Effect of fiber type on the bending and uniaxial tensile properties of high-strength high-ductility cementitious composites

2019-01-17GuoLipingChenBoWuYueLeiDongyi

Guo Liping Chen Bo Wu Yue Lei Dongyi

(1 School of Materials Science and Engineering, Southeast University, Nanjing 211189, China)(2 Jiangsu Key Laboratory of Construction Materials, Southeast University, Nanjing 211189, China)(3 State Key Laboratory of Hydrology-Water Resources and Hydraulic Engineering, Nanjing Hydraulic Research Institute, Nanjing 210029, China)

Abstract:To investigate the effect of fiber types on bending and tensile properties of high-strength, high-ductility cementitious composites (HS-HDCCs), ultra-high-molecular-weight polyethylene (PE) fibers, polyvinyl alcohol (PVA) fibers, and copper-plated micro steel fibers were selected as the reinforcement materials. The bending and tensile properties of HS-HDCCs with different fibers with a volume fraction of 2% were studied. The results indicate that PE, PVA, micro steel, and PVA-PE hybrid fibers impart varying degrees of toughening and improve the tensile strength. During the tensile and bending processes, HS-HDCCs with micro steel fibers exhibit a strain-softening phenomenon. HS-HDCCs with PVA fibers or with PVA-PE hybrid fibers can achieve multiple cracking behaviors and strain hardening phenomenon to a certain extent and show slight high-ductility characteristics. HS-HDCCs with PE fibers exhibit multiple cracking behavior and strain hardening phenomenon and show significant high-ductility characteristics. The test results can provide a basis for selecting fibers suitable for HS-HDCCs reinforcement.

Key words:fiber; high ductility; toughness; uniaxial tensile

High-ductility cementitious composites (HDCCs) are composite materials comprising of a cement-based matrix and short reinforcing fibers. They are highly ductile materials exhibiting multiple fine cracks and pseudo strain-hardening characteristics under uniaxial tensile stresses[1].

HDCCs have extensive application prospects in seismic strengthening, repairing, and beam and column joint reinforcement of fabricated buildings[2-3]. Currently, polyvinyl alcohol (PVA) fibers are commonly used to prepare HDCCs having a compressive strength of approximately 60 MPa[4]. The demand for high-strength (HS)-HDCCs is increasing with the development of prefabricated buildings. To achieve multiple cracking behavior and high-ductility characteristics, the energy and strength criteria need to be met. This requires the congruence of matrix materials and fiber properties[5]. A challenging aspect of research on HS-HDCCs materials is coordinating the fiber and matrix properties to achieve high ductility with a matrix strength of over 100 MPa.

This study aims to investigate the influence of fiber types, i.e., polyethylene (PE), PVA, and copper-plated micro steel fibers, on HS-HDCCs’ bending toughness and tensile properties. Also, the effect of PVA-PE hybrid fibers on HS-HDCCs’ performance is tested in experiments.

1 Experiment

1.1 Materials

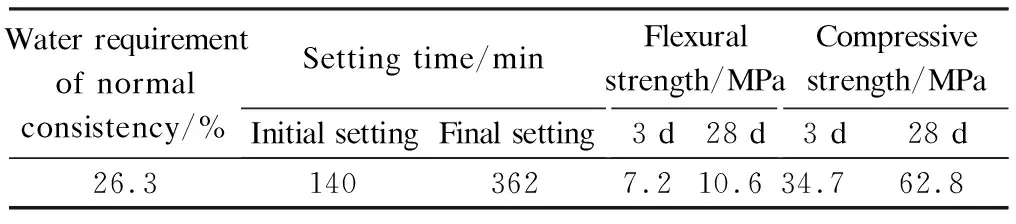

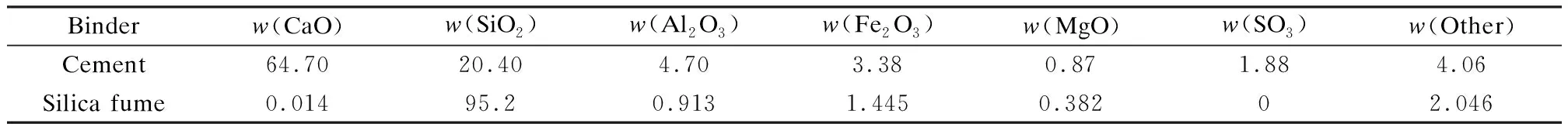

The cement used in the HS-HDCCs mixtures is P·I 52.5 Portland cement. Its physical properties and chemical composition are listed in Tab.1 and Tab.2, respectively. The silica fume, with its chemical composition listed in Tab.2, has a silicon dioxide content of 95.2%, a loss of 1.04% on ignition, a density of 2 500 kg/m3, and a specific surface area of 22 000 m2/kg. The aggregate used is sieved river sand with a maximum grain size of 0.60 mm. A polycarboxylate-type high-performance water-reducing agent with a solid content of 40% is used along with ordinary tap water.

