基于Menger海绵模型的煤矸石粉改良膨胀土微结构特征

2020-03-03王明磊殷潇潇

王明磊,张 雁,殷潇潇,2

基于Menger海绵模型的煤矸石粉改良膨胀土微结构特征

王明磊1,张 雁1※,殷潇潇1,2

(1. 内蒙古农业大学能源与交通工程学院,呼和浩特 010018;2. 城发投资集团有限公司,青岛 266555)

为解决膨胀土对工程结构以及农业生态环境的危害,进行煤矸石粉改良膨胀土的试验研究。对煤矸石粉掺量为0、3%、6%、9%的膨胀土土样进行压汞试验,测得微观孔隙特征值;选取Menger海绵模型建立孔隙分形模型,计算土体孔隙分形维数,探究土体孔隙分形维数与孔隙特征参数以及煤矸石粉掺量变化的关系。结果表明:随着煤矸石粉掺量增加,土中大孔隙所占的含量较素膨胀土减少61.5%,孔隙类型从团粒间孔隙转化为颗粒间孔隙;煤矸石粉的掺入改变了土体的孔隙结构特征,煤矸石粉与膨胀土发生胶结反应,孔隙连通性降低,使得总孔隙体积、孔隙率、孔隙平均孔径、孔隙临界孔径等孔隙特征参数呈减小趋势;基于分形理论分析孔隙分形维数,分形维数随煤矸石粉掺量的增加而增加,且与孔隙特征参数呈显著相关性。孔隙分形维数反应了孔隙特征参数以及孔隙发育程度,为土的孔隙表征提供方法借鉴。

膨胀土;孔隙度;煤矸石;Menger海绵模型;分形;压汞法

0 引 言

膨胀土具有显著的胀缩性、裂隙性、超固结性等一系列工程特性[1],对工程结构以及生态环境的稳定性造成较大危害[2-3]。膨胀土的特性与其土粒的孔隙大小、形态、分布特征有着重要联系,孔隙的大小与分布影响土体的众多工程地质性质,因此膨胀土孔隙方面的研究对防治膨胀土有重要意义。目前对膨胀土微观孔隙特性的研究主要有:张雁等[4]在干湿循环条件下,结合压汞法研究膨胀土孔隙结构参数与干湿循环次数的关系,随着干湿循环次数的增加,孔隙率、总孔隙体积、孔隙孔径等参数都呈递增趋势[5]。Pedarla等[6]对膨胀土进行压汞试验,将试验与模型相结合描述了在给定土壤中包含矿物学和孔隙结构细节的重要性。易远[7]利用压汞法和SEM电镜扫描对膨胀土进行微观结构研究,分析不同脱湿环境、压实度等对使土体的孔隙分布、孔隙结构的影响。Ma等[8]利用压汞试验和核磁共振试验对膨胀土在干湿循环过程中微观结构的演变进行研究,并对大孔和微孔在润湿过程中的变化进行分析。蔺建国等[9]等利用压汞法分析NaCl的浓度对膨胀土孔隙的影响,NaCl浓度的增加,土中微孔隙减少,孔隙比表面积减小,土中出现架空贯穿孔隙。大量研究表明,由形状与大小各异的颗粒和孔隙组成的岩土多孔介质具有分形特性[10-14],分形理论已成为描述岩土多孔介质颗粒和孔隙分布特性的有效手段。土的结构具有自相似性,可用分形维数来描述[15]。谢和平[16]在传统Koch岛、Sicrpinski垫片和Menger海绵模型基础上研究土体颗粒及孔隙分布。陶高梁等[17]和Zhang等[18]以理想的Sierpinski垫片和Menger海绵为基础,提出了由孔隙颗粒体积分形模型及孔径粒径分布分形模型组成的两大类岩土体分形模型,并在分析现有孔隙率模型不足的基础上,提出了新的孔隙率演化模型。鲍硕超等[19]采用压汞法对吉林延边地区路基边坡膨胀土进行测试,结合分形理论发现孔径越大,孔隙分布分形维数越大,孔隙分布复杂而均匀。陈毅等[20]基于分形理论分析定西市遗址土内外部土样的孔隙结构,结果表明随着风化时间的增长,外部土体的孔隙总体积和表面分形维数逐渐减小。Sun等[21]采用ESEM和MIP试验,研究不同干密度下膨润土的孔隙分形维数,基于盒计算法、Menger分形维数和热力学关系的方法,分析各分形维数对孔隙大小、干湿循环、吸压力数等的影响。陶高梁等[22]研究黏土压缩工程中孔隙的分形特征,根据压汞法获取的土体孔隙分布数据,结合分形维数,得出分形维数与大小孔隙的联系。由上述分析可知,大多数学者对膨胀土孔隙的研究主要集中在土体孔隙的固有特征,基于分形理论分析孔隙特征,孔隙分形维数可以更直观地描述孔隙结构的测定结果。孔隙结构是影响膨胀土稳定的重要因素,改变膨胀土孔隙的固有特征还可以采用添加固化剂的方法。选用煤矸石粉改良膨胀土,煤矸石粉的掺入对膨胀土孔隙的改变,以及从分形理论的角度上,不同煤矸石粉掺量对膨胀土孔隙的影响需要进一步探索。

本文在前人研究的基础上,对不同煤矸石粉掺量下的膨胀土土样进行压汞试验,基于其孔隙结构变化,建立孔隙分形模型,探究土体孔隙分形维数与孔隙特征参数以及煤矸石粉掺量变化的关系,对膨胀土多孔孔隙结构的分形量化进行表征,以掌握膨胀土孔隙的分形形貌结构特性,为获得膨胀土孔隙控制与改进的措施奠定理论基础。

