油菜联合收获机分离清选差速圆筒筛设计与试验

2018-08-10万星宇舒彩霞袁佳诚李海同廖庆喜

万星宇,舒彩霞,2,3,徐 阳,袁佳诚,李海同,廖庆喜,2,3

油菜联合收获机分离清选差速圆筒筛设计与试验

万星宇1,舒彩霞1,2,3,徐 阳1,袁佳诚1,李海同1,廖庆喜1,2,3※

(1. 华中农业大学工学院,武汉 430070;2. 南方粮油作物协同创新中心,长沙 410128;3. 农业农村部长江中下游农业装备重点实验室,武汉 430070)

为减少油菜联合收获机旋风分离清选系统负载和提高清选性能,该文设计了一种与旋风分离清选装置配合使用、可对油菜脱出物进行初步筛分的差速圆筒筛。分析计算了筛网与助流装置转速范围,开展了基于EDEM的性能指标正交试验,以筛分损失率与筛下物清洁率为指标,以筛网转速、助流装置转速和助流装置投影面齿数为影响因素,得出了最佳参数组合,并开展了台架及田间验证试验。仿真结果表明:最佳参数组合为筛网转速35 r/min,助流装置转速80 r/min,助流装置投影面锯齿数6个。台架验证试验表明:整机喂入量3 kg/s、脱出物喂入量为1 kg/s条件下,差速圆筒筛与旋风分离清选装置配合使用,清选系统油菜籽粒总损失率为4.83%,其中筛分损失率为3.97%,清洁率为85.7%,风机转速可降低36.9%。田间试验表明:清选系统损失率平均值为5.9 %,籽粒清洁率平均值为84.4%,平均功耗为3.48 kW,差速圆筒筛作业顺畅。该研究可减少旋风分离清选负载,为油菜联合收获机清选系统的结构改进和优化提供参考。

农业机械;设计;试验;油菜;清选;旋风分离;圆筒筛;EDEM

0 引 言

现阶段油菜机械化收获主要有分段收获和联合收获两种方式[1-4],联合收获一次性完成全部作业环节,生产效率高,其中清选系统是油菜联合收获机的关键部件,常用油菜联合收获机多为稻麦收获机改装,清选装置多采用风机与振动筛配合使用,通过增大割台深度、调节拨禾轮位置及传动比、增加主动分禾器、更换筛网等措施以适应田间油菜植株高大、分枝多且相互缠绕、成熟度不一致等因素导致的喂入量波动、油菜脱出物组分糅杂等复杂工况,常用往复式振动筛在处理含水率较高的油菜脱出物时,在无清筛装置的条件下物料运移过程中易出现油菜脱出物堵塞筛网即“糊筛”现象,导致物料透筛率降低,造成籽粒损失增大、清洁率降低等问题,在简化结构、减少损失、降低振动等方面有待优化[5-9]。旋风分离采用气流清选原理,结构相对简单,工作状态相对平稳、噪音低,多应用于粮食加工、工业除尘等领域[10-12],已有学者将旋风分离引入谷物联合收获机中[13-17]。旋风分离清选系统主要利用谷物脱出物各组分悬浮速度差异分离籽粒与杂余[18-20],但油菜脱出物成分复杂,清选负载较大,对油菜脱出物的适应性有待提高,增加初步筛选装置分离脱出物中尺寸较大的粗长杂余是减少旋风分离清选系统负载的解决方法之一。圆筒筛为回转运动筛,工作平稳,在粮食分级、精选等领域应用较为广泛[21-24],在谷物联合收获机中鲜有研究,其原因之一在于圆筒筛主要利用物料机械物理特性差异和离心力分离各物料组分,为增加物料流速以提高作业效率,圆筒筛多为倾斜配置[25-27],但传统机械传动方式安装复杂。本文为解决油菜联合收获机旋风分离清选系统负载较大的问题,设计了一种与旋风分离清选系统配合使用的差速圆筒筛,在圆筒筛内增加物料助流装置以提高作业质量,降低“糊筛”影响,初步筛分油菜脱出物中的粗长杂余,减少旋风分离清选系统的负载,提高旋风分离清选系统对油菜脱出物的适应性。

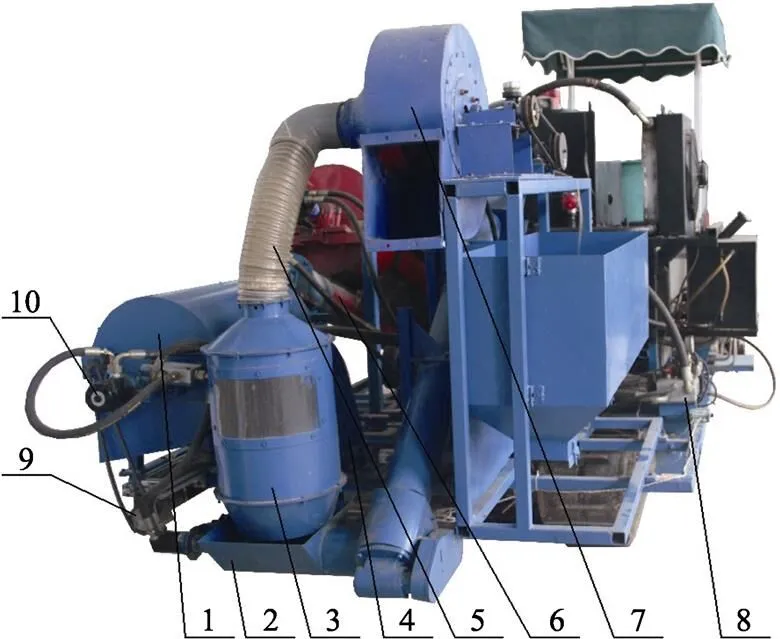

1 油菜联合收获机结构与参数

1.1 基本结构

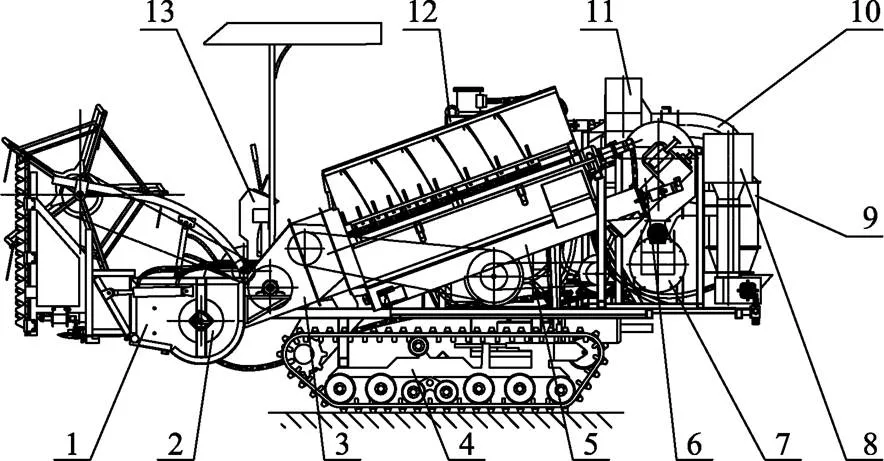

本研究清选系统适应多种油菜联合收获机,基于自制4LYZ-1.8型油菜联合收获机开展研究,其结构如图1所示,主要包括分体组合式割台、集成式纵轴流脱粒分离装置、清选系统等部分。已割油菜在分体组合式割台拨禾轮作用下进入脱粒分离装置,脱粒分离后的油菜脱出物由筛下物输送搅龙提升至后续清选系统中。整机参数如表1所示。

