Improvement of Temperature Uniformity of Instant Rice Inside Plastic Rectangular Container Under Microwave Reheating

2019-01-09WangXiaoruiXuHaoZhuYongLiuChaiLiuHanLiuChenghaiFuHanyuandZhengXianzhe

Wang Xiao-rui, Xu Hao, Zhu Yong, Liu Chai, Liu Han, Liu Cheng-hai, Fu Han-yu, and Zheng Xian-zhe

College of Engineering, Northeast Agricultural University, Harbin 150030, China

Abstract: To improve the temperature uniformity of instant rice in a plastic rectangular container, during microwave reheating, the changes of temperature distribution were analyzed by using experiment and simulation method. A three-dimensionalfinite element model was established to describe microwave reheating of instant rice to predict the temperature. The results showed that the highest temperature occurred at the corners and bottom layer. The cold spots were located in the sample interior center. The simulation results in the model matched relatively with the experimental results. A method of intermittent microwave reheating was proposed to improve the temperature uniformity of convenient rice, and the optimal combination was the time of microwave reheating was 180 s, and the intermittent ratio was 1 : 3.

Key words: microwave, rice, temperature uniformity, intermittent microwave reheating

Introduction

Instant cooked rice, a new convenience nutritional food, meets the needs of fast-paced life (Li et al.,2016). The mode of reheating is a necessary treatment before serving. Microwave heating, a volume heating mode (Guo et al., 2017), has wide application prospects in food processing (Yang, 2015). It has been applied to reheat frozen fried bread stick (Yin and Zhou,2014), roast whole lamb (Liu et al., 2017), duck meat(Yang et al., 2017) and quick-frozen pork braised(Zhao et al., 2017). Therefore, microwave reheating is suitable for instant cooked rice due to the advantages of easy operation and high efficient (Li et al., 2016).However, the occurrence of uneven heating caused by microwave irradiation influences the uniformity of temperature distribution inside container loading instant rice (Guo et al., 2017). The temperature distribution is considered as a key index for the utiliza-tion of microwave power and evaluation of heating quality of microwaveable food, such as agar gel (Dai et al., 2015), potatoes (Chen et al., 2016),blackberries (Song et al., 2018) and surimi (Cao et al., 2018). In the above studies, the microwave power and shapes are chosen as the factors, which influenced the temperature. And to improve the uniformity of temperature distribution, the method of turntable, microwave vacuum heating and microwave coupled with water bath heating are proposed. As the same time, existing studies focus on the effects of parameters on the temperature distribution in rice in cylindrical container, including the particle state(Wang et al., 2012) and size (Fan et al., 2012). The microwave absorption of sample was analyzed by using Lambert's law. And the cylindrical model was establish to simulate the process of microwave reheating. At present, the rectangular container is frequently used for package of instant rice in the market. However, there exist obvious focusing and overheating phenomenon at edges and corner of rectangular container to badly affect the heating quality of loaded food in microwave heating. Whereas there have been no reports published on temperature distribution of rectangular instant rice. This restrictes wide application of plastic rectangular container for reheating of cooked rice.

The distribution and change of temperature inside rectangular plastic container depend on the size and shape of container, physical properties of loaded food in terms of thermal properties and dielectric properties,microwave heating parameters, especially based on thermal and dielectric properties, which are directly related to the temperature distribution. The objectives of this study were to investigate the absorption of microwave energy inside instant rice in microwave heating con-sidering the variable physical properties and structure (edge and corner) of rectangular plastic container, analyze the changes and distribution of temperature of instant rice inside the plastic rectangular container microwave reheating, and to propose the intermittent microwave reheating process.

Materials and Methods

Preparation of instant cooked rice

Rice (provided by Harbin Dr. Shang Technology Development Co., Ltd., Harbin, China) was selected from head rice. Two hundred grams of the rice were weighed, washed three times and drained completely.The samples were prepared by adding water with the ratio of rice to water=1 : 1.3 (w/w), then placed at room temperature (25℃) for 30 min, put in a rice cooker (SR-CW15 type, Panasonic Co. Ltd.,Hangzhou, China) and heated for 40 min. The initial moisture content of rice was determined to be 63.45%±0.39% (w. b.), and the sample was packed in a rectangular container with length of 17.0 cm, width of 11.5 cm, height of 4.5 cm andfillet radius of 1.0 cm at room temperature and sealed with a plastic lid.The weight of sample was 455.11±0.39 g, and it was stored in a refrigerator at 4℃ for 24 h for the further experiments.

Moisture content measurement

The moisture content of instant rice was measured by using the method of direct drying (GB 5009.3-2016).The amount of 3.41±0.23 g of sample was weighed into aluminum box, and then placed in a vacuum oven(DHG-9053A, Yiheng experimental equipment Co.,Ltd., Shanghai, China). The samples were repeatedly dried until the difference in quality between the last two dried processes did not exceed 2.0 mg, which was constant weight, at the temperature of 105℃. And each sample of selected experimental temperature was measured in triplicate. The moisture content (M0) of instant rice was calculated as shown in Eq.(1).

Where, m1was the quality of aluminum box and initial instant rice (g), m2was the quality of dried aluminum box and instant rice (g), and m3was the quality of aluminum box (g).