Tab.1 Physical and mechanical properties of cement

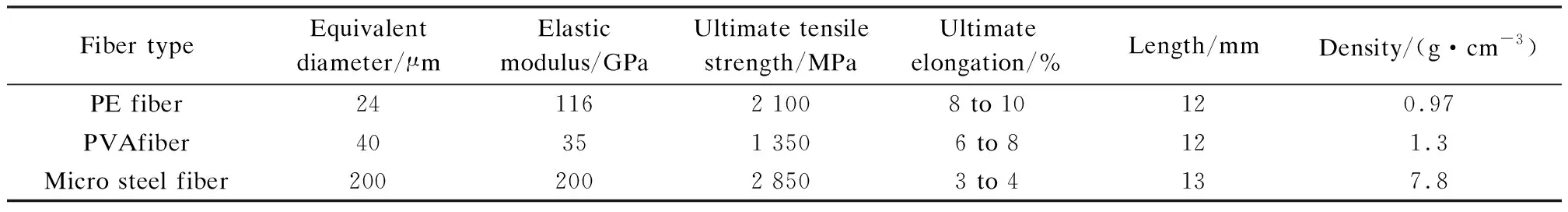

PE, PVA, and copper-plated micro steel fibers are used herein. The physical and mechanical properties of the fibers are listed in Tab.3.

1.2 HS-HDCCs mixing proportion and specimen preparation

The mix proportion parameters of HS-HDCCs are shown as follows: The water-to-binder ratio is 0.23, the silica fume replacement is 30%, the dosage of the water-reducing agent is 2%, and the fine aggregate-to-binder ratio is 0.36.

Tab.2 Chemical composition of cement and silica fume %

Tab.3 Physical and mechanical properties of fibers

The fiber volume fraction is maintained throughout as 2%. The fiber volume fractions of HS-HDCCs are shown in Tab.4.

Tab.4 The fiber volume fraction of HS-HDCCs %

The HS-HDCC specimen preparation process is as follows:

1) Cement, silica fume, and sand are mixed for 2 min.

2) Water and water-reducing agent are mixed with the above-mentioned mixture for 2 to 3 min to prepare a uniform paste.

3) The fibers are then evenly fed into a mixer within 1 min.

4) Subsequently, the mixture is then homogenized for another 5 min.

5) Next, the mixture is poured into a vibrating mold with two layers, and its top surface is covered with plastic sheeting.

22.I must send my child thither: The mother, horrified56 to see her youngest daughter receive such wealth, decides to send her preferred daughter to achieve the same goal. She still can t love the youngest daughter despite her new source of wealth.Return to place in story.

6) Finally, the mold is removed after 24 h and the specimen is placed into a curing box at a temperature of (20±3)℃ and a relative humidity of ≥95%.

1.3 Test methods

Flexural and compressive strength tests: The mechanical properties were measured by using prism specimens with a dimension of 40 mm×40 mm×160 mm at the age of 28 d according to the method of testing cements-determination of strength (ISO) (GB/T 17671—1999).

Bending toughness tests: According to the standard test methods for fiber-reinforced concrete (CECS13:2009), a four-point bending test was conducted by using thin-plate specimens with a dimension of 300 mm×75 mm×15 mm the at age of 28 d. Bending tests were conducted by using an MTS 810 servo-hydraulic testing system in the displacement-control mode with a loading rate of 0.5 mm/min. Complete bending stress-mid-span deflection curves were recorded.