1. 分体组合式割台 2. 复合式推运器 3. 集成式纵轴流脱粒分离装置 4. 底盘 5.筛下物提升搅龙 6. 差速圆筒筛 7. 抛扬机 8. 粮仓 9. 旋风分离筒 10. 吸杂管道 11. 风机 12. 液压油箱 13. 驾驶室

表1 油菜联合收获机主要技术参数

1.2 清选系统工作原理

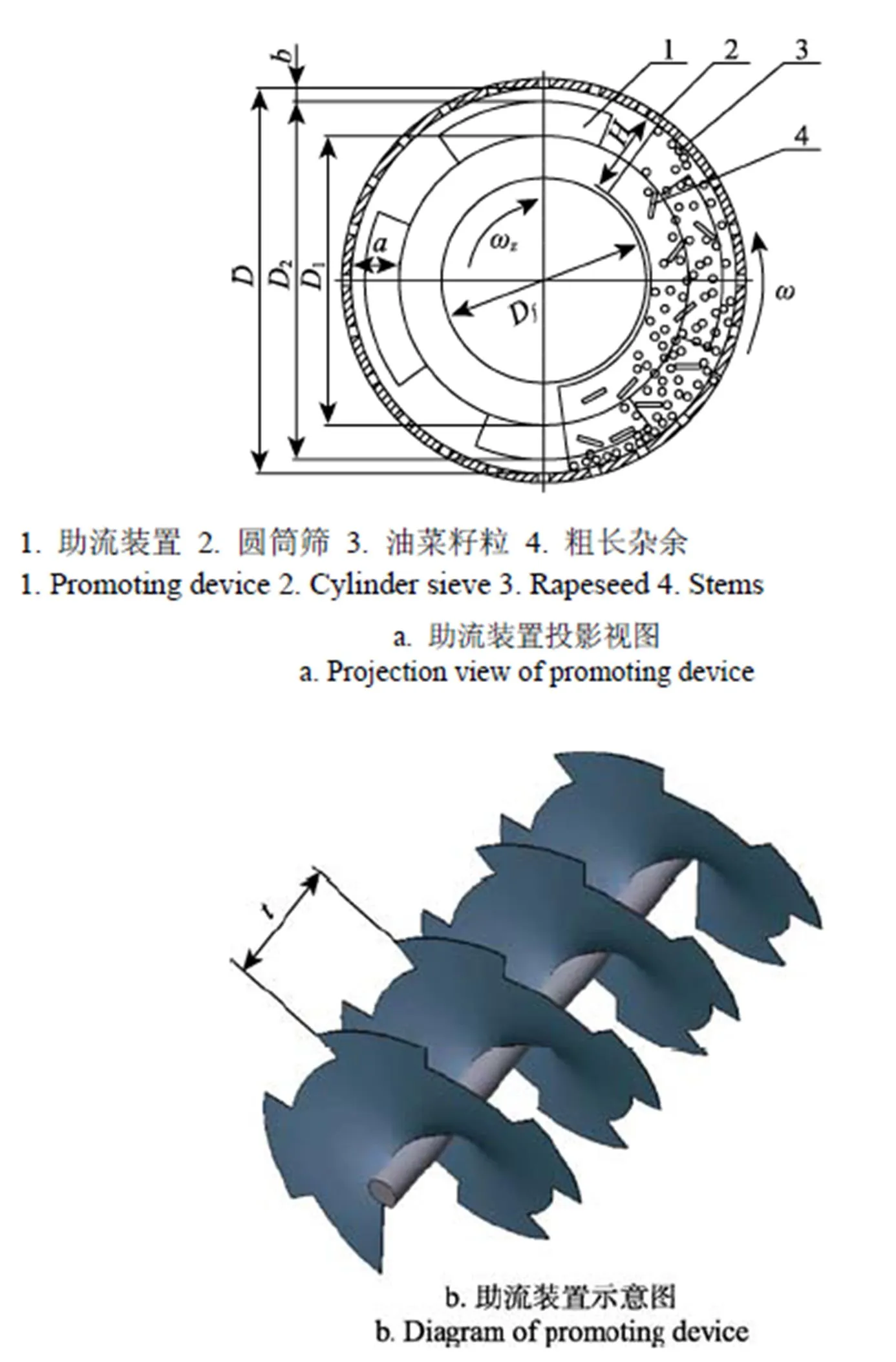

清选系统主要由差速圆筒筛与旋风分离清选装置组成,差速圆筒筛主要包括喂入搅龙、圆筒筛网、筛网内部的助流装置、罩壳等组成,旋风分离清选系统主要包括抛扬机、旋风分离筒、吸杂管道、离心风机、籽粒提升搅龙等。清选系统作业对象为油菜脱出物,主要包括油菜籽粒、粗长杂余(短茎秆及荚壳)及轻杂余。差速圆筒筛主要功能是完成油菜脱出物的初步筛分,喂入搅龙将脱出物喂入圆筒筛网内,筛网与助流装置差速转动、转向相反,助流装置扰动物料并促进物料向排草口移动,粗长杂余被排出机外,透过筛网的油菜籽粒及轻杂余则进入抛扬机,在抛扬机作用下以一定速度进入旋风分离筒,在旋风分离筒内负压气流作用下分离油菜籽粒及轻杂余,轻杂余经由吸杂管道及离心风机排出,油菜籽粒由旋风分离筒出粮口下落进入提升搅龙被提升至粮仓中,完成清选作业,清选系统作业流程如图2所示。

1. 喂料口 2. 罩壳 3. 圆筒筛 4. 助流装置 5.排草口 6. 粗长杂余 7. 抛扬机 8. 旋风分离筒 9. 吸杂管道 10. 离心风机 11. 轻杂余 12. 出粮口 13. 油菜籽粒

