Simulation of Air Source Heat Pump with Refrigerant Injection for Heating Operation

2018-11-21,,,

, , ,

1.College of Environmental and Energy Engineering, Beijing University of Technology, Beijing 100124, P.R.China;2.CAS Key Laboratory of Cryogenics, Technical Institute of Physics and Chemistry, Beijing 100190, P.R.China

Abstract: An air source heat pump (ASHP) with refrigerant injection is proposed for the air conditioning system of electric vehicles (EVs), especially for efficient heating in cold winter, when there is no wasted heat of engines. The simulation model is built with the framework of two-phase fluid network, where the compressor is separated as two compressors and the economizer is treated as two heat exchangers in the injection path and the main refrigerant path. With the validated simulation model, the heating performance is analyzed, and the results show that the coefficient of performance (COP) of ASHP with refrigerant injection is higher than 1.4 and the discharge temperature is less than 100 ℃ when the outdoor temperature is -20 ℃. The above performance ensures that the air conditioning system and EVs can operate normally with high efficiency even in the cold winter, which is much helpful for the practicability of EVs.

Key words: heat pump; refrigerant injection; air conditioning; simulation; electric vehicle (EV)

0 Introduction

The main concerns on environmental protection and energy conservations have accelerated the pace to plan and develop electric vehicle (EV) technologies[1]. Automobile exhaust emission is one of the most serious air pollution sources in most Chinese cities[2]. EVs are propelled by an electric motor (or motors) powered with rechargeable battery packs, which have several advantages over traditional cars with internal combustion engines (ICEs), such as significant reduction of urban air pollution, reduced greenhouse gas emissions, energy efficient application with night recharging, and less dependence on oil. Therefore, EV gets speedy development and catches research attentions for significant battery-related challenges: driving range, recharge time, battery cost, bulk and weight, and so on[3]. And, numerous policies have been implemented to develop it[4].

The air-conditioning system plays a very important role for not only providing the comfortable (temperature and humidity condition in car) and safe (defrost and demist) driving conditions, but also influencing the efficiency and working life of electric battery by temperature control[5]. Unlike the traditional car with ICE, the EV cannot possess the wasted heat of the ICE to keep the comfortable environment inside car in the cold winter[6]. Air conditioning system is the most energy consumptive auxiliary equipment, especially in the EVs[7]. If the cooling and heating were provided by the battery packs alone, the driving range will decrease up to 50%[8]. Therefore, it is essential to develop high efficacy air conditioning system, which will promote the industrialization and practicability of EVs[5].

It is a promising way to apply the air source heat pump (ASHP) for heating in winter besides for cooling in summer with sole system, which has been widely applied in residential and commercial buildings[9]. Yang et al.[10]presented an air conditioning system with double-swing compressor in EVs. Lee et al.[11]investigated the steady state and start-up performance of ASHP for heating in EVs. Wang et al.[12]provided experimental characterization of heat pipe battery cooling and heating in EVs. Zou et al.[13]proposed an ASHP coupling with battery cooling for EVs. Zhang et al.[14]investigated an ASHP with returned air utilization and anti-fogging for EVs.

However, as the moving machine, the working conditions of EVs are more serious than that of buildings. A common ASHP cannot be used in the winter of cold regions due to the high compressor discharge temperature, low heating capacity and low coefficient of performance (COP)[15]. Ma et al.[16]proposed the vapor or liquid injection technique to enhance the performance of ASHP system for cold regions. The vapor injection can be released by a flash tank or an economizer, and the later one catches more attentions for easier control[17]. Wang et al.[18]investigated heat pump with vapor injection using R410A as the refrigerant. Roh et al.[19]compared the heating performance of ASHP using R410A vapor injection into accumulator and compressor. Heo et al.[20]optimized the injection cycle of heat pump with a double-expansion sub-cooler. With the vapor injection, a quasi two-stage compression (QTSC) cycle is formed in the scroll compressor, which results in lower discharge temperature, higher heating capacity and higher COP. These advantages become practical in the residential ASHP with the refrigerant of R22 and R410A. The refrigerant injection technologies were applied in heat pump for EVs by Qin et al.[21], Zhou et al.[22]and Zhang et al.[23], which improved the heating capacity and heating efficiency of ASHP for EVs.