1 材料与方法

1.1 试验材料基本性质

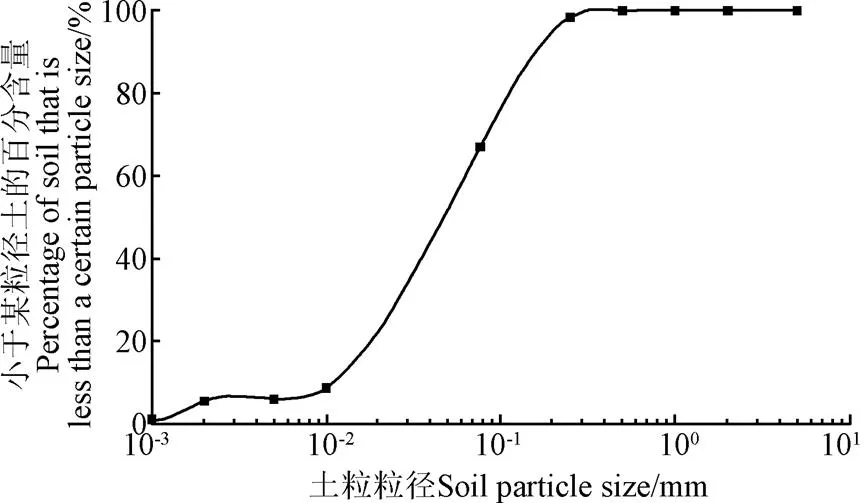

本研究采用的原材料分别为膨胀土和煤矸石。膨胀土选自内蒙古兴和县,根据T0118-2007、T0124-1993、T0103-1993法[23]测得膨胀土的基本指标:液限为57.1%,塑限为22%,塑性指数为35.1,天然含水率为8.7%,自由膨胀率为46%,根据自由膨胀率(>40%)可判断该膨胀土样属于弱膨土[24]。膨胀土的级配曲线如图1所示。

图1 膨胀土的级配曲线

由图1膨胀土的级配计算得到土粒不均匀系数为6,曲率系数为0.7,故土颗粒及配不良[25]。

煤矸石产于乌海市神五煤矿公乌素煤矿4号采区,坚硬,灰黑色,呈片麻状。采用X射线荧光光谱仪XFS(Axios Pw4400, PANalytical B.V, Almelo, Netherlands)按照ASTM: E 1621-05[26]检测煤矸石化学成分如表1所示。

表1 煤矸石基本化学成分

由表1可知,煤矸石中SiO2、Al2O3和Fe2O3的含量总和为91.2%。再根据T0348-2005、T0307-2005、T0316-2005、T0314-2000、T0302-2005法[21]测得煤矸石的物理指标:吸水率为0.5%,自由膨胀率为14.3%、压碎值为20.6%、烧失率为14.4%,不均匀系数为3.3,曲率系数为2,其中压碎值<30%,烧失量<20%,煤矸石的化学成分和物理指标均满足《公路路基设计规范》(JTG D30-2015)[27]的要求。

将煤矸石磨成粉后过0.5 mm筛[23],以掺量为0、3%、6%、9%掺入膨胀土中,根据T0118-2007、T0112-1993法[23]测量混合料的基本物理指标;并采用T0131-2007法[23]对混合料进行击实试验,计算其最佳含水率和最大干密度,结果如表2所示。随着煤矸石粉掺量的增加,改良膨胀土的最佳含水率逐渐增大,最大干密度逐渐减小。

表2 混合料的基本物理指标

1.2 压汞试验

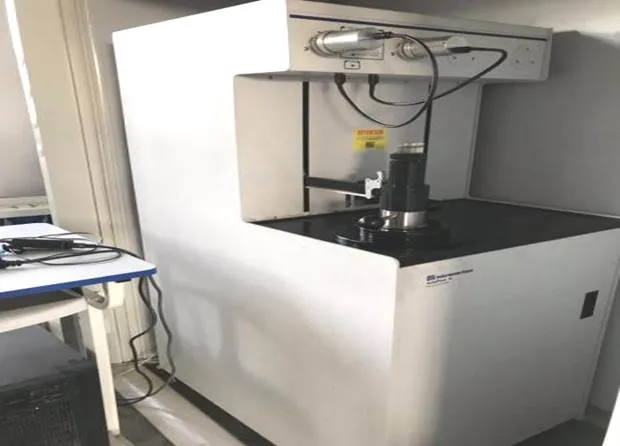

为了观察煤矸石粉改良后的膨胀土微观孔隙特征的变化情况,选取图2所示压汞仪(美国麦克公司制造,型号为Auto Pore9500)对土样进行孔隙结构测定。

图2 压汞仪

首先冷冻干燥土样试件,然后将水银经过不同压力压入土体孔隙中,根据不同压力和进汞量绘制关系图,然后计算出不同大小孔隙所占孔隙总体积的比例关系。假设孔隙为圆柱体,孔径为,进汞压力与孔径间的关系式采用Washnurn方程如式(1)[28]所示:

式中为进汞压力,MPa;为汞液表面张力,N/m,取值0.48 N/m;为汞液与材料的接触角,取值140°;为所测孔隙孔径,m。

将制好的击实试件抽气饱和至真空饱和状态,然后取出放在冻干机内进行24 h冷冻干燥处理,使土中冰升华,再切成体积为1 cm3小方块,放入膨胀计中,用硅脂真空膏密封好,抽真空至0.3 MPa左右,使改良膨胀土土样的孔隙气体压强近似为零,将膨胀计放入压汞仪中;先对土样进行低压压汞分析,分析结束后取出膨胀计放在天平上秤取质量,天平的精确度为万分之一;再对土样进行高压压汞分析,直至压力逐渐降为大气压时,压汞试验分析完成。