2 差速圆筒筛设计

差速圆筒筛作为清选系统的初选装置,其结构如图3所示,主要包括圆筒筛、助流装置、罩壳及传动装置。圆筒筛为平面筛环形弯折定型,助流装置为锯齿形螺旋结构且安装于圆筒筛内部,二者同轴转动;液压马达为助流装置提供动力,通过过渡传动轴齿轮传动将动力传递给圆筒筛,由齿轮传动完成换向功能,实现圆筒筛与助流装置同轴转动、转向相反的差速运动以促进物料流动;助流装置主体为锯齿形螺旋叶片,其轴向投影具有若干均分锯齿,通过转动过程中叶片的高度变化,实现对紧贴筛网物料的间断输送以及对远离筛面物料的连续输送即实现分层输送,增加紧贴筛网处物料的筛分时间,促进远离筛网物料的轴向流动使物料到达前方筛分区域,增加筛分效率。差速圆筒筛筛分效果与筛网有效筛分面积、筛网转速、筛网类型、筛孔布局、助流装置转速等有关。

1. 液压马达 2. 下罩壳 3. 助流装置 4. 过渡传动轴 5. 上罩壳 6. 圆筒筛 7. 喂料口 8. 筛下物出口 9. 排草口

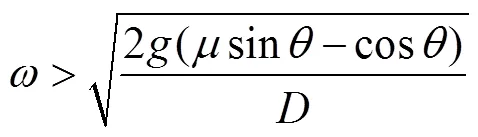

2.1 有效筛分面积与筛网转速

物料进入圆筒筛后在筛面摩擦力作用下沿筛面上升至一定高度,然后在重力作用下下落至筛面底部,为周期性运动,物料运动过程中可接触筛网部分的面积即筛网有效筛分面积,有效筛分面积越大,筛网可承担的物料喂入量越大。有效筛分面积与筛网直径、筛网长度、筛网转速等参数有关。在有效筛分面积内为保证油菜籽粒能及时透过筛网、减少筛分损失,以油菜籽粒为对象分析其在筛网内运动范围最低点与最高点的临界受力状态,如图4所示。

最低平衡点处油菜籽粒受力分析可知:

计算得

1. 圆筒筛 2. 油菜籽粒

1. Cylinder sieve 2. Rapeseed

注:为油菜籽粒质量,g;为平衡状态最低点的油菜籽粒与圆心的连线和垂直中心线之间的夹角,rad;1为最低点处摩擦力,N;为圆筒筛角速度,rad×s-1;为圆筒筛内径,mm;1为最低点处支撑力,N;为油菜籽粒与筛网的摩擦系数,油菜籽粒与筛网摩擦角为15°[28],故tan=0.27;为平衡状态最高点的油菜籽粒与圆心的连线和垂直中心线之间的夹角,rad;2为最高点处摩擦力,N;2为最高点处支撑力,N;为透筛油菜籽粒与圆心的连线和垂直中心线之间的夹角,rad,ϵ[,p-];3为甩出摩擦力,N;3为甩出时筛面支撑力,N;1为有效筛分面积,m2。

Note:is the rapeseed mass, g;is the angle between the lines between rapeseed at lowest point and circle center and the vertical center line in force balance state, rad;1is the friction at the lowest point, N;is the angular velocity of cylinder sieve, rad×s-1;is the internal diameter of cylinder sieve, mm;1is the supporting force at the lowest point, N;is thefriction coefficient between rapeseed and the sieve. The friction anglebetween rapeseed and sieve is 15°[28], sotan=0.27;is the angle between the lines between rapeseed at highest point and circle center and the vertical center line in force balance state, rad;2is friction at the highest point, N;2is the supporting force at highest point, N;is the angle between the lines between rapeseed going through sieve holes and circle center with the vertical center line,ϵ[,p-], rad;3is the friction when the rapeseed goes through sieve holes, N;3is the supporting force when the rapeseed goes through sieve holes, N;1is the effective screening area, m2.

图4 临界位置处油菜籽粒受力分析

Fig.4 Stress analysis of a rapeseed at the critical location

最高平衡点处受力分析可知:

计算得

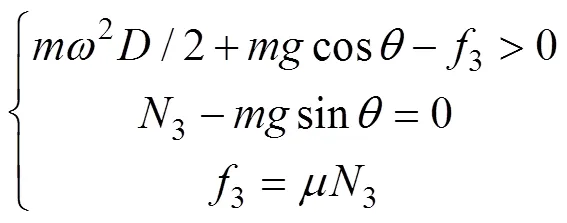

为保证油菜籽粒能够穿过筛孔,油菜籽粒在筛孔内受力应满足

计算得

为防止油菜籽粒由顶部排出,需大于0,取0即油菜籽粒位于筛网垂直方向顶端时,油菜籽粒所受重力需大于离心力使油菜籽粒回落至筛网内部,即

计算得

1为截面内有效筛分弧长,有效筛分面积1满足

式中为筛网长度,mm。由式(9)可知,有效筛分面积与圆筒筛直径、长度与转速有关。

圆筒筛面为平面筛网环形弯折成型,不考虑材料拉伸和压缩,筛孔在平面上的投影为椭圆形,如图5所示。

注:l0为折弯后筛孔最小弧长,mm;d为折弯前平面筛孔直径,mm;i为单个筛孔在折弯后对应的圆弧角,rad;dk为折弯后筛孔投影短轴长,mm。

长轴长度为弯折前筛孔直径,则短轴长度满足:

为保证油菜籽粒顺利透过筛孔,短轴长度需满足:

d>0(11)

式中0为油菜籽粒直径,取2 mm[29]。

根据农业机械设计手册可知,筛网单位面积可承担的脱出物喂入量q为1.5~2.5 kg/(s∙m2),油菜籽粒较小,q可取2.5 kg/(s∙m2)[30],有效筛分面积需满足:

式中Q为脱出物喂入量,割台喂入量为3 kg/s时测得脱出物喂入量为1 kg/s。计算得1≥0.4 m2。

考虑到整机安装空间,取筛网内径=500 mm,代入式(6)与式(8)可得圆筒筛转动角速度范围为:

3.25 rad/s< 6.26 rad/s

转换为转速

31.1 r/min< n<59.8 r/min

由式(2)与式(4)可知:

解得

将=0.27代入解得

+=1.04 rad (15)

计算得1= 0.525 m,则≥0.76 m,设计取整数= 800 mm,实际有效筛分面积1=0.42 m2,筛网总面积=1.256 m2。

由筛孔短轴计算得>3.9 mm,考虑通用性,选择=5 mm。

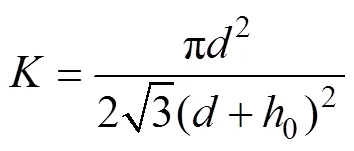

筛网面积一定条件下,筛孔数量与筛孔面积有效系数有关,越大筛孔数越多,常规筛面中正三角形排布筛孔的面积有效系数较大,如图6所示,设筛网孔距为0,为保证筛网整体刚度,取0=3 mm,筛孔按正三角形排布的筛面面积有效系数为:

计算得=0.35。

注:0为筛孔间距,mm。

Note:0is the spacing of the sieve holes, mm.