By now, the investigations on ASHP for EVs are mainly carried out by experiments, which consume much time and energy. Computer simulation is an efficient way to analyze the performance and optimize the system design for refrigeration systems[24]. Tian et al.[25]built a simulation model for air conditioning system for EVs based on artificial neural network. Shao et al.[26]proposed a simulation model for complex refrigeration systems based on two-phase fluid network, which is used for steady state simulation of different refrigeration systems[27]and dynamic simulation of multi-evaporator air conditioning system[28].

Currently, R134a is the dominant refrigerant in the air conditioner of vehicles. And the outside condition has more serious influence on the performance of air conditioner of cars. However, there is lack of simulation tool for performance analysis and system optimization of ASHP with refrigerant injection for EVs. Therefore, a QTSC ASHP with the economizer and scroll compressor with R134a is proposed in this paper for air conditioning and battery packs temperature control. The simulation model with the two-phase fluid network is built and validated for performance analysis and optimization of QTSC ASHP.

1 ASHP with Refrigerant Injection

1.1 System and cycle analysis

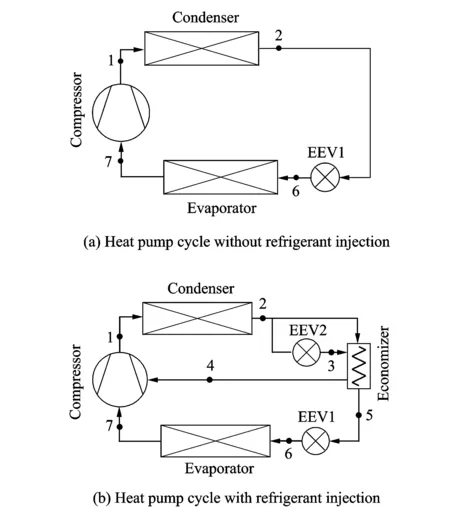

Fig.1 Configuration of air source heat pump cycle in heating mode

Fig.2 Heat pump cycle analysis in P-H diagram

ASHPs without and with the refrigerant injection through the economizer and scroll compressor are shown in Fig.1 for the heating mode. And Fig.2 shows the refrigerant cycle in P-H diagram of the ASHP in one stage compression (without economizer working) and QTSC (with economizer working). When the economizer works, the liquid refrigerant from the condenser is divided into two parts. One part flows through electronic expansion valve (EEV2). Its pressure and temperature decrease and it becomes two-phase fluid, then it flows into the economizer and cools the other part liquid refrigerant which flows into the economizer directly from the condenser. As the result, the former part of refrigerant becomes vapor then is injected into the scroll compressor from the injection hole; the temperature of the later part of refrigerant decreases for larger subcooling degreeTsc, then it passes EEV1 and the evaporator and at last returns to the compressor through the suction hole. Thus, QTSC is formed with one compressor. It can be seen from Fig.2 that under the same condensing pressurePc, evaporating pressurePeand suction temperatureTs, (1) the discharging temperatureTdof compressor decreases for that the injected vapor cools the compression process, (2) the mass flow rate through the compressor and the condenser increases for that the density of the injected vapor is much higher than that of the suction vapor, thus the heating capacity can be increased, and (3) with the increase ofTsc, the enthalpy difference between the inlet and outlet of the evaporator increases, which can improve the performance of the evaporator and the COP of ASHP.