Thermal properties measurements

The thermal properties of the instant rice were measured by using a differential scanning calorimeter(DSC, Q2000, TA, New Castle Delaware, USA)with the method of three-line. For each sample, three aluminum foils of equal quality were prepared for test sample, the standard substance (potassium chloride,chemically pure) and the baseline blank, respectively.The sample (10.0±0.3 mg) was sealed into the aluminum foil to prevent moisture loss, during the measurement, the temperature was allowed down to 10℃ at the rate of 10℃ • min-1, holding for 15 min,then the samples were heated from 0 to 80℃, at the rate of 10℃ • min-1and measured in triplicate.

Dielectric property measurements

The dielectric properties of instant rice were measured by using a vector network analyzer (Agilent E5071C,Agilent Technologies, CA, USA) with the open-ended coaxial probe technique, connected to dielectric Probe(Agilent 85070E, Agilent Technologies, CA, USA).The instrument was calibrated by using air, shorting block and water at 25℃, to insure the accuracy of the measurements. The samples werefirst required placing in the centre of the microwave workstation(MWS, MAN-00074 R1 type, FISO, Quebec, Canada),which consisted of magnetrons andfiber optic sensors installed on the drying chamber. The temperature of rice was monitored by FISO software in real time,until it was consistent with the desired temperature(T =10, 20, 30, 40, 50, 60, 70 and 80℃). Afterward the dielectric parameters, in terms of dielectric constant ε' and dielectric loss factor ε'' of instant rice were automatically computed with Agilent Technologies 85070 software at 2 450 MHz, and each sample was measured in triplicate.

Temperature measurements

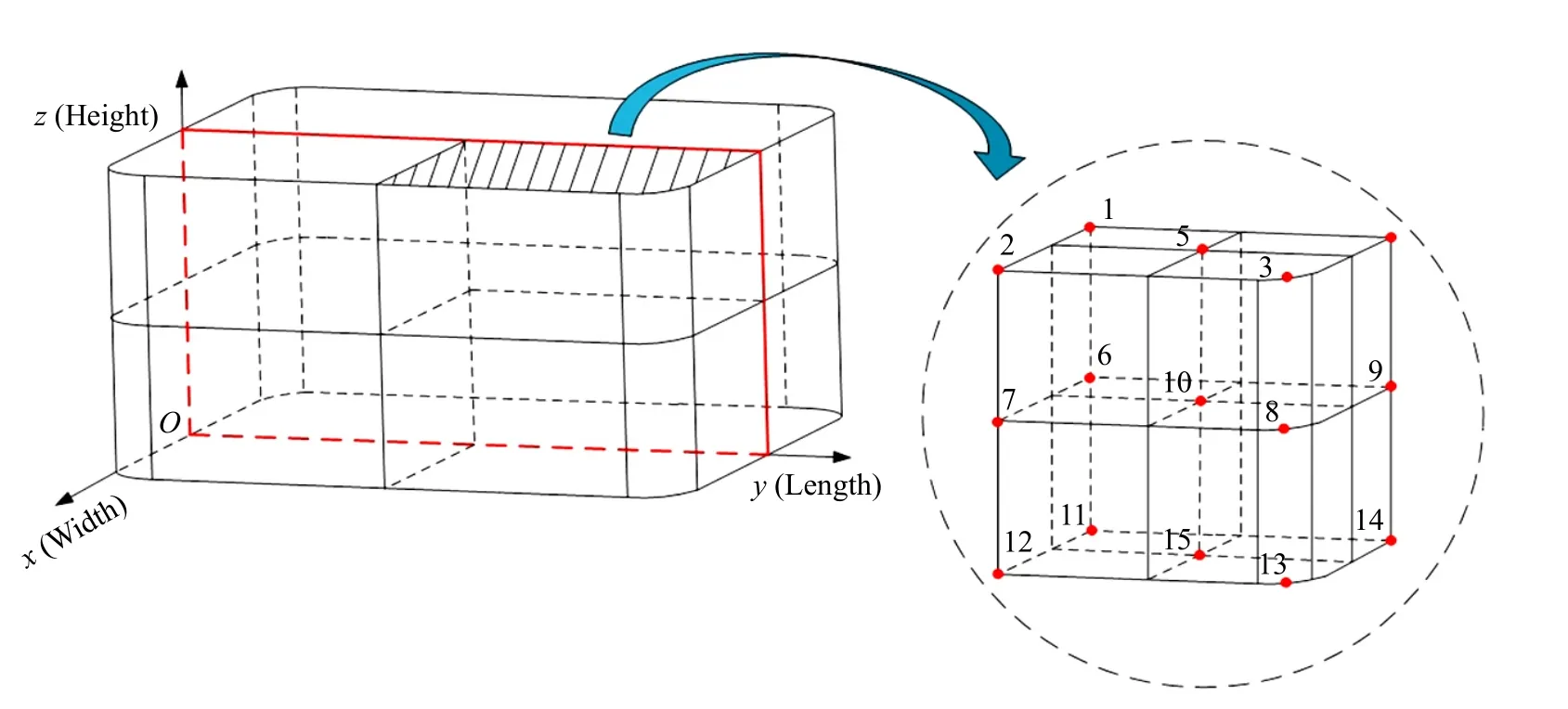

The temperature distribution of instant rice in rectangular container was measured by using MWS.The samples were placed in the centre of MWS. The microwave power was set at 800 W, the time was set at 180 s, which obtained the better sensory evaluation for the instant rice (Zhang, 2014). The temperature of rice was monitored by using FISO software every second at 15 positions, and each position was monitored three times. The opticalfiber probe positions are presented in Fig. 1.