图6 筛孔排布

Fig.6 Arrangement of sieve holes

设筛面横截面处筛孔数量相等,则筛孔总数量满足

计算得=2.24×104。

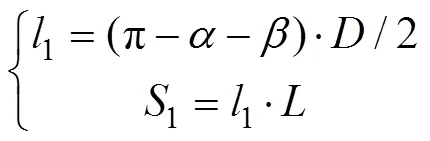

2.2 物料助流装置

物料助流装置为螺旋锯齿形结构,安装在圆筒筛内部,与圆筒筛同轴反向转动,以锯齿齿根圆为分界线,锯齿部分对紧贴筛面的物料进行间断输送,可将油菜脱出物打散,保证筛分时间,锯齿齿根圆以下叶片部分为连续输送,可持续输送远离筛面的物料,紧贴筛网部分与远离筛网部分物料输送速度不同,即实现分层输送,为提高筛面利用率,分层输送设计为均分物料层,结构图与轴向投影视图如图7所示。

注:Df为助流装置叶片内径,mm;D1为锯齿叶片齿根圆直径,mm;D2为齿顶圆直径,mm;a为连续叶片外圆与筛网间隙,mm;b为锯齿齿顶与筛网间隙,mm;H为物料流动层高度,mm;ωz为助流装置角速度,rad×s-1;t为叶片螺距,mm。

为保证脱出物充分的筛分时间,物料轴向运动速度不宜太快,设物料轴向平均输送速度v=0.25 m/s[27],则单位时间内物料流动层高度满足:

式中0为脱出物密度,取粗长茎秆密度80 kg/m3计算,计算得=119 mm,取120 mm。

助流装置叶片内径即叶片中心轴直径满足:

计算得D<260 mm,在叶片外径一定情况下,叶片内径越小,叶片高度即叶片作用面积越大,针对喂入量波动现象,宜取较小的叶片内径以增强助流装置对物料喂入量适应性和对物料的促流作用,同时考虑实际加工对管料的通用性,取D=50 mm。

为实现分层输送,连续叶片外圆直径保证均分物料层,物料层厚度由式(18)计算为120 mm,则1380 mm,连续叶片外圆与筛网间隙为=(–1)/2= 60 mm,叶片与筛网之间的间隙一般为5~10 mm[30],油菜籽粒易破损,为减少对油菜籽粒的碾压,筛网间隙可取较大值,故锯齿齿顶与筛网间隙取=10 mm,则齿顶圆直径2480 mm。

助流装置输送能力需要大于粗长杂余的喂入量[18],锯齿形叶片按照螺旋叶片输送能力计算需大于脱出物喂入量,同时为减少油菜籽粒筛分损失,助流装置叶片锯齿底径以下部分的连续螺旋输送量需小于油菜脱出物喂入量:

式中1为助流装置模拟螺旋叶片连续输送的输送量,kg/s;2为助流装置锯齿以下部分螺旋叶片连续输送的输送量,kg/s;为充满系数,取0.3[30];为叶片螺距,考虑叶片通用性,取螺旋输送常用螺距200 mm[30];为助流装置转速,r/min;为物料密度,取80 kg/m3[30];为倾斜输送系数,水平输送取1[30]。计算得:

76.2 r/min≤≤244.6 r/min

锯齿按圆周均匀分布,其数量z与锯齿间隙角满足:

锯齿数量过少会降低助流装置输送能力,过多则会增加油菜籽粒筛分损失,以助流装置投影面锯齿数为因素,后续取投影面均按锯齿数为2、4、6三个水平开展相关试验。

3 基于EDEM的性能仿真试验

清选系统作业对象包括油菜籽粒、粗长杂余(短茎秆及荚壳)及轻杂余,测量脱粒分离装置筛下物成分可知,割台喂入量为3 kg/s时,脱粒分离装置脱出物输出量为1 kg/s,油菜脱出物中油菜籽粒、粗长杂余及轻杂余质量之比为1∶1.5∶0.5。

差速圆筒筛作为清选系统的关键部件,其性能直接影响籽粒清洁率与损失率,因此,采用EDEM建立差速圆筒筛的仿真模型,以油菜脱出物成分含量最高的油菜籽粒、粗长杂余及轻杂余为研究对象,开展正交试验分析运行参数与结构参数变化对差速圆筒筛筛下物油菜籽粒清洁率与排草口筛分损失率的影响,得出最佳参数组合。