Uniaxial tensile tests: The tensile properties were evaluated according to the Japan Society of Civil Engineers’ codeRecommendationsforDesignandConstructionofHighPerformanceFiberReinforcedCementCompositeswithMultipleFineCracks. The dumbbell-shaped specimens with a thickness of 13 mm, parallel portion width of 30 mm, parallel portion length of 100 mm, and original reference point distance of 100 mm were used. Uniaxial tensile tests were conducted by using the MTS 810 servo-hydraulic testing system in displacement-control mode at a loading rate of 0.3 mm/min. Aluminum plates were glued on both sides of the dumbbell-shaped specimens to facilitate gripping. Two external linear-variable displacement transducers with a gauge length of about 100 mm were attached to the specimens in order to measure the elongation of the specimens. Complete tensile stress-strain curves were recorded. Herein, the ultimate tensile strain of each HDCCs specimen is defined as the strain at the softening point of the uniaxial tensile stress-strain curves, whereas the ultimate tensile stress is defined as the value of the maximum stress obtained in the strain-hardening region.

2 Results and Discussion

2.1 Flexural and compressive strengths of HS-HDCCs

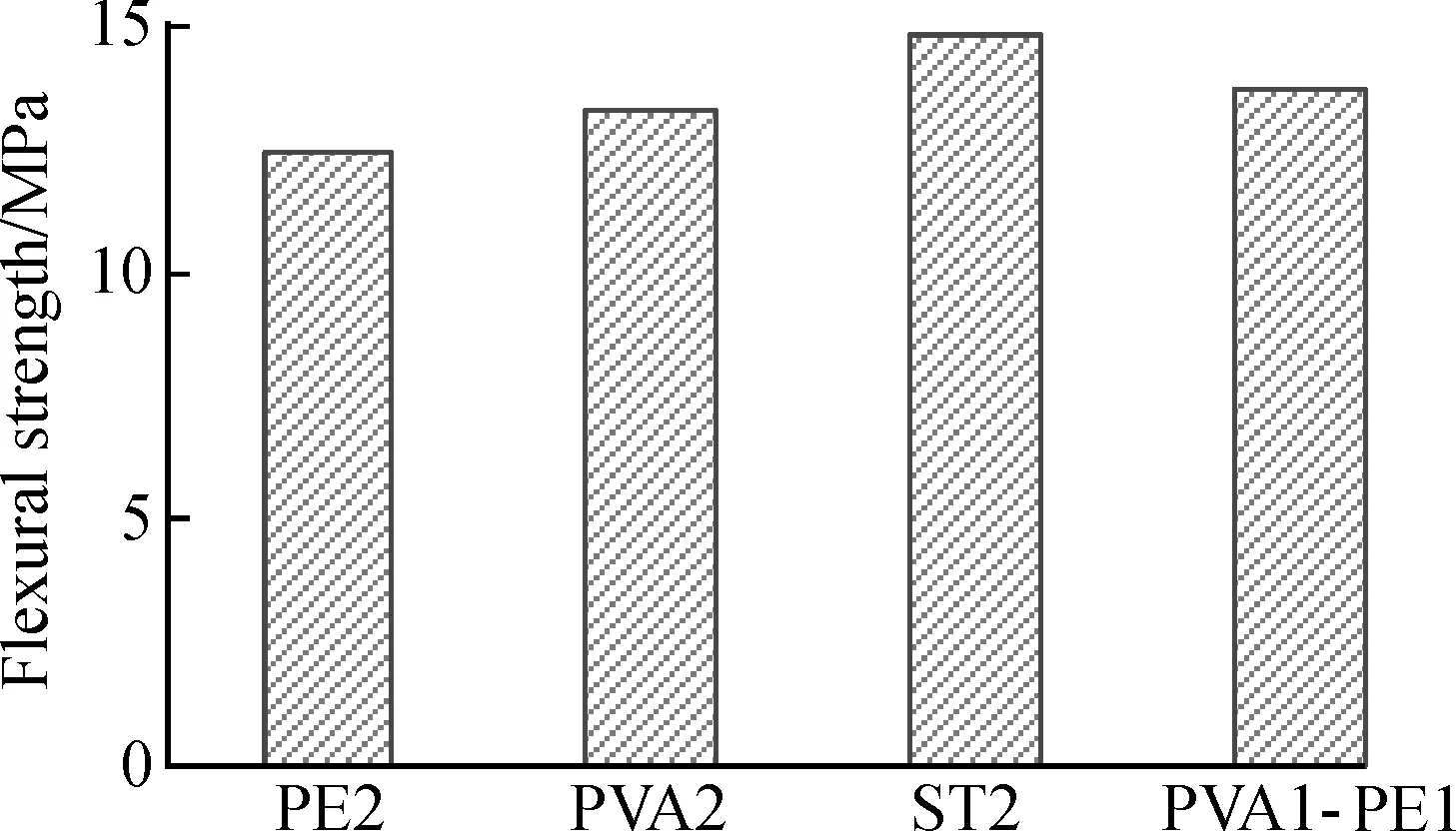

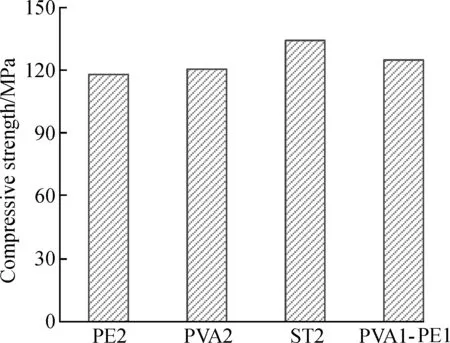

The results of the flexural and compressive strength tests of four HS-HDCCs are presented in Fig.1 and Fig.2.

Fig.1 Flexural strength of HS-HDCCs

Fig.2 Compressive strength of HS-HDCCs

With a water-to-binder ratio of 0.23 and a silica fume replacement level of 30%, the flexural and compressive strengths of the four HS-HDCCs were in the ranges of 12.4 to 14.8 MPa and 118.1 to 134.2 MPa, respectively. HS-HDCCs with PE fibers and those with PVA fibers exhibited similar mechanical properties. HS-HDCCs with PVA-PE hybrid fibers exhibited greater strength compared with the HS-HDCCs reinforced with either PE or PVA fibers. The fiber hybrid effect improves the mechanical