2 结果与分析

2.1 累计进汞量

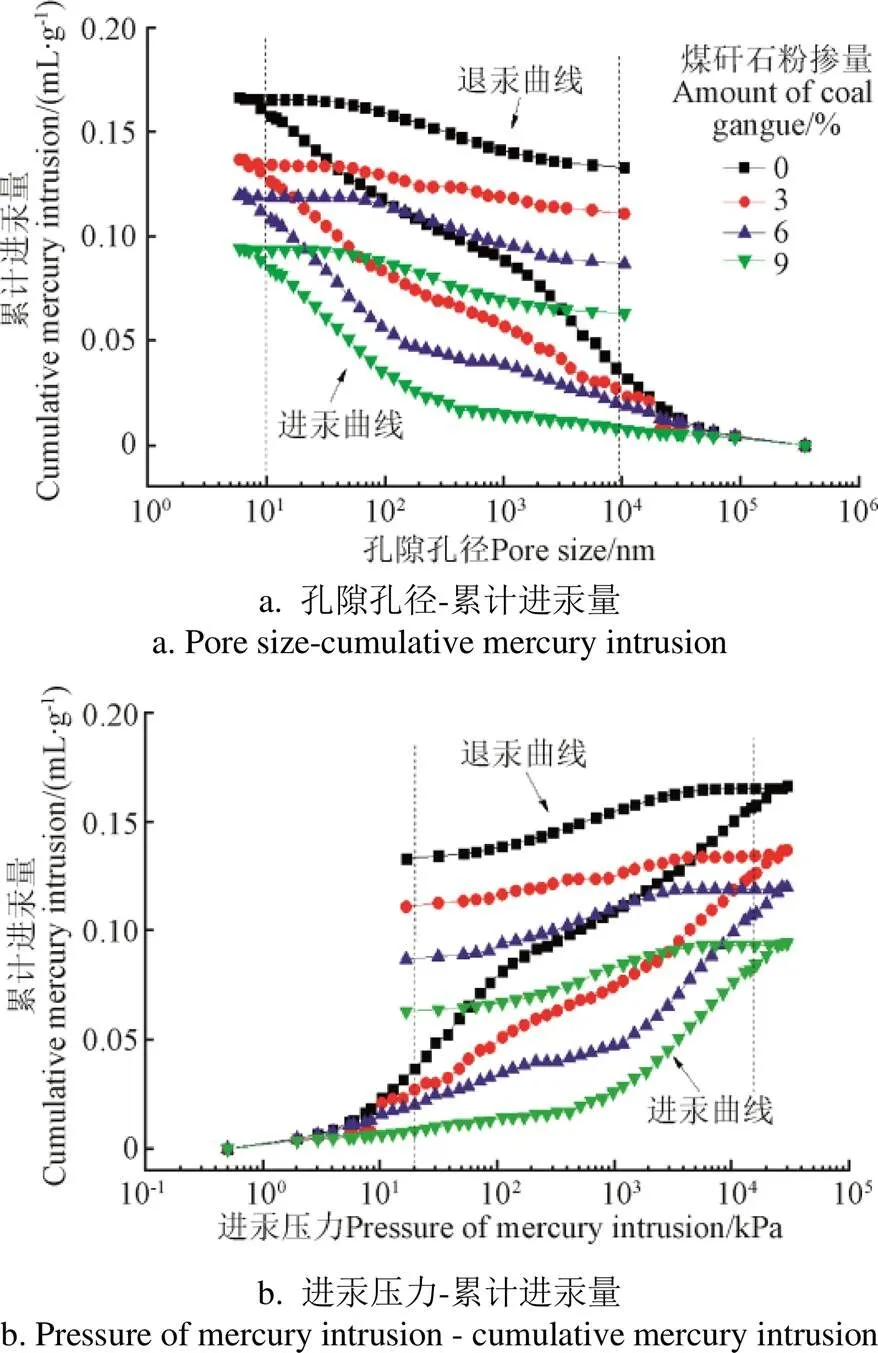

压汞试验测得不同煤矸石粉掺量条件下土样的累计进汞量曲线如图3所示。

图3 改良土的累计进汞量曲线

压汞试验分为进汞过程和退汞过程,进汞曲线即为大于某孔径累计孔隙体积曲线。将图3与公式(1)相结合,当压力较小时,与对应的当量孔径较大,汞只能进入土样中较大的孔隙,累计进汞量较小。随着压力的增大,孔径逐渐减小,汞能进入土体中较小的孔隙,累计进汞量则逐渐增大。在进汞曲线中,以孔径10 nm和104nm为分界分为3个阶段,当孔径大于104nm时,累计进汞量较小,随着汞液被压入孔径分布在10~104nm的孔隙中,累计进汞量迅速增长;当压力持续增大,孔径小于10 nm时,此阶段的累计进汞量基本不再增加。而退汞过程中随着压力的减小,累计进汞量减小,相同外界压力下,退汞过程中的累计进汞量明显大于进汞过程中的累计进汞量。与煤矸石粉掺量相结合分析,在相同进汞压力下,改良土的累计进汞量逐渐减小,表明随着煤矸石粉掺量的增加膨胀土的孔隙逐渐减小。