3.1 仿真参数设置

3.1.1 变量参数设置

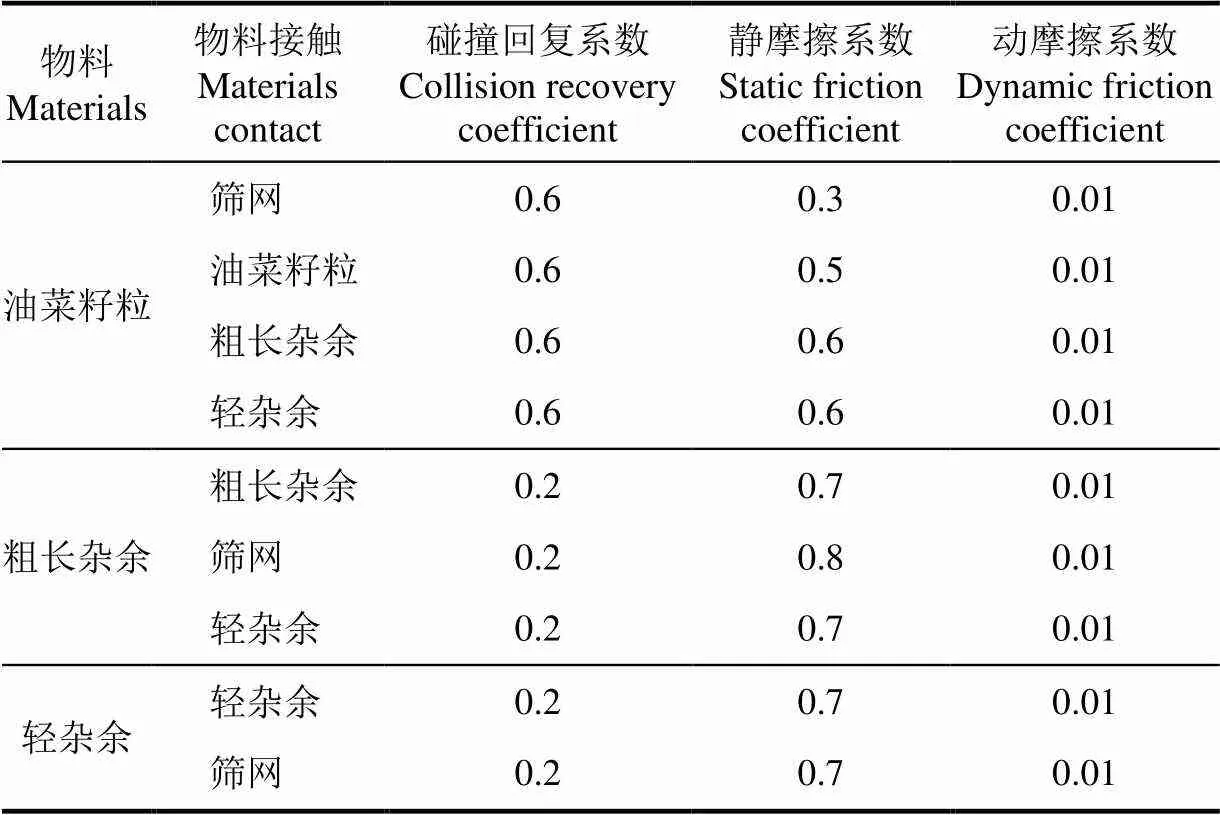

差速圆筒筛筛分过程的实质是通过筛面及助流装置与颗粒之间以及颗粒与颗粒之间的接触、碰撞促使颗粒运动、透筛。为描述碰撞过程,本文采用Hert-Mindlin无滑移模型。各物料颗粒的力学特性参数及和其他物体的接触系数[19]设置见表2和表3。

表2 物料力学参数

表3 接触系数

3.1.2 颗粒模型

为保证差速圆筒筛作业过程的真实模拟,参照相关文献及对油菜脱出物中油菜籽粒、粗长杂余及轻杂余相关参数测定,建立颗粒模型,如图8所示,其中油菜籽粒为球形,直径2 mm;粗长杂余为长圆柱形,外径8 mm,长度60 mm[31];轻杂余为长方体,选取油菜脱出物中轻杂余,主要为破碎荚壳薄片,外形近似为长方体,开展三轴尺寸测量取平均值并取整,仿真中取长4 mm,宽 3 mm,高1 mm。

图8 颗粒模型

3.1.3 差速圆筒筛仿真模型

利用Pro/E软件在合理简化、保留主要工作部件的基础上,按照理论计算得出的结构参数1:1建模,对差速圆筒筛进行三维建模,主要包括罩壳、圆筒筛、助流装置等部件,如图9所示。颗粒工厂位于模型喂料口内,按照脱出物总质量及各成分比例设定油菜籽粒、粗长杂余和轻杂余生成总质量分别为0.3、0.45和0.15 kg,各颗粒同时产生,产生方式均为动态,颗粒产生时间为1 s,时间步长设定为Rayleigh时间步长的20%,即10–5s,数据记录间隔0.01 s,为保证颗粒完整输送,将圆筒筛与助流装置运动模拟时间总长设为10 s。

1. 喂料口 2. 罩壳 3. 助流装置 4. 圆筒筛 5. 排草口 6. 出粮口

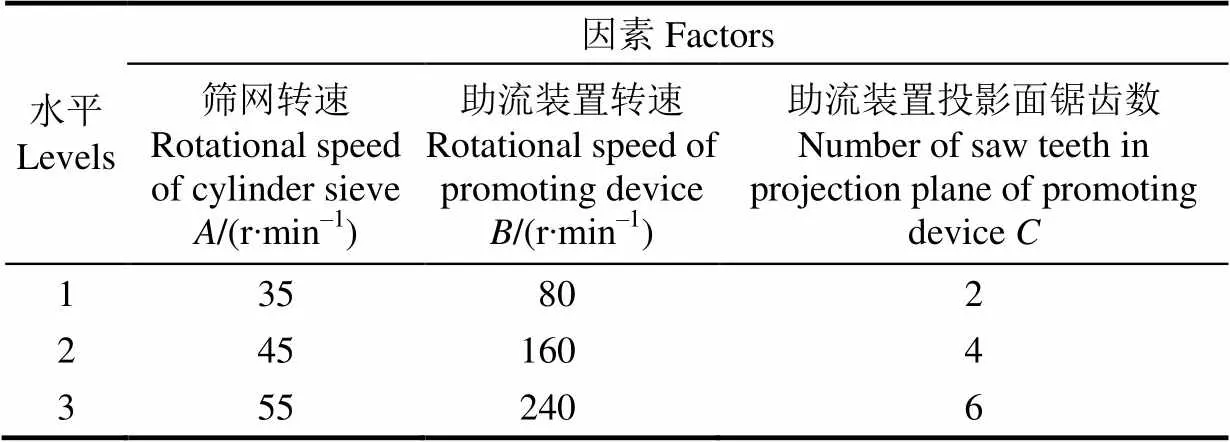

3.2 正交试验

上文理论分析已确定筛网类型、筛孔排列、筛网内径、筛面长度等结构参数,对筛网转速、助流装置转速等运行参数范围进行了分析,故仿真过程中以助流装置转速、筛网转速及助流装置投影面锯齿数为影响因素,以差速圆筒筛出粮口油菜籽粒清洁率与排草口筛分损失率为评价指标,开展三因素三水平正交试验,因素水平如表4所示。仿真结束后统计排草口与出粮口物料总质量与油菜籽粒总质量,计算清洁率与损失率:

式中Y为油菜籽粒清洁率,%;1为出粮口油菜籽粒质量,kg;0为出粮口物料总质量,kg;Y为筛分损失率,%;2为排草口油菜籽粒质量,kg。

表4 因素水平

正交试验设计及试验结果如表5所示,采用综合评分法分析[13],实际生产中需优先保证损失率低,其次保证清洁率高,拟定清洁率权重为0.35,损失率权重为0.65,以加权后的综合分作为评价标准,得分越高效果越好。

综合分=清洁率隶属度´0.35–损失率隶属度´0.65 (23)

正交试验仿真结果表明:最佳参数组合为助流装置转速80 r/min,圆筒筛转速35 r/min及助流装置投影面锯齿数为6个,影响差速圆筒筛效果的因素主次为助流装置转速、筛网转速及助流装置投影面锯齿数;最佳参数组合条件下,仿真得出差速圆筒筛筛分损失率为2.54%,清洁率为83.58%,差速圆筒筛中筛网转速过高时,物料在离心力作用下紧贴筛面,导致糊筛,减少油菜籽粒透筛概率,造成筛分损失率增大;助流装置转速较高则促进物料流动能力提高,物料输送过快,油菜籽粒来不及透过筛网亦会造成筛分损失率提高;同理,若助流装置投影面齿数过少,对物料流动的促进作用也会增强,导致筛分损失率增加,符合圆筒筛相关研究结果[27]。差速圆筒筛筛网转速需在满足透筛率要求的前提下采用较低转速,助流装置需在满足物流输送能力条件下采用较低转速及较多锯齿数。

