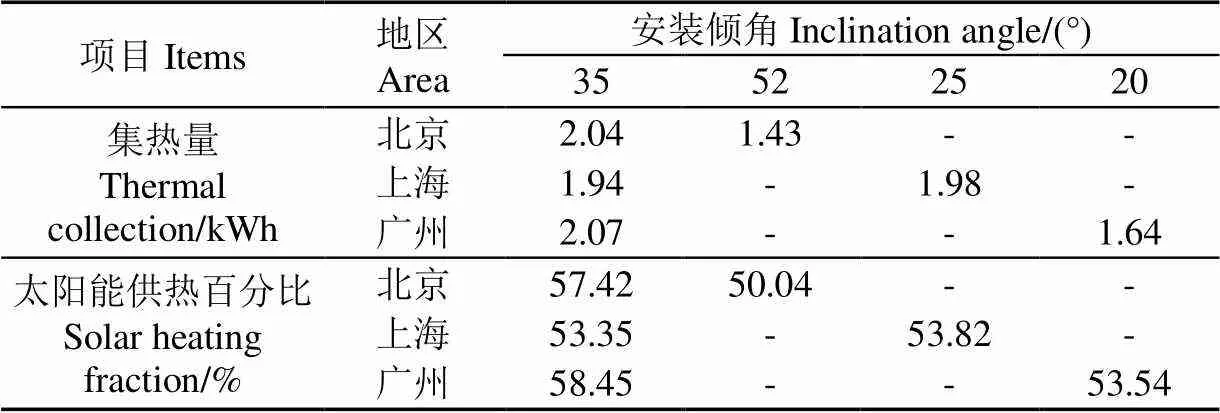

首先,基于纬度修正法,确定安装倾角的变化范围,北京选取35°、40°、45°、52°,上海选取25°、30°、35°、40°,广州则以18°、23°、28°、33°为代表。基于上述不同倾角,模拟计算了集热器表面月平均辐射量、系统的发电量和集热量,计算结果显示:系统的集热量与发电量变化趋势与月平均辐射量保持一致。以集热器表面接收更多辐射量为目标,初步选定3个地区的较优安装倾角,北京为35°、52°,上海为35°、25°,广州则是35°、20°。基于此,进一步模拟分析了系统在3种地区运行性能随安装倾角的变化情况,结果如表1所示。以太阳能供热百分比最大为目标,最终选定系统在北京、上海、广州的理想安装倾角分别为35°、25°、35°。