Fig. 1 Temperature probe positions in rectangular instant rice (17.0 cm×11.5 cm×4.5 cm)

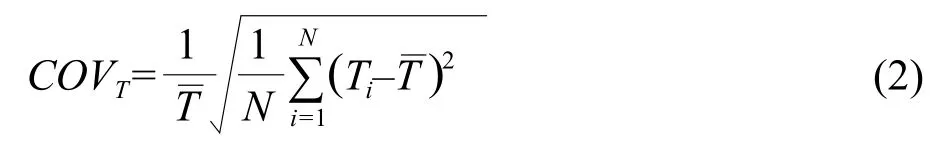

Uniformity coeきcient

To quantitatively evaluate the microwave reheating uniformity of the instant rice, the uniformity coefficient (COVT) was introduced to evaluate the degree of temperature uniformity. The lower COVTrepresented the greater uniformity of the temperature in instant rice, and it was defined as Eq. (2) (Lin et al., 2017).

Where, Tiwas the temperature (℃) at each position, T was the average value of Ti, and N was the data quantity.

Data processing

SigmaPlot software (12.5, Systate Software Incorporation, USA) was used tofit the most suitable regression equations, according to the highest correlation coefficient (R2) and the lowest standard mean deviation(SMD). COMSOL software (V5.3, COMSOL In-corporation, Sweden) was employed to establish the model to predict the temperature of instant rice, during microwave reheating.

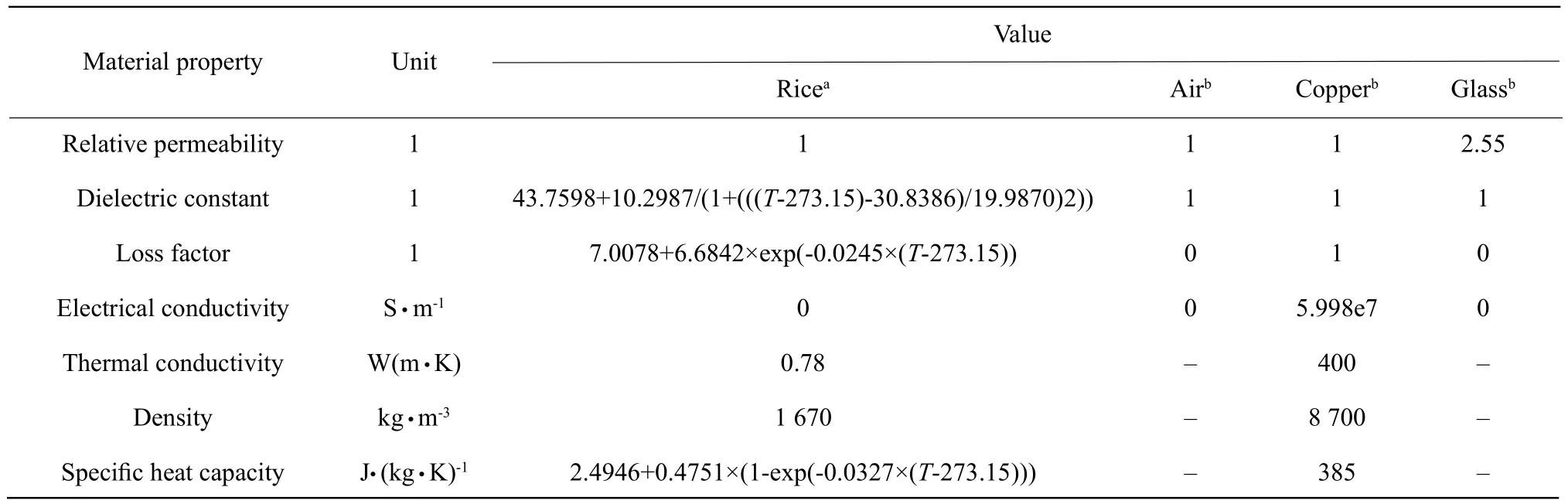

Model establishment

The geometric model was established for the microwave workstation and samples of instant rice by COMSOL software. The details of microwave oven,waveguide, turntable and experimental sample are presented in Fig. 2. And the thermal and electrical properties of materials used in model are illustrated in Table 1.