2.2 孔隙分布密度

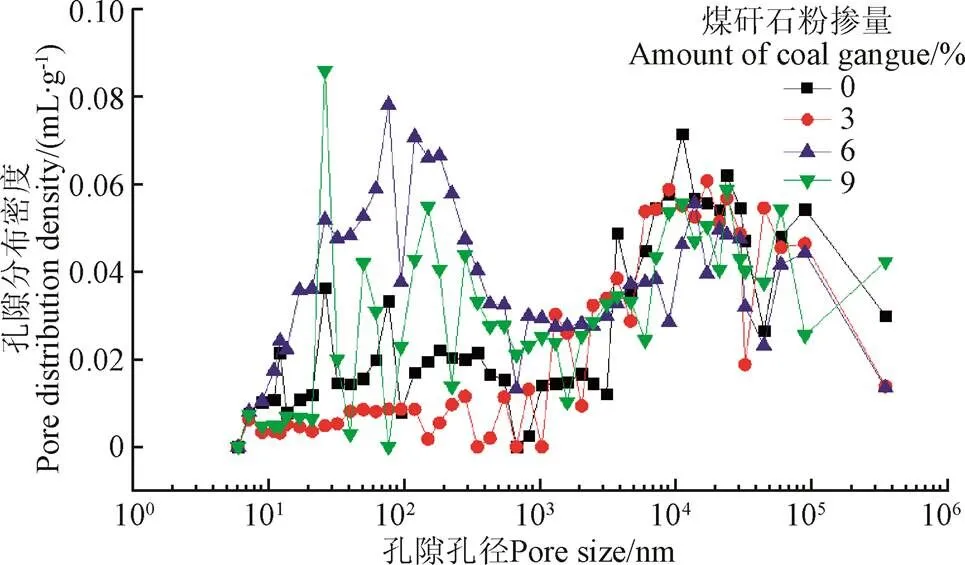

对累计孔隙体积(即累计进汞量)进行求导可得到改良土的孔隙分布密度,如图4。

由图4可看出,在试验开始阶段,当孔径大于104nm时,素膨胀土的峰值高于改良膨胀土,随着孔径的减小,改良土与素膨胀土孔隙分布密度没有明显区别;当孔径分布在102~103nm之间,曲线再次呈现峰值状态,且煤矸石粉掺量为6%和9%的土样的峰值明显高于素膨胀土;当孔径小于102nm时,煤矸石粉掺量为9%的土样呈双峰状态。随着煤矸石粉掺量的增加,土中大孔隙逐渐减少,孔隙类型逐渐从团粒间孔隙转化为颗粒间孔隙,煤矸石粉的掺入可明显改善膨胀土的膨胀性。

图4 孔隙孔径与孔隙分布密度的关系

2.3 孔隙分布特性

依据张平等[29]提出的孔隙划分方法,可对膨胀土的孔隙分为5大类:团粒间的大孔隙(>30 000 nm);团粒内的中孔隙(2 500 nm<≤30 000 nm);颗粒间或者部分团粒内的小孔隙(350 nm<≤2 500 nm);颗粒间的微孔隙(100 nm<≤350 nm);颗粒内的超微孔隙(≤100 nm)。不同煤矸石粉掺量下土体孔隙大小的分布如图5所示。

图5 孔隙分布

从图5可看出,随着煤矸石粉掺量的增加大孔和中孔逐渐减少,煤矸石粉掺量为9%时,改良土的大孔较素膨胀土减少61.5%;小孔、微孔和超微孔逐渐增加,其中小孔和超微孔的增长幅度最为明显,分别增加了8.51%和6.38%。由此表明在膨胀土中掺入煤矸石粉后,大孔隙和中孔隙都被煤矸石粉的填充,孔隙向小孔径转移,煤矸石粉的掺入对膨胀土小孔隙和超微孔隙的占比影响最大。

2.4 孔隙总体特征

根据压汞试验得到土样的总孔隙体积、孔隙率、孔隙平均孔径和孔隙临界孔径等孔隙总体特征指标如表3所示。

由表3可以看出,随着煤矸石粉掺量的增加,改良土的总孔隙体积较素膨胀土降低0.072 cm3/g、孔隙率减少10.5%、平均孔径和临界孔径呈减小趋势,煤矸石粉的掺入降低了孔隙的连通性,改变了土体的孔隙结构特征。而土样经压汞前后对比可以发现,无论理论计算的孔隙率或者压汞后的土体孔隙率都随着煤矸石粉掺量的增加而减小,压汞试验后的孔隙率明显小于理论计算的孔隙率,由于膨胀土具有裂隙性,且土样受尺寸效应以及压汞仪测量范围的影响,压汞试验并不能测出土中含有的部分宏观裂隙所占的孔隙体积[30],因此试验后的孔隙率小于理论孔隙率。