表1 不同安装倾角下系统的运行性能对比

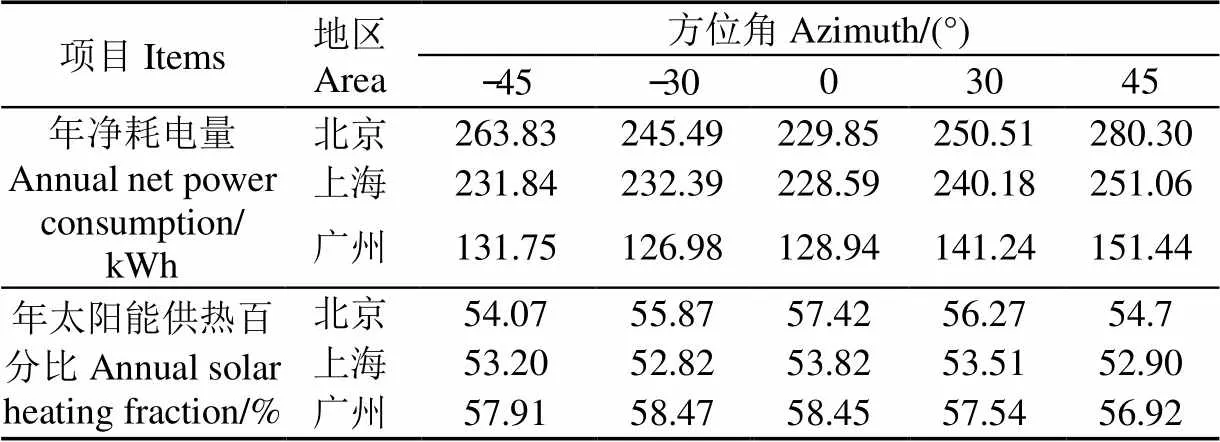

基于最优安装倾角,进一步模拟计算了系统运行性能随方位角的变化规律,考虑的朝向有−45°、−30°(南偏东为负),0°(正南),30°、45°(南偏西为正),结果如表2所示。由结果可以得出,在北京,PV/T集热/蒸发器朝正南方向安装时,年太阳能供热百分比最高,达57.42%;年净耗电量最低,与其他朝向相比依次减少12.9%、6.4%、8.3%及18.0%。在上海,PV/T集热/蒸发器朝正南方向安装时,年净耗电量和太阳能供热百分比最佳,与南偏西45°相差最大,与其余朝向相比,略有优势。在广州,则朝向−30°安装时性能最优,与0°和−45° 2个朝向相差不多,与南偏西的2个系统相比,节能率分别提升10.1%和16.15%。

表2 年净耗电量和太阳能供热百分比

注:0°表示正南。

Note: 0° represents the south.

综上可得,在不同气候条件下,安装倾角和朝向不同,对系统性能影响程度也不同。在所推荐的理想安装倾角和朝向下,北京、广州两地的节能效果较优,太阳能供热百分比分别为57.42%和58.45%,上海稍低为53.82%。

3 经济效益分析

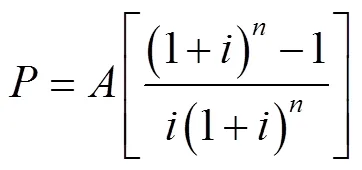

基于上述性能模拟分析结果,进一步采用全寿命周期成本(life cycle cost,LCC)分析方法评估优化后的系统在不同气候区应用的经济可行性。LCC由初投资费用与运行、维护费用组成,系统的现值可由下式计算

式中为系统的现值,元;为系统第一年运行维护费用,元;为折现率;为寿命周期。

系统初投资根据各部件在当地的平均价格取值,系统第一年的维修费用按初投资的2%计算,运行和维护费用的通货膨胀率和折现率分别为2%和5%,设定系统的发电量采用“全额上网”模式提供给国家电网,并将获取发电补贴考虑到系统运行费用中,计算结果列于表3、表4。可以看出,所研究系统的初投资是传统空气源热泵系统的2.5倍。但是,由于其年耗电量只有空气源热泵系统的一半左右,并且系统的年发电量占其耗电量的一半以上,北京、上海、广州的太阳能供电比例分别为53%、51%和66%,因此,整个寿命周期内,与传统空气源热泵系统相比,该系统运行维护费用降幅明显,北京、上海、广州分别减少了67.86%、59.00%、62.21%,系统的LCC分别减少58.75%、49.83%及53.09%。综上,虽然所研究系统初投资较高,但从全寿命周期来看,其运行经济效果显著。

表3 光伏-环路热管/热泵热水系统的LCC分析

表4 空气源热泵热水系统LCC分析

4 结 论

本文以太阳能光伏-环路热管/热泵热水系统为研究对象,模拟分析了系统在3种不同气候区的运行性能,优化了PV/T集热/蒸发器的安装倾角与朝向。在此基础上,采用LCC分析方法评估了系统的经济效益。主要结论如下:

1)PV/T集热/蒸发器按照相同安装倾角和朝向设置时,系统在广州的太阳能供热百分比最高,达到58.45%,耗电量最少,节能效果最显著。从太阳能光电光热综合利用的角度出发,系统在广州适用性最强,其次是上海、北京。

2)不同气候条件下,安装倾角和朝向对系统性能的影响程度不同,为提高系统的太阳能利用效率,应对其安装倾角和朝向进行优化。在理想的安装倾角和朝向下,北京、广州两地的节能效果较优,太阳能供热百分比分别可达57.42%和58.45%,上海稍低,为53.82%。

3)与传统空气源热泵系统相比,系统初投资显著提高,但在整个寿命周期内,系统的运行维护费用降幅明显,LCC依次减少58.75%、49.83%及53.09%,经济效益显著。

[1] Musarrat J, Muhammad U, Muhammad Z, et al. Social- economic prospect of solar technology utilization Abbottabad, Pakisutan[J]. Renewable and Sustainable Energy Reviews, 2014, 39: 1164-1172.