Fig. 2 Structure schematic of microwave workstation and instant rice

Table 1 Thermal and electrical properties of materials

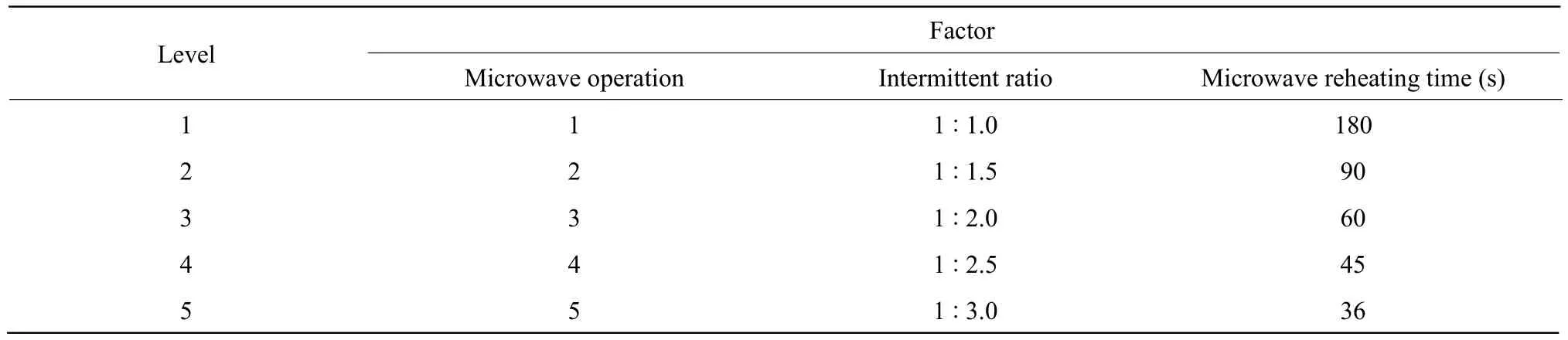

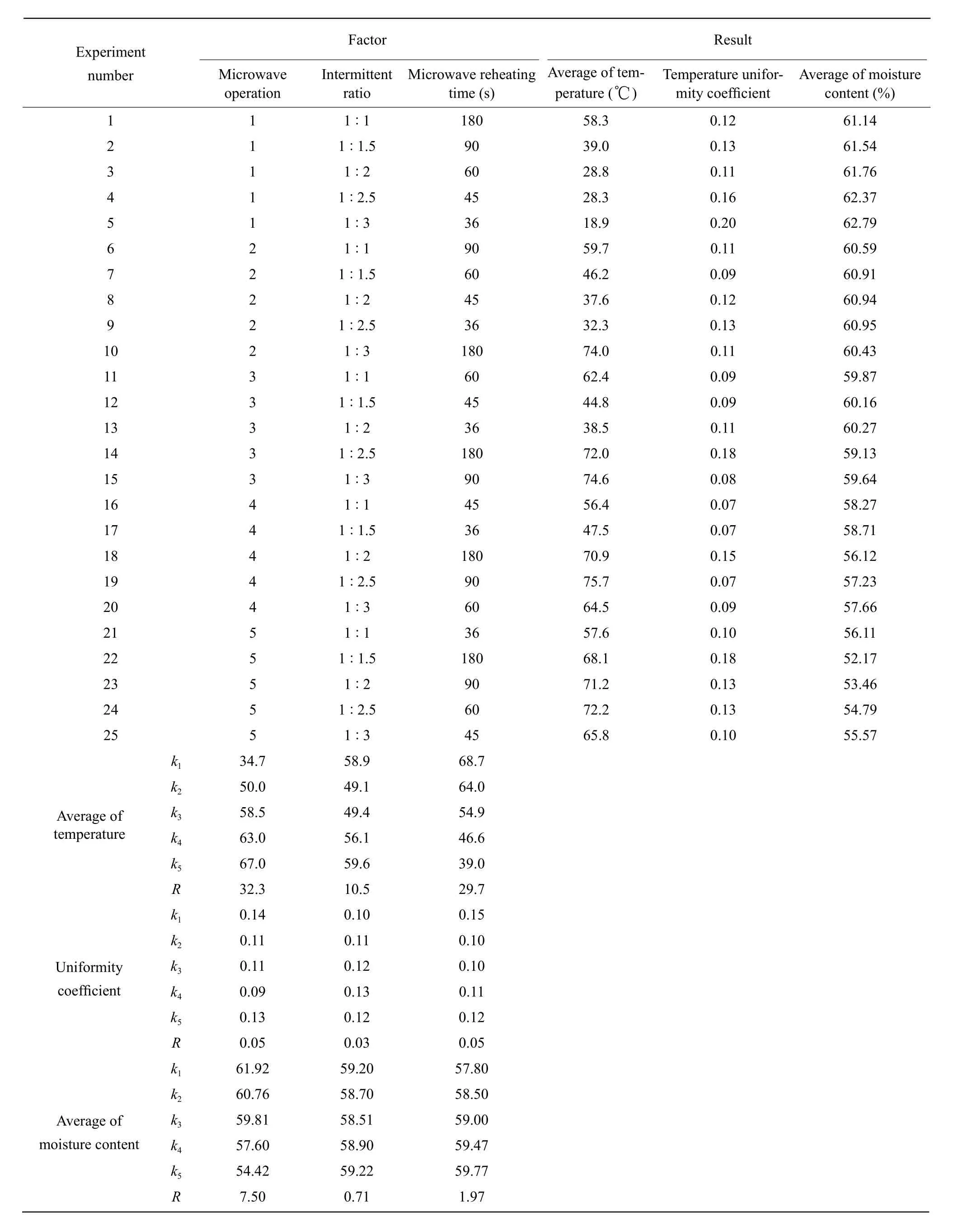

Method of intermittent microwave reheating

To improve the uniformity of instant rice during microwave reheating, a method of intermittent microwave reheating was proposed. The microwave operations,the intermittent ratio (microwave reheating time/intermittent time) and the microwave reheating time were selected as the influencing factors. The orthogonal experiment design method was used to determine the effect of various influencing factors on temperature uniformity. According to the previous experiments,the in fluencing factors are shown in Table 2.