表3 改良膨胀土孔隙总体特征指标

3 孔隙分形维数与孔隙特征参数的关系

3.1 海绵模型的建立

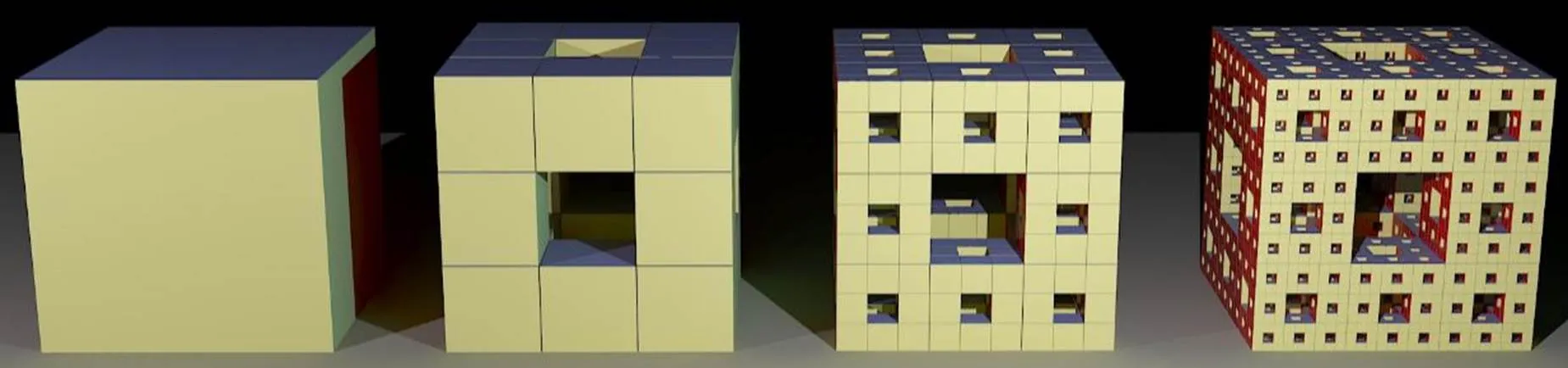

分形理论在研究岩土体的孔隙分形模型有多种,包括空间填充模型[31]、Menger海绵模型[32]、基于热力学关系[33]和孔轴线分形模型[34]等。由于Menger海绵模型模拟颗粒间孔隙结构各级孔径并存的状态,能对各个空间的尺度孔径进行完整而连续的表征,故本研究采用Menger海绵模型研究煤矸石粉改良后膨胀土的孔隙分形维数。采用逐级生成海绵模型,第0级为选择一边长的正方体生成初始元(图6a),以后各级逐级形成生成元。第1级将初始元27等分,去掉体心与面心处的7个小立方体,剩下20个小立方体为生成元(图6b)。随着重复次数的增加,逐级形成各级生成元,更小孔径的孔隙生成,土颗粒尺寸越来越小,孔隙体积越来越大。将上述操作无限重复下去,就得到了Menger海绵,如图6d所示。

a. 初始元(级数=0)a. Initialelement (Series=0)b. 生成元(级数=1)b. Generators (Series=1)c. 生成元(级数=2)c. Generators (Series=2)d. 生成元(级数=4)d. Generators (Series=4)

3.2 分形维数求解

孔隙体积分形维数的计算如公式(2)[28]:

式中为进汞压力,MPa;为进汞压力的累计进汞体积,mL/g;为常数;为孔隙分形维数。

根据压汞试验数据可得lg(d/d)和lg,以lg为横坐标,lg(d/d)为纵坐标构建散点图并进行线性拟合(图7)。

注:p为进汞压力,MPa;V为进汞压力p的累计进汞体积,( mL·g-1)。

煤矸石粉掺量为0、3%、6%和9%的4种土样拟合直线方程如图7所示,线性决定系数2分别为0.99、0.98、0.99、0.98;拟合直线的斜率分别为−1.41、−1.34、−1.27、−1.13;根据式(2)求得孔隙分形维数D分别为2.59、2.66、2.73、2.87。分形维数在2.59~2.87之间变化,土体的孔隙结构分形维数的合理范围为2~3,改良膨胀土在分形理论角度上具有物理意义。由于4条曲线的相关系数均在0.9以上,具有较好的线性关系,表明4种土样都具有良好的分形特性。

3.3 分形维数与孔隙特征参数的关系

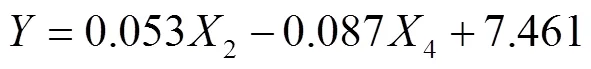

为研究孔隙分形维数与孔隙特征参数的关系,本文采用多元线性逐步回归分析法进行分析。将孔隙分形维数记为;总孔隙体积、孔隙率、平均孔径和临界孔径,分别记为1~4;采用逐步线性回归的变量引入方式,获得孔隙分形维数与孔隙参数的模型为

式中仅引入了孔隙率(2)和临界孔径(4),说明二者对孔隙分形维数影响最大。模型的参数估计及方差分析如表4和表5所示。

表4 模型参数估计

表5 模型方差分析

由表4可以看出,经过检验,各项回归系数的相伴概率值都小于剔除因子标准值0.1,故以上因素不能从回归方程中剔除,且对因变量影响显著。表5中当=218.108时,相伴概率值小于显著性水平,说明回归方程通过了显著检验(检验),所建立的线性回归模型具有统计学意义。多元线性回归模型代表应变量与自变量之间的依存规律,因此可较好的表征孔隙分形维数与孔隙特征参数之间的联系。

3.4 分形维数与煤矸石粉掺量间的关系

不同煤矸石粉掺量条件下膨胀土样的孔隙分形维数如图8所示。

图8 煤矸石粉掺量与孔隙分形维数的关系

由图8可知,随着煤矸石粉掺量逐渐增加,土体孔隙分形维数逐渐增大,且煤矸石粉掺量与土体孔隙分形维数之间的决定系数为0.96,表明土体孔隙分形维数与煤矸石粉的掺量有很强的相关性,孔隙分形维数越大孔隙结构分布形态越复杂[35],土的结构越密实,孔隙越少,则对膨胀土改良效果越好。