1.2 System configuration

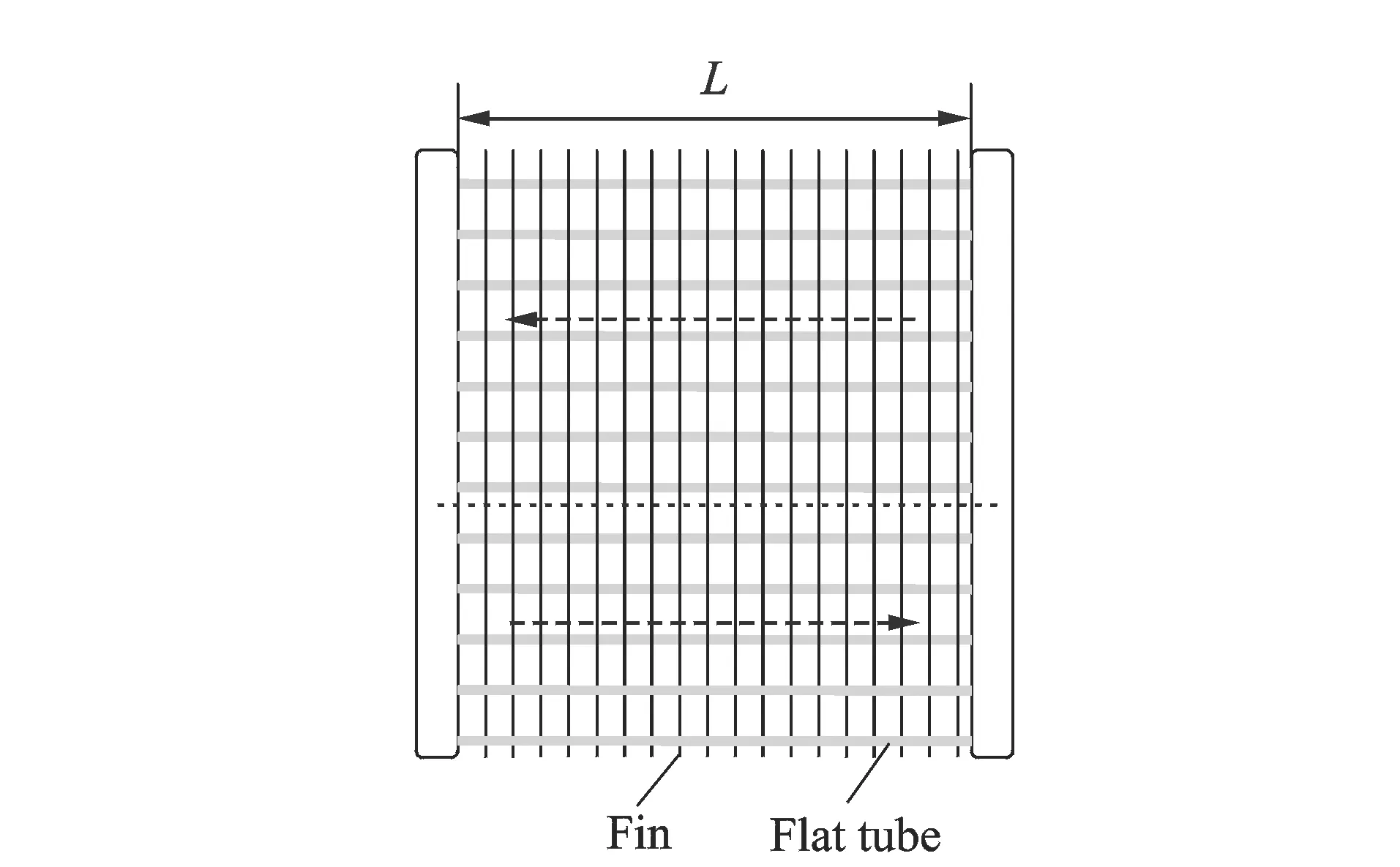

The proposed ASHP with refrigerant injection consists of a variable speed scroll compressor, a parallel flow aluminum flat-tube condenser, a parallel flow aluminum flat-tube evaporator, a double-tube economizer and two EEVs. The flat tube heat exchanger for the condenser and/or the evaporator is shown in Fig.3.