Table 2 Factors and levels of orthogonal experiment

Results

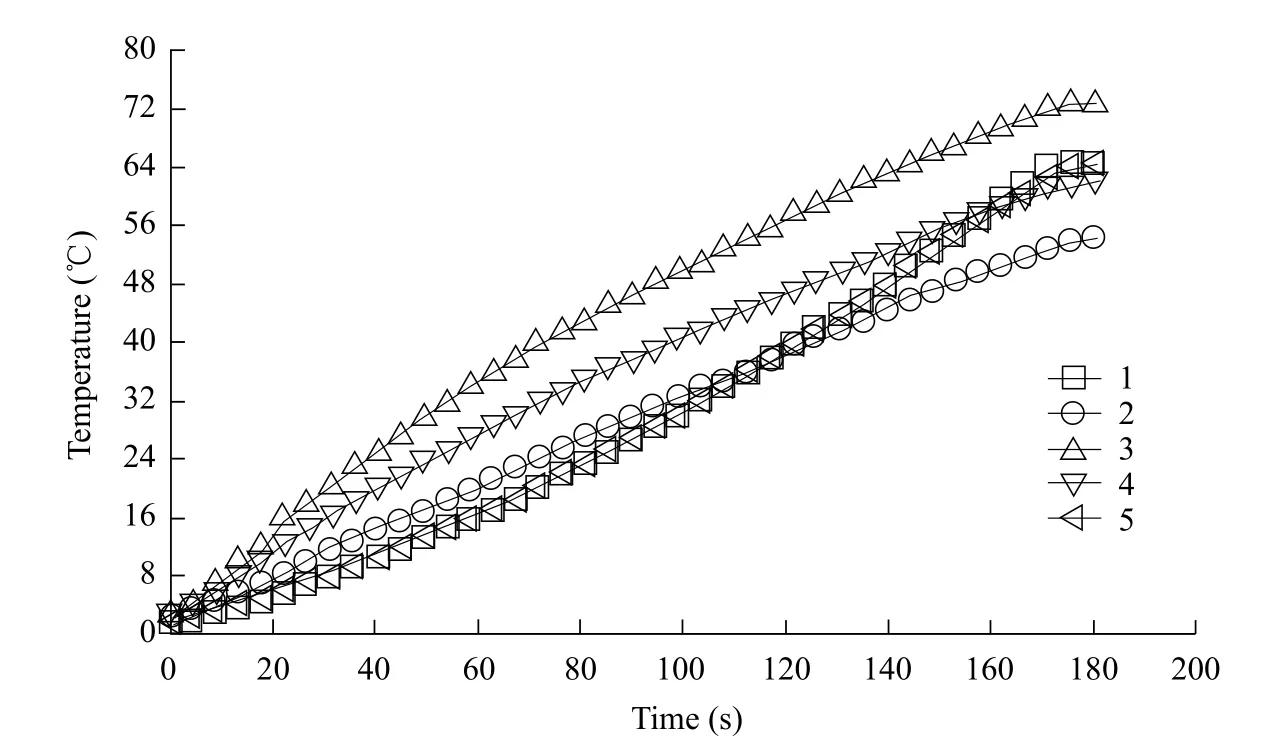

Fig. 3 showed the temperature atfive sampling positions of top layer of the rectangular instant rice during 180 s of microwave reheating at 800 W.

The temperature at the middle and bottom layers was linearly dependent on time. And the regression equation of temperature with time wasfitted as shown in Eq. (3).