综上所述,土体积孔隙分形维数是孔隙体积不规则性、粗糙性的度量值,反映了土体孔体积、孔径、孔隙率等参数。分形维数越大,土颗粒之间的连接越紧密,孔隙结构越密实。分形维数可以更直观地描述孔隙结构的测定结果,深化对孔隙结构的认识,可以一定程度上表征孔隙特征参数以及孔隙发育程度,反应土体的非均质性及复杂性。分形维数为改良土的研究上提供了新的指标,对孔隙中较复杂的问题提供新的依据。

4 结 论

本文通过压汞试验,分析改良膨胀土的孔隙特征,建立孔隙分形模型,获得孔隙分形维数,揭示孔隙分形维数与孔隙特征参数的关系,得到如下结论:

1)在压汞过程中,孔径在102~103nm之间,煤矸石粉掺量对膨胀土的孔隙影响较大,掺量为6%和9%时变化最明显。随着煤矸石粉掺量的增加,土中大孔隙逐渐减少,大孔所占的含量较素膨胀减少61.5%;改良土总孔隙体积、孔隙率、孔隙平均孔径、孔隙临界孔径等指标皆呈减小趋势。

2)基于Menger海绵模型表征改良土的孔隙分形维数,通过回归模型得到孔隙分形维数与孔隙特征参数之间的依存规律,孔隙率与临界孔径对分形维数的影响较为显著。孔隙分形维数使孔隙结构特征参数从定性描述转变为定量计算。

3)分形维数的大小可以表征不同煤矸石粉掺量下膨胀土的孔隙发育程度。孔隙分形维数随着煤矸石粉掺量增加而增加,分形维数越大表明改良土的孔隙排列、形状特征更加有序,进而实现通过分形特性来指导固化剂研制和膨胀土孔隙结构控制的目的。

[1]陆定杰,陈善雄,罗红明,等. 南阳膨胀土渠道滑坡破坏特征与演化机制研究[J]. 岩土力学,2014,35(1):189-196.

Lu Dingjie, Chen Shanxiong, Luo Hongming, et al. Study of failure characteristics and evolution mechanism of canal slope of Nanyang expansive soil[J]. Rock and Soil Mechanics, 2014, 35(1): 189-196. (in Chinese with English abstract)

[2]杨振北,胡东旭,汪时机. 膨胀土胀缩裂隙演化及其扰动规律分析[J]. 农业工程学报,2019,35(17):169-177.

Yang Zhenbei, Hu Dongxu, Wang Shiji. Evolution law of expansion-shrinkage crack and its disturbance rule of expansive soil[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE),2019, 35(17): 169-177. (in Chinese with English abstract)

[3]王晓燕,姚志华,党发宁,等. 裂隙膨胀土细观结构演化试验[J]. 农业工程学报,2016,32(3):92-100.

Wang Xiaoyan, Yao Zhihua, Dang Faning, et al. Meso-structure evolution of cracked expansive soils[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(3): 92-100. (in Chinese with English abstract)

[4]张雁,殷潇潇,刘通. 煤矸石改良膨胀土特性及其最佳掺量条件下的孔隙结构表征[J]. 农业工程学报,2018,34(22):267-274.

Zhang Yan, Yin Xiaoxiao, Liu Tong. Strength properties of solidified expansive soil with coal gangue and its pore structure characterization under condition of optimum dosage[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(22): 267-274. (in Chinese with English abstract)

[5]曾召田,吕海波,赵艳林,等. 膨胀土干湿循环过程孔径分布试验研究及其应用[J]. 岩土力学,2013,34(2):322-328.

Zeng Zhaotian, Lü Haibo, Zhao Yanlin, et al. Study of pore size distribution of expansive soil during wetting-drying cycle and its application[J]. Rock and Soil Mechanics, 2013, 34(2): 322-328. (in Chinese with English abstract)

[6]Pedarla A, Aravind A, Puppala, et al. Evaluation of swell behavior of expansive clays from internal specific surface and pore size distribution[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2016, 142(2):1943-5605.

[7]易远. 基于分形理论的膨胀土微观结构演变规律研究[D]. 武汉:武汉轻工大学,2018.

Yi Yuan. Study on the Evolution Law of Microstructure of Expansive Soil Based on Fractal Theory[D]. Wuhan: Wuhan Polytechnic University, 2018. (in Chinese with English abstract)

[8]Ma T, Wei C, Yao C, et al. Microstructural evolution of expansive clay during drying-wetting cycle[J]. Acta Geotechnica, 2020, 15(8): 2355-2366.

[9]蔺建国,叶加兵,邹维列. 孔隙溶液对膨胀土微观结构的影响[J]. 华中科技大学学报:自然科学版,2020,48(4):12-17.

Lin Jianguo, Ye Jiabing, Zou Weilie. Effect of pore fluid on microstructure in expansive soil[J]. Journal of Huazhong University of Science and Technology: Natural Science Edition, 2020, 48(4): 12-17.(in Chinese with English abstract)

[10]Turcotte D. Fractals and fragmentation[J]. Journal of Geophysical Research, 1986, 91(B2): 1921-1926.

[11]Zhang B, Li S. Determination of the surface fractal dimension for porous media by mercury porosimetry[J]. Ind Eng Chem Res., 1995, 34(4): 1383-1386.

[12]Dathe A, Eins S, Niemeyer J, et al. The surface fractal dimension of the soil–pore interface as measured by image analysis[J]. Geoderma, 2001, 103(1/2): 203-229.

[13]Li Peng, Zheng Min, Bi He, et al. Pore throat structure and fractal characteristics of tight oil sandstone: A case study in the Ordos Basin, China[J]. Journal of Petroleum Science and Engineering, 2017, 149: 665-674.