Fig.3 Flat tube heat exchanger for the heat pump

The detailed information of these components is listed in Table 1, and the structure parameters of the condenser and the evaporator are listed in Table 2.

Table 1 Components of ASHP with refrigerant injection

Continued

Table2EvaporatorandcondenserofASHPwithrefrigerantinjection

ParameterCondenserEvaporatorTube length / mm170330Coil height / mm210580Coil width / mm25.420.6Flow path number22Tube width / mm25.420.6Tube height / mm1.31.3Fin height / mm8.18.1Fin thickness / mm0.080.08Fins per inch1818Header outer diameter / mm3226Header thickness / mm2.51.9

2 Numerical Simulation Model

2.1 System model

There are two refrigerant loops in QTSC ASHP with the economizer operating, which cannot be calculated with the traditional heat pump simulation model[24]. There was a specific simulation model proposed with the steady-state system model and dynamic scroll compressor model, by which the high accuracy could be achieved but the simulation was complicated and hard to be applied for other systems[29].

The simulation model for complex refrigeration systems was presented with the framework of two-phase fluid network. In the network the components models,such as the compressor model,the heat exchanger model, the EEV model, the tube model,etc, are embedded in the system models, which leads to convenient application of different types of components model and easy simulation of different systems[26]. This model has been applied for simulations of multi-unit air conditioners, two-stage compression heat pumps and multi-unit heat pump drying system. Moreover, the simulation results can agree with the experimental results well[27].

Therefore, the two-phase fluid network model is applied to the simulation of QTSC ASHP for EVs. The framework is shown in Fig.4, in which the compressor is calculated as an upper stage compressor (Compressor 1) and a lower stage compressor (Compressor 2), and the economizer is also modeled as two economizers (Economizer 1 for main loop and Economizer 2 for injection loop).

There are six nodes (n1—n6), seven branches (b1—b7), and two loops (L1andL2), whose relationship can be described as the node-branch incidence matrixAand the base circuit matrixC, as shown in Eqs.(1) and (2).

Fig.4 Fluid network model of ASHP with refrigerant injection

(1)

where

(2)

where

The pressure and enthalpy are selected as the dominant variables to represent the refrigerant states. This model is calculated with the energy, mass and momentum conservation equations of the nodes, branches and loops with the iterative method, which is independent with the component model. The detailed calculation process of the ASHP with refrigerant injection is referred to the general calculation process of the two-phase fluid network model of refrigeration cycles[26]. The model of the scroll compressor with vapor injection is calculated as two compressors with the graphic model according to the actual working performance data and the isobaric mixing for injection process[30]. The heat exchanger model is calculated with the equations of R134A in small channels[31]. And the EEV is calculated as the orifice[26].

2.2 Model validation

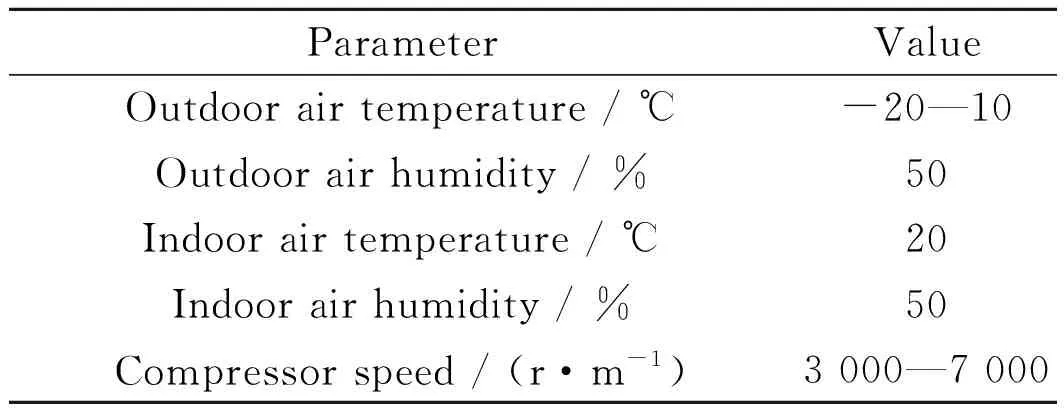

The two-phase fluid network model can give reasonable trends of different refrigeration systems under different working conditions with high accuracy[26-28]. To validate the simulation model, the ASHP with refrigerant injection is tested in the calorimeter with two environmental chambers for the indoor unit and the outdoor unit at the conditions shown in Table 3.