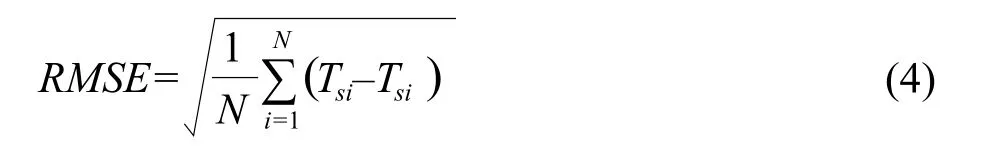

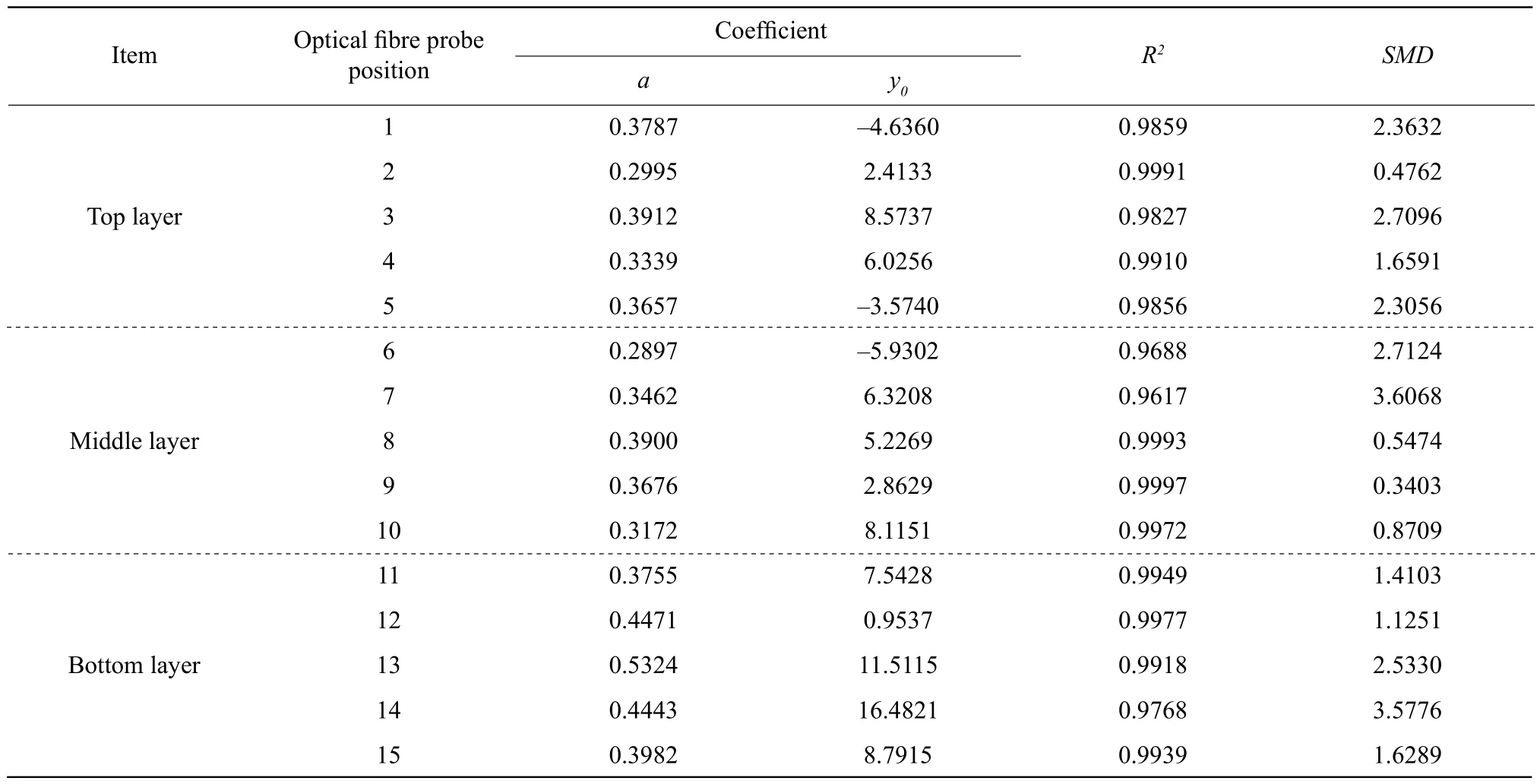

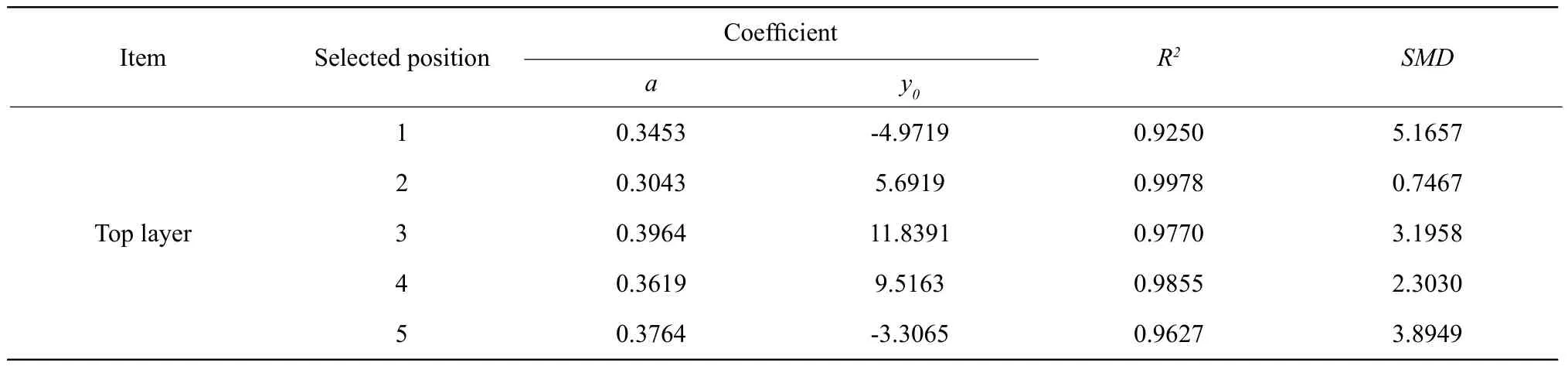

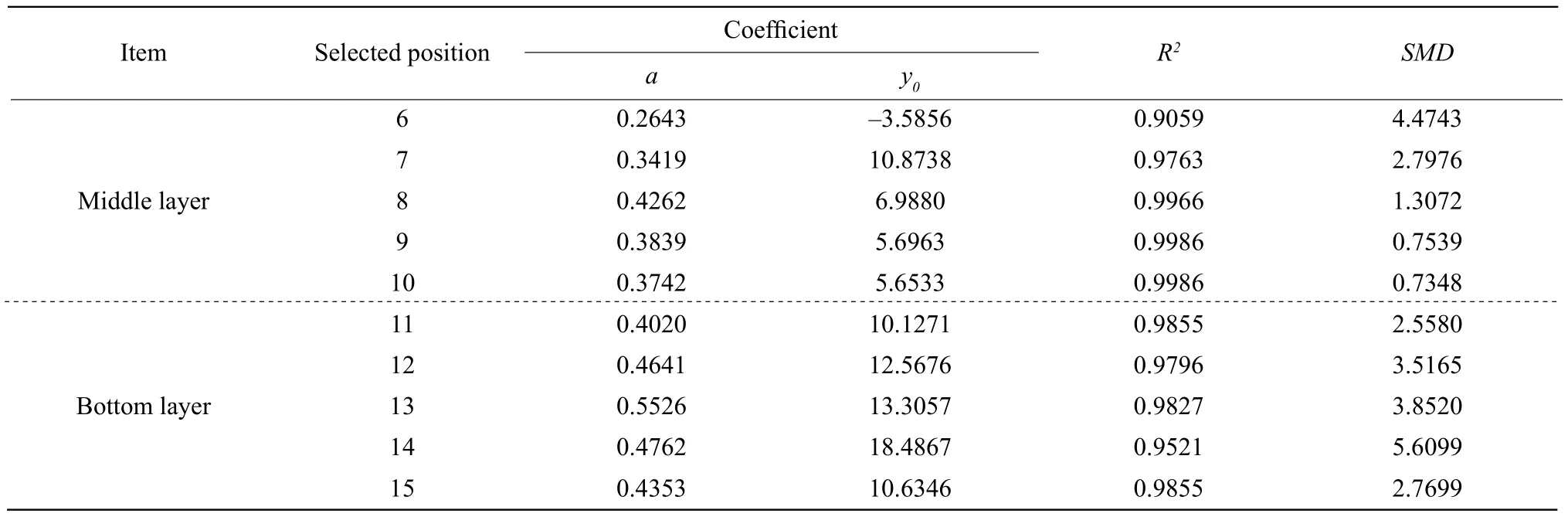

Table 3 showed the statistical analysis results of top, middle and bottom layer of contain loaded instant rice sample at 15 opticalfiber probe positions. Fig. 4 showed the temperature atfive positions of the top layer in the model. The 15 positions of the top, middle and bottom layer in the model were selected as the same as the experimental probe positions. Table 4 showed the statistical analysis results of top, middle and bottom layer of samples in the model at 15 selected positions. And the regression equation of simulation temperature is shown in Eq. (3). To quantitatively evaluate the accuracy of the model, the root mean square error (RMSE) was defined as Eq. (4) (Lin et al., 2017).

Where, Tsiand Teiwere the simulation and experimental temperature (℃) at each position, respectively.

Table 5 showed the values of RMSE between the experimental and simulation results at 15 selected positions. Table 6 showed the interaction between microwave and material during reheating. And the microwave absorption was calculated by coupling electromagneticfield and heat transferfield. Table 7 showed the design and results of the intermittent microwave reheating experiment.

Fig. 3 Temperature atfive opticalfiber probe positions of top layer of rectangular instant rice (17.0 cm×11.5 cm×4.5 cm),during 0-180 s of microwave reheating at 800 W

Table 3 Statistical parameters and values of coefficients specific to Eqn.(3) at 15 opticalfiber probe positions

Fig. 4 Simulation temperature atfive positions of top layer in model during 0-180 s of microwave reheating at 800 W

Table 4 Statistical parameters and values of coefficients specific to Eq. (3) at 15 selected positions

Continued

Table 7 Design and results of intermittent microwave reheating experiment

Discussion

Point 3 indicated the highest temperature, while the lowest temperature was located in point 1 and point 5,when the time was from 0 to 120 s, then turned to point 2 till 180 s. The variation of temperature at point 1 was similar to that at point 5. It indicated that the temperature of each point increased with reheating time at linear relationship.