properties of HDCCs. Micro steel fibers were found to remarkably improve the mechanical properties. In comparison with PE2, the ST2 specimen’s flexural strength and compressive strength increased by approximately 20% and 15%, respectively. Compared with organic synthetic fibers, the effect of micro steel fiber on improving the mechanical properties of concrete is more obvious.

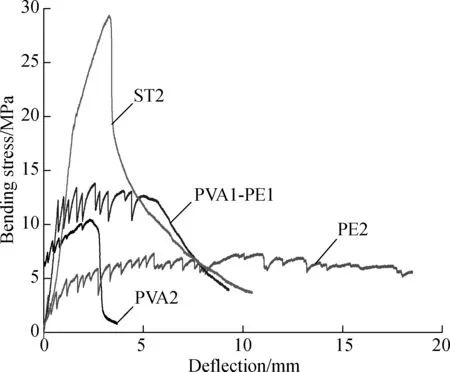

2.2 Bending toughness of HS-HDCCs

The bending stress-mid-span deflection curves of the four groups of HS-HDCCs are presented in Fig.3. The bending strength of PE2, PVA2, ST2, and PVA1-PE1 are 7.3, 10.5, 29.4, and 13.8 MPa, respectively. The corresponding values of mid-span deflection curves, also known as the absorbed energy, are 7 781, 1 980, 8 501, and 6 392 N·mm, respectively. As shown in Fig.3, ST2 has the highest bending strength and energy absorption capacity, indicating that the micro steel fibers have significant toughening effects. It can also be observed that the deflection of ST2 is small and that the load-carrying capacity rapidly decreases beyond the peak point. This is the typical strain-softening behavior, which shows no multiple cracking characteristics. PE2 has the lowest bending strength and the highest mid-span deflection. The multiple cracking characteristics are obvious during bending (see Fig.4), and the energy absorption capacity is at an upper-middle level. Although the bending strength of PVA2 is higher than that of PE2, the toughening effect of PVA fibers is not significant and the strain-hardening characteristics are not prominent. The energy absorption capacity and mid-span deflection of the PVA1-PE1 group are between the PVA2 and PE2 values. The hybrid PVA-PE fibers improve the bending strength. The bending stress-mid-span deflection curve is clearly serrated and has multiple cracking characteristics, indicating a strain-hardening failure mode. The hybrid fibers have a superior toughening effect compared with PVA fibers.