[14]Peng Lei, Chen Bing, Pan Yongjian. Evaluation and comparison of bentonite surface fractal dimension and prediction of swelling deformation: Synchrotron radiation SAXS and N2-adsorption isotherms method[J]. Construction and Building Materials, 2020. doi:10.1016/j.conbuildmat.2020.121331.

[15]Rieu M, Sposito G. Fractal fragmentation, soil porosity,and soil water properties: I Theory[J]. Soil Science Society of America Journal, 1991, 55(5): 1231-1238.

[16]谢和平. 岩土介质的分形孔隙和分形粒子[J]. 力学进展,1993,25(2):145-164.

Xie Heping. Fractal pores and fractal particles of rock and soil materials[J]. Advances in Mechanics, 1993, 25(2): 145-164. (in Chinese with English abstract)

[17]陶高梁,张季如. 表征孔隙及颗粒体积与尺度分布的两类岩土体分形模型[J]. 科学通报,2009,54(6):838-846.

Tao Gaoliang, Zhang Jiru. Two categories of fractal models of rock and soil expressing volume and size-distribution of pores and grains[J]. Chinese Science Bulletin, 2009, 54(6): 838-846. (in Chinese with English abstract)

[18]Zhang J, Tao G, Huang L, et al. Porosity models for determining the pore-size distribution of rocks and oils and their applications[J]. Chinese Science Bulletin, 2010, 55(34): 3960-3970.

[19]鲍硕超,王清,陈剑平,等. 吉林省延边地区路基边坡膨胀土孔隙分布特性[J]. 东北大学学报:自然科学版,2017,38(1):132-137.

Bao Shuochao, Wang Qing, Chen Jianping, et al. Pore size distribution of expansive soil of the subgrade slope in Yanbian region, Jilin province[J]. Journal of Northeastern University: Natural Science Edition, 2017, 38(1): 132-137. (in Chinese with English abstract)

[20]陈毅,张虎元,杨龙. 遗址土劣化进程中微观结构变化的类比研究[J]. 岩土力学,2018,39(11):4117-4124,4141.

Chen Yi, Zhang Huyuan, Yang Long. Analogy study on evolution of microstructure of earthen monument during natural weathering process[J]. Rock and Soil Mechanics, 2018, 39(11): 4117-4124, 4141. (in Chinese with English abstract)

[21]Sun H, Masin D, Najser J, et al. Fractal characteristics of pore structure of compacted bentonite studied by ESEM and MIP methods[J]. Acta Geotechnica, 2019, 15(6): 1655-1671.

[22]陶高梁,朱学良,胡其志,等. 黏性土压缩过程临界孔径现象及固有分形特征[J]. 岩土力学,2019,40(1):81-90.

Tao Gaoliang, Zhu Xueliang, Hu Qizhi, et al. Critical pore-size phenomenon and intrinsic fractal characteristic of clay in process of compression[J]. Rock and Soil Mechanics, 2019, 40(1): 81-90. (in Chinese with English abstract)

[23]中华人民共和国行业标准. 公路土工试验规程:JTG E40-2007[S]. 北京:人民交通出版社,2007.

[24]中华人民共和国行业标准. 膨胀土地区建筑技术规范:GB 50112-2013[S]. 北京:中国建筑工业出版社,2013.

[25]中华人民共和国行业标准. 公路工程集料试验规程:JTGE42-2005[J]. 北京:人民交通出版社,2005.

[26]Subcommittee: E01.20. Standard Guide for Elemental Analysis by Wavelength Dispersive X-Ray Fluorescence Spectrometry: ASTM E1621-13[S]. ASTM International: West Conshohocken, PA, USA, 2013.

[27]中华人民共和国行业标准. 公路路基设计规范:JTG D30-2015[S]. 北京:人民交通出版社,2015.

[28]León y León C A. New perspectives in mercury porosimetry[J]. Advances in Colloid and Interface Science, 1998, 76/77: 341-372.

[29]张平,房营光,闫小庆,等. 不同干燥方法对重塑膨润土压汞试验用土样的影响试验研究[J]. 岩土力学,2011,32(增刊1):388-391.

Zhang Ping, Fang Yingguang, Yan Xiaoqing, et al. Study of different dry methods for drying remolded bentonite sample with mercury intrusion test[J]. Rock and Soil Mechnics, 2011, 32(Supp.1): 388-391. (in Chinese with English abstract)

[30]孔元元,王清,张学飞,等. 镇赉县裂隙土孔隙分布特征试验研究[J]. 工程地质学报,2016,24(S):1196-1202.

Kong Yuanyuan, Wang Qing, Zhang Xuefei, et al. Experimental study on pore distribution characteristics of fissure soil in Zhenlai County[J]. Journal of Engineering Geology, 2016, 24(S): 1196-1202. (in Chinese with English abstract)

[31]陈三强,刘永忠,程光旭,等. 用压汞法计算冻干物料的表面分形维数[J]. 食品科学,2004(7):25-28.

Chen Sanqiang, Liu Yongzhong, Cheng Guangxu, et al. Computation on surface fractal dimension of freeze-dried product by mercury porosimetry[J]. FoodScience, 2004(7): 25-28. (in Chinese with English abstract)

[32]Ye Z, Hou E, Duan Z. Micrometer-scale pores and fractures in coals and the effects of tectonic deformation on permeability based on fractal theory[J]. AIP Advances, 2020, 10(2): 025118.