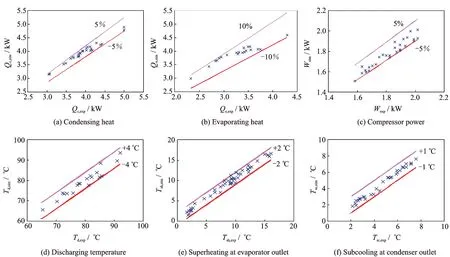

The accuracy of the calorimeter is as follow: Temperature ≤±0.5 ℃, refrigerant pressure ≤±0.1%, heating capacity ≤±5.0%, and power consumption≤±3.0%.In the QTSC ASHP for EVs, the experiments are carried out with the changes of compressor speed, air temperatures and air volumes, opening pulse of EEV1 and EEV2 for several decade cases. And the simulation model can work well to calculate its performance, and the comparison of simulation results with the experiments shows that the simulation model can accurately catch the trends of the performance of ASHP without and with the refrigerant injection. The differences are shown in Fig.5 with the condensing heatQc, the evaporating heatQe, the compressor powerW, the discharging temperature of compressorTd, the superheating degree at the outlet of evaporatorTshandTsc. With such accuracy, the model can be used to analyze the performance of ASHP without and with refrigerant injection for EVs.

Table3TestconditionsofASHPwithrefrigerantinjectionformodelvalidation

ParameterValueOutdoor air temperature / ℃-20—10Outdoor air humidity / %50Indoor air temperature / ℃20Indoor air humidity / %50Compressor speed / (r·m-1)3 000—7 000

3 Results and Discussions

With the validated simulation model, the performance of ASHP is analyzed with and without refrigerant injection under different ambient air temperatures.