The data of 15 sampling positions were indicated the temperature distribution of rectangular instant rice samples, in the top layer of the rectangular container,the hot spots occurred at the corners and the cold spots occurred at the midpoint of the length. However, in the middle layer and the bottom layer, the cold spots moved toward the center. It also suggested that the temperature of the corners was higher than that of the width midpoints, followed by the midpoints of length, and the temperature of center points was the lowest. The overheating reason was attributed to the focus effect of microwave irradiation, leading to the formation of high intensity electromagneticfields at the edges and corners of the instant rice (Knoerzer et al., 2017). The location of the cold spots in the center of the middle and bottom layers was due to the depth of penetration. The excessive thickness of the sample resulted in limited penetration of microwave irradiation inside the sample. The irradiation of microwave energy giving rise to a surface heating phenomenon. Therefore, an uneven distribution of electricfield existed in the height direction of the sample,which affected the temperature distribution (Mohammad et al., 2010). In addition, when the height of the sample was much longer than the penetration depth, it resulted in the greater gradient of temperature inside samples(Fan et al., 2012), which in fluenced the uniformity of temperature distribution. COVTof temperature of the whole instant rice was 0.18, the uniformity of the top layer was the best, followed by the bottom layer, while the middle layer was the worst.

In the rectangular container of instant rice, the highest temperature was always located at the bottom layer. It was attributed to two reasons. Firstly, the water contents were transported to the top layer of the instant rice with the increasing temperature, which brought about the heat loss of evaporation, in order to decrease the temperature (Knoerzer et al., 2017).Secondly, the electromagnetic waves caused multiple reflections inside the metal wall of the microwave oven with complex and intense electricfield, which formed between the instant rice and the nearest metal wall (Zhang et al., 2017). It generated the phenomenon of increasing temperature, which arouse from the absorption of more microwaves at the bottom layer. In microwave reheating progress, the area of cold spots gradually clustered to the center of the rectangular instant rice. The uniformity of temperature in microwave reheating was determined according to penetration depth and electricfield distribution (Fan et al., 2012). The microwave energy could not reach the center of the sample interior from the top and sides, due to the uneven distribution of electricfield and the decreasing penetration depth with temperature.

The temperature of point 3 was the highest in the simulation results, and the temperature of point 4 was higher than that of point 2, which was similar to the experimental results. The temperature of simulation results was slightly higher than the experimental results. This was due to the fact that moisture evaporation of sample surface was neglected in the model, and the absorption of microwave energy was consumed for the elevation of temperature.

The agreement between the experimental and simulation temperature was quite reasonable, compared with the previous results (Lin et al., 2017; Chen et al., 2016). And the simulation resulted in the model showed a relatively agreement with the experimental results.

The temperature of edges and corners of the three layers was higher than other regions, and the temperature distribution of simulation tended to be consistent with infrared photos. The area of hot spots was due to the fact that the electricfield at the edges and corners of the layers was superimposed, so that more microwave energy was absorbed by the sample. The microwave was attenuated in the sample, contributed to the non-uniformity of microwave absorption. The microwave absorption of the material directly affected the increase rate of temperature, so the temperature distribution trend was consistent with the microwave absorption. As the temperature increased, the dielectric properties of the instant rice gradually decreased,the capacity of microwave absorption decreased, the absorption amount tended to be stable, and the center area was in the low value area of the microwave volume heat distribution, thus causing the nonuniformity of temperature distribution of the instant rice.

The effects of microwave operations, intermittent ratio and microwave reheating time on the temperature uniformity of instant rice were studied in the intermittent microwave reheating. The average of temperature, temperature uniformity coefficients and average of moisture contents were used as the response indicators.

According to the results, for the index of the average of temperature, the order of the factors was A>C>B, and for the index of the temperature uniformity coefficients, the order of the factors was A=C>B, and for the index of the average of moisture contents, the order of the factors was A>C>B. The microwave operations had the greatest influence on the uniformity of the temperature of the instant rice, followed by the microwave reheating time,and the influence of the intermittent ratio was the smallest. The optimal combination of each factor was determined, according to different level averages of each indicator, for the index of the average of temperature, the optimal combination was A5B5C1, and for the index of the temperature uniformity coefficient,the optimal combination was A1B4C1, and for the index of the average of moisture content, the optimal combination was A1B5C5. The optimization conditions analyzed by the above three indicators were inconsistent, and the optimal process conditions must be determined, based on the influence of factors.Therefore, the optimal combination was A1B5C1,the time of microwave reheating was 180 s, and the intermittent ratio was 1 : 3.

Conclusions

Temperature distribution of instant rice in the rectangular container was non-uniform during microwave reheating with corner overheating phenomenon.The highest temperature was always located at the bottom layer, and the area of cold spots gathered to the center of the sample interior. The predict temperature in the model showed a relatively agreement with the experimental temperature. This study would provide the theoretical basis for further package design of microwave reheating rectangular instant rice. The intermittent microwave reheating process optimal combination was the 180 s of microwave reheating,and the intermittent ratio was 1 : 3, which improved the temperature uniformity of instant rice.

杂志排行

Journal of Northeast Agricultural University(English Edition)的其它文章

- GIS Based Aroma Characteristic for Regional Distribution of Tobacco Using Kriging Interpolation Method Set in Henan Province of China

- Hepatoprotective Effects of Folium syringae Extracts Against Ethanolinduced Acute Liver Injury

- Isolation and Characterization of E. Coli O157 : H7 from Infected Newborn Calves in Northeast China

- Porcine Parvovirus Inducing Autophagy to Benefit Its Replication

- Function of RanGAP1 in Mouse Oocyte Fertilization

- FSH Promoting Proliferation of Calf Sertoli Cells Through Wnt/β-catenin Signaling Pathway with CDC25B Being Involved