[33]Yan C, Tang Y, Liu Y. Study on fractal dimensions of the silty soil around the tunnel under the subway loading in Shanghai[J]. Environmental Earth Sciences, 2013, 69(5): 1529-1535.

[34]李克升,刘传孝,李全新,等. 黄河三角洲盐碱土微观孔隙特征的分形研究[J]. 山东农业大学学报:自然科学版,2020,51(5):828-832,880.

Li Kesheng, Liu Chuanxiao, Li Quanxin, et al. Fractal study on microscopic pore features of saline-alkali soil in Yellow River Delta[J]. Journal of Shandong Agricultural University: Natural Science Edition, 2020, 51(5): 828-832, 880. (in Chinese with English abstract)

[35]孙秀丽,宋碧颖,刘文化,等. 基于分形理论的疏浚淤泥固化土孔隙结构定量化研究[J]. 大连理工大学学报,2018,58(2):153-158.

Sun Xiuli, Song Biying, Liu Wenhua, et al. Quantitative study of pore structure of dredged silt solidified soil based on fractal theory[J]. Journal of Dalian University of Technology, 2018, 58(2): 153-158. (in Chinese with English abstract)

Microstructure characteristics of expansive soil with coal gangue based on Menger sponge model

Wang Minglei1, Zhang Yan1※, Yin Xiaoxiao1,2

(1. College of Energy and Transportation Engineering, Inner Mongolia Agricultural University,Hohhot 010018, China; 2. Chengfa Investment Group, Qingdao 266555, China)

Expansive soil is a type of highly plastic clay, where the volumetric expansion upon water absorption (hygroscopic expansion), while the shrinkage upon water loss. This property can be detrimental to the soil structure, resulting in a series of civil engineering problems, such as soil surface cracking, subgrade settlement, and road surface uplift. Alternatively, coal gangue is a kind of rock waste discharged from coal mining, washing, and processing during coal production. Serious influences have occurred in the social, environmental, and economic respects. An eco-friendly way to save energy is to effectively reuse the coal gangue as a substitute resource. This study aims to improve the properties of expansive soil using the coal gangue, in order to alleviate the damage of expansive soil in engineering, thereby to explore the porosity characters of improved expansive soil with coal gangue. A Menger sponge model was selected to characterize the fractal dimension of pores, in order to guide the development of curing agent, and thereby control the pore structure of expansive soil via the fractal characteristics. A mercury injection test was performed on the samples of expansive soil with the content of coal gangue of 0, 3%, 6% and 9%, respectively. Prior to the mercury injection test, compaction specimens were fabricated from the state of extraction saturation to vacuum saturation state. The gas pressure of pores was approximate to zero in the sample of improved expansive soil for the dilatometer in mercury injection apparatus. A low-pressure mercury injection was first used to analyze the soil samples. The dilatometer was then taken out to weigh the mass on a high precision balance. A mercury pressure analysis was carried out on the soil samples until the pressure gradually decreased to atmospheric pressure. The results show that the mercury injection can be divided into the process of mercury injection and removal. When the pressure was small, there was the large equivalent diameter of pores corresponding to the pressure, where mercury can only enter the large pores in the soil sample, resulting the small cumulative amount of mercury injection. The pore diameter gradually decreased as the pressure increased, where mercury can enter the smaller pores in the soil, and thereby the accumulated amount of mercury gradually increased. With the increase in the content of coal gangue powder, the accumulative content of mercury in the improved soil significantly decreased, where the most obvious content were 6% and 9%. Large micropores decreased by 61.5% in the expansion content of macropores. There was a trend of decrease in the total volume of pores, the critical aperture porosity, average pore diameter, and pore porosity index. Pore types were transformed from the pores between the aggregates to the pores between particles, indicating an obviously enhanced effect in the addition of coal gangue to the expansive soil. In order to study the relationship between the pore fractal dimension and pore characteristics, a Menger sponge model was used to characterize the fractal dimension of pores in the improved soil, where the values varied from 2.59-2.87. A dependent law was obtained between the fractal dimension of pores and the characteristic parameters of pores in multiple linear regressions. In “F” and “t” test of regression model, it was found that the porosity and critical pore size had a significant influence on the fractal dimension of pores. The fractal dimension of pores increased in the improved expansive soil with the increase in powder content of coal gangue. The large fractal dimension indicated that there was an orderly arrangement of pores and shape characteristics in the improved soil. The fractal dimension of pores can be used to visually represent the measurement data of pore structure, further to verify the pore characteristic parameters, and pore development degree, serving as an indirect indicator of the heterogeneity and complexity of soil.

expansive soils; porosity; coal gangue; MENGER sponge model; fractal; mercury intrusion

王明磊,张雁,殷潇潇. 基于Menger海绵模型的煤矸石粉改良膨胀土微结构特征[J]. 农业工程学报,2020,36(23):124-130.doi:10.11975/j.issn.1002-6819.2020.23.015 http://www.tcsae.org

Wang Minglei, Zhang Yan, Yin Xiaoxiao. Microstructure characteristics of expansive soil with coal gangue based on Menger sponge model[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(23): 124-130. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2020.23.015 http://www.tcsae.org

2020-09-25

2020-11-17

国家自然科学基金项目(51669025)

王明磊,主要研究方向为道路工程材料。Email:377968494@qq.com

张雁,博士,教授,博士生导师,主要从事路基材料性能方面的研究。Email:zhangyanli@imau.edu.cn

10.11975/j.issn.1002-6819.2020.23.015

TU411

A

1002-6819(2020)-23-0124-07