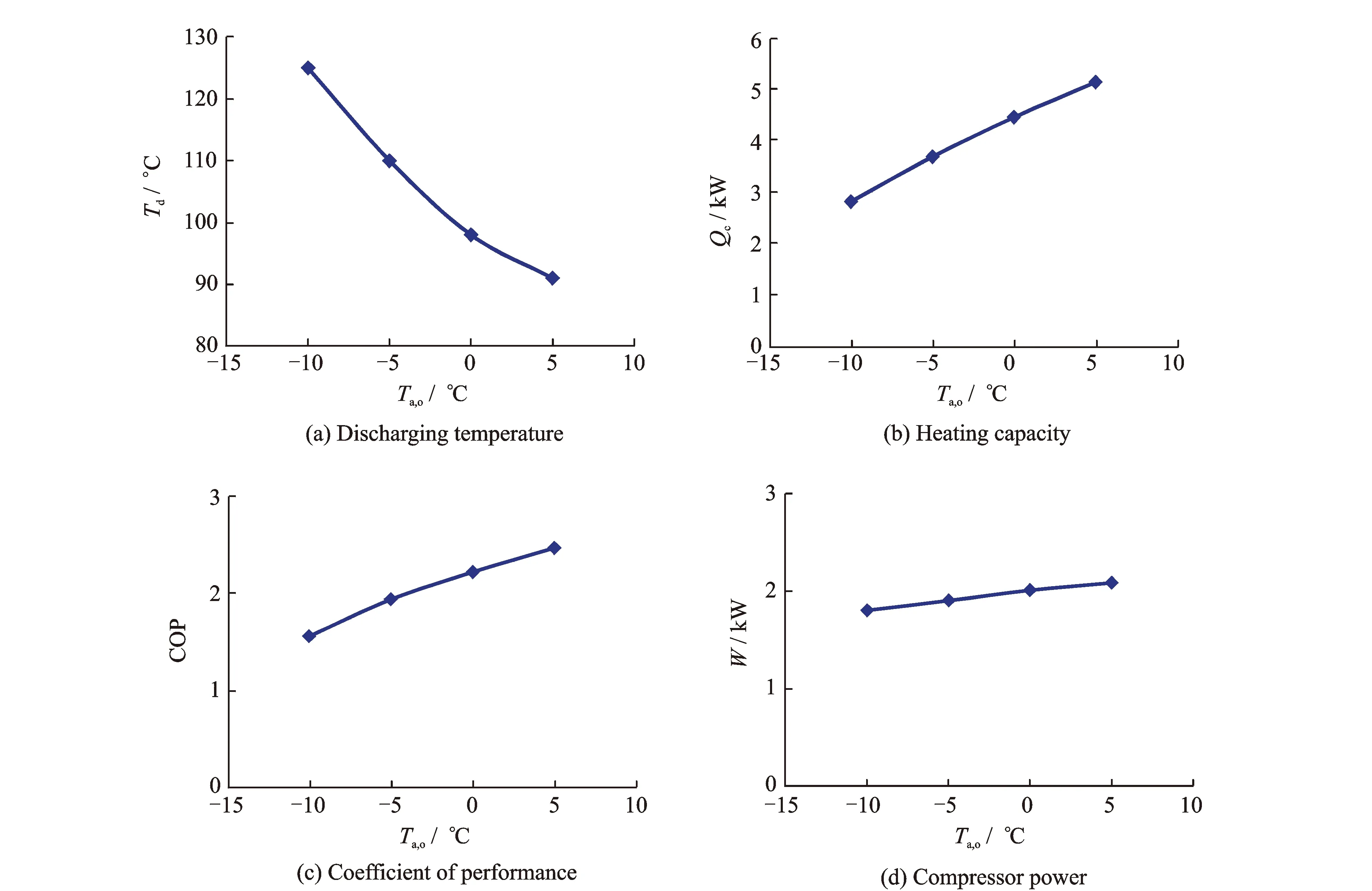

3.1 Performance of ASHP without refrigerant injection

When EEV2 is closed, there is no refrigerant injection, and ASHP works as a common heat pump. Fig.6 shows the calculated performance variation with the change of ambient air temperatureTa. As the decrease of ambient air temperature, the discharging temperature increases. When the air temperature is lower than -10 ℃, the discharge temperature will be higher than 125 ℃, which will result in shutting down the compressor for compressor protection and ASHP cannot provide heating normally. As the decrease of suction pressure, the density of refrigerant decreases, so the mass flow rate decreases, and the heating capacity, compressor power input and COP also decrease. Moreover, the heating capacity decreases from 5.12 kW to 2.81 kW while COP decreases from 2.46 to 1.56 when the outdoor air temperature decreases from 5 ℃ to -10 ℃.

Fig.5 Model validation with experimental data

Fig.6 Performance of ASHP without refrigerant injection

3.2 Performance of ASHP with refrigerant injection

The performance of ASHP with vapor injection is shown in Fig.7 at different ambient air temperatures and different opening ratios of EEV2.

Fig.7 Performance of ASHP with refrigerant injection

Firstly, the refrigerant injection decreases the discharge temperature. As the increase of the opening rate of EEV2, the injected refrigerant rate increases and the refrigerant enthalpy decreases, which achieve better cooling of compressor and make the discharge temperature decrease. Even in -25 ℃ ambient air temperature, the discharge temperature can be controlled lower than 100 ℃, even can be decreased to 60 ℃ or so at high opening rate of EEV2. Therefore, refrigerant injection can make ASHP work normally for heating of EVs at low ambient temperature.

Secondly, the injection mass flow rate increases with increasing the mass flow rate of compressor and condenser, so both the power input and heating capacity increase. Therefore, COP of ASHP with refrigerant injection is higher than 1.4 at -20 ℃ ambient air temperature, which means that the refrigerant inject can make ASHP heating much more efficient than the electric heating by the battery.