[2] Halawa E, Chang K C, Yoshinaga M. Thermal performance evaluation of solar water heating system in Australia, Taiwan and Japan: A comparative review[J]. Renewable Energy, 2015, 85: 1279-1286.

[3] Joubara H, Milko J, Danielewicz J, et al. The performance of a novel flat heat pipe based thermal and PV/T (photovoltaic and thermal systems) solar collector that can be used as an energy active building envelope material[J]. Energy, 2016, 108: 148-154.

[4] Zhang Bingzhi, Lv Jian, Yang Hongxing, et al. Performance analysis of a heat pipe PV/T system with different circulation tank capacities[J]. Applied Thermal Engineering, 2015, 87: 89-97.

[5] Liu Lingkun, Jia Yuting, Lin Yaxue, et al. Performance evaluation of a novel solar photovoltaic thermal collector with dual channel using microencapsulated phase change slurry as cooling fluid[J]. Energy Conversion and Management, 2017, 145: 30-40.

[6] Chung-Feng J K, Lee Y W, Mega L U, et al. Dynamic modeling, practical verification and energy benefit analysis of a photovoltaic and thermal composite system[J]. Energy Conversion and Management, 2017, 154: 470-481.

[7] Zhao Xudong, Wang Zhangyuan, Tang Qi. Theoretical investigation of a novel loop heat pipe solar water heating system for use in Beijing, China[J]. Applied Thermal Engineering, 2010, 30: 2526-2536.

[8] Bennett K W, Mahmoud A, Jiang Lun, et al. Design simulation and experimental characterization of a novel parabolic trough hybrid solar photovolticathermal (PVT) collector[J]. Renewable Energy, 2017, 101: 1379-1389.

[9] Azad E. Theoretical and experimental investigation of heat-pipe solar collector[J]. Experimental Thermal and Fluid Science, 2008, 32: 1666-1672.

[10] Chaabane M, Charfi W, Mhiri H. et al. Performance evaluation of concentration solar photovoltaic and photovoltaic/thermal systems[J]. Science Direct, 2013, 98: 315-321.

[11] Sudhakar P, Kumaresan G, Velraj R. Experimental analysis of solar photovoltaic unit integrated with free cool thermal energy storage system[J]. Solar Energy, 2017, 158: 837-844.

[12] Salem M R, Ali R K, Elshazly K M. Experimental investigation of the performance of a hybrid photovol/thermal solar system using aluminium cooling plate with straight and helical channels[J]. Solar Energy, 2017, 157: 147-156.

[13] Pei Gang, Zhang Tao, Fu Huide, et al. Experimental study on a noval heat pipe-type photovoltaic/thermal system with and without glass covers[J]. Green Energy, 2012, 10: 72-89.

[14] 王璋元,杨晚生,赵旭东. 新型环路热管太阳能热水系统节能减排评估[J]. 太阳能学报,2014,35(5):825-829.

Wang Zhangyuan, Yang Wansheng, Zhao Xudong. Energy-saving and carbon emission reduction evaluations of a novel loop heat pipe solar water heating system[J]. Acta Energiae Solaris Sinica, 2014, 35(5): 825-829. (in Chinese with English abstract)

[15] Sweidan A, Ghaddar N, Ghali K. Optimized design and operation of heat-pipe photovoltaic thermal system with phase change material for thermal storage[J/OL]. Joumal of Renewable and Sustainable Energy, 2016, 8: 023501.

[16] Moradgholi M, Mostafa S N, Abrishamchi I. Application of heat pipe in an experimental investigation on a novel photovoltaic thermal (PV/T) system[J]. Science Direct, 2014, 107: 82-88.

[17] Pei Gang, Zhang Tao, Yu Zhi, et al. Comparative study of a noval heat pipe photovoltaic/thermal collector and a water thermos siphon photovoltaic/thermal collector[J]. Power Energy, 2011, 225: 271-278.