表5 正交试验结果

4 台架及田间试验

4.1 台架试验

为验证差速圆筒筛效果,依据仿真结果试制差速圆筒筛,与旋风分离清选系统配合使用开展台架试验,试验台主要由差速圆筒筛、抛扬机、旋风分离筒、离心风机、吸杂管道、粮仓、支架及配套液压传动系统组成,如图10所示。差速圆筒筛中筛网由电机带动,助流装置由液压系统驱动,转速转向均可调。试验物料为油菜脱出物,油菜品种为华油杂62,油菜脱出物主要包括油菜籽粒、轻杂余及粗长杂余,粗长杂余包括短茎秆及荚壳(长度在20 mm以上),籽粒千粒质量为4.2 g,油菜籽粒、粗长杂余及轻杂余按质量比1∶1.5∶0.5混合均匀。

台架试验拟开展功能性验证与对照试验,功能性验证差速圆筒筛与旋风分离清选组合的清选形式的可行性,对照试验为对比差速圆筒筛与旋风分离清选组合作业和旋风分离清选单独作业效果,分析增加差速圆筒筛以减少旋风分离清选负载;对照验证中设置差速圆筒筛与旋风分离组合作业工况为试验组,为先筛分后风选的清选形式;仅旋风分离清选装置工作为对照组,为风选清选形式;2组试验在清选效果即清洁率稳定在85%~90%,损失率稳定在5%~6%范围内时,以离心风机转速表征旋风分离清选装置负载并作为对照试验评价指标。

1. 差速圆筒筛 2. 籽粒提升搅龙 3. 旋风分离筒 4. 抛扬机 5. 吸杂管道 6. 筛下物提升搅龙 7. 风机 8. 调速装置 9. 电机 10. 液压马达

功能性验证试验时将物料由筛下物提升搅龙喂入,差速圆筒筛与旋风分离清选装置配合使用,以仿真结果最佳参数组合启动清选系统,收集差速圆筒筛排草口、旋风分离筒出粮口及离心风机出口处物料并称质量,筛分其中油菜籽粒并称质量,计算油菜籽粒总损失率与清洁率分别为4.83%与85.7%,其中排草口处筛分损失率为3.97%。

对照试验组按最佳参数组合设定差速圆筒筛相关参数,仅调节风机转速,采用功能性验证试验的取样方法多次试验直至清洁率、损失率与对照组范围相同后,记录离心风机转速。对照试验结果表明:在相同清洁率与油菜籽粒总损失率范围内,旋风分离清选系统风机转速可由无差速圆筒筛前的2 300 r/min降至1 450 r/min,转速降低36.9%,有效减少旋风分离清选负载。

4.2 田间试验

2017年5月于华中农业大学试验田开展田间试验,如图11所示。试验对象为机直播华油杂62号油菜,平均种植密度为40株/m2,油菜籽粒、茎秆及荚壳含水率分别为23.47%、20.9% 和33.98%。试验选取株高、密度等植株性状一致性较好的区域进行田间试验,在选定试验区内划分5个10 m的满割幅区域作为测试区,机具在测试区内满割幅作业,每次试验前清理差速圆筒筛、抛扬机、粮仓内物料,单次试验保证割茬高度一致,试验过程中保持工况不变,前进速度2.9~3.6 km/h,作业效率为0.52~0.65 hm2/h。每次试验后收集差速圆筒筛排草口、旋风分离筒出粮口、风机出口处物料并称质量,筛分并称量出各自出口物料内的油菜籽粒质量,计算得出差速圆筒筛筛分损失率、出粮口油菜籽粒清洁率和风机损失率,记录清选系统液压管路油压与流量,计算清选系统功耗。因油菜成熟度不一致,田间沟壑较多、行走速度不稳定等因素导致整机喂入量波动,清选系统损失率平均值为5.9%,油菜籽粒清洁率平均值为84.4%,清选系统平均功耗为3.48 kW,差速圆筒筛作业顺畅。

图11 清选系统田间试验

5 结 论

1)设计了一种与旋风分离清选系统配合使用的差速圆筒筛,对油菜脱出物进行初步筛分,可有效减少油菜联合收获机旋风分离清选系统负载并提高清选性能,满足油菜联合收获清选需要。

2)基于EDEM仿真正交试验结果表明:影响差速圆筒筛筛分效果的因素主次为助流装置转速、筛网转速和助流装置投影面锯齿数,最佳参数组合为助流装置转速80 r/min、筛网转速35 r/min及助流装置投影面锯齿数6个。

3)台架及田间验证试验结果表明:在最佳参数组合条件下,差速圆筒筛与旋风分离清选系统配合使用时系统籽粒总损失率与清洁率分别为4.83%与85.7%,离心风机转速可降低36.9%,减少旋风分离负载;田间试验表明清选系统籽粒总损失率平均值为5.9%,油菜籽粒清洁率平均值为84.4%,清选系统平均功耗为3.48 kW,差速圆筒筛作业顺畅。

差速圆筒筛助流装置输送物料过程中对物料的喂入量波动的适应性有待进一步探讨。

[1] 吴崇友,肖圣元,金梅. 油菜联合收获与分段收获效果比较[J]. 农业工程学报,2014,30(17):10-16.Wu Chongyou, Xiao Shengyuan, Jin Mei. Comparation on rape combine harvesting and two-stage harvesting[J]. Transactionsof the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2014, 30(17): 10-16. (in Chinese with English abstract)

[2] 刘德军,赵秀荣,高连兴,等. 不同收获方式含水率对油菜收获物流损失的影响[J]. 农业工程学报,2011,27(10): 339-342. Liu Dejun, Zhao Xiurong, Gao Lianxing, et al. Effect of moisture content on rape harvest logistics losses under different harvest methods[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(10): 339-342. (in Chinese with English abstract)

[3] 左青松,黄海东,曹石,等. 不同收获时期对油菜机械收获损失率及籽粒品质的影响[J]. 作物学报,2014,40(4):650-656. Zuo Qingsong, Huang Haidong, Cao Shi,et al. Effects of harvesting date on yield loss percentage of mechanical harvest and seed quality in rapeseed[J]. Acta Agronomica Sinica, 2014, 40(4): 650−656. (in Chinese with English abstract)

[4] 黄小毛,宗望远. 油菜联合收获的研究现状及发展趋势[J]. 农业工程,2012,2(1):14-19. Huang Xiaomao, Zong Wangyuan. Research status and development trend of rape combine harvester[J]. Agricultural Engineering, 2012, 2(1): 14-19. (in Chinese with English abstract)

[5] 罗海峰,汤楚宙,官春云,等. 适应机械化收获的田间油菜植株特性研究[J]. 农业工程学报,2010,26(13): 61-66. Luo Haifeng, Tang Chuzhou, Guan Chunyun, et al. Plant characteristic research on field rape based on mechanized harvesting adaptability[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2010, 26(13): 61-66. (in Chinese with English abstract)