Thirdly, the refrigerant injection will increase the COP by improving the compressor condition at beginning. However, if the opening ratio of EEV2 keeps increasing, there is less refrigerant going into the evaporator to take heat from the ambient air. The increase of heating capacity is mainly caused by the increase of compressor power, thus the COP will go down. So, for higher performance of ASHP, the injected refrigerant mass flow rate should be optimized to balance the discharge temperature, heating capacity and COP.

Finally, when the ambient air temperature is about -20 ℃, the evaporating temperature is about -25 ℃ and the saturation pressure of R134a is about 0.1 MPa. Because of the pressure loss of the evaporator and the suction tube, the pressure of refrigerant inside ASHP may be lower than the ambient pressure. If there is some leakage of the system, which is very common in the automobile air conditioner, the air will go into the system and the ASHP cannot work normally. So the ASHP with R134a cannot work at very low ambient air temperature, and it is better to make it work at above -20 ℃. If it is required to work at lower ambient air temperature, it is better to select some other refrigerants.

4 Conclusions

ASHP with refrigerant injection is presented as the air conditioning system of EVs for decreasing the discharge temperature and increasing the heating capacity and COP. A simulation models are built with the framework of two-phase fluid network, in which the components models are embedded. The simulation model is validated with the experiments for high accuracy on predicting the parameters of ASHP, such as the condensing heat, the evaporating heat, the compressor power, the discharging temperature of compressor, the subcooling degree at the outlet of condenser, the superheating degree at the outlet of evaporator, and so on. With the simulation model, the heating performance of ASHP with and without vapor injection is analyzed, and some conclusions can be drawn as follows.

(1) As the decrease of the ambient air temperature, the compressor discharge temperature of ASHP will increase the heating capacity and COP of ASHP will decrease. The increased discharge temperature (i.e. higher than 125 ℃) will cause the protection of the compressor, which makes the ASHP cannot work.

(2) In the QTSC ASHP, the vapor injection can decrease the compressor discharge temperature. With the increase of the injection ratio (injection EEV opening pulse), the discharge temperature can be decreased greatly, and the heating capacity and COP can also be improved. In this case, COP is higher than 1.4 and the discharge temperature is lower than 100 ℃ when the ambient temperature reaches -20 ℃.

(3) If the injection ratio is too high, the economizer cannot secure that all injected refrigerant becomes vapor. If too much liquid refrigerant is injected into the compressor, the compressor will be destroyed.

(4) When the evaporation temperature decreases to -26 ℃ or so, the saturation pressure of R134a is about 0.1 MPa. The refrigerant pressure lower than the ambient pressure is harmful to air leakage into ASHP, which will cause abnormal operations of ASHP for the non-condensable gases and water vapor. ASHP with R134a is better to work at above -20 ℃ ambient temperature and some new refrigerants are needed for lower ambient temperature.

In summary, we proposed and numerically investigated the QTSC ASHP with refrigerant injection technologies. The optimization on such system will be carried out and we will conduct more detailed simulation and experiments in the future work.

Acknowledgements

The work was supported by the National Key Research and Development Program of China (No.2016YFB0601602) and National Natural Science Foundation of China (No.51676199).

杂志排行

Transactions of Nanjing University of Aeronautics and Astronautics的其它文章

- Analysis on Deflection Characteristics of Steel Cable-Stayed Bridge

- Nonlinear Control Method for Hypersonic Vehicle Based on Double Power Reaching Law of Sliding Mode

- Dynamic Analysis and Optimization of Pneumatic Wedge-Shaped Launcher for UAV

- Modal and Fatigue Life Analysis on Beam with Multiple Cracks Subjected to Axial Force

- Random Vibration of Steel Catenary Riser Conveying Fluid Under Wave Excitation

- Two Classes of Quaternary Codes from 4-valued Quadratic Forms