[18] Fu Huide, Pei Gang, Ji Jie, et al. Experimental study of a photovoltaic solar assisted heat-pump/heat-pipe system[J]. Applied Thermal Engineering, 2012, 40: 343-350.

[19] Zhao Xuxin, Fu Huide, Ji Jie. et al. Comparative study on performances of a heat-pipe PV/T system and a heat-pipe solar water heating system[J]. International Journal of Green Energy, 2016, 13(3): 229-240.

[20] 李洪,侯平炜,孙跃. 太阳能光伏环路热管热水系统光电光热性能试验[J]. 农业工程学报,2018,34(7):235-240.

Li Hong, Hou Pingwei, Sun Yue. Experimental study on a solar photovoltaic/loop-heat-pipewater heating system[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(7): 235-240. (in Chinese with English abstract)

[21] Zhang Xingxing, Zhao Xudong, Shen Jingchun, et al. Design, fabrication and experimental study of a solar photovoltaic/ loop-heat-pipe based heat pump system[J]. Acta Energiae Solaris Sinica, 2013, 97: 551-568.

[22] He Wei, Hong Xiaoqiang, Zhao Xudong, et al. Theoretical investigation of the thermal performance of a novel solar loop-heat-pipe facade-based heat pump water heating system[J]. Energy and Buildings, 2017, 77: 180-191.

[23] 张龙灿,裴刚,张涛,等. 新型光伏-太阳能环形热管/热泵复合系统[J]. 化工学报,2014,65(8):3228-3236.

Zhang Longcan, Pei Gang, Zhang Tao, et al. A new photovoltaic solar-assisted loop heat pipe/heat pump system[J]. Journal of Chemical Industry, 2014, 65(8): 3228-3236. (in Chinese with English abstract)

[24] Li Hong, Sun Yue. Operational performance study on a photovoltaic loop heat pipe/solar assisted heat pump water heating system[J]. Energy and Buildings, 2018, 158: 861-872.

[25] Li Hong, Sun Yue. Performance optimization and benefit analyses of a photovoltaic loop heat pipe/solar assisted heat pump water heating system[J]. Renewable Energy, 2019, 134: 1240-1247.

[26] Zhang Xingxing, Shen Jingchun, Adkins D. et al. The early design stage for building renovation with a novel loop-heat-pipe based solar thermal facade (PV-LHP-STF) heat pump water heating system: Thchno-economic analysis in three European climates[J]. Energy Conversion and Management. 2015, 106: 964-986.

[27] 李啸宇,唐润生. 太阳能热水器安装倾角的优化[J]. 云南师范大学学报,2017,37(4):10-16.

Li Xiaoyu, Tang Runsheng. Optimizing the tilt angle of domestic solar water heater[J]. Journal of Yunnan Normal University, 2017, 37(4): 10-16. (in Chinese with English abstract)

[28] Jafarkazemi F, Saadabadi S A. Optimum tilt angle and orientation of solar surfaces in AbuDhabi[J]. Energy Conversion, 2013, 56(4): 44-49.

[29] Stanciu C, Stanciu D. Optimum tilt angle for flat plate collectors all over the World-A declination dependence formula and comparisons of three solar radiation models[J]. Energy Coversion & Management, 2014, 81(2): 133-143.

[30] 何适均,张雨,周文君. 太阳能热水系统集热器最佳倾角的确定[J]. 太阳能学报,2012,33(6):924-926.