[6] 王刚,关卓怀,沐森林,等. 油菜联合收获机种子籽粒脱粒装置结构及运行参数优化[J]. 农业工程学报,2017,33(24):52-57. Wang Gang, Guan Zhuohuai, Mu Senlin, et al. Optimization of operating parameter and structure for seed thresher device for rape combine harvester[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(24): 52-57. (in Chinese with English abstract)

[7] 徐立章,李耀明,马朝兴,等. 4LYB1-2.0型油菜联合收获机主要部件的设计[J]. 农业机械学报,2008,39(8):54-57.Xu Lizhang, Li Yaoming, Ma Chaoxing, et al. Design of main working parts of 4LYB1 -2.0 rape combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2008, 39(8): 54-57. (in Chinese with English abstract)

[8] 高志朋,徐立章,李耀明,等. 履带式稻麦联合收获机田间收获工况下振动测试与分析[J]. 农业工程学报,2017,33(20):48-55. Gao Zhipeng, Xu Lizhang, Li Yaoming, et al. Vibration measure and analysis of crawler-type rice and wheat combine harvester in field harvesting condition[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(20): 48-55. (in Chinese with English abstract)

[9] 李耀明,王智华,徐立章,等. 油菜脱出物振动筛分运动分析及试验研究[J]. 农业工程学报,2007,23(9):111-114. Li Yaoming, Wang Zhihua, Xu Lizhang, et al. Motion analysis and experimental research of rape extractions on vibration sieve[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2007, 23(9): 111-114. (in Chinese with English abstract)

[10] 黄炎,赵满全. 基于数值模拟与风洞试验的旋风分离式集沙仪优化设计[J]. 农业工程学报,2015,31(16):50-56. Huang Yan, Zhao Manquan. Optimization design of performance test of cyclone separator sand sampler based on numerical simulation and wind erosion tunnel experiment[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(16): 50-56. (in Chinese with English abstract)

[11] 董玉平,董磊,强宁,等. 旋风分离器内生物质焦油湍流特性的数值模拟[J]. 农业工程学报,2010,26(9):171-175.Dong Yuping, Dong Lei, Qiang Ning, et al. Numerical simulation of biomass gas and tar torrential flow characteristics in cyclone separator[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2010, 26(9): 171-175. (in Chinese with English abstract)

[12] Elsayed K, Lacor C. Optimization of the cyclone separator geometry for minimum pressure drop using mathematical models and CFD simulations[J]. Chemical Engineering Science, 2010(65): 6048-6058.

[13] 廖庆喜,万星宇,李海同,等. 油菜联合收获机旋风分离清选系统设计与试验[J]. 农业工程学报,2015,31(14):24-31. Liao Qingxi, Wan Xingyu, Li Haitong, et al .Design and experiment on cyclone separating cleaning system for rape combine harvester[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(14): 24-31. (in Chinese with English abstract)

[14] 任述光,谢方平,王修善,等. 4LZ-0.8型水稻联合收割机清选装置气固两相分离作业机理[J]. 农业工程学报,2015,31(12):16-22. Ren Shuguang, Xie Fangping, Wang Xiushan, et al. Gas- solid two-phase separation operation mechanism for 4LZ-0.8 rice combine harvester cleaning device[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2015, 31(12): 16-22. (in Chinese with English abstract)

[15] 伊文静,刘师多,师清翔,等. 旋风分离清选系统结构及工况对清选性能的影响[J]. 农机化研究,2013,35(5): 170-174. Yi Wenjing, Liu Shiduo, Shi Qingxiang, et al. Influence of cleaning system and working condition[J]. Journal of Agricultural Mechanization Research, 2013, 35(5): 170-174. (in Chinese with English abstract)

[16] 倪长安,张利娟,刘师多,等. 无导向片旋风分离清选系统的试验分析[J]. 农业工程学报,2008,24(8):135-138. Ni Chang’an, Zhang Lijuan, Liu Shiduo, et al. Experimental analysis on cyclone separating cleaning system of no-guide vanes[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2008, 24(8): 135-138. (in Chinese with English abstract)

[17] 师清翔,马萌,闫卫红,等. 双扬谷器旋风分离清选系统试验与参数优化[J]. 农业机械学报,2014,45(11):124-128. Shi Qingxiang, Ma Meng, Yan Weihong, et al. Two-stage winnower cyclone separating cleaning system performance testing and optimization[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(11): 124-128. (in Chinese with English abstract)

[18] 马征,李耀明,徐立章. 油菜脱出物漂浮速度及摩擦与浸润特性的测定与分析[J]. 农业工程学报,2011,27(9): 13-17. Ma Zheng, Li Yaoming, Xu Lizhang. Testing and analysis on rape excursion components characteristics in floating, friction and wettability[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2011, 27(9): 13-17. (in Chinese with English abstract)

[19] 陈立,廖庆喜,宗望远,等. 油菜联合收获机脱出物空气动力学特性测定[J]. 农业机械学报,2012,43(增刊1): 125-130. Chen Li, Liao Qingxi, Zong Wangyuan, et al. Aerodynamic Characteristics Measurement of Extraction Components for Rape Combine Harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2012, 43(Supp. 1): 125-130. (in Chinese with English abstract)

[20] 陈翠英,王志华,李青林. 油菜脱出物在气流中的运动分析[J]. 农业机械学报,2004,35(5):90-93.

Chen Cuiying, Wang Zhihua, Li Qinglin. Analysis of aerodynamic properties of rape extractions [J]. Transactions of the Chinese Society for Agricultural Machinery, 2004, 35(5): 90-93. (in Chinese with English abstract)

[21] 胡良龙,田立佳,王海鸥,等. 5XY-5型种子圆筒筛分级设备的研制[J]. 农机化研究,2007(2): 90-92, 96. Hu Lianglong, Tian Lijia, Wang Haiou, et al. Design of 5XY-5 cylinder screen grader. Journal of Agricultural Mechanization Research, 2007(2): 90-92, 96. (in Chinese with English abstract)

[22] 汪正保,鲍昌华,龚为. 一种新型圆筒筛分装置的设计研究[J]. 机电产品开发与创新,2012,25(3):58-59. Wang Zhengbao, Bao Changhua, Gong Wei. Research on the design of new type rotary sieve[J]. Development & Innovation of Machinery & Electrical Products, 2012, 25(3): 58-59. (in Chinese with English abstract)

[23] 宋井玲. 圆筒筛式玉米种子分级机的设计[J]. 农机化研究,2007(1):146-147. Song Jingling. Design of the cylinder screen seed corn grader. Journal of Agricultural Mechanization Research,2007(1): 146-147. (in Chinese with English abstract)

[24] 闸建文,何芳,汪裕安. 一种新型圆筒筛的性能分析[J].农业机械学报,1996,27(3):67-70.