Fig.3 A plot of bending stress vs. mid-span curve of HS-HDCCs

Fig.4 Multiple cracks of bending HS-HDCCs specimens with PE fibers

2.3 Uniaxial tensile properties of HS-HDCCs

The uniaxial tensile test results of HS-HDCCs are shown in Fig.5. The initial crack strengths of PE2, PVA2, ST2, and PVA1-PE1 are 3.2, 3.5, 6.4, and 4.4 MPa, respectively. PE, PVA, and micro steel fibers as well as hybrid PVA-PE fibers were all found to increase the tensile strengths of HS-HDCCs. The ultimate tensile strengths of PE2, PVA2, ST2, and PVA1-PE1 are 4.7, 6.0, 8.2, and 5.9 MPa, respectively, whereas the ultimate tensile strains are 3.15%, 0.62%, 0.80%, and 0.90%, respectively. As shown in Fig.4, although ST2 has the highest tensile strength, it only develops one crack during the tensile process and does not show high-ductility characteristics. The tensile strengths and ultimate tensile strains of PVA2 and PVA1-PE1 are similar wherein the tensile strain is less than 1% and the strain-hardening and multiple cracking phenomena are observed; however, their characteristics are not significant. The hybrid PVA-PE fibers exhibit enhanced strain-hardening effects. PE2 has the lowest tensile strength; however, its strain-hardening and multiple cracking characteristics are rather significant (see Fig.6). Additionally, it can be classified as a high-ductility material.

Fig.5 A plot of uniaxial tensile stress vs. strain curve of HS-HDCCs

Fig.6 Multiple cracks of uniaxial tensile HS-HDCCs with PE fibers

In summary, PE, PVA, and micro steel fibers as well as hybrid PVA-PE fibers were found to improve the tensile strength of HS-HDCCs in the uniaxial tensile test. The micro steel fibers only increased the tensile strength of HS-HDCCs and did not exhibit high ductility. In contrast, the PVA fibers and hybrid PVA-PE fibers exhibited high ductility; however, the effect was not obvious. Furthermore, PE fibers were found to exhibit significantly high ductility.

A comprehensive analysis of Fig.3 and Fig.5 indicates that the bending stress-mid-span deflection curves of the HS-HDCCs were similar to the uniaxial tensile stress-strain curves. This is mainly related to the physical and mechanical properties of the fibers.

The micro steel fibers have high tensile strength and strong matrix adhesion that can significantly increase the toughness of the matrix. However, once debonding occurs between steel fibers and the matrix, the friction between them sharply decreases and the slip-hardening coefficient value becomes less than zero. Therefore, steel fibers exhibit strain softening behavior during bending and uniaxial tensile tests[6].

As PVA fibers have hydrophilic surfaces, they exhibit high adhesive strengths when a low water-to-binder ratio and high-strength matrix are used. Additionally, PVA fibers have certain toughening effects and can cause high frictional bonding that can ultimately fracture the fiber and reduce the energy absorption capacity during the bending or tensile process[7-8].

PE fiber surfaces are hydrophobic; therefore, the adhesive forces between PE and the matrix are relatively low. Moreover, PE fibers have considerably high tensile strength that causes them to be pulled out rather than be fractured during tension. They continue to bear the tensile load after debonding, and the slip-hardening coefficient is greater than zero[9-10]. Consequently, PE2 exhibits strain-hardening characteristics. In comparison with the PVA and micro steel fibers, the diameters of the PE fibers used are smaller. If there are more fibers with the same fiber volume fraction, the strain-hardening phenomenon will be more significant.

3 Conclusions

1) PVA, PE, and PVA-PE hybrid fibers have little effect on the flexural and compressive strengths of HS-HDCCs. The micro steel fibers can improve the mechanical properties of HS-HDCCs in the range of 15% to 20%.

2) PE, PVA, and micro steel fibers as well as hybrid PVA-PE fibers, all have a toughening effect and can increase the tensile strength of HS-HDCCs.

3) During the tensile and bending processes, HS-HDCCs with micro steel fibers exhibit the strain-softening phenomenon. The HS-HDCCs with PVA fibers and those with hybrid PVA-PE fibers achieve multiple cracking behavior and strain hardening phenomenon to a certain extent and exhibit slightly high ductile characteristics. The HS-HDCCs with PE fibers achieve remarkable multiple cracking behavior and strain-hardening phenomena and exhibit significant high-ductility characteristics.

杂志排行

Journal of Southeast University(English Edition)的其它文章

- Failure load prediction of adhesive joints under different stressstates over the service temperature range of automobiles

- Effects of secondary water curing on the long-term strength and durability of concrete after steam-autoclave curing

- Multi-target range and velocity measurements of a digital phased array radar system

- Variable structure control for descriptor Markovian jump systems subject to partially unknown transition probabilities

- Cooperative spectrum sensing algorithm based on bilateral threshold selection against Byzantine attack

- Joint resource allocation scheme based on evolutionary game for mobile edge computing