He Shijun, Zhang Yu, Zhou Wenjun. The affirmance of optimum tilt angle for solar collector[J]. Acta Energiae Solaris Sinica, 2012, 33(6): 924-926. (in Chinese with English abstract)

Feasibility comparison and optimization on a loop-heat-pipe type PV/T heat pump water heating system in different climatic regions

Li Hong, Wang Meifang, Zhang Man

(,,066004,)

In this paper, energy performance of a loop-heat-pipe (LHP) type solar photovoltaic/thermal (PV/T) heat pump water heating system is studied to evaluate its feasibility in three different climatic regions. A mathematic model of this system in our former study is built and validated using outdoor test data. On the basis of this model, influences of main structural design parameters including the installation angle and the orientation of the PV/T collector/evaporator are discussed and main parameters are optimized to further improve system operation performance. Based on optimal design parameters, economic feasibility of the proposed system under different weather conditions is analyzed using the life cycle cost (LCC) method. The system is integrated with solar PV/T, loop heat pipe and solar assisted air source heat pump technologies. This combined approach is benefit for improving solar energy comprehensive application efficiency of conventional solar PV/T systems. Moreover, it enlarges the application region of traditional air source heat pump water heating systems. Depending on different solar radiation conditions, this system can operate in different modes including solar photovoltaic LHP mode, solar assisted air source heat pump mode and the only air source heat pump mode. In this study, Beijing, Shanghai and Guangzhou were selected as typical representative cities in cold area, hot summer and cold winter area, hot summer and warm winter area. Typical meteorological year (TMY) data of three cities were extracted from TRNSYS. Based on TMY data, annual operation performance of the proposed system is calculated through the validated dynamic mathematic model. Firstly, PV/T collector/evaporators of three systems are all fixed in the south direction and the same installation angle (35°) was chosen. In this case, annual net power consumptions and solar heating fractions of three systems are calculated and compared. Then installation angles and orientations are optimized to ensure maximum solar energy application. The investigation results show that, among three cities, the solar heating fraction in Guangzhou is the largest. And the least electricity is consumed in Guangzhou, which is decreased by 43.9% and 44.7% respectively compared with those in Beijing and Shanghai. The comprehensive photothermal efficiency in Guangzhou is 8.19%, 5.58% higher than those in Beijing and Shanghai. Therefore, from the view of solar energy comprehensive efficient utilization, the application of the system is most proposed in Guangzhou, and then followed by Shanghai and Beijing. Considering impacts of installation angles and orientations, the ideal installation inclination of the system in Beijing, Shanghai and Guangzhou are 35°, 25°, and 35°, and the optimal installation directions of Beijing and Shanghai are facing the south, while that of Guangzhou is 30°east to the south. With the optimal parameters, it is found that solar heating fractions in Beijing and Guangzhou (i.e. 57.42% and 58.45%) are slightly higher than that in Shanghai. It is concluded that influences of two structural parameters are different for such system in different climatic areas. To ensure maximal solar energy application, it was necessary to optimize these two parameters. For the life cycle cost analysis, a traditional air source heat pump hot water heating system is chosen as the base system. The analysis results indicate that the initial investment of the system increases significantly, which is 2.5 times of that of the base system. However, the annual power consumption of the system is about half of that of the traditional system. Besides, solar power supply fractions in Beijing, Shanghai and Guangzhou are 53%, 51% and 66% respectively. As a result, the total operation and maintenance fees in the life cycle drop significantly, which are reduced by 67.86%, 59.00%, and 62.21% in Beijing, Shanghai and Guangzhou. The life cycle cost is correspondingly reduced by 58.75%, 49.83% and 53.09% in three cities. In conclusion, the application of this system is feasible for considered weather conditions in terms of both the operating performance and economic benefits.

solar energy; heat pump; efficiency; climatic conditions; operation performance

李 洪,王美芳,张 曼. 光伏-环路热管/热泵热水系统在不同气候区性能对比与优化[J]. 农业工程学报,2020,36(1):252-256.doi:10.11975/j.issn.1002-6819.2020.01.030 http://www.tcsae.org

Li Hong, Wang Meifang, Zhang Man. Feasibility comparison and optimization on a loop-heat-pipe type PV/T heat pump water heating system in different climatic regions[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(1): 252-256. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2020.01.030 http://www.tcsae.org

2019-06-28

2019-08-26

河北省高等学校科学技术研究项目(ZD2018031)

李 洪,博士,副教授,研究方向为复合热源热泵技术及太阳能光热综合利用技术。Email:be_leecandy@163.com

10.11975/j.issn.1002-6819.2020.01.030

TE0

A

1002-6819(2020)-01-0252-05