[25] 杨冬生. 圆筒筛筛选焦粒的设计及应用[J]. 煤矿机械,2007,28(2):170-172. Yang Dongsheng. Design and application of cylindric screen [J]. Coal Mine Machinery, 2007, 28(2): 170-172. (in Chinese with English abstract)

[26] 尹健,黄年月,吴兵,等. 微型水稻联合收割机新型圆筒筛设计研究[J]. 现代机械,2011(3):62-64, 72.

[27] 连政国,张岩,姜学东. 栅条圆筒筛内物料轴向运动分析[J]. 莱阳农学院学报,1996,13(2):72-76. Lian Zhengguo, Zhang Yan, Jiang Xuedong. Analysis on materials’axial movement in the grid cylindrical screen. Journal of Laiyang Agricultural College, 1996, 13(2): 72-76. (in Chinese with English abstract)

[28] 李海同,廖庆喜,李平,等. 油菜联合收获机分体组合式割台的设计[J]. 华中农业大学学报,2014,33(5):111-116. Li Haitong, Liao Qingxi, Li Ping, et al. Design on separating- combined header of rape combine harvester[J]. Journal of Huazhong Agricultural University, 2014, 33(5): 111-116. (in Chinese with English abstract)

[29] 雷小龙,廖宜涛,王磊,等. 油麦兼用型气送式集排器增压管气固两相流仿真与参数优化[J]. 农业工程学报,2017,33(19):67-75. Lei Xiaolong, Liao Yitao, Wang Lei, et al. Simulation of gas-solid two-phase flow and parameter optimization of pressurized tube of air-assisted centralized metering device for rapeseed and wheat[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(19): 67-75. (in Chinese with English abstract)

[30] 中国农业机械化科学研究院. 农业机械设计手册下册[M]. 北京:中国农业科学技术出版社,2007.

[31] 吴崇友. 油菜机械化收获技术[M]. 镇江:江苏大学出版社,2017.

Design and experiment on cylinder sieve with different rotational speed in cleaning system for rape combine harvesters

Wan Xingyu1, Shu Caixia1,2,3, Xu Yang1, Yuan Jiacheng1, Li Haitong1, Liao Qingxi1,2,3※

(1.430070,; 2.410128,; 3.430070,)

Combine harvesters and windrowers were conventional machines for rape harvesting. Rape combine harvesters could simultaneously complete cutting, threshing, separation and cleaning at high production efficiencies. Cleaning systems played an important role in rape combine harvesters. The conventional rape combine harvesters were modified based on grain combine harvesters. The majority of cleaning system of combine harvesters was vibrating screen working with fan. Some changes like increasing the depth of header, adjusting reel position and transmission ratio, increasing active divider and so on were made to adapt to the rape plant in the field and there were still some problems like blocking of screen and the structure remained to be optimized. In conclusion, there were some problems like excessive vibration and relatively complicated structures due to vibration sieves in traditional combine harvesters. Cyclone separation was based on the principle of airflow cleaning. It was widely applied to grain processing, industrial dust removal and other fields. It could be used in rape combine harvesters taking the advantages of simple structures. However, short stems and pods made it hard for cyclone separation cleaning system to make the seeds clean. Adding a cylinder sieve was a solution to reduce the burden of cyclone separation cleaning system. The main limitation of the development of cylinder sieve was its relatively low efficiency. To reduce the burden of cyclone separation cleaning system and improve the efficiency of preliminary screening, a kind of cylinder sieve with promoting device in different rotational speed for rape combine harvesters based on EDEM was designed and relative experiments were carried out. As the primary process to separate the stems for the cleaning system, the cylinder sieve with promoting device in different rotational speed was mainly consist of the cylinder sieve, promoting device, the cover shell and the transmission device. The sieve was bent and shaped based on annular plane screen. The promoting device was mounted inside the cylinder sieve. Both of them were rotating around the same center axis. The hydraulic motor to provide power to the promoting device and to the cylinder sieve though the transition gear on transmission shaft. The rotation direction of cylinder sieve was changed by the gear transmission to realize the different rotational speed and direction of cylinder sieve and promoting device. Analysis and calculation of the rotational speed range of promoting device and cylinder sieve were carried out. Orthogonal experiments based on EDEM was obtained. The loss ratio and cleaning ratio of cylinder sieve was taken as the indexes while the rotational speed of sieve and the rotational speed and tooth number of promoting device were the factors. The optimal parameter combination was obtained. Test-bed and field experiments were carried out to verify the results of simulation. The simulation results show that the optimum combination of the parameters was 35 r/min and 80 r/min of rotational speed of sieve and promoting device respectively and 6 of the saw teeth in the projection plane of the promoting device. In addition, the loss ratio and cleaning ratio of cyclone separation cleaning system working with the cylinder sieve were 4.83% and 85.7% respectively while the rotational speed of the fan could be reduced by 36.9% under the condition of best combination of parameters. Field experiments were carried out in the experimental field of Huazhong Agricultural University in May 2017. The materials of experiments were rape planted by direct rapeseed planter. The average planting density was 40 plants/m2, and the water content of rapeseed, stems and pod shells were 23.47%, 20.9% and 33.98%, respectively. The working speed of 4LYZ-1.8 type rape combine harvester was 2.9-3.6 km/h and the working efficiency was 0.52-0.65 hm2/h. The average loss rate of rapeseed was 5.9% and the average cleaning rate of rapeseed was 84.4%. The average power consumption of the cleaning system was 3.48 kW. This research provided a reference for the improvement and optimization of cleaning system for rape combined harvesters.

agricultural machinery; design; experiments; rape; cleaning; cyclone separation; cylinder sieve; EDEM

万星宇,舒彩霞,徐 阳,袁佳诚,李海同,廖庆喜.油菜联合收获机分离清选差速圆筒筛设计与试验[J]. 农业工程学报,2018,34(14):27-35.doi:10.11975/j.issn.1002-6819.2018.14.004 http://www.tcsae.org

Wan Xingyu, Shu Caixia, Xu Yang, Yuan Jiacheng, Li Haitong, Liao Qingxi.Design and experiment on cylinder sieve with different rotational speed in cleaning system for rape combine harvesters[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2018, 34(14): 27-35. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2018.14.004 http://www.tcsae.org

2018-01-08

2018-03-04

国家重点研发计划项目(2017YFD0700405A);农业农村部科研杰出人才与创新团队项目

万星宇,男,湖北钟祥人,博士生,研究方向为现代农业装备设计与测控。Email:821786261@qq.com

廖庆喜,男,湖北江陵人,教授,博士生导师,主要从事油菜机械化生产技术与装备等方面的研究。Email:liaoqx@mail.hzau.edu.cn

10.11975/j.issn.1002-6819.2018.14.004

S225.99

A

1002-6819(2018)-14-0027-09